Professional Documents

Culture Documents

Design and Optimization of Water Cool Condenser For Central Air Conditioner.

Uploaded by

ijripublishersOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Optimization of Water Cool Condenser For Central Air Conditioner.

Uploaded by

ijripublishersCopyright:

Available Formats

International Journal of Research and Innovation on Science, Engineering and Technology (IJRISET)

International Journal of Research and Innovation in

Thermal Engineering (IJRITE)

DESIGN AND OPTIMIZATION OF WATER COOL CONDENSER FOR CENTRAL AIR

CONDITIONER.

Chitturi Nagavamsi Ravi Teja1, S.Raja Sekhar2.

1 Research Scholar, Department of Mechanical Engineering, Godavari Institute of Engineering And Technology, Andhra Pradesh, India.

2 AssociateProfessor, Department of Mechanical Engineering, Godavari Institute of Engineering And Technology, Andhra Pradesh, India.

Abstract

Water-cooled chiller systems have typically been designed around entering condenser water temperatures of 85F with

a Optimization of Water - Cooled Chiller Cooling Tower Combinations The warm water leaving the chilled water coils

is pumped to the evaporator of the chiller, where the unwanted heat from the building is transferred by the latent heat

of vaporization of the refrigerant. The compressor of the chiller then compresses the refrigerant to a higher pressure,

adding the heat of compression in the process. The high pressure refrigerant then moves to the economical condenser

water flow of 3.0 USGPM/ton and a 10F denser, where the unwanted heat is rerange. In recent years, there has been

considerable debate on the merits of designing around lower condenser water flow rates with a higher range in order to

improve system lifecycle costs. However, two other parameters must also be considered in any analysis - approach and

design wet bulb. The question to be answered is: What nominal condenser water flow rate and approach is best from a

first cost standpoint as well as from a full load energy standpoint at any given wet bulb.

*Corresponding Author:

Central Air Conditioner System

Chitturi Nagavamsi Ravi Teja,

Research Scholar,Department of Mechanical Engineering, Godavari Institute of Engineering And Technology,

Andhra Pradesh, India.

Email: chitturivamsi09@gmail.com

Central air conditioner unit is an energy moving or converted machines that are designed to cool or heat the entire house. It does not create heat or cool. It just removes

heat from one area, where it is undesirable, to an area

where it is less significant.

Year of publication: 2016

Review Type: peer reviewed

Volume: III, Issue : I

Central air conditions has a centralize duct system. The

duct system (air distribution system) has an air handler,

air supply system, air return duct and the grilles and register that circulates warm air from a furnace or cooled air

from central air conditioning units to our room. It returns

that air back to the system and starts again.

Citation:Chitturi Nagavamsi Ravi Teja, Research Scholar "Design And Optimization of Water Cool Condenser

For Central Air Conditioner." International Journal of

Research and Innovation on Science, Engineering and

Technology (IJRISET) (2016) 84-91

INTRODUCTION

Refrigeration for personal comfort was first used in 1902.

By 1997, 72% of all American households had air-conditioning and 47% of all households were cooled with

central air. According to the Air-Conditioning and Refrigeration Institute (ARI), 81% of all new homes constructed

were equipped with central air-conditioning in 1996.

For a single family, detached home, the amount of energy

dedicated to air-conditioning can be quite significant. In

Atlanta, for example, air-conditioning accounts for approximately 19% of energy costs, which includes both gas

and electricity, or 310 dollars per year.

It also accounts for 32% of the total peak power demand

of electricity in these homes. Obviously, improving the

efficiency of residential air-conditioning units would decrease utility bills and pollution produced by the power

generation.

It uses AC refrigerant (we may know it as Freon) as a

substance to absorb the heat from indoor evaporator coils

and rejects that heat to outdoor condenser coils or vice

versa.

Central air conditioner units used a blown, which is

mounted indoor to a furnace to circular that cold air to

the entire house through air distribution system (duct). It

uses the same duct system for heating and cooling.

