Professional Documents

Culture Documents

2004 - He Yiyan - Thetransformershortcircuittestandthehighpowerlabor (Retrieved 2016-11-21)

Uploaded by

emilioaraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2004 - He Yiyan - Thetransformershortcircuittestandthehighpowerlabor (Retrieved 2016-11-21)

Uploaded by

emilioaraCopyright:

Available Formats

F

The Transformer Short-Circuit Test and

the High Power Laboratory in Chinathe

Past, Present, and Future

Key words: Transformer, short-circuit test, test laboratory, list of tested transformers, China.

Introduction

ver the last half century, the transformer industry in China

has experienced substantial development. Prior to 1949, only

distribution transformers up to 2000 kVA/33 kV were produced;

however, by the end of last century, China was producing 360720

MVA/500 kV power transformers [1], [2]. Nevertheless, the transformer short-circuit test held up transformer development in China.

In this paper, we review distribution transformer short-circuit

testing from 1965 to 1993, power transformers from 1994 to the

present, and include a list of 110220kV power transformers tested

up to February 2002. We will describe the HUSHITAI High Power

Test Laboratory (HST), its main equipment, and test capabilities.

HST, the largest high power testing laboratory in China, belongs to

the China National Transformer Quality Supervision Testing Center (CTQC), an independent section of Shenyang Transformer Research Institute (STI). The testing center was approved by the China

State Bureau of Quality and Technical Supervision (Ministry of the

State Council) and is an official government testing center. The

potential for future development will also be discussed.

The layout of HST is shown in Figure 1. It is located near the

railway station in Hushitai, a satellite city of Shenyang, a major

city in northeastern China.

Transformer Short-circuit Testing Between

19651993

Power transformers operating in power systems are exposed to

short circuits, including single-phase, two-phase, or three-phase

short circuits. Short circuits cause high short-circuit currents of more

than 10 times the rated current and are dangerous to the transformer.

Thus, it is necessary to study the short-circuit performance of transformers using short-circuit tests. According to the IEC standards,

such tests are special tests.

14

He Yiyan and Wang Maosong

Shenyang Transformer Research Institute

We review the short-circuit testing of distribution

and power transformers, and include a list of

110-220kV power transformers tested up to

February 2002.

Prior to the 1960s, the pioneers of the Chinese transformer industry, Tang Ming-qi and Zhou Mao-pei, believed that a distribution transformer of 630 kVA/10 kV should be tested in the network. Thus, they performed the first short-circuit test of a distribution transformer in China in 1965.

In the 1960s and 1970s, four laboratoriesXian High Voltage

Apparatus Research Institute, Shanghai Switchgear Works,

Shenyang Switchgear Works, and Beijing Electric Power Research

Institutewere set up as high power test laboratories for switchgear.

They could also test distribution transformers.

At the beginning of the 1980s, STI designed a prototype power

transformer SJ-8000 kVA/35 kV with some pressure sensors installed in the tank for research purposes. The transformer was sent

to Xian High Voltage Apparatus Research Institute for testing in

1984; this was the first short-circuit test of a power transformer in

China. A 100% short-circuit current test of each phase was carried

out and the pressures at specific locations measured. The transformer withstood the test and critical design data were derived.

IEEE Electrical Insulation Magazine

By the end of 1993, HST was equipped with:

Two sets of intermediate test transformers (IT), 1200 MVA/220/

8224 kV, which can be arranged in series/parallel with eight

no-load tap-changes each to get 36 voltage steps regulated from

4448 kV, and 560 kA on the secondary side for testing

Circuit breaker with breaking capacity of 40 kA 0.2 ms

Automatic computer control device can control 24 channels at

the same time, with a time resolution of 0.1 ms

The measurement system of current transformers, voltage dividers, and transient recorders can measure several signals

Transport equipment consisting of a fixed outdoor lift 200-ton,

and four 100-ton special vehicles that can be combined

An assembly shop: 50 18 20 (H) m3, 32-ton lift, oil and

vacuum treatment equipment.

Test Methods in HST

Figure 1. HST test lab location. 1. A 220 KV substation; 2.

Northeast Electrical Bureau Electric Power Research Institute

H.V. test field; 3 Shenyang High Voltage Switchgear Works test

lab; and 4. HST high-power test lab.

According to the requirement of the State Machinery Ministry,

STI designed the SL7 series (aluminum wire) of 50 kVA to 1600

kVA/10kV transformers and the S9 series of 50 kVA to 1600 kVA/

10 kV in the early 1980s. Xian, Beijing, Shenyang and Shanghai

Laboratories tested about 20 sets of each series as a type test. At

the same time, 20-kV to 60-kVclass test transformers were tested,

with voltages of 110 to 132 kV (not listed in this article).

