Professional Documents

Culture Documents

Chapter 17 Product Recovery

Uploaded by

Carlos Miguel DacaimatCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 17 Product Recovery

Uploaded by

Carlos Miguel DacaimatCopyright:

Available Formats

Chapter 17 Product Recovery

Product recovery in bioprocessing plays a vital role. Sometimes, the product

recovery costs may even decide the economic viability of the process. They

vary anywhere between 20-60% of the product cost. In some extreme cases,

the costs may go up to 90%, as in the case of recombinant DNA fermentation

products.

The product recovery operations are also known as downstream processing

steps. They include all the steps we take up after the fermentation step is

completed in the bioreactor. They play a very crucial role because the

products that come out of the bioreactor may consist of the following, in

addition to the metabolic product:

Microorganisms

Whole cells

Cell debris/fragments

Soluble and insoluble medium products

Pellets of aggregated proteins

Undissolved nutrient components, etc.

In view of the large number of unnecessary products being present in the

fermented broth, downstream processing steps are important. They may be

broadly classified into

Initial isolation

Product recovery

Purification and concentration

The type of the downstream processing step to be adopted for a particular

fermentation process depends upon the product, its value and the use for

which it is meant. A very costly product to be used for medicinal purposes in

small quantities will be purified and concentrated using very sophisticated

downstream processing steps; whereas those meant for industrial use in bulk

quantities, may be recovered with some of the initial isolation steps. If the

solids are present in suspension, they will be separated by simple

sedimentation or filtration or centrifugation. It also depends upon the

location of the product in the presence of cells, viz. extracellular or

intracellular, i.e. whether the product is independently existing of the cells or

the product is trapped inside the cells. In the latter case, we may have to go

for some of the steps for disrupting the cells.

The cell disruption techniques may be classified as

Physical methods

Chemical methods

Various unit operations involved in product isolation and purification

are highlighted as Step 6 in Fig. 1.1 the specific choice of the recovery

of the product may be summarized as follows (Stanbury and Whitaker,

1993):

The location of the product, viz. intracellular or extracellular, and the

heat labile nature of the product

The quantity of the product in the fermentation broth, i.e. whether it is

available in a concentrated form or in a very dilute form

The cost of the product

The end use of the product

The minimal acceptable standards of the product

The impurities present in the fermentation product, and their nature of

interference with the product recovery steps.

FILTRATION

Filtration is a physical method of separation of suspended particles of

any size from the liquid medium. Here, the only criterion is that the particle

size should be larger than the molecules size of the liquid, which is always

true. It is a very effective and convenient method of separating the

suspended solids from the slurries. In this method of separation, either solids

or the liquid or both could be the desired products.

The liquid along with the suspended solids will be transferred on to a

filter medium. The filter medium will retain all the particles which are bigger

than the size of its aperture, and will pass on all the liquid medium along

with some of the very fine suspended solid particles. All the material

remaining on the filter medium is known as residue or filter cake, and all

the material passing through (the filter medium) is known as filtrate (Fig.

17.). The filter medium, usually known as filter cloth, is kept on a perforated

screen to provide mechanical support to the filter aid. As the filtration

process continues, more and more solids build up in the filter cake and offer

more resistance for the flow of the fluids. But as the filter cake builds up, the

filtration efficiency will also improve, that is to say that still finer particles can

be retained in the residue and the filtrate can be more clear of the solids.

Thus, filtration efficiency will improve, but the filtration rate will reduce.

You might also like

- Downstream ProcessingDocument20 pagesDownstream ProcessingDrishti MalhotraNo ratings yet

- Downstream ProcessingDocument5 pagesDownstream ProcessingLuis Hernandez AlvarezNo ratings yet

- Downstream ProcessingDocument21 pagesDownstream ProcessingNasir Ahmed YusufNo ratings yet

- Down Stream ProcessingDocument44 pagesDown Stream ProcessingShifa ChoudharyNo ratings yet

- Downstream ProcessingDocument72 pagesDownstream ProcessingTrainer NIANo ratings yet

- Slurry - Separation Mechanism-Product-Solid or Liquid OR BothDocument77 pagesSlurry - Separation Mechanism-Product-Solid or Liquid OR Both259Katkar PrathmeshNo ratings yet

