Professional Documents

Culture Documents

Coating Procedure Rev.0

Uploaded by

Samir Chaudhary0 ratings0% found this document useful (0 votes)

11 views10 pagesCoating Procedure Rev.0

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCoating Procedure Rev.0

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views10 pagesCoating Procedure Rev.0

Uploaded by

Samir ChaudharyCoating Procedure Rev.0

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 10

Approved oo Mokd

Work instructions for Pipe Fitting Protection Coating Specification - Longshan

2.x 700 MWe PHWR - Rajasthan Atomic Power Project, Rawatbhata- Unit 7&8 BOT! Package.

OWNER: NUCLEAR POWER CORPORATION OF INDIA LIMITED

: & (A GOVERNMENT OF INDIA ENTERPRISE)

MAIN BOTIP ® LARSEN & TOUBRO LIMITED,VADODRA

| CONTRACTOR: (EPC-POWER)

i

ENGINEERING a7

CONSULTANT: TATA TATA CONSULTING ENGINEERS,MUMBAI

cument Name : Work instructions for Pipe Fitting Protection Coating Specifieation-

Longshan

L&T Document No. zi LETILSISBPIOOL of FRE

@

Document Revision. apr Ro mG WS A)

Project Name 22X70 MWe a a ATOMIC POWER PROJECT 788

NPGIL REF. P.O. NO + CMMIMEG/22-40-2-1067/PO16468 & 6489 DATED 3-DEC-2012

LAT Reference, PO No. EPCIE14/2100035598/SUS DT. 16.03.2015,

DOCUMENT ISSUED FOR APPROVAL

is) Ticluded NPCIL comments y

i SusmttovToranprov [P0225

‘Agency Lat NPCIL'S ACCEPTANCE

wane agit

checken By | A Prere kom Ei |

NAME sicn | DATE

REVIEWED BY | Vinod Sx} rvse-ll

EN JIGnore (hy | 26]

aeenovenay | SKF BG, [levi Trap Gam ant leisy

: Shot Blasting and Painting,

Bestngnaraine lesan ba ag Z

wssueno| FEY | pescriprion cme Parone a A, ¥

Maney S [Ve [etchuitnaet)

Kr

TC BATH EL LAs IRA

‘angyia Longshan Pipe Sottiens Co.Lid

LS

TOBA TH 2B LL SLA RA]

Jiangyin Longshan Pipe Solutions CO.,LTD

Pe TL AMI

Work instructions for Pipe Fitting Protection Coating Specification

(Only for NPCIL~ L&T)

Ri | oes |ypty |B | wy,

RO 25-03-2015

Hab hy | Zoe. | ay,

Wa AM Sat aK Het

Version Date —_| Prepared by | Reviewed by | Approved By

Note: Only English Language mentioned in the procedure is approved

Page (of 5

oe,

A

YB TH Us BA BRA

Fiangyin Langshan Pie Solutions Cod

CONTENTS

1, Purpose

2. Scope

3. Responsibilities

4. Workshop Coating activity procedure

5, Varnish Coating Inspections

6. Reporting

7. Appendix

&.. Tb RWELAB AA

a Deon ouatrecseeie ec

1. Purpose

‘The main purpose of this procedute is to control varnish coating process for the pipe fittings in order

to ensure the pipe fittings are weather protected from rust formation.

2. Scope

This procedure is applicable for pipe fittings being produced For NPCIL RAPP (7&8) Project at

Longshan Work shop.

3. Responsibili

3.1. Produetion department is responsible in preparing and review of this procedure.

3.2 Varnish coating team will perform coating in compliance with this procedure.

3.3 QC department will be in charge of in-process inspection including preparation work, varnish

Coating application and dry film thickness (DFT) inspection.

4, Workshop Coating activity procedure

4.1 Preparation work before workshop painting: The coating surface shall be free from mill scale,

Oil, dust ete,

4.2. Preparation of paint: The varnish ingredients should be completely stired to reach for an even

ture after the lid is opened. The coating should be performed after required stirring to

‘ensure the varnish coating uniformity. If coating system was made up of two materials, drying

agent must mix well with the mein ingredient.

43. Any expired paint is pro

5. Varnish Coating Inspection:

5.1 Varnish Coating Brand Outside: Q04-2 Black Nitro Enamel (Technique: Spray)

‘amish Coating Brand Inside: suggested material VPCI-377 (Water washable)

Composition & Ingredients: Symthetic resin, Nitrocellulose, High quality pigments, Auxiliary,

and the mixed solvent

amish Coating DFT( Dry Film Thickness ): Outsidez 40 microns, Inside % 40 microns.