There are two short-circuit testing methods, namely pre- and

postestablished short circuits when testing a main winding.

In service, faults can occur when the transformer is energized

and in normal operation. Hence, they bear the character of a postestablished short circuit, and, in general, it is preferable to reproduce such a situation during tests. With the postestablished shortcircuit procedure, one can prevent the inrush current from being

superimposed onto the test current, independent of the relative position of the energized and short-circuited windings. The

postestablished short-circuit procedure requires the power of the

test station be significantly larger than that of the testing station

during pre-established short-circuit testing. This depends on the

necessity to limit the transformer overexcitation to 1.15 p.u. in the

former case, while the problem does not arise in the latter. Figure 2

shows the power requirements of the testing station.

HST between 1994 and 2002

HST Set Up

Because a high power test laboratory is very important in the

development of power transformers [3], the China State Government funded a project in its 7th 5-year plan to build HST, a high

power test laboratory in a Shenyang suburb. The design of HST

was made by Xian 7th Design Research Institute in cooperation

with EDF, Renerdieres, France, as a consultant [4]. The HST was

approved by the state committee [5] and became operational in the

beginning of 1994.

The HST has an area of 40,000 m2, including 5000 m2 floor

space. It has the following advantages/features:

Close to Shenyang Transformer Co. Ltd., the biggest transformer

manufacture in China

Close to a 220-kV substation of the northeast network in China

Convenient railway and highway transportation in Shenyang,

which is an industrial center in northern China

The lab has a 220-kV line for its power supply and has available

a three-phase short-circuit power of 12,000 MVA.

January/February 2004 Vol. 20, No. 1

Figure 2. Power requirements of the testing station

Where Pa is the minimum short-circuit power of the testing

station; Pt is the power required by the transformer under test;

Va is the no-load voltage of the testing station power supply; and

Vt is the rated voltage of the transformer under test.

15

Table 1: Laboratory Test Limits

110 kV

transformer

(MVA)

1 phase test

1.5 phase test *

3 phase test

150 MVA

3-phase

transformer

100 MVA

3-phase

transformer

31.5 MVA

3 phase

transformer

50 MVA

Single-phase

transformer

220 kV

transformer

(MVA)

80 MVA

Single-phase

transformer

under test, and Xs is the power system reactance including the intermediate transformer [IT]), the transformer under test can absorb

1/4 of the system capability; Table 1 lists the maximum limits of

the transformers that can be tested.

If post-short-circuit is used, the capability of the transformer

under test should be reduced to half the above values in the table.

Figure 3 shows the high power lab outline and photographs.

New High Voltage Test Laboratory in HST

120180 MVA

Single-phase

transformer

*1.5 phase as phase A in series with phases B and C in parallel.

With the postestablished short-circuit method, the burden imposed by the required power of the testing station is balanced by

the following benefits:

The test is more representative of the real situation

The control of the peak value of test current is accurate

In the preestablished short-circuit procedure, the control of the

test current peak value becomes more difficult if the unit under

test is fed through a short-circuit transformer and the make switch

is placed upstream of this transformer

Assuming a test capability of a transformer under test for a preshort-circuit at Xt = Xs (Xt is the reactance of the transformer

To complete all routine tests of transformers up to the 63-MVA,

110-kV class, after the short-circuit test, a new high voltage lab in

HST was completed in 2000. The dimension of the high voltage

hall is 24 24 15 (H) m3 and contains a 750-kV cascade power

frequency transformer, and an 1800-kV impulse generator. The

power supplies are housed in a separate room. Figure 4 shows an

outline and photographs of the HV lab.

Transformer Short-Circuit Test

From the beginning of 1994 to the end of 2001, HST tested 1000

10- to 35-kV S9 oil-immersed and 2000 S8S9 cast-resin transformers. The first-time qualification rate for the former was 90%,

and for the latter was 95%.

From 1996 to 2002 we have tested 53 110220-kV power transformers [6], [7]. The data are tabulated in Table 2. The test standards and methods are according to our GB 1094.5 national standard that is similar to IEC60076-2000, Part 5 (Power TransformersAbility to withstand short circuit).

Figure 3. The HST high power test lab. (a) The view of the lab, (b) the intermediate transformers, (c) and (d) 220-kV, 120-MVA

transformer under test.

16

IEEE Electrical Insulation Magazine

Figure 4. High-voltage test lab. (a) General view, (b) power frequency transformer, (c) impulse generator, (d) generator hall.