Technical Data of Shell and tube Heat Exchanger:

Heat duty = 345000 Kcal/hr

Quantity of oil = 43.33 m3/hr

Quantity of water = 200 m3/hr

Cooling water inlet temperature, T1 = 32.00C

Oil out let temperature, T2 = 45C

Fouling factor on oil side = 0.0004 hrm2 C / Kcal

Fouling factor on water side = 0.0002 hrm2 C/ Kcal

Tube material =Admiralty brass

Thermal conductivity of tube material= 104.12 Kcal/

hrmC

Number of tubes = 776

Number of passes = 4

Length of the tube = 2300mm

Outside diameter of the tube do =15.875mm

84

International Journal of Research and Innovation on Science, Engineering and Technology (IJRISET)

Model graphs:

Thickness of the tube =1.245mm

Inside diameter of the tube = 0.013385m

Inside surface area of the tube = xdi*L = Ai

= x(0.013385) * 2.3

= 0.0967m2

Outside surface area of the tube = do*L =Ao

= x 0.015875*2.3

= 0.1147 m2

Ratio of outside to inside surface area = Ao/Ai = 1.1862

Number of baffles = 11

Baffle cut = 28%

Type of cooler = Shell and tube heat exchanger

Tube pitch/ type =20.64 mm/30

Baffle thickness = 6mm

Shell inside diameter = 700mm

Number of tubes per pass =776/4=196

Baffle pitch = 141mm

No. of passes vs Heat transfer

OIL PROPERTIES AT AVERAGE TEMPERATURE (53 C): Density = 850 Kg/m3

Specific heat =0.471 Kcal/Kg C

Thermal conductivity =0.12925 Kcal/hrmC

Oil bulk viscosity = (b)oil = 73 Kg/hr m

Oil viscosity at tube wall temperature (w)oil =159 Kg/

hr m

WATER PROPERTIES AT AVERAGE TEMPERATURE (34

C): Density = 1000 Kg/m3

Specific heat = 1 Kcal/Kg C

Thermal conductivity = 0.5425 Kcal/hrmC

Viscosity (W) = 2.6 Kg/hr m

No. of passes vs Heat transfer

Simulation of Heat Exchanger:

In order to implement experimental data in the model,

boundary conditions of each part of the system should

bedetermined accurately.

Oil cooler heat exchanger

Oil circulates in a closed loop so the outlet and inlet oil

temperatures are dependent and they can be correlated

asfollows:

Q = mw Sw(t2-t1)

Manual Method Results:

Number of

passes

Ht Kcal/

hr-m2 C

Hs Kcal/

hr-m2 C

Uf Kcal/

hr-m2 C

Dp Kg/m2

2650

332

245

1432

4590

341

261

3645

8013.48

351.28

274.35

4178

11,144.68

364.45

290.14

14724

No. of passes vs Overall heat transfer coefficient

Results of Manual method

This table represents the experimental results. in this

the even number of passes increases the shell side heat

transferor efficient, tube side heat transfer and overall

heat transfer co efficient increases and pressure drop also

increases.

No. of passes vs Pressure drop

85

International Journal of Research and Innovation on Science, Engineering and Technology (IJRISET)

INTRODUCTION TO CREO PARAMETRIC (PRO-ENGINEER)

Pro/ENGINEER Wildfire is the standard in 3D product

design, featuring industry-leading productivity tools that

promote best practices in design while ensuring compliance with your industry and company standards. Integrated CREO parametric CAD/CAM/CAE solutions allow

you to design faster than ever, while maximizing innovation and quality to ultimately create exceptional products.

Customer requirements may change and time pressures

may continue to mount, but your product design needs

remain the same - regardless of your project's scope, you

need the powerful, easy-to-use, affordable solution that

CREO parametric provides.

ASSEMBLY PARTS OF HEAT EXCHANGERS:

Design view part of heat exchanger passage 6

This is the total assembly part of HEAT EXCHANGER

The following parts were used to design the assemble

parts to make a HEAT EXCHANGER.

SHELL.PRT

BUFFEL_PLATE.PRT

BUFFEL_PLATE.PRT

BUFFEL_PLATE1.PRT

BUFFEL_PLATE2.PRT

PATTERN.PRT

DOME.PRT

INTRODUCTION TO ANSYS

Design view part of heat exchanger passage 1

ANSYS is general-purpose finite element analysis (FEA)

software package. Finite Element Analysis is a numerical method of deconstructing a complex system into very

small pieces (of user-designated size) called elements.

