Professional Documents

Culture Documents

Chapter 2 Basic Principles of Industrial Automation 2010 Instrumentation Reference Book Fourth Edition

Uploaded by

Motasim_mCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 2 Basic Principles of Industrial Automation 2010 Instrumentation Reference Book Fourth Edition

Uploaded by

Motasim_mCopyright:

Available Formats

Chapter 2

Basic Principles of Industrial Automation

W. Boyes

2.1 Introduction

There are many types of automation, broadly defined. Industrial

automation, and to some extent its related discipline of building automation, carries some specific principles. The most

important skills and principles are discussed in Chapter 1 of

this book.

It is critical to recognize that industrial automation differs from other automation strategies, especially in the enterprise or office automation disciplines. Industrial automation

generally deals with the automation of complex processes,

in costly infrastructure programs, and with design life cycles

in excess of 30 years. Automation systems installed at automotive assembly plants in the late 1970s were still being

used in 2008. Similarly, automation systems installed in

continuous and batch process plants in the 1970s and 1980s

continued to be used in 2008. Essentially, this means that it

is not possible to easily perform rip-and-replace upgrades to

automation systems in industrial controls, whereas it is simpler in many cases to do such rip-and-replace in enterprise

automation systems, such as sales force automation or even

enterprise requirements planning (ERP) systems when a

new generation of computers is released or when Microsoft

releases a new version of Windows. In the industrial automation environment, these kinds of upgrades are simply not

practical.

2.2 Standards

Over the past three decades, there has been a strong movement

toward standards-based design, both of field instruments and

controls themselves and the systems to which they belong.

The use of and the insistence on recognized standards for

sensor design, control system operation, and system design

and integration have reduced costs, improved reliability, and

enhanced productivity in industrial automation.

There are several standards-making bodies that create

standards for industrial automation. They include the

2010 Elsevier Inc. All rights reserved.

doi: 10.1016/B978-0-7506-8308-1.00002-4

International Electrotechnical Commission (IEC) and the

International Standards Organization (ISO). Other standards bodies include CENELEC, EEMUA, and the various

national standards bodies, such as NIST, ANSI, the HART

Communication Foundation, and NEC in the United States;

BSI in the United Kingdom; CSA in Canada; DIN, VDE,

and DKE in Germany; JIS in Japan; and several standards

organizations belonging to the governments of China and

India, among others.

For process automation, one of the significant standards

organizations is ISA, the International Society of Automation. ISAs standards are in use globally for a variety of

automation operations in the process industries, from process

and instrumentation diagram symbology (ISA5 and ISA20)

to alarm management (ISA18) to control valve design

(ISA75), fieldbus (ISA50), industrial wireless (ISA100),

and cyber security for industrial automation (ISA99).

Three of the most important global standards devel

opedby ISA are the ISA84 standard on safety instrumented

systems, the ISA88 standard on batch manufacturing,

and the ISA95 standard on manufacturing operations

language.

Other organizations that are similar to standards bodies

but do not make actual standards include NAMUR, OMAC,

WBF (formerly World Batch Forum), WIB (the Instrument

Users Association), and others.

In addition, with the interpenetration of COTS computing devices in industrial automation, IEEE standards, as

well as standards for the design and manufacture of personal

computers, have become of interest and importance to the

automation professional.

There are also de facto standards such as the Microsoft

Windows operating system, OPC (originally a Microsoft

standard called Object Linking and Embedding for Process

Control, or OLE for Process Control, and now called simply

OPC), and OPC UA (Universal Architecture).

It is important for the process automation professional to

keep current with standards that impinge on the automation

system purview.

19

20

PART | I The Automation Knowledge Base

2.3 Sensor and system design,

installation, and commissioning

It is not generally in the purview of the automation professional to actually design sensors. This is most commonly

done by automation and instrumentation vendors. What are

in the purview of the automation professional are system

design, installation, and commissioning. Failure to correctly

install a sensor or final control element can lead to serious

consequences, including damage to the sensor, the control

element, or the process and infrastructure themselves.

2.3.1The Basics

The basics of sensor and system design are:

Identification of the application

Selection of the appropriate sensor/transmitter

Selection of the final control element

Selection of the controller and control methodology

Design of the installation

Installing, commissioning, and calibrating the system

2.3.2 Identification of the Application

Most maintenance problems in automation appear to result

from improper identification of the application parameters.

