Professional Documents

Culture Documents

GMW 14829 PDF

Uploaded by

Ed RiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GMW 14829 PDF

Uploaded by

Ed RiCopyright:

Available Formats

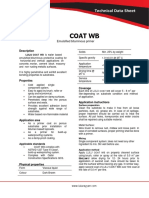

WORLDWIDE

ENGINEERING

STANDARDS

Test Method

Materials

GMW14829

Tape Adhesion Test for Paint Finishes

Peel strength, steel ASTM D3330M 760 N/m min

1 Scope

This standard specifies the test method to be used

to evaluate the adhesion properties of painted

metal and plastic before and after environmental

testing. This standard describes the cross hatch

tape test using the cutting tool or cutting guide. All

paint systems must meet the adhesion

requirements when either method is used. Unless

otherwise specified, the dry film thickness will

determine which guide or tool is required. If either

method is not usable due to size and/or shape

constraints (typically found in small parts) the

sense of the test shall be utilized

Note: Nothing in the specification supersedes

applicable laws and regulations unless specific

exemption has been obtained.

Note: In the event of conflict between the English

and domestic language, the English language shall

take precedence.

2 References

Note: Only the latest approved standards are

applicable unless otherwise specified.

2.1 External Standards/Specifications.

ASTM D3330M

ASTM D3652

ASTM D3759

2.2 GM Standards/Specifications.

GM4365M

3 Test Equipment

3.1 Pressure Sensitive Adhesion Tape. It is

extremely important that the tape adhesively bonds

to steel according to ASTM 3330M with a minimum

180 degree peel strength value of 430 N/m.

Weaker adhesives will reduce the severity of the

test results. The tape backing should exhibit low

elongation. The following describes the various

parameters of the recommended tape:

3.1.1 Nominal Dimensions.

Width = 20 mm minimum thickness,

ASTM D3652M.........> 0.14 mm.

3.1.2 Properties.

total

Elongation ASTM D3759M...5% max.

3.1.3 Shelf Life 12 months max.

3.1.4 Recommended Products.3M 8981, 3M 898

3.2 Sharp razor knife, retractable carbide cutter by

Reider (Swiss) Rico Marker, or cutting tool by

Gardco or BYK Gardner cross-cut tester.

3.3 Cutting guide at 1 mm, 2 mm and 3 mm.

3.4 Rubber eraser or equivalent instrument for

applying tape.

3.5 Stiff pencil brush.

.4 Test Material

The test pieces wherever possible shall be the

finished part. If size, shape, etc. of the finished part

is unsuitable, tests shall be conducted on specially

prepared coated test panels.

5 Test Method

5.1 Summary of Test Method. The adhesion of

organic coatings as determined by this test method

shall be defined as the tendency of the coating to

become detached in the vicinity of scribed lines in

the shape of a lattice pattern cut through the

coating, before and after exposure to defined

environmental conditions.

5.2 Test Sample Preparation.

5.2.1 Parts in the as received conditions should be

clean and dry before conducting the test. Oil, wax

or any residue in the painted surface shall be

removed with soap and water or any other cleaner.

Dry the samples by blotting with an absorbent

paper or cloth.

5.1.2 When specified the coated test specimens

shall be subjected to an environmental test, such

as water immersion, humidity or salt spray test,

etc. before conducting the tape adhesion test. In

this case, conduct the environmental test as

required and dry samples by blotting with an

absorbent paper or cloth.

5.3 Test Procedure.

5.3.1 Select a representative area or an area

suspected of having poor film adhesion on the

paint surface to be tested. Do not select sagged,

Copyright 2006 General Motors Corporation All Rights Reserved

October 2006

Originating Department: North American Engineering Standards

Page 1 of 3

GMW14829

GM WORLDWIDE ENGINEERING STANDARDS

solvent popped or obviously defective areas as

these defects should be rated separately.