- Assignment On Installation Qualification and Operational Qualification of Membrane FilterDocument27 pagesAssignment On Installation Qualification and Operational Qualification of Membrane FilterVenkat Kumar50% (2)

- Mohsin My New Down Stream ProcessingDocument56 pagesMohsin My New Down Stream Processingchintan kapadiaNo ratings yet

- Chap9 Downstream ProcessingDocument25 pagesChap9 Downstream ProcessingsadatrafiaNo ratings yet

- Mohsin Downstream ProcessingDocument20 pagesMohsin Downstream Processingchintan kapadiaNo ratings yet

- Department of Pharmacy: The Extraction MR - Ahmed AlmohhmmedDocument10 pagesDepartment of Pharmacy: The Extraction MR - Ahmed AlmohhmmedcrtgyhujikNo ratings yet

- Bioseperation 12Document47 pagesBioseperation 12César D. Ybarra MeléndezNo ratings yet

- Bioprocessing Part 2Document5 pagesBioprocessing Part 2Liyan Fajar Gintara100% (2)

- Downstream Processing: Reported By: Angela Marie M. DiwaDocument20 pagesDownstream Processing: Reported By: Angela Marie M. DiwaAngela Miranda DiwaNo ratings yet

- Recovery of Bio-ProductsDocument32 pagesRecovery of Bio-ProductsH.J.Prabhu67% (3)

- Chapter 6 - FiltrationDocument20 pagesChapter 6 - Filtrationmanan modiNo ratings yet

- Development and Manufacturing of Injectable (Parenteral) Drug Products UnitDocument10 pagesDevelopment and Manufacturing of Injectable (Parenteral) Drug Products UnitParul SrivastavaNo ratings yet

- HVAC Design For Pharmaceutical FacilitiesDocument57 pagesHVAC Design For Pharmaceutical FacilitiesShams MInhaz Monzur100% (4)

- Bios Era Part Ion 2Document10 pagesBios Era Part Ion 2Pooja Singh JainNo ratings yet

- HVAC Design for Pharma FacilitiesDocument57 pagesHVAC Design for Pharma Facilitiessai manojNo ratings yet

- Product Isolation in FermentationDocument18 pagesProduct Isolation in FermentationdeltaoperativNo ratings yet

- Biopharmaceuticals Chapter 3-2023Document75 pagesBiopharmaceuticals Chapter 3-2023Anh NguyễnNo ratings yet

- Presentation1 22Document24 pagesPresentation1 22Hadia ShahidNo ratings yet

- HVAC DesignDocument58 pagesHVAC DesignrejithkmNo ratings yet

- Q. Define Drag Sampling. What Is Composite Sampling? Drag SamplingDocument12 pagesQ. Define Drag Sampling. What Is Composite Sampling? Drag SamplingSudipta kumar muduliNo ratings yet

- HVAC Design For Pharmaceutical FacilitiesDocument57 pagesHVAC Design For Pharmaceutical FacilitiesSiddharth GupteNo ratings yet

- Aeration and its role in fermentation processesDocument6 pagesAeration and its role in fermentation processesRoxan Bueno MoraNo ratings yet

- HVAC Design For Pharmaceutical Facilities (GMPS)Document59 pagesHVAC Design For Pharmaceutical Facilities (GMPS)sasat1801No ratings yet

- TOPIC 8 Downstream Processing in Industrial BiotechnologyDocument22 pagesTOPIC 8 Downstream Processing in Industrial BiotechnologySara Layla50% (2)

- FiltrationDocument9 pagesFiltrationyosifNo ratings yet

- Lec1 PDFDocument17 pagesLec1 PDFKrishnendu RejNo ratings yet

- Intro to FiltrationDocument3 pagesIntro to FiltrationRifka AisyahNo ratings yet

- HVAC Design Guide For Pharmaceutical FacilitiesDocument59 pagesHVAC Design Guide For Pharmaceutical FacilitiesKasturirangan NarayananNo ratings yet

- P 1 1 Leung DDocument10 pagesP 1 1 Leung DMasha NikolovaNo ratings yet

- Downstream Processing Ppt1Document17 pagesDownstream Processing Ppt1Garima AwasthiNo ratings yet

- Filtration PDFDocument34 pagesFiltration PDFmusuka gabrielNo ratings yet

- Problem Set 1.2: 2. VariationsDocument6 pagesProblem Set 1.2: 2. VariationsKylle SaligumbaNo ratings yet