This leads to incorrect selection of sensors and controls and

improper design of the installation. For example, it is impossible to produce an operational flow control loop if the flowmeter is being made both inaccurate and nonlinear by having

been installed in a location immediately downstream of a

major flow perturbation producer such as a butterfly valve or

two 90-degree elbows in series. The most common mistake

automation professionals make is to start with their favorite

sensors and controls and try to make them fit the application.

2.3.3 Selection of the Appropriate Sensor/

Transmitter

The selection of the most appropriate sensor and transmitter

combination is another common error point. Once the application parameters are known, it is important to select the most

correct sensor and transmitter for those parameters. There are

11 basic types of flow measurement devices and a similar

number of level measurement principles being used in modern

automation systems. This is because it is often necessary to

use a niche instrument in a particular application. There are

very few locations where a gamma nuclear-level gauge is the

most correct device to measure level, but there are a number

where the gamma nuclear principle is the only practical way to

achieve the measurement. Part of the automation professionals

skill set is the applications knowledge and expertise to be able

to make the proper selection of sensors and transmitters.

2.3.4 Selection of the Final Control Element

Selection of the final control element is just as important as

selection of the transmitter and sensor and is equally based on

the application parameters. The final control element can be

a control valve, an on/off valve, a temperature control device

such as a heater, or a pump in a process automation application. It can be a relay, a PLC ladder circuit, or a stepper motor

or other motion control device in a discrete automation application. Whatever the application, the selection of the final

control element is critical to the success of the installation.

Sometimes, too, the selection of the final control element

is predicated on factors outside the strict control loop. For

example, the use of a modulating control valve versus the

use of a variable-speed drive-controlled pump can make the

difference between high energy usage in that control loop

and less energy usage. Sometimes this difference can represent a significant cost saving.

2.3.5 Selection of the Controller and Control

Methodology

Many automation professionals forget that the selection of

the control methodology is as important as the selection of

the rest of the control loop.

Using an advanced process control system over the top

of a PID control loop when a simple on/off deadband control

will work is an example of the need to evaluate the controller and the control methodology based on the application

parameters.

2.3.6Design of the Installation

As important as any other factor, properly designing the

installation is critical to the implementation of a successful

control loop. Proper design includes physical design within

the process.

Not locating the sensor at an appropriate point in the

process is a common error point. Locating a pH sensor on

the opposite side of a 1,000-gallon tank from the chemical

injection point is an example. The pH sensor will have to

wait until the chemical injection has changed the pH in the

entire vessel as well as the inlet and outlet piping before it

sees the change. This could take hours. A loop lag time that

long will cause the loop to be dysfunctional.

Another example of improper location is to locate the

transmitter or final control element in a place where it is difficult or impossible for operations and maintenance personnel to reach it after startup. Installations must be designed

with an eye to ease of maintenance and calibration. A sensor

mounted 40 feet off the ground that requires a cherry-picker

crane to reach isnt a good installation.

Another example of improper installation is to place a

device, such as a flowmeter, where the process flow must

21

Chapter | 2 Basic Principles of Industrial Automation

be stopped to remove the flowmeter for repair. Bypass lines

should be installed around most sensors and final control

elements.

2.3.7 Installing, Commissioning, and

Calibrating the System

Installation of the system needs to be done in accordance

with both the manufacturers instructions and good trade

craft practices, and any codes that are applicable. In hazardous areas, applicable national electrical codes as well as any

plant specific codes must be followed. Calibration should

be done during commissioning and at regularly scheduled

intervals over the lifecycle of the installation.

2.4Maintenance and operation

2.4.1 Introduction

Automation professionals in the 21st century may find themselves working in maintenance or operations rather than in

engineering, design, or instrumentation and controls. It is

important for automation professionals to understand the

issues and principles of maintenance of automation systems, in both continuous and batch process and discrete factory automation. These principles are similar to equipment

maintenance principles and have changed from maintenance

practices of 20 years ago. Then maintenance was done on

a reactive basisthat is, if it broke down, it was fixed. In

some cases, a proactive maintenance scheme was used. In

this practice, critical automation assets would be replaced at

specific intervals, regardless of whether they were working

or not. This led to additional expense as systems and components were pulled out when they were still operational.