The short-circuit reactance in ohms, evaluated for each phase at

the end of the tests, should not differ from the original values by

more than 2% (GB and IEC standards); but in practice, for the power

transformers listed in Table 2, the differences are less than 1%. The

largest reactance deviation is 0.70%, the smallest is 0.02%, and the

average of the total 53 sets is 0.28%.

For 220-kV transformers, the deviations in reactance are smaller.

Figure 5 shows the test oscillogram of a 220-kV/120-MVA transformer during a short-circuit test.

The reports of the test center (CTQC) are effective all over the

China.

Summary

Fifty-three sets 110- to 220-kV transformers from 44 factories

(note that the 30- to 60-kV system in the northeast network is the

same class as 110 kV in other parts of China) passed the shortcircuit test. The rate of first-time-qualified 110-kV transformers

was close to 100%. If transformer manufacturers need to pass the

short-circuit test, they can usually do it by themselves; otherwise,

STI (R&D department) can provide help.

Forty transformers that passed the test were delivered to customers and they are now in operation in the power system all over

China. The remaining 13 transformers are in the process of assembly and delivery. Feedback from clients suggests that all these transformers function well. They have been operating from a few months

to more than five years. The report from the State Electric Com-

January/February 2004 Vol. 20, No. 1

Figure 5. Test oscillograms of a 220-kV/120-MVA transformer. 1,

3, 5 = test oscillograms of voltage supplied to transformer; 2, 4,

6 = test oscillograms of current supplied to transformer.

17

Table 2. Transformers Tested from 1996 to Feb. 2002.

18

No.

Works name

Model

Date

Test station

Result

Shenyang Transformer Co., Ltd

SF8-50000/110

1996.8

China National

Transformer Quality

Supervision Testing

Center (CTQC)

Passed

Hengyang Transformer Works

SFZ8-31500/110

1996.7

(CTQC)

Passed

Yunnan Transformer Works

SF3-QY-31500/110

1997.2

(CTQC)

Passed

Nantong Transformer Works

SFSZ8-31500/110

1997.10

(CTQC)

Passed

Jinan Transformer Works

SFZ8-31500/110

1997.12

(CTQC)

Passed

Xinjiang Special Transformer Electrical Co., Ltd

SFZ8-31500/110

1998.2

(CTQC)

Passed

Hubei Transformer Works

SFZ8-40000/110

1998.5

(CTQC)

Passed

Jiangshu Hua Peng Transformer Works

SFZ8-31500/110

1998.7

(CTQC)

Passed

ChangzhouTransformer Works

SFZ8-40000/110

1998.8

(CTQC)

Passed

10

Qingdao Transformer Works

SFZ9-31500/110

1998.9

(CTQC)

Passed

11

Shanghai Transformer Works

SFZ7-31500/110

1998.9

(CTQC)

Passed

12

Wuxi Electric Power Transformer Works

SFZ9-40000/110

1998.10

(CTQC)

Passed

13

Shenyang Transformer Co., Ltd

SFZ7-26000/132

1998.10

(CTQC)

Passed

14

Lianyungang Transformer Co., Ltd

SFZ8-31500/110

1999.1

(CTQC)

Passed

15

Zhejiang Third Transformer Group Co., Ltd

SFSZ8-31500/110

1999.1

(CTQC)

Passed

16

Changzhou TransformerWorks

SSZ10-50000/110

1999.3

(CTQC)

Passed

17

Nanjing power Transformer Works

SFZ9-31500/110

1999.4

(CTQC)

Passed

18

Shenyang Transformer Co., Ltd

SFZ7-31500/132

1999.5

(CTQC)

Passed

19

Ningbo Transformer Works

SFZ9-40000/110

1999.6

(CTQC)

Passed

20

Zhejiang Power Transformer Works

SFZ8-31500/110

1999.6

(CTQC)

Passed

21

Jiangxi Transformer Works

SZ9-40000/110

1999.6

(CTQC)

Passed

22

Shandong Jinmanke Electric Applance Co., Ltd

DCZ9-10500/110

1999.8

(CTQC)

Passed

23

Chengdu Shuangxing Electric Applance Co., Ltd

SFZ9-40000/110

1999.8

(CTQC)

Passed

24

Guangzhou Power Equipment Works

SFZ9-40000/110

1999.9

(CTQC)

Passed

25

Yunnan Transformer Works

SFZ-QY-25000/110

1999.11

(CTQC)

Passed

26

Changsha Transformer Works

SFZ9-31500/110

1999.12

(CTQC)

Passed

27

Shenyang Transformer Co., Ltd

SFZ10-40000/110

1999.12

(CTQC)

Passed

28

Nangtong Transformer Works

SFZ9-M-40000/110

1999.12

(CTQC)