- Rajalakshmi Engineering College, Thandalam Department of Biotechnology Finalyear-Vii Semester Sec A&B Bt-2401 Downstream ProcessingDocument54 pagesRajalakshmi Engineering College, Thandalam Department of Biotechnology Finalyear-Vii Semester Sec A&B Bt-2401 Downstream ProcessingsumiNo ratings yet

- Bioburden TestingDocument5 pagesBioburden TestingApar Dholakia100% (1)

- Stages of Downstream ProcessingDocument7 pagesStages of Downstream ProcessingNitin KhodifadNo ratings yet

- Chapter 11 PDFDocument36 pagesChapter 11 PDFMuthu KumarNo ratings yet

- 807 Term Paper 1Document16 pages807 Term Paper 1Yinka OlatunjiNo ratings yet

- Black Soldier Fly Products: Generic Description and Analysis of the Production Process for Chitosan, Proteins and Lipid from Black Soldier Fly Larvae.From EverandBlack Soldier Fly Products: Generic Description and Analysis of the Production Process for Chitosan, Proteins and Lipid from Black Soldier Fly Larvae.Rating: 4 out of 5 stars4/5 (1)

- Downstream ProcessDocument40 pagesDownstream ProcessVamsi KrishnaNo ratings yet

- BioproductsDocument41 pagesBioproductschristina raju100% (1)

- HVAC Design For Pharmaceutical FacilitieDocument62 pagesHVAC Design For Pharmaceutical FacilitieHai PhanNo ratings yet

- Histopathology diagnosis techniquesDocument8 pagesHistopathology diagnosis techniquesPaul BandaNo ratings yet

- 11 Chapter 11 UpdatedDocument33 pages11 Chapter 11 UpdatedJoyatideb SinhaNo ratings yet

- DocumentDocument5 pagesDocumentJosielaPayosNo ratings yet

- Organic Chemistry: Basra University College of Science and Technology Pharmacy DepartmentDocument10 pagesOrganic Chemistry: Basra University College of Science and Technology Pharmacy DepartmentcrtgyhujikNo ratings yet

- Broch Microbiological Testing SM-4017-eDocument32 pagesBroch Microbiological Testing SM-4017-eAtta KhanNo ratings yet

- Broch Microbiological TestingDocument28 pagesBroch Microbiological TestingMudassir Ali QazalbashNo ratings yet

- Final SampleDocument28 pagesFinal SampleJoshua ArrojoNo ratings yet

- Stages of BioprocessingDocument8 pagesStages of BioprocessingMd Shahjalal Sagor0% (1)

- Life-Cycle Assessment of BiorefineriesFrom EverandLife-Cycle Assessment of BiorefineriesEdgard GnansounouNo ratings yet

- Handbook of Microbiological Criteria for FoodsFrom EverandHandbook of Microbiological Criteria for FoodsNo ratings yet

- DACAIMAT DAY2 WORKSHEET5yDocument1 pageDACAIMAT DAY2 WORKSHEET5yCarlos Miguel DacaimatNo ratings yet

- Toll FeeDocument1 pageToll FeeCarlos Miguel DacaimatNo ratings yet

- January, February, March calendarDocument2 pagesJanuary, February, March calendarRuiz Arenas AgacitaNo ratings yet

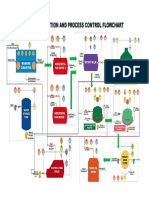

- Instrumentation FlowchartDocument1 pageInstrumentation FlowchartCarlos Miguel DacaimatNo ratings yet

- Sheet1 FinalDocument1 pageSheet1 FinalCarlos Miguel DacaimatNo ratings yet

- Field EngineerDocument3 pagesField EngineerCarlos Miguel DacaimatNo ratings yet

- DAY2 WORKSHEET5xDocument1 pageDAY2 WORKSHEET5xCarlos Miguel DacaimatNo ratings yet

- CHE Problems - ChopeyDocument11 pagesCHE Problems - ChopeyCarlos Miguel DacaimatNo ratings yet

- January, February, March calendarDocument2 pagesJanuary, February, March calendarRuiz Arenas AgacitaNo ratings yet