Recent practice has become that of predictive maintenance.

Predictive maintenance uses the recorded trends of physical measurements compared to defined engineering limits to

determine how to analyze and correct a problem before failure occurs. This practice, where asset management software

is used along with sensor and system diagnostics to determine

the point at which the automation asset must be replaced, is

called life-cycle maintenance or life-cycle optimization.

2.4.2Life-cycle Optimization

In any automation system, there is a recognized pattern to

the life cycles of all the components. This pattern forms the

well-known bathtub curve. There are significant numbers of infant mortality failures at the start of the curve;

then, as each component ages, there are relatively few failures. Close to the end of the products life span, the curve

rises, forming the other side of the bathtub. Using predictive maintenance techniques, it is possible to improve the

operational efficiency and availability of the entire system

by monitoring physical parameters of selected components.

For example, it is clear that the mean time between failures

(MTBF) of most electronics is significantly longer than the

design life of the automation system as a whole, after infant

mortality. This means that it is possible to essentially eliminate the controller as a failure-prone point in the system and

concentrate on what components have much shorter MTBF

ratings, such as rotating machinery, control valves, and

thelike.

2.4.3Reliability Engineering

For the automation professional, reliability is defined as

the probability that an automation device will perform its

intended function over a specified time period under conditions that are clearly understood. Reliability engineering

is the branch of engineering that designs to meet a specified probability of performance, with an expressed statistical confidence level. Reliability engineering is central to the

maintenance of automation systems.

2.4.4Asset Management, Asset

Optimization, and Plant Optimization

Asset management systems have grown into detailed, layered software systems that are fully integrated into the

sensor networks, measure parameters such as vibration and

software diagnostics from sensors and final control elements, and are even integrated into the maintenance systems

of plants. A modern asset management system can start with

a reading on a flow sensor that is out of range, be traced to

a faulty control valve, and initiate a work order to have the

control valve repaired, all without human intervention.

This has made it possible to perform workable asset

optimization on systems as large and complex as the automation and control system for a major refinery or chemical

process plant. Using the techniques of reliability engineering and predictive maintenance, it is possible to maximize

the amount of time that the automation system is working

properlythe uptime of the system.

Asset optimization is conjoined to another subdiscipline

of the automation professional: plant optimization. Using

the control system and the asset management system, it is

possible to operate the entire plant at its maximum practical

level of performance.

Suggested Reading

Mather, Darryl, Lean Strategies for Asset Reliability: Asset Resource

Planning, Industrial Press Inc., 2009.

EAM Resource Center, The Business Impact of Enterprise Asset Management, EAM, 2008.

You might also like

- Control Loop Performance Monitoring - ABB's Experience Over Two DecadesDocument7 pagesControl Loop Performance Monitoring - ABB's Experience Over Two DecadesAzamat TastemirovNo ratings yet

- Understanding The Key Elements For Machine Condition MonitoringDocument3 pagesUnderstanding The Key Elements For Machine Condition MonitoringKhor Tze MingNo ratings yet

- Programmable Motion Control Fundamentals Technical ReportDocument23 pagesProgrammable Motion Control Fundamentals Technical ReportZaheer AhamedNo ratings yet

- Department of Electrical Engineering: Subject: Industrial Automation and Control (EEC18116)Document29 pagesDepartment of Electrical Engineering: Subject: Industrial Automation and Control (EEC18116)ANISH KUMARNo ratings yet

- Basic Continuous ControlDocument2 pagesBasic Continuous ControlAnonymous BW9mIv22NNo ratings yet

- PID Controllers and Algorithms: Selection and Design Techniques Applied in Mechatronics Systems Design - Part IIDocument13 pagesPID Controllers and Algorithms: Selection and Design Techniques Applied in Mechatronics Systems Design - Part IITI Journals PublishingNo ratings yet

- Maintaining A Modern Industrial Automation SystemDocument4 pagesMaintaining A Modern Industrial Automation Systemsifusz100% (1)

- Advanced Automation and Project Management ArticleDocument5 pagesAdvanced Automation and Project Management Articlesarfaraz055No ratings yet