5.3.2 The recovery time after exposure to

environmental cycle tests and before tape

adhesion test and before tape adhesion tests shall

be 1 hour unless otherwise specified in the

appropriate specifications (Example: GM4365M or

998XXXX).

5.3.3 Make a cross hatch cut with the sharp cutting

tool. The number of lines and spacing between the

lines shall depend upon the coating film thickness

as shown in Appendix A Table A1. Make all cuts

about 20 mm long. Cut through the film in one

steady motion using just sufficient pressure on the

cutting tool to have the cutting edge reach the

substrate. When making successive single cuts

with the aid of a guide, place the guide on the

uncut area and cut through the film to the

substrate. Make the similar type and number of

cuts perpendicular and centered on the original

cuts. Avoid cutting so deeply that the substrate is

displaced.

5.3.4 After making the required cuts, brush the film

lightly with a soft bristle brush or tissue to remove

any detached flakes or ribbons of coating.

5.3.5 Dispense or cut a strip of tape approximately

75 mm long being careful not to allow the adhesive

side to come in contact with anything before the

test application. Place the center of the tape over

the grid so that the tape covers the crosshatch

diagonally.

5.3.6 Press the tape down firmly on the surface

with sufficient rubs of the eraser to remove air

bubbles and to insure good contact between the

tape and paint surface.

5.3.7 After 5 to 10 seconds, grasp the tail end of

the tape between thumb and fore finger and pull

upward with a rapid jerking motion perpendicular to

the paint film.

6 Evaluation and Rating

6.1 Rate the adhesion performance per

Appendix A Table A2.

6.2 Paint adhesion should be reviewed on both the

part and the tape.

6.3 Multiple tape adhesion tests shall be conducted

(minimum of three), space permitting larger parts

will require more and should consider geometric

configuration and processing characteristics.

7 Report

7.1 Record the tape adhesion rating per

Appendix A Table A2.

7.2 Record the failure mode indicating where the

failure occurred, that is, within substrate, between

first coat and substrate, between firs and second

coat, etc.

7.3 Submit both painted sample and tape for

review. Tape should be submitted on an overhead

(acetate film). The tape should never be placed

back on the sample.

8 Safety

This method may involve hazardous materials,

operations, and equipment. This method does not

propose to address all the safety problems

associated with its use. It is the responsibility of the

user of the method to establish appropriate safety

and health practices and determine the

applicability of regulatory limitations prior to use.

9 Notes

9.1 Glossary. Not applicable.

9.2 Acronyms, Abbreviations, and Symbols. Not

applicable.

10 Coding System

This test method shall be referenced in other

documents, drawings, VTS, CTS, etc. as follows:

Per GMW14829-Rating 0

11 Release and Revisions

11.1 Release. This standard originated in

November 2005, replacing GM9071P, GME 60401,

and GMW14697. It was first approved by Paint in

September 2006. It was first published in October

2006.

Copyright 2006 General Motors Corporation All Rights Reserved

Page 2 of 3

October 2006

GM WORLDWIDE ENGINEERING STANDARDS

GMW14829

Appendix A

Table A1: Cutting Guide

Film Thickness

(Microns)

Spacing (mm)

Number of cuts

(In each direction)

60

60 to 200

200

Table A2: Cross Hatch Classification/Rating Scale

Surface of cross-cut

area from which flaking

has occurred

Rating

(classification)

Greater

than

65%

None

Note: Key for rating scale.

Rating

Description

The edges of the cuts are completely smooth; none of the squares of the lattice is

detached.

Detachment of small flakes of the coating at the intersections of the cuts.

Across cut area of 5% max is affected.

The coating has flaked along the edges and/or at the intersections of the cuts.

Across cut area of 5% minimum but 15% maximum.

3

4

5

The coating has flaked along the edges of the cuts partly or wholly in large ribbons,

and/or it has flaked partly or wholly on different parts of the squares.

