Professional Documents

Culture Documents

Key Words: Arduino Uno, Induction Motor

Uploaded by

hariOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Key Words: Arduino Uno, Induction Motor

Uploaded by

hariCopyright:

Available Formats

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

Abstract

The main aim of this project is to monitor and protect the induction motor with the help of

Arduino controller for large scale Industrial Environment. Protection of induction motor has been

done using the microcontroller, current transformer, and voltage transformer. This protection

scheme protects the induction motor from under voltage, over voltage and over current and

overheating conditions. The overall process is monitored by Arduino Uno microcontroller.

Microcontroller sends signal through transistor to relay for operation. The current transformer is

an i-v converter, which gives output in terms of voltage and can be fed to the microcontroller

directly. The output of these transformers will vary proportionately with respect to its input. The

microcontroller senses the voltage, compares with the reference value and sends control signals

to the respective protective relays. The overall system is cheap and reliable. It has been tested

several times and gives the good results. The induction motor can be started and stopped through

the relay developed with this system. It is also possible to protect the motor against some faults

such as over current, higher/lower voltage, over temperature in windings, overloading of motor

through the sensors output. Therefore, protections of the system are realized in real time.

Key Words: Arduino Uno, Induction Motor

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 1

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

CHAPTER ONE

1INTRODUCTION

Induction machines are very popular in industries because of their vast applications. Hence it

becomes necessary to protect them against faults so as to ensure uninterrupted operation and

function. Various parameter protecting and monitoring systems are therefore other types of

machine, but in case of induction machine the controlling and monitoring systems are not

extensively used due to high cost of installation and physical constraints. So as to overcome the

limitations in monitoring and protecting, Arduino microcontroller based System is used which

makes it simple and cost-effective.

Induction motor is the most widely used motor in the industry due to its simple and rugged

construction. It requires least maintenance as compare to the other electrical motors. Induction

motor speed control is nowadays more easy and versatile due to the advancement in the field of

power electronics and hence is easy to replace other costly and controllable motors. The

protection of induction motor plays an important role in its long life service. Researchers have

done costly and limited protection for the stator windings protections, broken rotor bars

protection, thermal protection etc. Mainly the induction motor needs protection from the variation

of the input supply for small motors which is in common use not only in big industry but also in

small scale industries. The small scale industries are not able to provide costly protection to the

drives in use as it will increase their capital cost. Hence a cheap and compact design has been

done for protection of induction motor against unbalance voltage, under voltage, over voltage,

short circuit and thermal protection. It has been also designed for critical loads which need to be

run even under single phasing condition. Due to the poor power quality the damage of induction

motors in small scale industries needs to be taken care of. The proposed design can be also used

for speed control, improvement of efficiency under poor power quality service manually by

introduction of a single two way switch. Many researches have been done in this area but they are

costly and unfeasible in our condition. The overall cost of the protection equipment should not be

more than 15% of the total cost of the actual machine. Keeping this in mind the design has been

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 2

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

proposed using microcontroller, relays, small CTs and PTs, so that the overall cost is low. But the

efficiency of the protection scheme should not be compromised.

The motor protection is required as day to day life induction motor usage increases a lot as it has

some specific merits. The circuit was fully controlled by the arduino microcontroller and the

micro controller will continuously monitor the voltage of phase and if the voltage goes abnormal

then it will switch off the motor until they are normal. It is not only protecting motor from

transient voltage, it also switch on the motor automatically when power comes without manual

requirement and off the motor after predetermined time. This motor is manually monitoring is

difficult so automatic protection of induction motor has such an importance. Induction motors are

widely used-as industrial drive motors. In order to reduce the-size and to minimize the cost, large

capacity motors are designed so that, the magnetic and current densities are close to the limiting

levels. Such motors are sensitive to abnormal operating conditions like overvoltage or over

loading etc. and hence require high speed and reliable protection scheme. The digital relays based

on microprocessors or microcontrollers can provide accurate high speed protection. This study

presents a protection scheme for phase induction motor from incipient faults using Arduino

microcontroller. The induction motor experiences several types of electrical faults like over/under

voltage, over load, phase reversing, unbalanced voltage, single phasing and earth fault. Due to

these electrical faults, the windings of the motor get over heated which lead to insulation failure

and thus reduce the life time of the motor.

1.1 BACKGROUND OF THE PROJECT

Induction motor electrical faults numerous faults can occur in an induction motor during its

course of operation. These faults if left undetected can lead to catastrophic failures. The following

are common electrical faults which can be found in induction motors. Over loading, single

phasing, Unbalanced supply voltage, under voltage and over voltage. A brief description of these

faults and their characteristics is given below

Protection of these motors is an important task which has been challenging to engineers.

Protective relays were used to monitor the faults and disconnect the motor in case of a fault.

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 3

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

Overloading

Overload fault occurs when the mechanical torque exceeds the threshold point by applying

mechanical load to the motor greater than full load rating. Overloading causes increase in phase

currents, over heating the machine. In a traditional relay protection system, the over current relay

trips the motor off-line when the over load encounter over current in the line.

Single phasing: Single phasing is one of the unbalanced cases of the motor. It occurs when one of

the three lines are open. More current flows through the other two lines and more heat is

generated in stator winding. In the traditional protection systems, a high-set instantaneous trip

unit relay is used. Single phasing also gives rise to negative sequence current. A negative

sequence relay can also be used to protect against this fault [9]

Unbalanced supply voltage

There are many causes of unbalance supply voltages such a unbalance loading, open delta

transformers and unequal tap setting. This condition leads to reduction in motor efficiency, raises

the motor temperature and excessive unbalanced full load current.

Under Voltage

Under voltage fault is reducing the supply voltage on the three phases by specific Percentage,

which makes the motor from attaining rated speed in specified time, increases the Current and

overheats the machine? Low voltage protection relays are used in traditional systems. However,

in order to avoid unwanted relay shutdowns due to momentary voltage drops, the AC contacts

need a delay mechanism which delays the under voltage protection for a time period.

Over Voltage

Over voltage occur if the three phase voltages are greater than rated voltage. The effect of this

fault is increasing current flow which leads unacceptable stress on the motor insulation due to

high heat dissipation. Conventional protection systems use the over voltage relays to protection

the motor during this condition [1].

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 4

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

The approximate percentages of by these individual faults are:

overload 30%, insulation damage 20%,phase failure 14%, bearing damage 13%, ageing

10%,rotor damage 5%&others 8% Therefore, the following points must be observed to guarantee

fault-free operation of an electrical drive:

Correct design: a suitable motor has to be selected for each application.

Professional operation: professional installation and regular maintenance are preconditions for

fault-free operation.

Good motor protection: this has to cover all possible problem areas.

- It must not be tripped before the motor is put at risk.

- If the motor is put at risk, the protection device has to operate before any damage occurs.

- If damage cannot be prevented, the protection device has to operate quickly in order to restrict

the extent of the damage as much as possible.