Passed

29

Shichuan Shuneng Electric Applance Co., Ltd

SFSZ9-31500/110

1999.12

(CTQC)

Passed

30

Anshan Electric Power Equipment Works

SFZ9-31500/66

1999.12

(CTQC)

Passed

31

Guiyang Transformer Works

SFZ9-40000/110

2000.3

(CTQC)

Passed

32

Fuzhou Transformer Works

SFZ8-31500/110

2000.3

(CTQC)

Passed

33

Panyu Mingzhu Electric Applance Co., Ltd

SZ8-40000/110

2000.4

(CTQC)

Passed

34

Xinjiang Sprcial Transformer Electrical Co., Ltd

SZ10-M-50000/110

2000.4

(CTQC)

Passed

35

Taiyuan Transformer Works

SFZ9-40000/110

2000.5

(CTQC)

Passed

36

Hefei Transformer Works

SFZ9-40000/110

2000.6

(CTQC)

Passed

37

Beijing Transformer Works

SFZ9-50000/110

2000.6

(CTQC)

Passed

38

Henan Nanyang Transformer Co., Ltd

SFZ9-25000/110

2000.7

(CTQC)

Passed

39

Shandong Xiandai-dachi Transformer Works

SFZ9-31500/110

2000.7

(CTQC)

Passed

IEEE Electrical Insulation Magazine

Table 2. (continued) Transformers Tested from 1996 to Feb. 2002.

No

Works name

Model

Date

Test station

Result

40

Saanxi Hanzhong Transformer Co., Ltd

SFZ9-31500/110

2001.1

(CTQC)

Passed

41

Shenyan Zhonghui Transformer Co., Ltd

SFZ9-30000/66

2001.1

(CTQC)

Passed

42

Luohe Hongda Transformer Co., Ltd

SFZ9-40000/110

2001.1

(CTQC)

Passed

43

Liuzhou Jiali Transformer Works

SFZ-20000/110

2001.4

(CTQC)

Passed

44

Shandong Electric Equipment Works

SZ-50000/110

2001.5

(CTQC)

Passed

45

Saanxi Tongchuan Transformer Co., Ltd

SFZ9-31500/110

2001.7

(CTQC)

Passed

46

Shandong Luneng Transformer Co., Ltd

SFZ9-31500/110

2001.7

(CTQC)

Passed

47

Guangzhou Guanggao Transformer Co., Ltd

SZ10-M-40000/110

2001.7

(CTQC)

Passed

48

Changsha Shunte Transformer Works

S8-QY-20000/110

2001.9

(CTQC)

Passed

49

Baoding Tianwei Transformer Co., Ltd

SF-PQY-25000/110

2001.11

(CTQC)

Passed

50

Dalian Transformer Works

SZ10-31500/110

2001.11

(CTQC)

Passed

51

Yinchuan Transformer Co., Ltd

SFQY-31500/110

2002.1

(CTQC)

Passed

52

Wuhan Transformer Co., Ltd

SFZ10-31500/110

2002.1

(CTQC)

Passed

53

Shenyang Transformer Co., Ltd

SF9-120000/220

2002.2

(CTQC)

Passed

pany indicates that there is no fault in the system due to the new

products from 40 factories (the same series type produced after

special short-circuit test). This suggests that transformer manufacturing and testing in China has improved and become more reliable

than previously and that HST contributes significantly to the Chinese transformer industry.

Future Development

In the next two to three years, we will fully solve the problem of

110-kV power transformers withstanding short circuits. This means

that all types of transformers (no-load and on-load tap change,

double- or triple-winding transformers) from each factory can pass

the short-circuit test.

We have successfully tested a 220-kV, 120-MVA power transformer. We will pay more attention to 220-kV class power transformers and test a few 220-kV, 120-MVA to 180-MVA power transformers in the near future.

The rate of qualification of distribution transformers has improved (Table 2), indicating further improvements in the manufacture and assembly of the active part of the transformers.

Although HST has reached a high industrial level and tested

many power transformers, the equipment for testing higher voltage

classes is still not up to date. Currently, we are not capable of testing 330- to 500-kV class power transformers. In the future, we will

expand HST by adding one generator with a short-circuit power

capacity of 6500 MVA and two IT with the same specifications,

combining the generator with the network. Thus, the test voltage

can potentially reach the 500-kV level and we will be capable of

testing a variety of transformers and further developing transformer

short-circuit tests in China.

January/February 2004 Vol. 20, No. 1

References

[1] Y.-Y. He, H.-W. Je, D.-B. Zhu, and J.-X. Yang, The rapid development of the transformer industry in China, IEEE Electrical Insulation Magazine, vol.14 , No.4, pp.23-27, 1998.