The software implements equations that govern the behaviour of these elements and solves them all; creating a

comprehensive explanation of how the system acts as a

whole. These results then can be presented in tabulated

or graphical forms. This type of analysis is typically used

for the design and optimization of a system far too complex to analyze by hand. Systems that may fit into this

category are too complex due to their geometry, scale, or

governing equations.

MATERIAL PROPERTIES

Admiraltybrass:

Design view part of heat exchanger passage 2

Design view part of heat exchanger passage 4

Properties of Admiralty-Brass

86

International Journal of Research and Innovation on Science, Engineering and Technology (IJRISET)

Copper:

Imported model of condenser of one pass

Analysis Results of condenser with Admiralty Brass:

Thermal Analysis of Condenser with 1 passage with

Admiralty Brass:

Temperature result with one pass

Properties of Copper

Copper -Aluminum alloy

Time vs Temperature with one pass

Properties of Copper-Aluminum Alloy

THERMAL ANALYSIS of a condenser with Admiralty

Brass:

Thermal Analysis of Condenser with 1 Passageof Admiralty Brass:

Heat flux result with one pass

87

International Journal of Research and Innovation on Science, Engineering and Technology (IJRISET)

Analysis Results of condenser of four passages with

Admiralty Brass:

Time vsHeat flux with one pass

Analysis Results of condenser of two passages with

Admiralty Brass:

Temperature results with four passes

Temperature results with two pass

Time vsTemparature results with four passes

Time vs Temperature results with one pass

Heat flux results with four passes

Heat fluxresults with two pass

Time vs Heat fluxresults with four passes

88

International Journal of Research and Innovation on Science, Engineering and Technology (IJRISET)

Analysis Results of condenser of six passages with Admiralty Brass:

THERMAL ANALYSIS of a condenser with Copper:

Thermal Analysis of Condenser with 6 Passages with

Copper:

Temperature results with six passes

Temperature results with six passes

Time vsTemparature results with six passes

Heat fluxresults with six passes

Time vs Temperature results with six passes

Heat fluxresults with six passes

Thermal Analysis of Condenser with six Passageswith

Cu-Al Alloy

Time vs Heat fluxresults with six passes

Temperature results with six passes

89

International Journal of Research and Innovation on Science, Engineering and Technology (IJRISET)

Bar charts of results with Admiralty Brass:

Time vs Temperature results with six passes

Temparature with all passages

Heat fluxresults with six passes

OVERALL RESULTS AND DISCUSSION

In this project work central air conditioner condenser

(heat exchanger) has analyzed with the variation of 3 materials and 1/2/4/6 passages to suggest the optimum design material.

Heat flux with all passages

As per the analysis result tables & graphs has been produced as below for easy understanding:

Admiralty Brass:

TEMPERATURE

HEAT FLUX

1 PASSAGE

45.227

0.079431

2 PASSAGES

45.058

0.092678

4 PASSAGES

45.037

0.097065

6 PASSAGES

48.031

0.092771

Thermal Error with all passages

Copper:

TEMPERATURE

HEAT FLUX

1 PASSAGE

45.626

0.57876

2 PASSAGES

45.070

0.25650

4 PASSAGES

45.052

0.70758

6 PASSAGES

48.232

0.23366

Bar charts of results with Copper:

Cu-Al Alloy:

TEMPERATURE

HEAT FLUX

1 PASSAGE

45.234

0.19974

2 PASSAGES

45.063

0.23342

4 PASSAGES

45.044

0.24360

6 PASSAGES

48.232

0.23366

Temparature with all passages

90

International Journal of Research and Innovation on Science, Engineering and Technology (IJRISET)

plications (IJERA).

3.THEORETICAL ANALYSIS OF THE PERFORMANCE OF

DUAL PRESSURE CONDENSER IN A THERMAL POWER

PLANT

K.K.Anantha Kirthan, S. Sathurtha Mourian, P. Raj Clinton

International Journal of Mechanical Engineering and

Technology (IJMET).

Heat flux with all passages

4.PERFORMANCE ANALYSIS OF FINNED TUBE AIR

COOLED CONDENSING UNIT OF SPLIT AIR CONDITIONER

B. SREELAKSHMI,

Advanced Engineering and Applied Sciences.