1.2 STATEMENT OF THE PROBLEM

Reducing the life time of motors.

Increase the extra financial losses due to maintenance.

Over loading, Unbalanced supply voltage, under voltage

The motor heat up quickly and damage

The motor protected manually from unbalance voltage and over load,

This project develops a fault detection method for three-phase induction motors to detect faults in

all over circuit of the induction motor by using arduino microcontroller and overload relay

technique. The thermal protection for induction motors fed by motor control devices is great

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 5

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

importance for the reliable protection of induction Motors, increasing the service time of the

motor, and reducing the extra financial losses due to maintenance. It is also difficult to protect the

motor manually from unbalance voltage and over load, but using microcontroller it is possible to

control unbalance voltage and over load by adjust rated operation value voltage and current of

motors. Three phase induction motor can continue to run one phase of the supply gone out of

service. The motor heat up quickly and damage.

When we see in the internship period the main problem of the company the relay or the coil does

not close even if below the minimum rated voltage, at that time the motor is run but not normal

condition. So the project it protects and fixes the above problem.

1.3 OBJECTIVES

1.3.1 General Objective

The general objective of this project is to design Arduino based protection of three phase

induction motor from electrical faults

1.3.2 Specific Objective

To design temperature, current, and voltage sensing circuit that will be interfaced to the

microcontroller for monitoring

To develop arduino microcontroller based protecting system

To identify and prevent faults in induction motor

1.4 SCOPE OF THE PROJECT

The scope of this project is to develop continuous protection for induction motor based on

Arduino. All the sensors are used to acquire data from the induction motor and transfer the data

they acquire to Arduino Uno microcontroller board. Finally, we give highest emphasis to the

software design and implementation in order to develop a suitable algorithm that will promptly

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 6

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

interact with the, microcontroller and the LCD. This contributes to detect and repair induction

motor as soon as fault occur so as to reduce man power required which saves time and energy.

1.5 SIGNIFICANCE OF THE STUDY

To reduce maintenance cost

To increase operational safety

To detect and repair induction motor as soon as fault occur

To reduce unforeseen expenditure due to motor operation interruption.

To save wastage time

increasing the service time of the motor To protect the motor from phase failure

Induction motors are the most common electrical machines, because of their relatively low

manufacturing cost and the easy of control. They represent about 80% of the electro mechanical

energy conversion machines. As indicated before, Identifying faults in these motors and

protecting them is an important aspect to reduce loss and cost. Microcontroller based techniques

is used to identify these faults and to take action to correct the faults. It reduces the manual

system of the protection of induction motor from unbalanced voltage source

1.6 THESIS ORGANIZATION

The thesis is organized into five chapters. The contents of these chapters are summarized as:Chapter 1 introduces overall background information of the system. This includes

Background, problem of the statement, objective, proposed methodology of the work and its

scope and contribution.

Chapter 2 focuses revision of related literatures to this system.

Chapter 3 covers the system design and detail analysis of the system components. This consists

Controlling and monitoring system, types faults, and explanation system components in detail.

Chapter 4 investigates the observed results and discussions.

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 7

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

Chapter 5 summarizes the conclusion and recommendation for future work.

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 8

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

CHAPTER TWO

2. LITERATURE REVIEW

A lot of research work has been published in the field of induction motor protection and various

techniques have been proposed.

William H. Kersting [1] stated that three phase induction motor can continue to run when one

phase of the supply gone out of service. This may be due to any fuse blowing or opening of

protective device of the motor, at step-down transformer or at feeder end. At this condition the

three-phase induction motor continue to run but the motor will heat up quickly and it should be

protected by removing it from the service at the instant of single phasing. When phase opens at

step down transformer or at feeder end, the stator and rotor losses increases. To protect the motor

all the terminal should be open.

Sudha M. and Anbalagan [2] proposed a technique to save the three phase induction motor from

single phasing. In this technique, PIC16F877 microcontroller has been used to sample the values

of each phase and converted them to low voltage ac by means of transformer. The signals are

converted to digital value using ADC converter. The controller continuously compares the digital

value with the reference value and when the fault occurs, it opens the normally close contactor

and disconnects it from the power supply. Single phasing, under voltage and over voltage

protection is done practically on a 2kW motor and the motor is isolated if any of these condition

occurs.

Pragasen Pillay et.al. [3] Examines the three phase induction motor under the influence of under

voltage and over voltage. The voltage at motor terminals may be higher than the nominal value in

a complex industrial system and can be well below from nominal value in a heavily loaded

industrial system. IEEE, NEMA and other power communities have different defined the voltage

unbalance. The complex algebra is avoided in these definitions. In this paper calculation of the

unbalance of voltage have been done on true basis with complex algebra and compared with

NEMA standards.

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 9

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

Javed A. and Izhar T. [5] have proposed the protection of three phase induction motor based on

voltage measurement and is not enough to protect the motor if the fault occurs at distribution

transformer or at substation feeder. If fault occurs at motor terminals then the voltage

measurement can protect the motor very well. The current measurement device should be

implemented within the protective device. They have also proposed a phase measurement device

which can measure the phase difference of the voltages because when the fault occurs at any

other location rather than the motor terminals, then the faulted phase will draw negative sequence

current and work as a voltage generator. The voltage developed is close to line voltage but the

measurement scheme is not able to detect the fault, however the phase difference of the faulted

phases changes.

Chattopadhyay et.al. [6] Analyzed the stator current of three phase induction motor by using

different techniques. The single phasing can also be measured by the zero crossing detection

method and has proposed to use 8085 microprocessor for doing this work. The accuracy can be

increased by increasing the sampling time. The phase shift can also be measured by the use of

microprocessor. The phase shift helps to protect the motor from any increased or decreased phase

difference.

Cunkas A. et.al. [7] Described the protection of the induction motor under various conditions like

over voltage, under voltage, voltage unbalance and over current using PIC16C84 microcontroller.

Potential transformer and current transformer are used for this process. Later the values from this

transformer are converted into digital values using ADC converter. The tripping circuit has been

given some delay.

Bayindir Ramazan [8] explained the three phase induction motor protection using sensors.

PLC based protection has been employed and compared with PIC based protection. PLC has

proved to be cost efficient. Need of ADC card has been eliminated by using PLC. PLC can be

implemented on different kind of motors by applying small changes.

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 10

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

CHAPTER THREE

3. METHODOLOGY

The methodology used to address the research problem is described in this section.

Study Restate problem and objectives of the project.

The next section describes the procedures used for this study which includes a detailed

account of microcontroller technique.