5.2 The bevel ends shall be protected while carrying out the vamish coating,

5.3 All the fittings shall be end capped to protect the edge preparation during transit

6. Reporting:

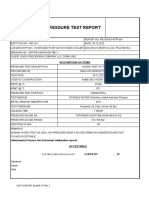

6.1 Painting Inspection Record !1LSZJ-YQ-0}

7. Appendix: Sample Vanish Certificate

\e\

£ ig

a Ay

Page 3 ofS ane

& YODA THA LL HLA IRA A]

ace Jiangyin Longstan Fp Soins Cod

YC BATE AE LL MLA HEA F/ sianayin Longshan Pipe Solutions Co,Ltd

‘Whee IZRYDET checking record sheet

MILSZJ-YQ-01

BIR Peet. {RI Popa Ne

RRS Pom

ARERR Acton eee sini

aR Sel emp before,

SRIERLAP ITE vsry teorepsntings

ribet we

Dosen DT of rite Due

ee TAT te BRE Acul DETER)

Po Peceriek | Quy c [oe

15

16

7

©

©

2

Te nS A, OE.

evsteS pope ocean ed econ three vai

aaa wi we is

cs a aro Bae

Pages of 5

AE “4

OTHE ul EL BRAS

angyin Longsian Pipe Solutions Co,Ltd

Appendix -- Vanish Certificate

Deets ah

Lae aw B

duo nguTaenuE

SSDSONOMERWE ERLE

RGB MRI ARE AD

varnish certificate

ER AB

PibBH O04-% aa Storage

Prodyct G04 Black nitro. eoane!

I GB/T25271-2010 MAH AEF LT + regutation | GB/T25271-2010

fa, navn

| eG | eerste usr

1 | NEAR Bee,

2 wien >

3 | fibitcak He 150 he abight ate

4 [aerarscam [080 ere

5 [aR

You might also like

- IEP for BrendonDocument1 pageIEP for BrendonSamir ChaudharyNo ratings yet

- Competency Matrix - Tech TemplateDocument7 pagesCompetency Matrix - Tech TemplateSamir ChaudharyNo ratings yet

- HydroDocument4 pagesHydroSamir ChaudharyNo ratings yet

- CV - Linkedin 4Document6 pagesCV - Linkedin 4Samir ChaudharyNo ratings yet

- Amit Tank's Professional Profile and ExperienceDocument5 pagesAmit Tank's Professional Profile and ExperienceSamir ChaudharyNo ratings yet

- Flat Bottom Tank Inspection Checklist - LinkedinDocument9 pagesFlat Bottom Tank Inspection Checklist - LinkedinSamir ChaudharyNo ratings yet

- Urea Plant Equipment InspectionDocument12 pagesUrea Plant Equipment InspectionKashif Zaheer AlviNo ratings yet

- CV - Linkedin 5Document9 pagesCV - Linkedin 5Samir ChaudharyNo ratings yet

- QC PointsDocument2 pagesQC PointsSamir ChaudharyNo ratings yet

- CV LinkedinDocument3 pagesCV LinkedinSamir ChaudharyNo ratings yet

- Code & Standard Linkedin.Document34 pagesCode & Standard Linkedin.Samir ChaudharyNo ratings yet

- CV - Linkedin 3Document5 pagesCV - Linkedin 3Samir ChaudharyNo ratings yet

- QAQC Engineer - KolkataDocument1 pageQAQC Engineer - KolkataSamir ChaudharyNo ratings yet

- Pressure Test Report: Dolphin Radiators & Cooling Systems L.L.CDocument1 pagePressure Test Report: Dolphin Radiators & Cooling Systems L.L.CSamir ChaudharyNo ratings yet

- CV - Linkedin 2Document5 pagesCV - Linkedin 2Samir ChaudharyNo ratings yet

- Ics Rail Tube 2Document7 pagesIcs Rail Tube 2Samir ChaudharyNo ratings yet

- Pressure Test Report: Dolphin Radiators & Cooling Systems L.L.CDocument1 pagePressure Test Report: Dolphin Radiators & Cooling Systems L.L.CSamir ChaudharyNo ratings yet

- Pressure Test Report: Dolphin Radiators & Cooling Systems L.L.CDocument1 pagePressure Test Report: Dolphin Radiators & Cooling Systems L.L.CSamir ChaudharyNo ratings yet

- C002 SP 141468 201905 PDFDocument1 pageC002 SP 141468 201905 PDFSamir ChaudharyNo ratings yet

- Procedure - Designer QualificationDocument5 pagesProcedure - Designer QualificationSamir ChaudharyNo ratings yet

- Samir Hasan Chaudhary: ContactDocument2 pagesSamir Hasan Chaudhary: ContactSamir ChaudharyNo ratings yet

- Pressure Test Report: Dolphin Radiators & Cooling Systems L.L.CDocument1 pagePressure Test Report: Dolphin Radiators & Cooling Systems L.L.CSamir ChaudharyNo ratings yet

- Klingersil: Klingersil C-4400 - Leading Soft Gasket Material For Safe and Reliable SealingDocument2 pagesKlingersil: Klingersil C-4400 - Leading Soft Gasket Material For Safe and Reliable SealingSamir ChaudharyNo ratings yet

- Panchal Jatin D. Quality Control: Production Quality Related IssuesDocument2 pagesPanchal Jatin D. Quality Control: Production Quality Related IssuesSamir ChaudharyNo ratings yet

- Specialty Complete Catalog BWDocument13 pagesSpecialty Complete Catalog BWSamir ChaudharyNo ratings yet

- What's New - PV Elite 2018Document28 pagesWhat's New - PV Elite 2018SathiyaseelanNo ratings yet

- C002 SP 141468 201905 PDFDocument1 pageC002 SP 141468 201905 PDFSamir ChaudharyNo ratings yet

- SB - 622 PDFDocument10 pagesSB - 622 PDFSamir ChaudharyNo ratings yet

- Is 8270 Part 2 1976Document9 pagesIs 8270 Part 2 1976Samir ChaudharyNo ratings yet

- SB - 622 PDFDocument10 pagesSB - 622 PDFSamir ChaudharyNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)