[2] Y.-Y. He, 500kV power transformer and its partial discharge, ICEM,

1998.

[3] Y.-Y. He, Feasibility study of Transformers High Power Test Station, Transformer, 12, 1985.

[4] Y.-L. Jing, H. Yiyan, T.-L. Zhang, J.P. Martin (EDF) Shenyang high

power test station present and future, ICAAA, 1993.

[5] Y.-Y. He, HUSHITAI high power test laboratory, Transformer, 5,6,

1995.

[6] Y.-Y. He, M.-S. Wang, W.-G. Tian, J.-S. Du, Test capability of high

power test lab. For distribution, middle, large transformer in the world,

Transformer, 4, 2000.

[7] Y.-Y. He, Present state and improving measures of power transformer

short-circuit withstanding capability in China and IEC standard, Electrical Equipment, vol. 2, 2001.

He Yiyan was born in Wuhan Hubei, China on Jan. 13, 1931. He

received his B.S. degree from the Department of Electrical Engineering at Wuhan University and joined the Xiangtan Electrical

Machinery Works in 1952. He joined the Shenyang Transformer

Works and Institute in 1956 for H.V. Technology, High Power Test

Lab for R&D. He is a deputy director and a professor of engineering.

Wang Maosong was born in Shenyang, Liaoning, China on Nov.

23, 1968. He received his B.S. degree from the Department of Mechanical Engineering in Shenyang Polytechnic University in1991.

He joined the Shenyang Transformer Research Institute for highpower testing and research. He is a director and senior engineer of

the High-Power Test Lab.

19

You might also like

- Relays and FusesDocument39 pagesRelays and FusesNesarkiran Bagade100% (1)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- Of in EGAT 500 Transinission System: An Analysis Switching Overvoltages KVDocument5 pagesOf in EGAT 500 Transinission System: An Analysis Switching Overvoltages KVKarina LozadaNo ratings yet

- Summer Training Report On Unnao Sub Station PDFDocument59 pagesSummer Training Report On Unnao Sub Station PDFAnubhav SachanNo ratings yet

- Considerations Regarding The Short-Circuit Withstand Tests of Power TransformersDocument4 pagesConsiderations Regarding The Short-Circuit Withstand Tests of Power TransformersBash MatNo ratings yet

- MODULE 4 Extra Low Voltage SystemsDocument19 pagesMODULE 4 Extra Low Voltage SystemsVismithaNo ratings yet

- Power Grid Training ReportDocument43 pagesPower Grid Training ReportManasvi Dhariwal80% (5)

- High Voltage Engineering by DR Suhail KhokharDocument43 pagesHigh Voltage Engineering by DR Suhail KhokharSuhail KhokharNo ratings yet

- Energy Audit of A 400-220 KV SubstationDocument8 pagesEnergy Audit of A 400-220 KV Substationabhishekrathi09100% (2)

- Insulation Coordination Studies For 400 KV Gis in A Hydroelectric Project in IndiaDocument6 pagesInsulation Coordination Studies For 400 KV Gis in A Hydroelectric Project in IndiaAchint KumarNo ratings yet

- High Voltage Testing of TransformerDocument18 pagesHigh Voltage Testing of TransformerSrinivas Cnu100% (1)

- INSULATION COORDINATION STUDIES FOR 400 KV GIS PDFDocument6 pagesINSULATION COORDINATION STUDIES FOR 400 KV GIS PDFsorry2qazNo ratings yet

- BHEL TRAINING REPORT Transformer-2 PDFDocument65 pagesBHEL TRAINING REPORT Transformer-2 PDFPAWAN DAYAL100% (1)

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- High Voltage Testing of TransformerDocument18 pagesHigh Voltage Testing of TransformerDinesh mor100% (2)

- Selection Manual - EN PDFDocument394 pagesSelection Manual - EN PDFkhuzaimNo ratings yet

- Partial Discharge 1 PDFDocument8 pagesPartial Discharge 1 PDFsamsungloverNo ratings yet

- Examples Ferroresonance in High Voltage Power System: N. Jacobson, Membec IEEEDocument7 pagesExamples Ferroresonance in High Voltage Power System: N. Jacobson, Membec IEEE_FlyMan_No ratings yet

- A2 34+Transformer+maintenance+TutorialDocument64 pagesA2 34+Transformer+maintenance+Tutorialemilioara100% (1)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- Power Electronics Applied to Industrial Systems and Transports, Volume 3: Switching Power SuppliesFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 3: Switching Power SuppliesNo ratings yet