The ARDIUNO UNO software used for implementing the techniques

This project gives an artificial intelligence protective methods and their application in

fault identification. For successful completion of this project some steps will be followed

to carry out different tasks. Different literature will be revised relating to this project and

data will be collected about condition and control parameter of induction motor. Based on

this parameter system model was designed. Some software's were selected to develop the

software programing. So here a system is designed with an alternative method to prevent

the failures that happen in induction motors using microcontroller and sensors to measure

the different parameters related to induction motors such as current, voltage, and

temperature

Generally the methodology is concluded by the block diagram given bellow

Problem

identificati

on

Literature

review

Internship Report and Project

Data

collectio

n

Software

design

By Shumet Tizazu Wolaita Sodo University

Simulati

on

Page 11

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

Figure 1: sequence of methodology

IEEE Standard for insulation of squirrel cage induction motors

There are four classes according to IEEE-Std. 1-2000 standards for motors i.e. Class A, B, F and

H. External air is used for cooling the motor and insulation below at the maximum cooling air

temperature of 40 degree Celsius. Cooling and external air for the induction motor is necessary to

remove the heat. If the heat increases beyond the thermal limit of the motor then it may damage

the winding permanently. Excess heat also affects the insulation ageing. The insulation also

deteriorates in case of motor overloading.

Thermal Protections

Most of the motor failures occur due to the overheating. Modern techniques are making motor

more efficient and compact in size. Using of fiber glass and silicon resins has improved dielectric

capabilities as compare to cotton and varnish. But they are also more vulnerable to excessive

heating. The overheating can also be avoided by setting the correct thermal limit of the relay.

Sometimes the thermal limit is overestimated. The algorithm for designing the relay protection

system can be achieved more precisely by using the microprocessor or microcontroller based

protection system. The ideal device for looking the heating in the motor is the thermal image unit.

We cannot use the sensors in the rotor part because of technical difficulties, cost and reliability.

3.1 PROTECTION TECHNIQUES

Induction motor should be protected by different types of techniques in the power system. Some

of these are sensed by the protective devices and trip the motor. This protection process can be

done by different ways. Some of the techniques are discussed below:

i) Voltage transformer to detect the phase voltage

ii) Current transformer to detect the current

iii) Thermal sensor to detect the temperature of winding

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 12

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

This can be done by using ARDIUNO microcontroller. The protection device should be capable

of voltage and current detection. The current measure protection is important because any phase

fault occurrence is detectable by measuring the current but there is a chance when voltage

measurement device will not able to detect the phase failure. So voltage and current measurement

made the protection reliable, if the motor is influenced by the fault, which may occurs at any

location. If the fault occurs at motor terminals then voltage measurement device may be suitable.

3.2 BLOCK DIAGRAM OF THE PROJECT

AC

SUPPLY

DC SUPPLY

VOLTAGE

SENSING

LCD

CURRENT

SENSING

ARDNO UNO

INDUCTION

MOTOR

(SQUIRREL

CAGE)

TEMPRATURE

SENSOR

RELAY

Internship Report and Project

LED

RELAY DRIVER

By Shumet Tizazu Wolaita Sodo University

Page 13

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

Figure 2: Block diagram of the system

The design model is based on the analysis and architectural requirements of the system. It

represents the application components and determines their appropriate placement and use within

the overall architecture. In the design model, packages contain the design elements of the system,

such as design classes, interfaces, and design subsystems, that evolve from the analysis classes.

The real time monitoring and controlling method is implemented for the better performance of

the motor. The system developed is capable to perform such operations like measuring,

monitoring and controlling the parameters like voltage, current, and temperature of the induction

motor. The monitoring devices can provide additional information needed to maximize energy

savings. Monitoring systems also have the ability to providing guidance for preventive

maintenance, and predictive failure analysis

3.3 SYSTEM COMPONENTS AND CIRCUIT DESIGN

Based on the various reviews conducted on induction motor protection and the above block

diagram which was conceived out of those literature reviews conducted, numbers of components

are required in developing the protection system.

3.3.1 Power Supply

Power supply is the circuit from which we get a desired dc voltage to run the other circuits. The

voltage we get from the main line is 230V AC but the other components of our circuit require 5V

DC. Hence a step-down transformer is used to get 12V AC which is later converted to 12V DC

using a rectifier. The output of rectifier still contains some ripples even though it is a DC signal

due to which it is called as Pulsating DC. To remove the ripples and obtain smoothed DC power

filter circuits are used.

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 14

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

`A 5V regulated supply is taken as followed:

Figure 3 : Block diagram of regulated power supply system

Transformer

Transformer is the electrical device that converts one voltage to another with little loss of power.

Most power supplies use a step-down transformer to reduce the dangerously high mains voltage

to a safer low voltage. Here a step down transformer is used to get 12V AC from the supply i.e.

230V AC.

Rectifiers

A rectifier is a circuit that converts AC signals to DC. A rectifier circuit is made using diodes.

There are two types of rectifier circuits as Half-wave rectifier and Full-wave rectifier depending

Upon the DC signal generated. Here Full-wave bridge rectifier is used to generate dc signal.

Smoothing

Smoothing is performed by a large value electrolytic capacitor connected across the DC supply to

act as reservoir, supplying current to the output when the varying DC voltage from the rectifier is

decreasing. The diagram shows the unsmoothed varying DC and the smoothed DC. The capacitor

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 15

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

charges quickly to the peak of the varying DC and then discharges as it supplies current to the

output. Here the capacitor of 470uF is used as a smoothing circuit.

Voltage regulation

Fixed voltage regulator78xx, produce fixed DC output voltage from variable DC (a small amount

of AC on it). Fixed output is obtained by connecting the voltage regulator at the output of the

filtered DC. It can also be used in circuits to get low DC voltage from high DC voltage.

Mathematical modeling for power supply circuit

VREV (reverse voltage in diode) = VP VF

VP= VO max + 2VF = 12.6 + 2 (0.7) = 14V

VREV = 14V 0.7V = 13.3V

I (average forward current) =ILDC/2 = 35 mA

IFRM (forward repetitive current) = IL/t2 (t1+t2) = 500mA

Now from datasheet 1N4001 is chosen

For 1N4001 IF (surge) = 30A

So R surge = = 1430A = 0.5

Choose standard 1

Designers recommend;

C2 = C3 = 0.1F

For proper output of IC7805

Rectification circuit

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 16

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

Outputs 12VDC for 70mA load

Lets allow 10present ripple for the rectified output

Then: - R ripple = 0.1 * 12V

V max = 12V + 0.5 (1.2V) = 12.6V

V min = 12V 0.5 (1.6V) = 11.4V

T = 150 = 20m Sec

1 = sin-1() = 65o

2 = 900 650 =250

t2 = charging time = 2360 = 1.4m sec

t1 = discharging time = T2 2 = 8.6m sec

Then C1= I 1= 70m A 8.6m Sec1.2= 500F

Use standard C1 = 470F

Assume silicon diode

Vf = 0.7V, Vdc = 5v

Vprimary = 230v and

Vr = 10 percent of Vdc = 0.5v

Diode selection

Ideally, a diode will conduct current in the direction of anode to cathode defined by the arrow in

the symbol and act like an open circuit to any attempt to establish current in the opposite

direction. The characteristics of an ideal diode are those of a switch that can conduct current in

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 17

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

only one direction. In the description of the elements to follow, it is critical that the various letter

symbols, voltage polarities, and current directions be defined. If the polarity of the applied

voltage is consistent with that shown in figuer3.8a, the portion of the characteristics to be

considered in figuer3.8b is to the right of the vertical axis. If a reverse voltage is applied, the

characteristics to the left are pertinent.