Across cut area of 15% minimum but 35% maximum is affected.

The coating has flaked along the degrees of the cuts in large ribbons and/or some

squares have detached partly of wholly.

Across cut area of 35% minimum but 65% maximum is affected.

A cross-cut area of > 65% is affected

Copyright 2006 General Motors Corporation All Rights Reserved

October 2006

Page 3 of 3

You might also like

- GMW14829 PDFDocument3 pagesGMW14829 PDFAshley WileyNo ratings yet

- GMW15058 May 2015Document13 pagesGMW15058 May 2015Anonymous 8Z2HZ5JP7No ratings yet

- E M0140 2009-N PDFDocument11 pagesE M0140 2009-N PDFAna Georgina Vidrio Longoria75% (4)

- Hand Out To Borbet GMBH: Coating Adhesion TestDocument8 pagesHand Out To Borbet GMBH: Coating Adhesion Testferhat aydoganNo ratings yet

- Worldwide Engineering Standards: Neutral Salt Spray (NSS) TestDocument4 pagesWorldwide Engineering Standards: Neutral Salt Spray (NSS) Testjorgesalg100% (2)

- Astm D4000, 2004Document19 pagesAstm D4000, 2004aletapia100% (1)

- Distillation Column PipingDocument57 pagesDistillation Column PipingKaran Singh92% (13)

- ASTM D5420-04 - Gardner - Impact Resistance of Flat Rigid Plastic Specimen PDFDocument8 pagesASTM D5420-04 - Gardner - Impact Resistance of Flat Rigid Plastic Specimen PDFMehdi Gouader0% (1)

- Abrasion Resistance Test & ASTM D968Document5 pagesAbrasion Resistance Test & ASTM D968ManukantShrotriyaNo ratings yet

- GMW 14124 汽车环境循环测试 PDFDocument7 pagesGMW 14124 汽车环境循环测试 PDFlrobertothNo ratings yet

- Pre ASTM B117-19Document5 pagesPre ASTM B117-19Ranga100% (3)

- GMW15340Document24 pagesGMW15340Ed Ri50% (2)

- GMW15340Document24 pagesGMW15340Ed Ri50% (2)

- GMW15340Document24 pagesGMW15340Ed Ri50% (2)

- BS en 10268-2006Document16 pagesBS en 10268-2006liusf100% (2)

- Exterior Paint Requirements for Plastic Auto PartsDocument9 pagesExterior Paint Requirements for Plastic Auto PartsFrancesco VignaliNo ratings yet

- GMW14671 - Organic Coating UnderbodyDocument4 pagesGMW14671 - Organic Coating UnderbodyYosua Dimas Agus SriyantoNo ratings yet

- Innovative Use of Recycled Tyres in Civil Engineering ApplicDocument73 pagesInnovative Use of Recycled Tyres in Civil Engineering Applicparasgandhi187874100% (5)

- Hawker Battery Service ManualDocument59 pagesHawker Battery Service ManualBill Waters100% (1)

- Technical Data Sheet for Emulsified Bituminous PrimerDocument2 pagesTechnical Data Sheet for Emulsified Bituminous Primerhandhammer qatarNo ratings yet

- WSS M15P4 H PDFDocument11 pagesWSS M15P4 H PDFJolyeTorresNo ratings yet

- Worldwide Engineering Standards: Stone Impact Resistance of CoatingsDocument6 pagesWorldwide Engineering Standards: Stone Impact Resistance of CoatingsAlondra CVNo ratings yet

- Scope TestsDocument4 pagesScope TestsGonzalo TelleríaNo ratings yet

- Testing Water Resistance of Coatings Using Controlled CondensationDocument4 pagesTesting Water Resistance of Coatings Using Controlled CondensationErin JohnsonNo ratings yet

- VDA 4530 Disposable Small Load CarrierDocument32 pagesVDA 4530 Disposable Small Load CarrierEd RiNo ratings yet