- STN HiAv V2.0Document88 pagesSTN HiAv V2.0Sagar JadhavNo ratings yet

- What Every Instrument Engineer Should KnowDocument27 pagesWhat Every Instrument Engineer Should KnowK LandryNo ratings yet

- Trouble Shooting PrinciplesDocument6 pagesTrouble Shooting PrinciplesSANMINo ratings yet

- TUV Maintenance Overide ProcedureDocument3 pagesTUV Maintenance Overide ProcedurejidhinmlcetNo ratings yet

- Successfully Designing Integrated Substations: NtroductionDocument12 pagesSuccessfully Designing Integrated Substations: NtroductionHassanNo ratings yet

- Industrial Automation Industry Skills and Control SystemsDocument29 pagesIndustrial Automation Industry Skills and Control SystemsmpumeNo ratings yet

- Automation and Treatment of Sewage Plant: Miss. Rachana R. SangitraoDocument11 pagesAutomation and Treatment of Sewage Plant: Miss. Rachana R. SangitraoshahqazwsxNo ratings yet

- Basics of PLCSDocument45 pagesBasics of PLCSarsalankhurshid100% (1)

- Temperature Sensor Interfacing With Embedded PLCDocument5 pagesTemperature Sensor Interfacing With Embedded PLCInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Motion Control HandbookDocument38 pagesMotion Control Handbookvincentttt100% (1)

- Pump IIoTDocument5 pagesPump IIoTChandra SekarNo ratings yet

- Unit-I What Is "Mechatronics"?Document35 pagesUnit-I What Is "Mechatronics"?nagsanthosh3No ratings yet

- Intelligent System Design of Microcontroller Based Real Time Process Control Trainer .Document12 pagesIntelligent System Design of Microcontroller Based Real Time Process Control Trainer .Kelvin NnamaniNo ratings yet

- Control Engineering Design CriteriaDocument34 pagesControl Engineering Design CriteriaTimothy LeonardNo ratings yet

- Wollo UniversityDocument18 pagesWollo UniversityMikî MańNo ratings yet

- Chapter No 1: AutomationDocument91 pagesChapter No 1: AutomationengrmishtiaqNo ratings yet

- What Is Industrial AutomationDocument6 pagesWhat Is Industrial Automationatul narkhedeNo ratings yet

- Homework 1: Summary of Industry Engagement With Control Research: Perspective and MessagesDocument4 pagesHomework 1: Summary of Industry Engagement With Control Research: Perspective and MessagesemilioNo ratings yet

- Handbook McuDocument31 pagesHandbook McuMohd Hanif bin Che HasanNo ratings yet

- PLC 2Document18 pagesPLC 2Mikî MańNo ratings yet

- Commissioning of A PLCDocument10 pagesCommissioning of A PLCTahir DonNo ratings yet

- PLC - Open ElectricalDocument4 pagesPLC - Open ElectricalHerman DamanikNo ratings yet

- UDS Protocol Implementation in An ECUDocument6 pagesUDS Protocol Implementation in An ECULayon Bruno100% (4)

- Module 5Document73 pagesModule 5Achsah K VijuNo ratings yet

- My Notes PCTDocument36 pagesMy Notes PCTPortia ShilengeNo ratings yet

- STG Etg v1.0 PDFDocument158 pagesSTG Etg v1.0 PDFcosmin75No ratings yet

- Automatic Bottle Filling and Capping Control SystemDocument41 pagesAutomatic Bottle Filling and Capping Control Systemmahderina_218241157100% (12)

- Burner Management SystemDocument11 pagesBurner Management SystemMaurthi UppalapatiNo ratings yet

- PCEDO001Document12 pagesPCEDO001Nestor GalianoNo ratings yet

- C-54 NocDocument41 pagesC-54 NocRochdi SahliNo ratings yet

- Application of PLC's For Automation of Processes in IndustriesDocument7 pagesApplication of PLC's For Automation of Processes in IndustriesMHMDNo ratings yet

- QA Piping Systems FluidFlowDocument15 pagesQA Piping Systems FluidFlowleandroniedbalski100% (1)

- Iot ApplicationDocument27 pagesIot ApplicationAkshara VNo ratings yet

- Automatic Tuning and Adaptation For Pid Controllers - A SurveyDocument16 pagesAutomatic Tuning and Adaptation For Pid Controllers - A SurveyTwistiesFifie FafauNo ratings yet