Figure 4: characteristics of diode

Peak = Vmax + 2Vforward

= 5.25 + 2*0.7

= 6.65v

For a full wave rectifiers

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 18

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

V reverse = Vp = 6.65v

I forward (average) = IL/2 = 5mA

12 Volt DC Power Supply

V r = 0.1 * V dc

V max = 14.7 V

V min = 13.3 V

Figure 5: Power supply circuit

3.3.2 Microcontroller

The microcontroller IC which we used is Arduino Uno. The Arduino Uno is a microcontroller

board based on the ATmega328. It has 20 digital input/output pins of which 6 can be used as

PWM outputs and 6 can be used as analog inputs, a 16 MHz resonator, a USB connection, a

power jack, an in-circuit system programming (ICSP) header, and a reset button. It contains

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 19

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

everything needed to support the microcontroller; simply connect it to a computer with a USB

cable or power it with an AC-to-DC adapter or battery to get started.

The Uno differs from all preceding boards in that it does not use the FTDI USB-to-serial driver

chip. Instead, it features the Atmega16U2 programmed as a USB-to-serial converter. This

auxiliary microcontroller has its own USB boot loader, which allows advanced users to

reprogram it.

Therefore in order to achieve this task the Arduino mega microcontroller based on ATmega328

was chosen because of its suitability for this project such as speed, power consumption, and

universal syn RAM and ROM on the chip synchronous asynchronous receiver transmitter

(USART) functionality, in built ADC, and amount of RAM and ROM on the chip.

Figure 6: Arduino-Uno and pin configurations

Power (USB) and pin configuration

Every Arduino board needs a way to be connected to a power source. The Arduino UNO can be

powered from a USB cable coming from your computer or a wall power supplies. Its not allowed

to use a power supply greater than 20 Volts as you will overpower and thereby destroy the

Arduino. The recommended voltage for most Arduino models is between 6 and 12 Volts. The pins

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 20

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

on your Arduino are the places where it will connect wires to construct a circuit probably in

conjunction with a breadboard and some wire. They usually have black plastic headers that

allow you to just plug a wire right into the board. The Arduino has several different kinds of pins,

each of which is labeled on the board and used for different functions.

GND (3): Short for Ground. There are several GND pins on the Arduino, any of which can be

used to ground your circuit.

5V (4) & 3.3V (5): As we might guess, the 5V pin supplies 5 volts of power, and the 3.3V pin

supplies 3.3 volts of power. Most of the simple components used with the Arduino run happily

off of 5 or 3.3 volts.

Analog (6): The area of pins under the Analog In label (A0 through A5 on the UNO) is Analog

In pins. These pins can read the signal from an analog sensor (like a temperature sensor) and

convert it into a digital value that we can read.

Digital (7): Across from the analog pins are the digital pins (0 through 13 on the UNO). These

pins can be used for both digital input (like telling if a button is pushed) and digital output (like

powering an LED).

PWM (8): the digital pins (3, 5, 6, 9, 10, and 11 on the UNO). These pins act as normal digital

pins, but it can also be used for something called Pulse-Width Modulation (PWM).

AREF (Stands for Analog Reference) (9): Most of the time you can leave this pin alone. It is

sometimes used to set an external reference voltage (between 0 and 5 Volts) as the upper limit for

the analog input pins.

3.3.3 Temperature Sensor

The most common type of temperature sensors are; thermocouple, thermistor and Temperature

Detectors (RTDs). In this project a thermistor type LM35 temperature sensor is used due to the

following main advantage

Lower cost

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 21

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

Does not require any external calibration

Linear output

Precise and accurate output

LM35 is a basic temperature sensor that can be used for experimental purpose. It give the

readings in centigrade (degree Celsius) since its output voltage is linearly proportional to

temperature. It uses the fact that as temperature increases, the voltage across diode increases at

known rate (actually the drop across base-emitter junction of transistor). Its disadvantage is its

sluggish response.

LM35 has the following main features;

i. calibrated directly in degree Celsius(centigrade)

ii. Linear +10.0 mV/ degree Celsius

iii. 0.5 degree Celsius accuracy guarantee able (at +25degree Celsius)

iv. Rated for full -55 to +150 degree Celsius range

v. Suitable for remote application

Vi. Low cost due to wafer-level trimming

vii. Operates from 4 to 30 volts

viii. Less than 60 Micro ampere current drain

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 22

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

Figure 7: LM35 temperature

As shown in the figure above the sensor has three terminals.

i. Input source; it ranges from 2.7V to 5V

ii. Ground

iii. Output; analogue voltage output ranges from 201mV to 20v

The code will be written in c code. Before we can get a Celsius reading of the temperature, the

analog output voltage must first be read. This will be the raw value divided by 1024 times 5000.

It is divided by 1024 because a span of 1024 occupies 5V. We get the ratio of the raw value to the

full span of 1024 and then multiply it by 5000 to get the millivolt value. Since the output pin can

give out a maximum of 5 volts (1024), 1024 represents the possible range it can give out. The

raw voltage over this 1024 (value) therefore represents the ratio of how much power the output

pin is outputting against this full range. Once we have this ratio, we then multiply it by 5000 to

give the millivolt value. This is because there is 5000 millivolts in 5 volts. Once this analog

voltage in millivolts is calculated, we then can find the temperature in Fahrenheit by the equation:

((Celsius * 9)/5 + 32)

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 23

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

Figure 8 : temperature sensing circuit

3.3.4 Voltage measurement circuit

The voltage given to the induction motor is measured using the voltage transformer with the

transformation ratio of 220v. The voltage transformer will pass through rectification process

before fed to the ADC. The over voltage and under voltage protection circuit is capable of

measuring and monitoring voltage from 200 to 230VAC. In this project the voltage can be varied

by using the variable resistor and the output of the voltage monitoring circuit is fed to ADC

converter, whenever the voltage is varied to 200VAC, the microcontroller will detect under

voltage fault and whenever the voltage is varied to 230VAC, the microcontroller detects over

voltage fault, consequently the microcontroller sends a trip signal to the relay, and the relay trips

the motor from the AC mains, thereby protecting it from damage.

Voltage transformer

Two types of voltage transformer are used for protective-relaying purposes, as follows: (1) the

"instrument potential transformer," hereafter to be called simply "potential transformer," and (2)

the "capacitance potential device." A potential transformer is a conventional transformer having

primary and secondary windings. The primary winding is connected directly to the power circuit

either between two phases or between one phase and ground, depending on the rating of the

transformer and on the requirements of the application. A capacitance potential device is a

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 24

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

voltage transforming equipment using a capacitance voltage divider connected between phase

and ground of a power circuit.