- Organic Coat GMW 14670 PDFDocument4 pagesOrganic Coat GMW 14670 PDFYosua Dimas Agus SriyantoNo ratings yet

- Worldwide Engineering Standards: Tape Adhesion Test For Paint FinishesDocument3 pagesWorldwide Engineering Standards: Tape Adhesion Test For Paint FinishesRicardo Bavasso100% (1)

- Supplier Manual Rev03 2011 ThyssenkruppDocument38 pagesSupplier Manual Rev03 2011 ThyssenkruppEd Ri100% (1)

- Harmonized Document: Fluids Resistance To VariousDocument8 pagesHarmonized Document: Fluids Resistance To VariousJuliano Depetris100% (1)

- D1014Document5 pagesD1014manox007No ratings yet

- PR308 - 2+00+en - Invecchiamento BMWDocument10 pagesPR308 - 2+00+en - Invecchiamento BMWAnonymous 8Z2HZ5JP7100% (1)

- Performance Requirements For Engine Compartment Plastic PartsDocument5 pagesPerformance Requirements For Engine Compartment Plastic PartsAkmal Nizametdinov100% (1)

- GMW14671 (Dec 2016)Document5 pagesGMW14671 (Dec 2016)Ashley Wiley100% (2)

- GM 4350M-2004 部件涂层性能要求Document7 pagesGM 4350M-2004 部件涂层性能要求KESAVANNo ratings yet

- GMW14669Document10 pagesGMW14669Ricardo F. SNo ratings yet

- ATE N 553 81.09 (En)Document11 pagesATE N 553 81.09 (En)Miguel QueirosNo ratings yet

- GMW 14872 PDFDocument21 pagesGMW 14872 PDFJetesh Devgun100% (2)

- M0007 - 2014-1 Testing Method For Automotive PaintDocument164 pagesM0007 - 2014-1 Testing Method For Automotive PaintErick Hernández0% (1)

- Engineered Coating SDocument2 pagesEngineered Coating SHo Bach100% (1)

- EX-GM-006 - GMW 14698 - 200709 - EN - Scratch Resistance of Orangnic Coatings and Self-Adhesion Foils PDFDocument3 pagesEX-GM-006 - GMW 14698 - 200709 - EN - Scratch Resistance of Orangnic Coatings and Self-Adhesion Foils PDFEd RiNo ratings yet

- D271389 F' PDFDocument13 pagesD271389 F' PDFReza AbdolahiNo ratings yet

- Vda Libro 3 PDFDocument157 pagesVda Libro 3 PDFsofilanda100% (3)

- Atmospheric Crude Distillation UnitDocument2 pagesAtmospheric Crude Distillation UnitFahmi Ramadhan PutraNo ratings yet

- Worldwide Engineering Standards: Procedures For High Humidity TestDocument3 pagesWorldwide Engineering Standards: Procedures For High Humidity TestAkmal NizametdinovNo ratings yet

- Automotive PlatformsDocument13 pagesAutomotive PlatformsEd Ri71% (7)

- Physics of Radio Frequency Plasmas PDFDocument395 pagesPhysics of Radio Frequency Plasmas PDFdada12100% (1)

- m3018 en - 2008 08Document16 pagesm3018 en - 2008 08Ronaldo Rodrigues100% (1)

- Standard Conditioning of Organic Materials: Worldwide Engineering StandardsDocument3 pagesStandard Conditioning of Organic Materials: Worldwide Engineering StandardsAkmal Nizametdinov100% (2)

- D3363-05:2011 ASTM Pencil Hardness TestDocument3 pagesD3363-05:2011 ASTM Pencil Hardness TestJulia Dotto Giacomini100% (1)

- GMW 14057-2012Document11 pagesGMW 14057-2012JUAN CARLOS MURILLO LARROTANo ratings yet