- Intro To LV in S For Control and SimDocument76 pagesIntro To LV in S For Control and SimAdriano NavarroNo ratings yet

- ABB's Control Loop Performance Monitoring ExperienceDocument8 pagesABB's Control Loop Performance Monitoring Experiencecgoveia9No ratings yet

- GAMP4 Guide For The Validation of Automated SystemsDocument16 pagesGAMP4 Guide For The Validation of Automated Systemsmagtrol100% (1)

- Coordination of Operations by Relation Extraction For Manufacturing Cell ControllersDocument16 pagesCoordination of Operations by Relation Extraction For Manufacturing Cell ControllersJose Leonardo Simancas GarciaNo ratings yet

- Automation & ControlDocument41 pagesAutomation & Controlkaushal2442No ratings yet

- 2012 Mar MaintainingDocument5 pages2012 Mar MaintainingJoãoCarlosMidonNo ratings yet

- Considerations For Choosing A Controller: Consideration Information To Record Why This Is ImportantDocument2 pagesConsiderations For Choosing A Controller: Consideration Information To Record Why This Is ImportantRodrigo Iván Latorre AlmirallNo ratings yet

- Report On PLC & ScadaDocument30 pagesReport On PLC & ScadaRajmal Menariya60% (10)

- PID Auto TuningDocument84 pagesPID Auto TuningtrshaaaNo ratings yet

- Iare Iac PPT 0Document205 pagesIare Iac PPT 0Sabzgostar Avande ParsNo ratings yet

- Automatic Bottle FillingDocument41 pagesAutomatic Bottle FillingSanjana Singh100% (1)

- Introduction To AutomationDocument20 pagesIntroduction To AutomationGourav Solanki100% (1)

- Q24. Define An Automation? Explain The Basic Elements of An Automated System? Explain The Five Levels of Automation?Document8 pagesQ24. Define An Automation? Explain The Basic Elements of An Automated System? Explain The Five Levels of Automation?Rakesh ShNo ratings yet

- ProjectDocument15 pagesProjectayie94_fox8792No ratings yet

- Industrial Automation and Control Sample Paper with AnswersDocument3 pagesIndustrial Automation and Control Sample Paper with AnswersMatthew SibandaNo ratings yet

- Plant Intelligent Automation and Digital Transformation: Volume I: Process and Factory AutomationFrom EverandPlant Intelligent Automation and Digital Transformation: Volume I: Process and Factory AutomationNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- Chapter 35 Batch Process Control 2010 Instrumentation Reference Book Fourth EditionDocument2 pagesChapter 35 Batch Process Control 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- Chapter 34 Advanced Control For The Plant Floor 2010 Instrumentation Reference Book Fourth EditionDocument10 pagesChapter 34 Advanced Control For The Plant Floor 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- Chapter 26 Chemical Analysis Moisture Measurement 2010 Instrumentation Reference Book Fourth EditionDocument8 pagesChapter 26 Chemical Analysis Moisture Measurement 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- Programming With MatLabDocument23 pagesProgramming With MatLabZia SilverNo ratings yet

- Copyright 2010 Instrumentation Reference Book Fourth EditionDocument1 pageCopyright 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- Introduction 2010 Instrumentation Reference Book Fourth EditionDocument2 pagesIntroduction 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- Chapter 38 Instrument Installation and Commissioning 2010 Instrumentation Reference Book Fourth EditionDocument6 pagesChapter 38 Instrument Installation and Commissioning 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- Contributors 2010 Instrumentation Reference Book Fourth EditionDocument2 pagesContributors 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- 90 Days of ActionDocument92 pages90 Days of ActionPaula StanwyckNo ratings yet

- Simulation, Modeling, and Performance Analysis of IEEE 802.16e OFDMA Systems For Urban and Rural EnvironmentsDocument4 pagesSimulation, Modeling, and Performance Analysis of IEEE 802.16e OFDMA Systems For Urban and Rural EnvironmentsMotasim_mNo ratings yet

- Prepare For IELTSDocument169 pagesPrepare For IELTSapi-3818413100% (2)

- Avatar Upgrade Program PDFDocument33 pagesAvatar Upgrade Program PDFMotasim_mNo ratings yet