- Project Report of Transmission Type Eletrical SubstationDocument44 pagesProject Report of Transmission Type Eletrical SubstationChandan_92100% (4)

- Intoduction To 400Kv Switchyard: Single Line Diagram of 400kV SubstationDocument3 pagesIntoduction To 400Kv Switchyard: Single Line Diagram of 400kV SubstationPratik LahaneNo ratings yet

- Methods for Increasing the Quality and Reliability of Power System Using FACTS DevicesFrom EverandMethods for Increasing the Quality and Reliability of Power System Using FACTS DevicesNo ratings yet

- Cispr11 Amd1 (Ed4.0) en 2004Document4 pagesCispr11 Amd1 (Ed4.0) en 2004emilioaraNo ratings yet

- 2004 He Yiyan Thetransformershortcircuittestandthehighpowerlabor Retrieved 2016 11 21 PDFDocument6 pages2004 He Yiyan Thetransformershortcircuittestandthehighpowerlabor Retrieved 2016 11 21 PDFBash MatNo ratings yet

- A Synopsis On High Voltage Testing of Transformers: Adnan Iqbal M. Tech (T16EE015)Document14 pagesA Synopsis On High Voltage Testing of Transformers: Adnan Iqbal M. Tech (T16EE015)AdnanNo ratings yet

- Central Power Research Institute, BangaloreDocument20 pagesCentral Power Research Institute, BangaloreRetin RpkNo ratings yet

- Cable Resonance 2Document5 pagesCable Resonance 2joseNo ratings yet

- Study On Operational Tests For FACTS Thyristor ValvesDocument8 pagesStudy On Operational Tests For FACTS Thyristor ValvesMįhír PatelNo ratings yet

- CVVOZE PowerLab Technical SpecificationsDocument9 pagesCVVOZE PowerLab Technical SpecificationsTXEMANo ratings yet

- Summer Training Report On Unnao Sub StationDocument59 pagesSummer Training Report On Unnao Sub StationArpit PandeyNo ratings yet

- 1.1 Terms and Definitions Direct TestDocument7 pages1.1 Terms and Definitions Direct Testms_dasNo ratings yet

- DWG Isei12 p078Document7 pagesDWG Isei12 p078anurag_jay12464No ratings yet

- Overview of CPRIDocument21 pagesOverview of CPRIJ Naveen Kumar100% (1)

- CB TestingDocument19 pagesCB TestingSumukha KumarNo ratings yet

- Power Grid Training ReportDocument43 pagesPower Grid Training ReportJanmejey BarikNo ratings yet

- VIZIMAX - CIGRE Toronto - Using A Controlled Switching Device For A Power Transformer PDFDocument8 pagesVIZIMAX - CIGRE Toronto - Using A Controlled Switching Device For A Power Transformer PDFgeorge_cpp2No ratings yet

- Laboratory Report #04 Testing TransformersDocument5 pagesLaboratory Report #04 Testing TransformersCristian Camilo Díaz Piñeros0% (1)

- HTS Transformers PDFDocument7 pagesHTS Transformers PDFAnonymous vcadX45TD7No ratings yet

- Capacity Enhancement For Aging Single Wire Earth Return Distribution SystemsDocument8 pagesCapacity Enhancement For Aging Single Wire Earth Return Distribution SystemsGreg MavhungaNo ratings yet

- 2013 Short-Circuit Performance of Power Transformers PDFDocument8 pages2013 Short-Circuit Performance of Power Transformers PDFel_transfoNo ratings yet

- Study On Lightning Impulse Test Waveform For UHV-Class Electric PowerDocument9 pagesStudy On Lightning Impulse Test Waveform For UHV-Class Electric PowerBalajiNo ratings yet

- UNIT-3 of HVEDocument37 pagesUNIT-3 of HVEAayush Patidar100% (2)

- Cired2003 CernDocument5 pagesCired2003 Cernsoeng777No ratings yet

- Overvoltage Cycling and Endurance Tests On Full Scale CapacitorsDocument3 pagesOvervoltage Cycling and Endurance Tests On Full Scale CapacitorsBožidar Filipović-GrčićNo ratings yet

- Resonant TransformerDocument15 pagesResonant TransformerfelogonzaNo ratings yet

- 2011-LER-RC-Transformer Failure Due To Circuit-Breaker-Induced Switching TransientsDocument12 pages2011-LER-RC-Transformer Failure Due To Circuit-Breaker-Induced Switching Transientsjulio_nunes21No ratings yet

- SubstationDocument6 pagesSubstationSrinivas BkNo ratings yet

- Switcheo Controlado de Cierre de TR Corriente Inrush PDFDocument11 pagesSwitcheo Controlado de Cierre de TR Corriente Inrush PDFlibrosNo ratings yet