Connections - Potential Transformers

Potential transformers are normally connected across two lines of the circuit in which the voltage

is to be measured. Normally they will be connected L-L (line-to-line) or L-G (line-to-ground). A

typical connection is as follows:

When a phase relationship of direction of flow is of no consequence, such as in a voltmeter

which operates only according to the magnitude of the voltage, there is no need to observe the

polarity of the transformer. However, in watt hour meter applications, polarity must always be

observed. Most potential transformers have a single winding secondary as previously shown;

however, they may have tapped secondary windings, or dual secondary windings

Rectification stage

Rectifier is an electrical device that converts alternating current (AC), which periodically reverses

direction, to direct current (DC), which flows in only one direction. The process is known as

rectification and the stage is known as rectification stage. In this stage we use full wave bridge

rectifier .This type of single phase rectifier uses four individual rectifying diodes connected in a

closed loop bridge configuration to produce the desired output. Here we are used 1N4007.

Filtering stage

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 25

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

To smooth the output of the rectifier a reservoir capacitor is used - placed across the output of the

reciter and in parallel with the load. This capacitor charges up when the voltage from the rectifier

rises above that of the capacitor and then as the rectifier voltage falls, the capacitor provides the

required current from its stored charge.

The output V1 of the transformer is fed to voltage transformation unit which transforms the input

voltage into 5 volts range. The voltage transformation unit consists of diode, and resistive divider

network.

C 1 . (4)

Where:

= the overall resistance of the load for the supply

C= Value of capacitor in Farads

= the ripple frequency this will be twice the line frequency a full wave rectifier is used shown in

equation 5.

= 2 line frequency. (5)

= 2 50=100Hz

By rearrange equation (5)

C 1

C 1/10010K

C1

For perfect smoothing purpose we take the capacitor value is 100uF

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 26

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

Figure 9 : Voltage sensing circuit

3.3.5 Current measurement circuit

Current measurement is of vital importance in many power and instrumentation systems.

Traditionally, current sensing was primarily for circuit protection and control. However, with the

advancement in technology, current sensing has emerged as a method to monitor and enhance

performance. Knowing the amount of current being delivered to the load can be useful for wide

variety of applications. Current sensing is used in wide range of electronic systems, viz., Battery

life indicators and chargers over-current protection and supervising circuits, current and voltage

regulators, DC/DC converters, ground fault detectors, programmable current sources, linear and

switch-mode power supplies, communications devices , automotive power electronics, motor

speed controls and overload protection, etc. A current sensor is a device that detects and converts

current to an easily measured output voltage, which is proportional to the current through the

measured path. When a current flows through a wire or in a circuit, voltage drop occurs. Also, a

magnetic field is generated surrounding the current carrying conductor. Both of these phenomena

are made use of in the design of current sensors. Thus, there are two types of current sensing:

direct and indirect. Direct sensing is based on Ohms law, while indirect sensing is based on

Faradays and Amperes law.

Direct Sensing involves measuring the voltage drop associated with the current passing through

passive electrical components. Indirect Sensing involves measurement of the magnetic field

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 27

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

surrounding a conductor through which current passes. Generated magnetic field is then used to

induce proportional voltage or current, which is then transformed to a form suitable for

measurement, and/or control system. The current consumed by the induction motor is measured

using the current transformer.

Current transformer

The CT is a type of instrument transformer that is designed to produce an alternating current in

its secondary winding which is proportional to the current being measured in its primary. CTs

used with Ammeters, Wattmeters, Relays, and Watt transducers enable indication and control

demand as well as monitor in all current loads with either an analog or digital indicator. CT's are

also used with Current Transducers to provide an analog process current transformers (CT's)

provide a simple, inexpensive and yet accurate means of sensing current flow in power

conductors. They are available in 3 basic configurations:

1. Ring Core CT's are available for measuring currents from 50 to 5000 amps, with windows

(power conductor opening size) from 1" to 8" diameter.

2. Split Core CT's are available for measuring currents from 100 to 5000 amps, with windows in

varying sizes from 1" by 2" to 13" by 30". Split core CT's have one end removable so that the

load conductor or bus bar does not have to be disconnected to install the CT.

3. Wound Primary CT's are designed to measure currents from 1 amp to 100 amps. Since the load

current passes through primary windings in the CT, screw terminals are provided for the load and

secondary conductors. Wound primary CT's are available in ratios from 2.5:5 to 100:5 (Models

189 and 190 are examples of wound primary CT's). CT's used with watt transducers enable the

owner to control demand as well as monitor building and/or tenant power consumption. When

CT's are used with Current Transducers, the result is an excellent method of diagnosing the

performance of fans, pumps, chillers, etc. Current Transducers provide alarms for each motor so

the owner is warned immediately of any abnormal operating condition. Low pump flows will be

alarmed if the strainer is dirty or the coupling is broken. Low fan flows will be alarmed if filters

are dirty, belts are slipping, or dampers (fire, smoke, etc.) are closed. High motor loads will alarm

if bearings are dry or worn, or belts are out of alignment. CT's are designed to handle motor

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 28

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

inrush currents, so no extra precaution is needed to monitor motors. CT reduce high voltage

currents to a much lower value and provide a convenient way of safely monitoring the actual

electrical current flowing in an AC transmission line using a standard ammeter. Current

transformer with primary current 5Amps and rated secondary current of 1Amps is used. The

measured voltage and current are displayed in LCD. If the voltage and current exceeds the rated

value, the buzzer is used to indicate the overload condition of the motor.

We have to consider 60W load for our system so the current passing through the line is about 10A

which is 60W 220V ac induction motor. Therefore I1=10A the output current is required to about

25mA therefore by using equation 1 the turn ration is calculated.

= 1/ 2 . (1)

= 10/25=400

Some current transformers have a split core which allows it to be opened, installed, and closed,

without disconnecting the circuit to which they are attached. The steroidal current transformer

type which have one turn primary winding (N1=1) and secondary winding 400turns (N = 400).

The burden resister is about 35ohm which if the standard resister for lower current value so the

output voltage calculated using equation 2.

= IR (2)

2= 2R

2= 2535ohm=0.875v

Connections - Current Transformers

CTs with wound primaries always have their primary windings connected in series with the line

and the load and their secondary windings connected to the burden (the watt hour meter current

coil) as show below:

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 29

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

Current transformers having a center tapped secondary are referred to as a dual ratio CT.

Figure 10: Current sensing circuit

3.3.6 Relay

A relay is an electrically operated switch. Many relays use an electromagnet to operate a

switching mechanism mechanically, but other operating principles are also used. Relays are used

where it is necessary to control a circuit by a low-power signal (with complete electrical isolation

between control and controlled circuits), or where several circuits must be controlled by one

signal. A type of relay that can handle the high power required to directly control an electric

motor or other loads is called a contactor. Relays with calibrated operating characteristics and

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 30

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

sometimes multiple operating coils are used to protect electrical circuits from overload or faults;

in modern electric power systems these functions are performed by digital instruments still called

"protective relays".(Relay).