- 1001 Vocabulary and Spelling QuestionsDocument160 pages1001 Vocabulary and Spelling Questionssashi01092% (12)

- Switches ExplainedDocument3 pagesSwitches ExplainedMotasim_mNo ratings yet

- ISO 9000 Quality Assurance AcknowledgementsDocument1 pageISO 9000 Quality Assurance AcknowledgementsMotasim_mNo ratings yet

- Appendix 1 Imperial Metric SI Conversion Tables 2001 Measurement and Instrumentation Principles Third EditionDocument7 pagesAppendix 1 Imperial Metric SI Conversion Tables 2001 Measurement and Instrumentation Principles Third EditionMotasim_mNo ratings yet

- 1081app A 1 PDFDocument11 pages1081app A 1 PDFMotasim_mNo ratings yet

- Chapter 4 Simulation and Design Software1 2010 Instrumentation Reference Book Fourth EditionDocument2 pagesChapter 4 Simulation and Design Software1 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

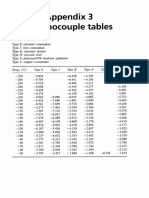

- Appendix 3 Thermocouple Tables 2001 Measurement and Instrumentation Principles Third EditionDocument6 pagesAppendix 3 Thermocouple Tables 2001 Measurement and Instrumentation Principles Third EditionMotasim_mNo ratings yet

- Appendix 4 Solutions To Self Test Questions 2001 Measurement and Instrumentation Principles Third EditionDocument4 pagesAppendix 4 Solutions To Self Test Questions 2001 Measurement and Instrumentation Principles Third EditionMotasim_mNo ratings yet

- Appendix C The Institute of Measurement and Control 2010 Instrumentation Reference Book Fourth EditionDocument4 pagesAppendix C The Institute of Measurement and Control 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- Appendix 4 Solutions To Self Test Questions 2001 Measurement and Instrumentation Principles Third EditionDocument4 pagesAppendix 4 Solutions To Self Test Questions 2001 Measurement and Instrumentation Principles Third EditionMotasim_mNo ratings yet

- Index 2001 Measurement and Instrumentation Principles Third EditionDocument7 pagesIndex 2001 Measurement and Instrumentation Principles Third EditionMotasim_mNo ratings yet

- Appendix 2 TH Venin S Theorem 2001 Measurement and Instrumentation Principles Third EditionDocument6 pagesAppendix 2 TH Venin S Theorem 2001 Measurement and Instrumentation Principles Third EditionMotasim_mNo ratings yet

- Appendix 3 Thermocouple Tables 2001 Measurement and Instrumentation Principles Third EditionDocument6 pagesAppendix 3 Thermocouple Tables 2001 Measurement and Instrumentation Principles Third EditionMotasim_mNo ratings yet

- Hsu 4 Information and Control Systems AbDocument43 pagesHsu 4 Information and Control Systems AbMotasim_mNo ratings yet

- Chapter 3 Measurement Methods and Control Strategies 2010 Instrumentation Reference Book Fourth EditionDocument2 pagesChapter 3 Measurement Methods and Control Strategies 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- Appendix D International Society of Automation Formerly Instrument Society of America 2010 Instrumentation Reference Book Fourth EditionDocument2 pagesAppendix D International Society of Automation Formerly Instrument Society of America 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- Preface 2001 Measurement and Instrumentation Principles Third EditionDocument3 pagesPreface 2001 Measurement and Instrumentation Principles Third EditionMotasim_mNo ratings yet

- Chapter 5 Security For Industrial Automation1 2010 Instrumentation Reference Book Fourth EditionDocument2 pagesChapter 5 Security For Industrial Automation1 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- Chapter 1 - Introduction To Machinery PrinciplesDocument27 pagesChapter 1 - Introduction To Machinery PrinciplesYousab CreatorNo ratings yet

- Abbey Pain Scale assessment toolDocument2 pagesAbbey Pain Scale assessment toolMuhammad RezgiaNo ratings yet

- Numerical Modelling of Laterally Loaded Piles Captures Field Test ResponseDocument244 pagesNumerical Modelling of Laterally Loaded Piles Captures Field Test ResponseXiang ming GeNo ratings yet

- Akshay 71 Seminar ReportDocument22 pagesAkshay 71 Seminar ReportSanket Yadav25% (4)