- Jin - 2019 - J. - Phys. - Conf. - Ser. - 1311 - 012010 (1) Asnwer Q2Document8 pagesJin - 2019 - J. - Phys. - Conf. - Ser. - 1311 - 012010 (1) Asnwer Q2musieNo ratings yet

- Sr. No. Name of The Experiment No.: Se-E&Tc Electrical Circuits and Machines List of ExperimentsDocument13 pagesSr. No. Name of The Experiment No.: Se-E&Tc Electrical Circuits and Machines List of ExperimentsjitbakNo ratings yet

- NCL ReportDocument20 pagesNCL ReportSwati Tripathi33% (3)

- BEE 4123 - Transformer TutorialDocument4 pagesBEE 4123 - Transformer TutorialMuhamad ZulhilmiNo ratings yet

- Vocational Training Report at C.S.E.B. Raipur 15 June To 14 JulyDocument29 pagesVocational Training Report at C.S.E.B. Raipur 15 June To 14 JulyMãñyä ShârmåNo ratings yet

- ETI - PSI - 124 (07-95) - ScottDocument60 pagesETI - PSI - 124 (07-95) - ScottaniketpawasheNo ratings yet

- Unit 2 Full PDFDocument94 pagesUnit 2 Full PDFJ VEERENDRA KUMARNo ratings yet

- Tutorial - 3 - ELL203 - 14th August - 2023Document2 pagesTutorial - 3 - ELL203 - 14th August - 2023Ujjawal MeenaNo ratings yet

- LECTUERE 6 E 1530 High Voltage EngineeringDocument30 pagesLECTUERE 6 E 1530 High Voltage Engineeringahmed372416No ratings yet

- Lec 3Document17 pagesLec 3mezo4326No ratings yet

- Fundamental Studies On Vacuum Circuit Breaker Arc Quenching Limits Using A Synthetic Test CircuitDocument5 pagesFundamental Studies On Vacuum Circuit Breaker Arc Quenching Limits Using A Synthetic Test CircuitAyanangshu ChakrabartyNo ratings yet

- Regulated 0 To 150 Kilovolt 42 Watts DC/DC Power SupplyDocument6 pagesRegulated 0 To 150 Kilovolt 42 Watts DC/DC Power SupplyOleg AnitoffNo ratings yet

- Enhancing The Life Span of 500 MVA ICT Through Controlled Switching Devices 230306 113912Document4 pagesEnhancing The Life Span of 500 MVA ICT Through Controlled Switching Devices 230306 113912Zeeshan AhmadNo ratings yet

- Vocational Training Report at C.S.E.B. Raipur 15 June To 14 JulyDocument28 pagesVocational Training Report at C.S.E.B. Raipur 15 June To 14 JulyBabar SaleemNo ratings yet

- Some Power Electronics Case Studies Using Matlab Simpowersystem BlocksetFrom EverandSome Power Electronics Case Studies Using Matlab Simpowersystem BlocksetNo ratings yet

- Resin Impregnated Paper Bushing, Oil To Air, Type GSB: Technical GuideDocument16 pagesResin Impregnated Paper Bushing, Oil To Air, Type GSB: Technical GuideemilioaraNo ratings yet

- Product CatalogueDocument96 pagesProduct CatalogueemilioaraNo ratings yet

- LW36A-126/145 Model Outdoor HV Sf6 Circuitbreaker: Technical DataDocument26 pagesLW36A-126/145 Model Outdoor HV Sf6 Circuitbreaker: Technical DataemilioaraNo ratings yet

- 2006 - N Murota - Earthquakesimulatortestingofbaseisolatedpowertrans (Retrieved 2016-11-23)Document9 pages2006 - N Murota - Earthquakesimulatortestingofbaseisolatedpowertrans (Retrieved 2016-11-23)emilioaraNo ratings yet

- Understanding Transformer Factory Testing Tutorial September 23, 2007Document10 pagesUnderstanding Transformer Factory Testing Tutorial September 23, 2007emilioaraNo ratings yet

- 4 Low Frequency TestingDocument50 pages4 Low Frequency TestingemilioaraNo ratings yet

- 2011 - A Prokhorov - Monitoringchangesinmechanicalstateofwindingsofpowe (Retrieved 2016-11-25)Document6 pages2011 - A Prokhorov - Monitoringchangesinmechanicalstateofwindingsofpowe (Retrieved 2016-11-25)emilioaraNo ratings yet

- The Use of Paperless CTC in Power TransformersDocument3 pagesThe Use of Paperless CTC in Power TransformersemilioaraNo ratings yet