3.3.7 Relay deriver (transistor)

A Relay driver IC is an electro-magnetic switch that will be used whenever we want to use a low

voltage circuit to switch a light bulb ON and OFF which is connected to 220V mains supply. The

MOSFET and BJT are used as the driver and the basic function of the driver circuit is to provide

the necessary current to energize the relay coil. The required current to run the relay coil is more

than can be supplied by various integrated circuits like Op-Amp, etc. Relays have unique

properties and are replaced with solid state switches that are strong than solid-state devices. The

output of most digital circuits and micro-processors is only five volts at most a few mill-amps.

Most electrical and electronic devices require voltages and currents that will destroy digital

circuits, so we must rely on what I'll broadly call driver circuits. Above illustrates a digital output

driving typical low-power fans. On this page we will look at transistor driver circuits using both

bipolar transistors and power MOSFETs and will use them as electrical switches.

3.3.8 LCD (liquid crystal display)

A liquid crystal display (LCD) is a thin, flat panel used for electronically displaying information

such as text, images and moving pictures. Its uses include monitor for computers, televisions,

instrument panels gamin device etc. using polarization of light to display objects. A typical liquid

crystal producing degree shift in the polarization of the light passing through when there is no

electric field present. When a voltage is applied, an electric field is produced in the liquid,

affecting the orientation of the molecules. This causes the polarization shift to be reduced. Liquid

crystal material emits no light of its own. For illumination of light-backlight and reflective

method used.

LCD pin description for interfacing with Arduino

Pin 1 (VSS): is a ground pin and it is certainly needed that this pin should be grounded for LCD

to work properly.

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 31

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

VEE and VDD: are given +5 volts normally. However VEE may have a potentiometer voltage

divider network to get the contrast adjusted. But VDD is always at +5V.

RS, R/W and E: These three pins are numbered 4, 5 and 6 as shown above. RS is used to make

the selection between data and command register. For RS=0, command register is selected and

for RS=1 data register is selected. R/W gives us the choice between writing and reading. If set

(R/W=1) reading is enabled. R/W=0 when writing.

D0-D7: The 8-bit data pins, D0-D7, are used to send information to the LCD or read the contents

of LCD's internal register.

Figure 11: LCD and pin configuration

3.3.9 LED

A Light-Emitting-Diode (LED) is a P-N junction device (diode) that gives off light radiation

when biased in the forward direction. LED chip materials are combinations of elements from the

III and V columns of the periodic chart. The light emitting phenomenon makes use of the

recombination within the P-N junction instead of thermal radiation, therefore, LEDs are free of

waste and wear and can be expected to have a long life time. By controlling the forward current,

the radiant flux of the LED can be easily controlled. The response time of an LED is very high (a

few hundred nanoseconds) and can be pulsed at greater forward currents, to obtain high intensity

radiant peaks. The resin packaging of LEDs allow for superb mechanical integrity and can

withstand dropping, vibration and shock. These semiconductor devices can be mounted in any

position. Just as it takes energy to generate a hole-electron pair, energy is released when an

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 32

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

electron recombines with a hole. If a forward current is passed through a semiconductor diode,

electrons and holes are injected into the P and N region respectively. Depending on the magnitude

of the current, are combination of charge carriers (electron and holes) takes place when an

electron falls from the conduction into the valence band. In silicon and germanium when this

recombination takes place, the surplus energy goes into the crystal as heat. In other

semiconductors, such as gallium arsenide, the released energy appears in the form of

electromagnetic radiation, ranging from visible to infrared. The wavelength of this radiation is

dependent on energy required to cause electrons to jump from the conduction band to the valence

band. A portion of the light generated within the LED is unable to emerge due to internal

absorption, Fresnel losses and internal reflection. Internal absorption occurs as a photon is

traveling from the junction region through the chip. Limiting the range of this travel will reduce

the internal absorption, thus smaller LED sizes will manifest increased conversion efficiencies.

Fresnel losses and internal reflection are minimized by covering the LED chip with an optical

coating material whose index of refraction will bridge the indices of refraction between the chip

and air. Light is concentrated near the junction because most of the carriers are to be found within

a diffusion length of the junction. Since this junction extends to and is exposed on all four sides

of the die, a considerable amount of energy is emitted from the sides as well as the top surface.

Typically, the LED chip is mounted in a conical cavity to reflect the side emitting energy forward.

3.3.10 Motor

The three-phase induction motor, also called an asynchronous motor, is the MOs commonly used

type of motor in industrial applications. In particular, the squirrel- cage design is the most widely

used electric motor in industrial applications.

Principles of Operation

The electrical section of the three-phase induction motor consists of the fixed stator or frame, a

three-phase winding supplied from the three-phase mains and a turning rotor. There is no

electrical connection between the stator and the rotor. The currents in the rotor are induced via the

air gap from the stator side. Stator and rotor are made of highly magnetizable core sheet

providing low eddy current and hysteresis losses.

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 33

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

Stator

The stator winding consists of three individual windings which overlap one another and are offset

by an electrical angle of 120. When it is connected to the power supply, the incoming current

will first magnetize the stator. This magnetizing current get for the smallest pole number of 2p =

2 in a 50 Hz circuit the highest synchronousnerates a rotary field which turns with synchronous

speed ns.

Rotor

The rotor in induction machines with squirrel-cage rotors consists of a slotted cylindrical rotor

core sheet package with aluminum bars which are joined at the front by rings to form a closed

cage. The rotor of three-phase induction motors sometimes is also referred to as an anchor. The

reason for this name is the anchor shape of the rotors used in very early electrical devices. In

electrical equipment the anchor's winding would be induced by the magnetic field, whereas the

rotor takes this role in three-phase induction motors.

Table 1: typical synchronous speeds in a 50 Hz circuit

The stopped induction motor acts like a transformer shorted on the secondary side. The stator

winding thus corresponds to the primary winding, the rotor winding (cage winding) to the

secondary winding. Because it is shorted, its internal rotor current is dependent on the induced

voltage and its resistance. The interaction between the magnetic flux and the current conductors

in the rotor generates a torque that corresponds to the rotation of the rotary field. The cage bars

are arranged in an offset pattern to the axis of rotation in order to prevent torque fluctuation. This

is called "skew". At idle the rotor almost reaches the synchronous speed of the rotary field, since

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 34

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

only a small counter-torque (no-load losses) is present. If it were to turn exactly synchronously,

voltage would no longer be induced, current would cease to flow, and there would no longer be

any torque.

Slip

The difference between the synchronous speed ns and the speed n in rated operation is called slip

s and is generally expressed in percent. Depending on the size of the machine, in rated operation

it is roughly 10 to 3%. Slip is one of the most important characteristics of an induction machine.

The induced rotor voltage UR is proportional to the slip s. In the stopped position, it peaks at n =

1 and s = 1, which also results in the strongest current flow. This fact is confirmed in real-life

applications by the high starting current (starting current inrush). The torque also peaks during

the stop period at a certain rotor resistance. This behavior can be modified by design variation.