5.DESIGN ANALYSIS OF A FINNED-TUBE CONDENSER

FOR A RESIDENTIAL AIR-CONDITIONER USING R-22

Emma May Sadler

Georgia Institute of Technology

6.Optimizing Design & Control Of Chilled Water Plants

Steven T. Taylor, P.E., Fellow ASHRAE

ASHRAE Journal

AUTHORS

Thermal error with all passages

CONCLUSION:

This project deals with DESIGN AND OPTIMIZATION

OF WATER COOLED CONDENSER FOR A CENTRAL

AIR CONDITIONING UNIT In this project work central

air conditioner condenser (heat exchanger) has analyzed

with the variation of 3 materials and 1/2/4/6 passages to

suggest the optimum design material.

Chitturi Nagavamsi Ravi Teja,

Research Scholar,

Department of Mechanical Engineering,

Godavari Institute of Engineering And Technology,

Andhra Pradesh, India.

Initially data collection and literature survey was conducted to understand the approach and methodology

through this material, boundary & lode conditions was

selected.

3d modeling and assembly for1/2/4/6 passages has been

done and exported to Ansys for further investigation.

Thermal analysis was conducted by varying 3 materials

as per the analysis results material2 & 3(copper & copper

-aluminum alloy) was showing better results than traditional material Admiralty brass. Copper is having more

features than copper-aluminum alloy but while considering the cost better to go with copper-aluminum alloy with

increased passages like 4 or 6 to improve performance.

S.Raja Sekhar,

AssociateProfessor,

Department of Mechanical Engineering,

Godavari Institute of Engineering And Technology,

Andhra Pradesh, India.

REFERENCES:

1. PERFORMANCE ANALYSIS ANDCALCULATION OFDIFFERENT PARAMETERS OFCONDENSER USING ANSYS

FLUENT SOFTWARE

Ram Mohan Gupta

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

2. PERFORMANCE ANALYSIS OF SURFACE CONDENSER UNDER VARIOUS OPERATING PARAMETERS

Ajeet Singh Sikarwar1, Devendra Dandotiya2, Surendra

Kumar Agrawal3

International Journal of Engineering Research and Ap91

You might also like

- Experimental Analysis On Compression Ignition Engine by Using Convergent Intake ManifoldDocument11 pagesExperimental Analysis On Compression Ignition Engine by Using Convergent Intake ManifoldijripublishersNo ratings yet

- Life Prediction Analysis of Tweel For The Replacement of Traditional WheelsDocument6 pagesLife Prediction Analysis of Tweel For The Replacement of Traditional WheelsijripublishersNo ratings yet

- CFD Analysis On Pulsating Heat Pipe To Improve Heat TransferDocument5 pagesCFD Analysis On Pulsating Heat Pipe To Improve Heat TransferijripublishersNo ratings yet

- Confidentiality Strategy Deduction of User-Uploaded Pictures On Information Sharing PortalsDocument3 pagesConfidentiality Strategy Deduction of User-Uploaded Pictures On Information Sharing PortalsijripublishersNo ratings yet

- Simulation and Analysis of 4 Stroke Single Cylinder Direct Injection Diesel EngineDocument4 pagesSimulation and Analysis of 4 Stroke Single Cylinder Direct Injection Diesel EngineijripublishersNo ratings yet

- Structural and Modal Analysis of An Engine Block by Varying MaterialsDocument4 pagesStructural and Modal Analysis of An Engine Block by Varying MaterialsijripublishersNo ratings yet

- Investigation On Thermal Properties of Epoxy Composites Filled With Pine Apple Leaf FiberDocument5 pagesInvestigation On Thermal Properties of Epoxy Composites Filled With Pine Apple Leaf FiberijripublishersNo ratings yet

- A Secluded Approval On Clould Storage ProceedingsDocument2 pagesA Secluded Approval On Clould Storage ProceedingsijripublishersNo ratings yet

- Performance Testing of Vortex Tubes With Variable ParametersDocument6 pagesPerformance Testing of Vortex Tubes With Variable ParametersijripublishersNo ratings yet

- Image Enhancement Aided Denoising Using Dual Tree Complex Wavelet TransformDocument4 pagesImage Enhancement Aided Denoising Using Dual Tree Complex Wavelet TransformijripublishersNo ratings yet