- KTS - Sarao.bakus Temple of Eternal FiireDocument176 pagesKTS - Sarao.bakus Temple of Eternal FiireK.T.S. SaraoNo ratings yet

- Natural Law Theory ApproachDocument35 pagesNatural Law Theory ApproachseventhwitchNo ratings yet

- Turbine Stress EvaluatorDocument14 pagesTurbine Stress EvaluatorsumitNo ratings yet

- Finite Element Simplified Fatigue AnalysisDocument4 pagesFinite Element Simplified Fatigue AnalysisJin Hwan KimNo ratings yet

- Vertical Jaw Relation Recording MethodsDocument17 pagesVertical Jaw Relation Recording MethodsHarish VsNo ratings yet

- F588 PDFDocument8 pagesF588 PDFOscar Gutiérrez-JuncoNo ratings yet

- NNDC Planning Applications 4oct - 11 OctDocument4 pagesNNDC Planning Applications 4oct - 11 OctRichard SmithNo ratings yet

- PCS PADDLE SHIFTER INSTALL GUIDEDocument21 pagesPCS PADDLE SHIFTER INSTALL GUIDEAndreas T P ManurungNo ratings yet

- Synchronized Natural Incubation by Free-Range Native ChickensDocument2 pagesSynchronized Natural Incubation by Free-Range Native ChickensFilbert John MillanNo ratings yet

- Sanoj Kumar - OriginalDocument5 pagesSanoj Kumar - OriginalHamid SaifNo ratings yet

- Parts of Speech 15Document16 pagesParts of Speech 15lost finNo ratings yet

- Inakyd 3623-X-70Document2 pagesInakyd 3623-X-70roybombomNo ratings yet

- Mathematics: Minimum Level Learning MaterialDocument60 pagesMathematics: Minimum Level Learning MaterialTusar SardarNo ratings yet

- Delay-Tolerant NetworksDocument66 pagesDelay-Tolerant NetworksMegi YantoNo ratings yet

- B.pharm Course Handbook 2017 18Document74 pagesB.pharm Course Handbook 2017 18Md RaquibNo ratings yet

- Stepan Pol BC 180Document2 pagesStepan Pol BC 180Parag RautNo ratings yet

- ASME B31.4-2016 Pipeline Transportation Systems For Liquids and SlurriesDocument1 pageASME B31.4-2016 Pipeline Transportation Systems For Liquids and SlurriesJose Rodrigo Salguero DuranNo ratings yet

- Hydraulic Power Steering System Design PDFDocument16 pagesHydraulic Power Steering System Design PDFAdrianBirsan100% (1)

- Outline 1. Background of Revision: JEITA CP-1104BDocument4 pagesOutline 1. Background of Revision: JEITA CP-1104BkksdnjdaNo ratings yet

- 20 N 60 C 3Document13 pages20 N 60 C 3rashidmirzaNo ratings yet

- Answer Section B and C and Paper 3Document21 pagesAnswer Section B and C and Paper 3Adnan ShamsudinNo ratings yet

- M. Valerio Assignment 6.1Document1 pageM. Valerio Assignment 6.1Mark Kristian ValerioNo ratings yet

- อัตราภาษีของไทยที่ลดให้เปรูDocument124 pagesอัตราภาษีของไทยที่ลดให้เปรูDante FilhoNo ratings yet

- Consumer preference towards branded milk: A comparative analysis of Verka milk and Amul milkDocument12 pagesConsumer preference towards branded milk: A comparative analysis of Verka milk and Amul milkBhawna RehanNo ratings yet

- Journal of Alloys and Compounds: Wei Li, Zhijun Xu, Ruiqing Chu, Peng Fu, Guozhong ZangDocument4 pagesJournal of Alloys and Compounds: Wei Li, Zhijun Xu, Ruiqing Chu, Peng Fu, Guozhong ZangSamah SamahNo ratings yet

- Gold Grade of Epithermal Gold Ore at Lamuntet, Brang Rea, West Sumbawa District, West Nusa Tenggara Province, IndonesiaDocument10 pagesGold Grade of Epithermal Gold Ore at Lamuntet, Brang Rea, West Sumbawa District, West Nusa Tenggara Province, Indonesiasukri arjunaNo ratings yet