However the rotor resistance is not usually used for this purpose. The following formula applies

to the rotor speed:

3.3.11 Motor connection

Star/Delta starters are the most common reduced voltage starters. They are used in an attempt to

reduce the starting current applied to the motor during starting as a means of reducing the

disturbances and interference on the electrical supply. The Star/Delta starter is constructed from

three contactors. The single contactor used in a Direct on Line starters they are controlling

winding currents only. The currents through the winding are 13 = 0.58 (58%) of the current in

the line. This connection amounts to approximately 30% of the delta values. The starting current

is reduced to one third of the direct starting current.

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 35

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

Working Principle of Star Delta Starter

There are three states of Star-Delta starters.

Star connected state.

Open state and.

Delta connected state.

During starting time Main and Star Contactors remain closed and complete Circuit. In Star

connected State voltage applied is reduced to 1/3 of the Line Voltage across each winding. As

and when motor attains good rotational speed, say about 90% of full r.p.m. after few seconds,

timer connected in starter disconnects Star Contactor while connects Delta Contactor. Between

these two, Star connected and Delta connected states, circuit becomes open and motor neither

remains in Star nor in Delta State. This is called open transition switching. In delta connected

state voltage applied to windings is equal to Line Voltage. Items Required to Make Star Delta

Starter Three Contactors (One Main Contactor, One Star Contactor and One Delta Contactor ),

Over Load Relay ( or OLR ), Timer, Fuse, Start Push Button ( NO ) , Stop Push Button(NC).

Contactor relays are often used in control and regulating functions. They are used in large

quantities for the indirect control of motors, valves, clutches and heating Equipment. In addition

to the simplicity which they offer in project engineering, panel building, Commissioning and

maintenance, the high level of safety which they afford is a major Factor in their favor there are

two contactors that are close during run, often referred to as the main contractor and the delta

contactor. The third contactor is the star contactor and that only carries star current while the

motor is connected in star. The current in star is one third of the current in delta, so this contactor

can be AC3 rated at one third of the motor rating. In operation, the Main Contactor (KM3) and

the Star Contactor (KM1) are closed initially, and then after a period of time, the star contactor is

opened, and then the delta contactor (KM2) is closed. The control of the contactors is by the

timer (K1T) built into the starter. The Star and Delta are electrically interlocked and preferably

mechanically interlocked as well. The motor has a spinning rotor and behaves like a generator

delta State. The Main and the Delta contactors are closed. The Star contactor is open. The motor

is connected to full line voltage and full power and torque are available.

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 36

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

Fig. 12

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 37

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

CHAPTER FOUR

4. RESULT AND DISCUSSION

This chapter discusses about the simulation results of the induction motor monitoring and

protection system. In The Fig below represents the complete view of the Proteus Software

implementation of the induction motor monitoring and protection system. The temperature of the

motor windings is measured using LM35 temperature sensor. The current transformer detects

current rating of induction motor and voltage transformer detects voltage rating of the induction

motor and it can be displayed in LCD display and it is also displayed in virtual terminal.

4.1 PROTEUS VSM

We simulate the prototype in Proteus. Proteus Virtual System Modeling (VSM) combines mixed

mode SPICE circuit simulation, animated components and microprocessor models to facilitate

co-simulation of complete microcontroller based designs. Proteus VSM uses our proven

Schematic Capture software to provide the environment for design entry and development.

Proteus capture is a long established product and combines ease of use with powerful editing

tools. It is capable of supporting schematic capture for simulation. The Proteus schematic capture

module also provides a very high degree of control over the drawing appearance. These

capabilities are used to the full in providing the graphics necessary for circuit animation. The

Proteus design enables us to progress in our project more rapid, giving us the ability to make

hardware or software changes which reduces hardware and software troubleshooting problems.

The project was built and tested in Proteus just by using the software prototype components

without using the physical hardware prototype. Therefore using Proteus software, the voltage

sensing circuit, current sensing circuit, temperature sensor, relays, LEDs, LCD display and serial

communication were all developed and tested .

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 38

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

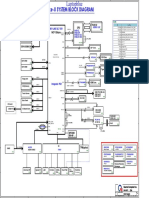

4.2 CIRCUTE DIAGRAME OF THE SYSTEM

Fig.13

Working principle of Diagram

As designed the circuit section consists of Arduino UNO microcontroller, step down transformer

circuit for voltage sensing, current sensing circuit, relay circuits, and a temperature sensor. The

step down transformer output been rectified and filtered to a pure dc which goes directly to

Arduino microcontroller analog pin for monitoring the load voltage. For the purpose of current

sensing, a current transformer was used for that purpose. It passes through rectification and

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 39

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

filtering process then directly connected to the microcontroller analog pin for monitoring the load

current. The motor temperature sensor is used to sense the motor winding temperature and the

sensor output pass through the conditional circuit which goes directly to Arduino microcontroller.

The arduino microcontrollers send the monitored parameters to LCD. While monitoring the

parameters, whenever a fault occurs which might be high voltage or over current, the arduino

microcontroller sends a trip signal to the relay and thereby protecting the motor from damaging.

The temperature of the induction motor is protection by varying the LM35 applied to the motor

the temperature of the motor is varied. The ON time and OFF time of the temperature waveform

can be varied. If the temperature increases the ON time of the waveform is increased and OFF

time is decreased. LED Shows the overload alert of the induction motor. If a current exceeds the

rated current the overload alert will be displayed in LCD display. The relay circuit will turn on

the LED to indicate the overload condition of the motor.

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 40

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

CHAPTER FIVE

5. CONCULUSION AND RECUMMENDATION

5.1 CONCULUSION

The utilization of induction motors becomes very popular when compared to other motors for

Many of the industries. In this project, induction motor monitor and protection using an Arduino

microcontroller is proposed. For motor voltage and current sensing circuits were designed and the

results have been verified with proteus simulation. The project we have undertaken has helped us

to gain a better perspective on various aspects related to our course of study as well as practical

knowledge of induction motor. The system developed is capable to perform such operations as

running the motor, stopping it, measuring, monitoring and protection the most parameters of the

motor like phase currents, phase voltages, winding temperature, basic parameters of the induction

motors were examined. The system achieved can be used for industrial applications. All of these

values can be transferred and displayed on the LCD. The system is very cheap as compared to

present protective devices available. The protection system can protect induction motor from

under voltage, over voltage, over current and unbalance voltages. The arduino microcontroller

which are used in protection Systems are easily available in the market and can be also used to

large protection system. This makes it possible for the operators to take the proper action which

leads to proper operation of the induction motor. Therefore the aim and objectives of the project

were achieved successfully and project is said to be industrious.

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 41

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

5.2 RECOMMENDATION

Any work and investigation on induction motor protection is very advantageous. At present time,

usage of induction motor is common in industry. Therefore, increasing demand of induction

motor and these will lead to demands of highly sophisticated protection devices, which will be

incorporated in induction motor protection schemes. The practical applications of this project are

immense and can have vast level of implementation. It can be implemented in a large scale to

encompass the entire induction motor in industrial plant by using a data base system. Based on

the work done in this project which protecting induction motor using microcontroller, some

improvements need to be made in the future work.