- Formulation Development and Evaluation of Sustained Release Tablets of AceclofenacDocument128 pagesFormulation Development and Evaluation of Sustained Release Tablets of Aceclofenacraju narayana padala0% (1)

- PV 3952 (2002)Document4 pagesPV 3952 (2002)Matthew Taylor100% (2)

- GMW - 4707-2002 Corrosion Protective Coating Zinc Plating OrganicDocument3 pagesGMW - 4707-2002 Corrosion Protective Coating Zinc Plating Organichorse888No ratings yet

- Vda 260Document9 pagesVda 260Ed Ri83% (6)

- D4585 PDFDocument3 pagesD4585 PDFten100% (1)

- GMW3059 - Material Specification PDFDocument7 pagesGMW3059 - Material Specification PDFJuanPeriquitan100% (2)

- GMW 8-2008Document9 pagesGMW 8-2008Clauco Tiago Seno RoqueNo ratings yet

- GMW 3044-0405Document5 pagesGMW 3044-0405GilmarasanNo ratings yet

- Mechanical ASTM B487Document1 pageMechanical ASTM B487Brajesh100% (1)

- GMW 14093jan2011Document3 pagesGMW 14093jan2011Ivan Dario Oyola Ravelo100% (1)

- ISO 6270 2 2005 Testing Methodology V1 PDFDocument3 pagesISO 6270 2 2005 Testing Methodology V1 PDFFadi MagdyNo ratings yet

- Test Method of Flammability of Interior Materials For AutomobilesDocument17 pagesTest Method of Flammability of Interior Materials For AutomobilesKarthic BhrabuNo ratings yet

- Astm D 3363-05Document3 pagesAstm D 3363-05briham100% (1)

- Worldwide Engineering Standards: Tape Adhesion Test For Paint FinishesDocument9 pagesWorldwide Engineering Standards: Tape Adhesion Test For Paint FinishesAkmal NizametdinovNo ratings yet

- Engineering Material Specification: Controlled Document at Page 1 of 6Document6 pagesEngineering Material Specification: Controlled Document at Page 1 of 6erik0007No ratings yet

- Worldwide Engineering Standards: Stone Impact Resistance of CoatingsDocument3 pagesWorldwide Engineering Standards: Stone Impact Resistance of CoatingsAnvarbek KarimovNo ratings yet

- Wss-m2p177 - Paint Performance, Chassis Low Level Visible - A1 A A5Document5 pagesWss-m2p177 - Paint Performance, Chassis Low Level Visible - A1 A A5Fab CarvalNo ratings yet

- Rust Protection by Metal Preservatives in The Humidity CabinetDocument9 pagesRust Protection by Metal Preservatives in The Humidity CabinettoanvmpetrologxNo ratings yet

- D 5628 - 96 R01 - Rdu2mjg - PDFDocument10 pagesD 5628 - 96 R01 - Rdu2mjg - PDFJuan Pablo ApazaNo ratings yet

- WSS M16J19 BDocument10 pagesWSS M16J19 BJuan Angel DechimaNo ratings yet

- WSS M8P16 BDocument16 pagesWSS M8P16 Berik0007No ratings yet

- GMW14829 AderenciaDocument8 pagesGMW14829 AderenciaRicardo F. SNo ratings yet

- Mandrel Bend Test of Attached Organic Coatings: Standard Test Methods ForDocument4 pagesMandrel Bend Test of Attached Organic Coatings: Standard Test Methods ForKarlos Albert Xukizuta100% (1)

- GMW15282 CorrosionUndercutting Scribe CreepbacDocument7 pagesGMW15282 CorrosionUndercutting Scribe CreepbacRicardo F. SNo ratings yet

- PPAP 4th EdDocument11 pagesPPAP 4th EdEd Ri0% (1)

- GME 6090M - Flammability of MaterialsDocument3 pagesGME 6090M - Flammability of MaterialsEd RiNo ratings yet