- Public Truthfulness Assessment For Shared Active Cloud Data Storage With Group User InvalidationDocument3 pagesPublic Truthfulness Assessment For Shared Active Cloud Data Storage With Group User InvalidationijripublishersNo ratings yet

- Modeling and Thermal Analysis of Air-Conditioner EvaporatorDocument6 pagesModeling and Thermal Analysis of Air-Conditioner EvaporatorijripublishersNo ratings yet

- Joint Data Hiding and Compression Based On Saliency and SMVQDocument5 pagesJoint Data Hiding and Compression Based On Saliency and SMVQijripublishersNo ratings yet

- Adaptive Temporal Averaging and Frame Prediction Based Surveillance Video CodingDocument5 pagesAdaptive Temporal Averaging and Frame Prediction Based Surveillance Video CodingijripublishersNo ratings yet

- An Experimental Analysis On Properties of Recycled Aggregate Concrete With Supplementary Mineral AdmixturesDocument8 pagesAn Experimental Analysis On Properties of Recycled Aggregate Concrete With Supplementary Mineral AdmixturesijripublishersNo ratings yet

- Ijricit-01-002 Enhanced Replica Detection in Short Time For Large Data SetsDocument3 pagesIjricit-01-002 Enhanced Replica Detection in Short Time For Large Data SetsijripublishersNo ratings yet

- A Prediction of Thermal Properties of Epoxy Composites Filled With Pine Apple Leaf FiberDocument5 pagesA Prediction of Thermal Properties of Epoxy Composites Filled With Pine Apple Leaf FiberijripublishersNo ratings yet

- Predictive Analysis of Gate and Runner System For Plastic Injection MouldDocument8 pagesPredictive Analysis of Gate and Runner System For Plastic Injection MouldijripublishersNo ratings yet

- Experimental Studies On High Performance Concrete Using MetakaolinDocument4 pagesExperimental Studies On High Performance Concrete Using MetakaolinijripublishersNo ratings yet

- Ijricit-01-005 PSCSV - Patient Self-Driven Multi-Stage Confidentiality Safeguard Supportive Verification SchemeDocument3 pagesIjricit-01-005 PSCSV - Patient Self-Driven Multi-Stage Confidentiality Safeguard Supportive Verification SchemeijripublishersNo ratings yet

- Ijricit-01-004 Progressive and Translucent User IndividualityDocument4 pagesIjricit-01-004 Progressive and Translucent User IndividualityijripublishersNo ratings yet

- Ijri Cce 02 004Document7 pagesIjri Cce 02 004ijripublishersNo ratings yet

- CFD Analysis On Ejector Cooling System With Variable Throat GeometryDocument6 pagesCFD Analysis On Ejector Cooling System With Variable Throat GeometryijripublishersNo ratings yet

- Ijricit-01-003 Privacy Protection in Online Social Networks Control Over Sharing of PhotographsDocument3 pagesIjricit-01-003 Privacy Protection in Online Social Networks Control Over Sharing of PhotographsijripublishersNo ratings yet

- Ijricit-01-001 Pipt - Path Backscatter Mechanism For Unveiling Real Location of Ip SpoofersDocument3 pagesIjricit-01-001 Pipt - Path Backscatter Mechanism For Unveiling Real Location of Ip SpoofersijripublishersNo ratings yet

- 9 Thermal Investigation (Pressure Distribution) On Box Type Cylinder Head of A 4 Stroke Single Cylinder Water Cooled Diesel Engine Material by Using Ansys15.0Document5 pages9 Thermal Investigation (Pressure Distribution) On Box Type Cylinder Head of A 4 Stroke Single Cylinder Water Cooled Diesel Engine Material by Using Ansys15.0ijripublishersNo ratings yet

- Study On Comparison of Self Curing of Concrete by Using Normal Coarse Aggregate and Recycled Coarse AggregateDocument8 pagesStudy On Comparison of Self Curing of Concrete by Using Normal Coarse Aggregate and Recycled Coarse AggregateijripublishersNo ratings yet