We are going forward to implement the project in real time applications.

The automatic efficiency and power factor of the induction motor should be calculated to

improve the performance of the Induction motor.

Induction motor parameters (values) in the industries should be monitored and updated in

industrial website through personal computer for providing the easy maintenance.

So this is not the end of the project but rather is a step towards exploring other

possibilities that it brings with it. We feel very happy to work in such a challenging

project which has tremendous application and possibilities.

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 42

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

REFERENCES

[1] Agbo D. O., Kureve D. T, Shittu D. H, Implementation Of An Automatic Induction Motor

Starter With Delay Using Microcontroller, International Journal Of Scientific & Technology

Research, Volume 3, Issue 5, May 2014.

[2] Kersting W.H., "Causes and effects of single-phasing induction motors," IEEE Transactions

on Industry Applications, Vol. 41, no. 6, pp. 1499-1505, Dec. 2005.

[3] Cunkas M., Akkaya R. and Ozturk A., "Protection of AC motors by means of

microcontrollers," 10th Mediterranean Electro technical Conference, MELECON 200, Vol.3,

May 2000

[4] Sudha M. and Anbalgan P., "A Novel Protecting Method for Induction Motor Against Faults

Due to Voltage Unbalance and Single Phasing," 33rd Annual Conference of the IEEE on

Industrial Electronics Society, 2007, pp. 1144-1148, 5-8 Nov. 2007, Taipei.

[5] Pillay P., Hofmann P. and Manyage M., induction motors operating with a combination of

unbalanced voltages and over or under voltages," IEEE Transactions on Energy Conversion, Vol.

17, no. 4, pp. 485-491, Dec. 2002

[6] Bayindir R., Sefa I, Colak I. and Bektas A., "Fault Detection and Protection of Induction

Motors Using Sensors," IEEE Transactions on Energy Conversion, Vol. 23, pp.734-741, Sept.

2000

[7] Javed A. and Izhar T., "An improved method for the detection of phase failure faults in poly

phase Induction machines," Third International Conference on Electrical Engineering, 2009,

ICEE '09, pp. 1-6, 9-11 April 2009, Lahore

[8] Chattopadhyay S.and Sengupta S., "Analysis of stator current of induction motor used in

transport system at single phasing by measuring phase angle, symmetrical components,

skewness, kurtosis and harmonic distortion in park plane," Electrical Systems in Transportation,

IET , Vol. 4, no. 1, pp. 1-8, March 2014

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 43

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

[9] Bayndr, R., Demirba, ., Irmak, E., Design and implementation of microcontroller based

starting and protection relay for induction motors, Journal of Polytechnic, (2007).

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 44

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

APPENDIX

Code of the system

#include <LiquidCrystal.h>

#include <SoftwareSerial.h>

// initialize the library with the numbers of the interface pins

LiquidCrystal lcd(12, 11, 5, 4, 3, 2);

//declare variables

float VoltOut;

float SD;

float I;

float tempC;

float volt;

float curt;

int voltOut;

float speed;

float D;

float current;

float T;

float V;

int speedlPin;

int tempPin=4;

int fanSpeed;

int voltPin=1;

int temp;

int fanLCD;

int fan = 13; // the pin where fan is

int led = 8; // led pin

int curtPin=0;

int speed1Pin=2;

int tempMin = 20; // the temperature to start the fan

int tempMax = 35;// the maximum temperature when fan is at 100%

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 45

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

int voltMax=250;

int voltMin=100;

float treshold=5;

void setup(){

// set up the LCD's number of columns and rows:

pinMode(fan, OUTPUT);

pinMode(led, OUTPUT);

lcd.begin(16, 4);

lcd.print("T=");

lcd.setCursor(0, 1);

lcd.print("V=");

lcd.setCursor(9, 0);

lcd.print("I=");

lcd.setCursor(9, 1);

lcd.print("S=");

Serial.begin(9600);

}

void loop()

{

int mytemp [5];

float avrtemp=0;

for (int i=0; i<= 4; i++)

{

mytemp [i]=analogRead(tempPin);

delay(10);

}

avrtemp=(mytemp [0]+mytemp [1]+mytemp [2]+mytemp [3]+mytemp [4])/5;

tempC = (5*avrtemp*100)/1023;

T = analogRead(tempPin); //read the value from the sensor

V = analogRead(voltPin);

I= analogRead(curtPin);

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 46

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

int myVolt [5];

float avrVolt=0;

for (int i=0; i<= 4; i++)

{

myVolt [i]=analogRead(voltPin);

delay(10);

}

avrVolt=(myVolt [0]+myVolt [1]+myVolt [2]+myVolt [3]+myVolt [4])/5;

SD = analogRead(speedlPin);

VoltOut = (5*avrVolt*46)/1023;

curt= (5*I)/1023;

current=(5*I*4)/1023;

speed=(5*SD*15)/1023;

D=(5*SD)/1023;

// print result to lcd display

lcd.setCursor(2, 0);

lcd.print(tempC,1);

lcd.print("C");

lcd.setCursor(11, 0);

lcd.print(current,1);

lcd.print("A");

lcd.setCursor(2, 1);

lcd.print(VoltOut,1);

lcd.print("V");

lcd.setCursor(11, 1);

lcd.print(speed,1);

lcd.print("rpm");

if(VoltOut> 230){

lcd.print("OVER VOLTAGE ");

delay(5);

}

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 47

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

if(current >16)

{

delay(5);

lcd.print(" OVER CURRENT ");

delay(5);

}

if(tempC>tempMax)

{

delay(5);

lcd.print(" HIGH TEMPRATURE ");

delay(5);

}

if(tempC < tempMin) { // if temp is lower than minimum temp

fanSpeed = 0; // fan is not spinning

digitalWrite(fan, LOW);

}

if((tempC >= tempMin) && (tempC <= tempMax)) { // if temperature is higher than minimum

temp

fanSpeed = map(tempC, tempMin, tempMax, 32, 255); // the actual speed of fan

fanLCD = map(tempC, tempMin, tempMax, 0, 100); // speed of fan to display on LCD

analogWrite(fan, fanSpeed); // spin the fan at the fanSpeed speed

}

if(tempC > tempMax) { // if temp is lower than minimum temp

fanSpeed = 0; // fan is not spinning

digitalWrite(fan, LOW);

}

if(tempC > tempMax) { // if temp is higher than tempMax

digitalWrite(led, HIGH); // turn on led

} else

{// else turn of led

digitalWrite(led, LOW);

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 48

Arduino Based Induction Motor Protection in Mugher Cement Enterprise

2016

}

if(speed >60){

lcd.print("the speed over");

delay(5);

}

}

Internship Report and Project

By Shumet Tizazu Wolaita Sodo University

Page 49

You might also like