- GMW15520Document10 pagesGMW15520Ed RiNo ratings yet

- GMW15516Document13 pagesGMW15516Ed Ri0% (1)

- WSS M99P9999 A1 2008Document68 pagesWSS M99P9999 A1 2008Ed RiNo ratings yet

- GMW15520Document10 pagesGMW15520Ed RiNo ratings yet

- PPAP 4th EdDocument11 pagesPPAP 4th EdEd Ri0% (1)

- GMW15516Document13 pagesGMW15516Ed Ri0% (1)

- Folder ILF Upstream Facilities enDocument4 pagesFolder ILF Upstream Facilities enSterling GordianNo ratings yet

- Small STNTechnical ManualDocument8 pagesSmall STNTechnical ManualMajid KhanNo ratings yet

- 1D Nano Porous Silicon Optical Sensor Detects Methyl ParathionDocument7 pages1D Nano Porous Silicon Optical Sensor Detects Methyl ParathionhesoyamyecgaaaNo ratings yet

- UWO Chem 3300g Computer MethodsDocument2 pagesUWO Chem 3300g Computer MethodsmejiasclaudiaNo ratings yet

- Refineria de Cartagena (Reficar) Refinery Expansion - Hydrocarbons TechnologyDocument3 pagesRefineria de Cartagena (Reficar) Refinery Expansion - Hydrocarbons TechnologyGjorgeluisNo ratings yet

- Tempcore ProcessDocument4 pagesTempcore Processvikassolanki2010No ratings yet

- GDocument3 pagesGjeas grejoy andrewsNo ratings yet

- Nanotechnology v1.0Document43 pagesNanotechnology v1.0Faizan AhmedNo ratings yet

- Ch11 CastingProcessesDocument102 pagesCh11 CastingProcessesFahmi PrayogiNo ratings yet

- Shell Rimula R3 Turbo 15W-40Document2 pagesShell Rimula R3 Turbo 15W-40HUM CIREBON DFLTSNo ratings yet

- MSDS 853021 Dry Charge BatteryDocument3 pagesMSDS 853021 Dry Charge Batteryjian0889No ratings yet

- Tds-Duraplate UhsDocument4 pagesTds-Duraplate UhsAlberto Acosta GongoraNo ratings yet

- 02 Filtros de Ingreso A CompresorDocument6 pages02 Filtros de Ingreso A CompresorLuis Alonso Dipaz ZeaNo ratings yet

- A 826 - A826m - 95 Qtgyni05nqDocument5 pagesA 826 - A826m - 95 Qtgyni05nqsachinguptachdNo ratings yet

- Information Booklet Elements Compounds and MixturesDocument40 pagesInformation Booklet Elements Compounds and MixturesnowhinesonchemistryNo ratings yet

- 01 January 2024 Daily Current Affairs QuizDocument4 pages01 January 2024 Daily Current Affairs QuizUttam PutelNo ratings yet

- Enthalpy Changes TestDocument14 pagesEnthalpy Changes TestSonic EightNo ratings yet

- Nuclear Medicine Inc.'s Iodine Value Chain AnalysisDocument6 pagesNuclear Medicine Inc.'s Iodine Value Chain AnalysisPrashant NagpureNo ratings yet

- 12.co Ordination CompoundsExerciseDocument34 pages12.co Ordination CompoundsExerciseMaster Of HakingNo ratings yet

- 005-1-Vocabulary Qs 2PsgsDocument2 pages005-1-Vocabulary Qs 2PsgsAlondra RezaNo ratings yet

- PhysioEx Exercise 1 Activity 4Document3 pagesPhysioEx Exercise 1 Activity 4Дмитро МарчукNo ratings yet

- Water Cycle Questions AnwarDocument4 pagesWater Cycle Questions Anwarapi-124758305No ratings yet

- Amino Acid For NeonateDocument13 pagesAmino Acid For NeonateHerti PutriNo ratings yet