- Cigre 015Document23 pagesCigre 015emilioaraNo ratings yet

- Paper C103: N.V. Buthelezi R. CormackDocument7 pagesPaper C103: N.V. Buthelezi R. CormackemilioaraNo ratings yet

- G740 - ACS 5000A Power Part - RevB2Document54 pagesG740 - ACS 5000A Power Part - RevB2nizarcec100% (2)

- MIDTERM-EXAM UtilitiesDocument3 pagesMIDTERM-EXAM Utilitiescristineangeljasmin04No ratings yet

- Automotive Power Seat Reference Design: TI Designs: TIDA-020008Document30 pagesAutomotive Power Seat Reference Design: TI Designs: TIDA-020008LiemNo ratings yet

- 71M651x Energy Meter IC: Using IR Diodes and PhototransistorsDocument7 pages71M651x Energy Meter IC: Using IR Diodes and Phototransistorsagus wiyonoNo ratings yet

- GE 1975 Lamp CatalogDocument68 pagesGE 1975 Lamp CatalogAlan Masters100% (2)

- 270 Mini Electronics Project With Circuit Diagram PDFDocument224 pages270 Mini Electronics Project With Circuit Diagram PDFCatch MeNo ratings yet

- Flyer - PCS-9691E Overcurrent RelayDocument2 pagesFlyer - PCS-9691E Overcurrent RelayRendieRamadhan100% (2)

- Eto-18 DiagnosticsDocument4 pagesEto-18 Diagnosticskidanemariam teseraNo ratings yet

- Minivac 601Document211 pagesMinivac 601ok18879No ratings yet

- 03CDT0902 - Eurotherm - 902 - 904 - HandbookDocument157 pages03CDT0902 - Eurotherm - 902 - 904 - HandbookSPMS_MELEC100% (1)

- E60 Battery Replacement Complete GuideDocument33 pagesE60 Battery Replacement Complete GuideNyírautó-Trade Bt.No ratings yet

- Module 4 Microwave Solid State DevicesDocument199 pagesModule 4 Microwave Solid State DevicesSachin RuikarNo ratings yet

- Azb 10 A 4Document7 pagesAzb 10 A 4ElectromateNo ratings yet

- Catalog Telecommunication Cable PDFDocument29 pagesCatalog Telecommunication Cable PDFVictor AxelsonNo ratings yet

- Experiment 3 (No Load Blocked Rotor Test On Single Phase Im)Document5 pagesExperiment 3 (No Load Blocked Rotor Test On Single Phase Im)Adarsh SinghNo ratings yet

- Distribution Substation Plant Manual Chapter 3 20230727Document140 pagesDistribution Substation Plant Manual Chapter 3 20230727Mohammed selimNo ratings yet

- Description: 1G BIT (128M 8 Bit) Cmos Nand E PromDocument52 pagesDescription: 1G BIT (128M 8 Bit) Cmos Nand E PromLuis SantosNo ratings yet

- Section7 1-DTT PT2 IexDocument12 pagesSection7 1-DTT PT2 Iexramkumartanwar100% (1)

- 1706 - Capbank CalculationDocument7 pages1706 - Capbank Calculationsofyan_shahNo ratings yet

- Tesla Wall - Connector - Installation - Manual - 80A - en - US PDFDocument37 pagesTesla Wall - Connector - Installation - Manual - 80A - en - US PDFBryan SalamatNo ratings yet

- Design of INDUCTOR Electrical Department IIT Dharwad: I.Venkata Raghavendra September 21, 2019Document5 pagesDesign of INDUCTOR Electrical Department IIT Dharwad: I.Venkata Raghavendra September 21, 2019Raghavendra VenkataNo ratings yet

- ETS Series AC Servo User's Manual: Version V1.06Document144 pagesETS Series AC Servo User's Manual: Version V1.06Joimir PerezNo ratings yet

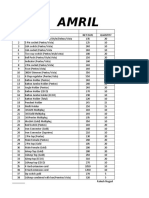

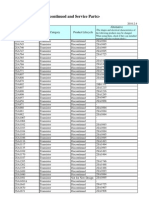

- AmrilDocument2 pagesAmrilRakesh NagpalNo ratings yet

- Sla 4037Document29 pagesSla 4037Franklin Miranda RoblesNo ratings yet

- 15SJ130Y14Document3 pages15SJ130Y14thcs.phucantctvNo ratings yet

- Blue 8x8x8 LED Cube Kit - PCB VersionDocument6 pagesBlue 8x8x8 LED Cube Kit - PCB VersionsiogNo ratings yet