- Appliance Watts Appliance Watts Appliance Watts: Kitchen Living Room ToolsDocument2 pagesAppliance Watts Appliance Watts Appliance Watts: Kitchen Living Room ToolsCarlos Miguel DacaimatNo ratings yet

- Che Laws QuestionnaireDocument3 pagesChe Laws QuestionnaireCarlos Miguel DacaimatNo ratings yet

- List of Equipment - CalciPlastDocument1 pageList of Equipment - CalciPlastCarlos Miguel DacaimatNo ratings yet

- MaterialsDocument1 pageMaterialsCarlos Miguel DacaimatNo ratings yet

- Anna'S Pinktastic Birthday Anna'S Pinktastic Birthday Anna'S Pinktastic BirthdayDocument1 pageAnna'S Pinktastic Birthday Anna'S Pinktastic Birthday Anna'S Pinktastic BirthdayCarlos Miguel DacaimatNo ratings yet

- BIOTECHDocument42 pagesBIOTECHCarlos Miguel DacaimatNo ratings yet

- 1 BtuDocument3 pages1 BtuCarlos Miguel DacaimatNo ratings yet

- Fencer DetailsDocument2 pagesFencer DetailsCarlos Miguel DacaimatNo ratings yet

- Prelim Exam in Instrumentation and Controls-1Document4 pagesPrelim Exam in Instrumentation and Controls-1Carlos Miguel DacaimatNo ratings yet

- Answers:: ST ND RD THDocument2 pagesAnswers:: ST ND RD THCarlos Miguel DacaimatNo ratings yet

- Development of Small Scale Wave Energy Converter Using Oscillating Water Column OWC With Power Management SystemDocument13 pagesDevelopment of Small Scale Wave Energy Converter Using Oscillating Water Column OWC With Power Management SystemCarlos Miguel DacaimatNo ratings yet

- July 25Document1 pageJuly 25Carlos Miguel DacaimatNo ratings yet

- Bill of Materials For Upgrading of Power Supply - NewDocument4 pagesBill of Materials For Upgrading of Power Supply - NewCarlos Miguel DacaimatNo ratings yet

- Campus ViolationsDocument2 pagesCampus ViolationsCarlos Miguel DacaimatNo ratings yet

- Energy unit conversions and calculationsDocument3 pagesEnergy unit conversions and calculationsCarlos Miguel DacaimatNo ratings yet

- Upgrading Farm Power Load Area High QualityDocument1 pageUpgrading Farm Power Load Area High QualityCarlos Miguel DacaimatNo ratings yet

- Micswell CafeDocument3 pagesMicswell CafeCarlos Miguel DacaimatNo ratings yet

- Bill of Materials and Cost Estimates For The Rehab and Repair of Farm Electrical SystemDocument4 pagesBill of Materials and Cost Estimates For The Rehab and Repair of Farm Electrical SystemCarlos Miguel DacaimatNo ratings yet

- Adv and Dis of Stepper and ServoDocument2 pagesAdv and Dis of Stepper and ServoCarlos Miguel DacaimatNo ratings yet

- Application SoftwareDocument3 pagesApplication SoftwareCarlos Miguel DacaimatNo ratings yet

- Motor MaintenanceDocument17 pagesMotor MaintenanceCarlos Miguel Dacaimat100% (1)

- Arduino The Ultimate Beginners Guide To Arduino Learn How To Get Started With Arduino Programming Projects and More PDFDocument33 pagesArduino The Ultimate Beginners Guide To Arduino Learn How To Get Started With Arduino Programming Projects and More PDFefrain100% (1)

- 4Ps of Marketing Among Selected Resorts in Cabanatuan CityDocument5 pages4Ps of Marketing Among Selected Resorts in Cabanatuan CityKomal sharmaNo ratings yet

- Positronic Industries Inc. FC4012D: SK2415 ECO B 23033 TK Yk Cole ECO C 52574 Cole CM ColeDocument1 pagePositronic Industries Inc. FC4012D: SK2415 ECO B 23033 TK Yk Cole ECO C 52574 Cole CM ColekamaveriyanNo ratings yet

- Checking Mixing Procedures for Compounds in Mixers 1 & 2Document1 pageChecking Mixing Procedures for Compounds in Mixers 1 & 2Dilnesa EjiguNo ratings yet