- Ijri Cce 01 008Document16 pagesIjri Cce 01 008ijripublishersNo ratings yet

- Ijri Cce 01 012Document9 pagesIjri Cce 01 012ijripublishersNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Evolution of the Human BrainDocument3 pagesEvolution of the Human Brainvidur_talrejaNo ratings yet

- Brooke Brackett Resume 1Document2 pagesBrooke Brackett Resume 1api-710146490No ratings yet

- ,,, Pou-Ieng Cheong,, ,,, andDocument23 pages,,, Pou-Ieng Cheong,, ,,, andSantiago GNo ratings yet

- Uml Lab ManualDocument38 pagesUml Lab ManualcomputerstudentNo ratings yet

- 41Cr4 Chemical PDFDocument2 pages41Cr4 Chemical PDFGayathriRajasekaranNo ratings yet

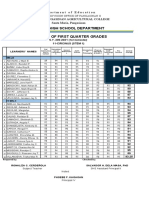

- Department of Education Senior High School 1st Quarter GradesDocument4 pagesDepartment of Education Senior High School 1st Quarter GradesRonaliza CerdenolaNo ratings yet

- Urban Real Estate and Urban PlanningDocument11 pagesUrban Real Estate and Urban Planningazelea92No ratings yet

- Role play teaching strategy evaluated for IT courseDocument9 pagesRole play teaching strategy evaluated for IT courseHitesh MishraNo ratings yet

- Ie2 - Week 4 - Speaking TestDocument3 pagesIe2 - Week 4 - Speaking TestNgan TranNo ratings yet

- Unit 2 Lect 1 Program StructureDocument14 pagesUnit 2 Lect 1 Program StructureManav JainNo ratings yet

- Purusha Suktam PDFDocument13 pagesPurusha Suktam PDFRamkumar SundaramNo ratings yet

- Minesight - Designing Cuts For STP and Calculating Reserves With ReserveDocument38 pagesMinesight - Designing Cuts For STP and Calculating Reserves With ReserveDody100% (1)

- Villa Palao HOA Management System with Email NotificationsDocument16 pagesVilla Palao HOA Management System with Email NotificationsCE ITNo ratings yet

- Alcohol Use Disorders Identification Test (AUDIT)Document2 pagesAlcohol Use Disorders Identification Test (AUDIT)Teresa Meehan100% (1)

- SKF 593629 SpecificationDocument3 pagesSKF 593629 Specificationlei songNo ratings yet

- Unsearchable Riches of Christ, TheDocument387 pagesUnsearchable Riches of Christ, ThejaufreNo ratings yet

- SCmod Readme v1 40Document4 pagesSCmod Readme v1 40Anonymous uJRFjt1W50% (2)

- BhaskarDocument37 pagesBhaskarchiragdbeckNo ratings yet

- Asthma DiaryDocument3 pagesAsthma Diarybrian@coombsmd.comNo ratings yet

- Introduction To Art & Cinema Unit IVDocument24 pagesIntroduction To Art & Cinema Unit IVSri vaishnavaNo ratings yet

- Pantoprazole Tablets USP-32Document7 pagesPantoprazole Tablets USP-32Nikhil SindhavNo ratings yet

- Grove AP206 SpecDocument10 pagesGrove AP206 SpecHoward HoacNo ratings yet

- ID Pengaruh Kejenuhan Kerja Beban Kerja DanDocument15 pagesID Pengaruh Kejenuhan Kerja Beban Kerja DanArif RcNo ratings yet

- InductionDocument26 pagesInductionDileep NaraharasettyNo ratings yet

- Tthhee Nnaattuurraall NnuummbbeerrssDocument36 pagesTthhee Nnaattuurraall NnuummbbeerrssStephen BankesNo ratings yet

- Body Defence MechanismsDocument11 pagesBody Defence MechanismsJoyce TaiNo ratings yet

- Chapter 10Document51 pagesChapter 10Nayeem HakimNo ratings yet

- Configure Document Record As Custom Loan Request FormDocument13 pagesConfigure Document Record As Custom Loan Request Formshu1706No ratings yet

- PDF Nitrile Astm d6319 StandardDocument6 pagesPDF Nitrile Astm d6319 StandardJHONATAN JUAREZ DE LA CRUZNo ratings yet

- System Analysis and DesignDocument69 pagesSystem Analysis and Designsam mydaxNo ratings yet