- Lexmark™ X950de, X952dte and X954dhe (7558-xxx) - Service ManualDocument1,178 pagesLexmark™ X950de, X952dte and X954dhe (7558-xxx) - Service ManualNikkiSpencerNo ratings yet

- Ling 390 Morphology HW ExercisesDocument9 pagesLing 390 Morphology HW ExercisesMAIMUNAH REIHANAHNo ratings yet

- Altamirov DishniDocument95 pagesAltamirov DishniEmersonJParedes100% (1)

- MGEC61 - LEC 01 & LEC 02 International Economics: Finance Summer 2021Document8 pagesMGEC61 - LEC 01 & LEC 02 International Economics: Finance Summer 2021Yutong WangNo ratings yet

- Sahil GuptaDocument1 pageSahil GuptaDreams FoodieNo ratings yet

- Grinding Process Within Vertical Roller Mills Experiment and SimulationDocument5 pagesGrinding Process Within Vertical Roller Mills Experiment and SimulationDirceu Nascimento100% (1)

- Epigraphs - SubtitleDocument2 pagesEpigraphs - Subtitle17ariakornNo ratings yet

- Designing The HighwayDocument13 pagesDesigning The HighwayHugo PainenoNo ratings yet

- Course 2 Unit 4Document90 pagesCourse 2 Unit 4amit aryaNo ratings yet

- G 20 Summit in Indian Presidency PDFDocument3 pagesG 20 Summit in Indian Presidency PDFSynergy BhavaniNo ratings yet

- B1 Unit 6 PDFDocument1 pageB1 Unit 6 PDFMt Mt100% (2)

- CASE 2901: Inquiry: Under What Requirements May External Loads (Forces and Bending Moments) Be Evaluated ForDocument2 pagesCASE 2901: Inquiry: Under What Requirements May External Loads (Forces and Bending Moments) Be Evaluated ForDijin MaroliNo ratings yet

- Pendola Suspendida MPK 450 1x150wDocument3 pagesPendola Suspendida MPK 450 1x150wwilber ticonaNo ratings yet

- J305GAC Trojan Data SheetsDocument2 pagesJ305GAC Trojan Data SheetsEdisson Alarcon MoraNo ratings yet

- Cummins KTA19-G4 Genset Spec SheetDocument6 pagesCummins KTA19-G4 Genset Spec SheetRonald BoocNo ratings yet

- Contanuity Case StudyDocument14 pagesContanuity Case StudyUsama TariqNo ratings yet

- Swot TowsDocument1 pageSwot TowsAshwiniNo ratings yet

- Webpage Evaluation GuideDocument1 pageWebpage Evaluation Guideankit boxerNo ratings yet

- Alice Inteligencia Artificial Promoting The Adoption and Development of Alicebot and AIML Free SoftwareDocument43 pagesAlice Inteligencia Artificial Promoting The Adoption and Development of Alicebot and AIML Free SoftwareBruno Silveira DinizNo ratings yet

- Nonlinear Control - An Overview: Fernando Lobo Pereira, Flp@fe - Up.ptDocument57 pagesNonlinear Control - An Overview: Fernando Lobo Pereira, Flp@fe - Up.ptSteve DemirelNo ratings yet

- United Kingdom & Ireland TelevisionDocument328 pagesUnited Kingdom & Ireland TelevisionPcnhs SalNo ratings yet

- HCTS Fabricated Products Group Empowers High Tech MaterialsDocument12 pagesHCTS Fabricated Products Group Empowers High Tech MaterialsYoami PerdomoNo ratings yet

- Mike-Rose - The-Language-of-Exclusion (Edited)Document20 pagesMike-Rose - The-Language-of-Exclusion (Edited)abankiNo ratings yet

- Swimming at Key Stages 1 and 2 Schemes of Work and Session Plans For Advanced SwimmersDocument20 pagesSwimming at Key Stages 1 and 2 Schemes of Work and Session Plans For Advanced SwimmersShadrack MutisoNo ratings yet

- MATH 10 Test Questions SY 2022-2023 QIIIDocument4 pagesMATH 10 Test Questions SY 2022-2023 QIIIRYAN C. ENRIQUEZNo ratings yet

- Paper H3 - Mock Set 6 - MSchemeDocument17 pagesPaper H3 - Mock Set 6 - MSchemeH Aslam100% (4)