Professional Documents

Culture Documents

Method of Increasing Strength of Welded Slat Assembly for Inflatable Packers

Uploaded by

mohammadreza91Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method of Increasing Strength of Welded Slat Assembly for Inflatable Packers

Uploaded by

mohammadreza91Copyright:

Available Formats

USOO5363542A

United States Patent [191

[11] Patent Number:

Sorem et a1.

[45]

[54]

METHOD OF ASSEMBLY FOR

4,951,747

8/1990 Coronado ......................... .. 166/187

INFLATABLE PACKER

5,143,154

5,195,583

9/1992 Mody et a1. ..

..... .. 166/187

3/1993 Toon et al. ........................ .. 166/187

[75]

Inventors:

[73] Assignee:

Robert M. Sorem, Tulsa; David M.

Nov. 15, 1994

Eslinger, Broken Arrow, bot}1 of

Prlmary ExammerT1mothy V. Eley

Ok1a_

Attorney, Agent, or FirmStephen A. Little?eld

Dowell Schlumberger Incorporated,

Sugar Land, TeX-

[21] Appl. No: 988,658

>

Date of Patent:

5 9 363 9 542

V [57]

ABSTRACT

The strength of slats attached to an in?atable packer

assembly by welding is increased by forming the slats of

an age-hardening materials, welding the slats to the

[22] F?ed

Dec' 11 1992

in?atable packer assembly in an annealed condition

[51] Int. (:1.5 ............................................ .. B23P 19/04

[52] us. Cl. ................................... .. 29/454; 29/5271;

166/187

followed by age-hardening of the welded slats- A Slat

structure having much greater strength than welded

cold-worked material is realized. Final assembly in

[58] Field of Search .................... .. 29/454, 458, 527.1;

cludes the steps of sliding an overlying sleeve over the

166/ 187; 277/34, 34.3, 34.6

end ?tting, the weld and a portion of the slats and en

[56]

References cued

US PATENT DOCUMENTS

3,837,947

9/1974

4,832,120

5/ 1989 Coronado ......................... .. 166/ 187

gaging threads on the interior of the sleeve with exter

nal threads on the end ?tting. The sleeve can thereby be

unaffected by the heat treatment steps.

Malone ................................ .. 156/69

1 Claim, 3 Drawing Sheets

US. Patent

7/

Nov. 15, 1994

Sheet 1 of 3

5,363,542

1/

/

/7

M, 1 4

//

M

''

1L/

Aim

ig. 1

//

14

/

12

/

/

,

/

/

/

24

y

7/

12

/

X

/\

aa

.6

22

W /

22

24

24

2o

24

/

C

/2.6 / /

Fig. 2

2o

US. Patent

'

Nov. 15, 1994

Sheet 2 of 3

5,363,542

16

g

/

ML

h

I,

u_

38/

5,363,542

METHOD OF ASSENIBLY FOR INFLATABLE

PACKER

This invention relates to the art of production of

subterranean ?uid through a wellbore and more partic

ularly, to an in?atable packer or bridge plug useful in

temporarily isolating portions of a wellbore.

BACKGROUND OF THE INVENTION

In?atable packers or bridge plugs have long been

used in wellbore operations. An in?atable packer typi

cally comprises a tubular base and a surrounding, in?at

able elastomeric bladder or sleeve. Fluid passages

within the tubular body allow ?uids to contact the

in?atable bladder and expand the bladder radially out

wardly to effect sealing engagement with a borehole or

well casing.

Since the elastomeric bladder is subjected to both

expansion pressure and abrasion or cutting forces, it has

vided on the collar to which the slats are welded. No

heat treatment of the welded slats to restore the

strength lost in the heat of the welding operation is

possible without a consequent loss in the desired high

strength properties of the surrounding sleeves. The

sleeves must be an integral part of the assembly prior to

welding.

SUMMARY OF THE INVENTION

The present invention overcomes the reduction in

packer strength as a result of welding high strength

cold-worked steel slats.

In accordance with the invention, the method of

assembly of an in?atable packer includes the attachment

of a plurality of reinforcing slats to an end connector of

the packer. The improvement comprises the sequential

steps of forming the slats of an age hardening material in

annealed condition, welding the slats to the end ?tting

and age hardening the resultant welded slats and end

?tting. Finally, a high strength surrounding sleeve is

been common to surround the exterior surface of the

threadably attached to the end fitting with a portion of

bladder with a plurality of peripherally overlapping,

the sleeve overlying the weld and end portions of the

resilient reinforcing slats or ribs. There is generally

slats.

suf?cient overlap of such slats that upon expansion of

Further in accordance with the invention, the afore

the in?atable bladder, the slats remain as a surrounding 25 mentioned age hardening step includes heat treatment

armor protecting the bladder from abrasion and cuts

of welded slats and end ?tting.

while also preventing extrusion of the bladder elasto

BRIEF DESCRIPTION OF THE DRAWINGS

mer between the slats in a localized area. The slats are

commonly welded to a portion of the assembly to retain

The invention will now be described in greater detail

their desired position and orientation. U.S. Pat. No.

with reference to the accompanying drawings forming

5,143,154 describes one form of slat weldment.

a part of the specification and in which:

Because the slats cannot effect the sealing of the

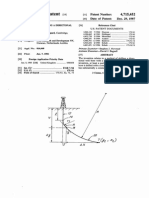

FIG. 1 is a schematic view of an in?atable packer in

packer against a wellbore or casing, at least some por

use prior to in?ation;

tions of the reinforcing slats are surrounded by and may

FIG. 2 is a schematic view similar to FIG. 1 showing

be bonded to an outer annular elastomeric cover or 35 the in?atable packer in the in?ated condition;

packing element which, upon expansion of the in?atable

packer, comes into pressure sealing engagement with

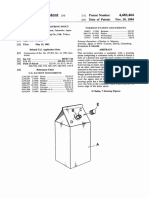

FIG. 3 is a cross-sectional elevation of a portion of

the end ?tting of an in?atable packer illustrating one

form of slat weldment in accordance with the present

the wellbore or casing.

The outer sealing cover generally comprises either a

invention, and

single or a plurality of annular circumferential elasto~ 40

FIG. 4 is a cross-sectional elevation of an alternative

meric pieces located on the outer surface of the rein

slat weldment and ?nal assembly in accordance with

forcing slats. When a single elastomeric piece is em

the invention.

ployed it may cover only a portion of the longitudinal

DETAILED DESCRIPTION OF THE

length of the slats or, alternatively, it may cover the

PREFERRED

EMBODIMENTS AND THE

entire outer surface of the slats. Such single piece cov 45

DRAWINGS

ers generally have a uniform thickness along their

length, the thickness generally being substantial. Such

Referring now to the drawings, wherein the show

arrangements are described in US. Pat. Nos. 3,837,947,

ings are for the purposes of illustrating the preferred

4,832,120 and 5,143,154.

embodiment of the invention only and not for the pur

Slat reinforced in?atable packers are typically con

poses of limiting same, FIG. 1 schematically illustrates

structed of high strength, cold-worked slats welded to

the in?atable packer device in its run-in condition prior

an end connector. The resulting heat affected zone of

to in?ation. It will be understood that the in?atable

the slats has signi?cantly lower strength (as much as

70% lower strength) than the unwelded portions of the

packer may be one packing element of a bridge plug or

only a single packer employed to isolate one part of a

slats. Such a condition substantially reduces the overall 55 wellbore from another. The packer element 10 includes

strength of the packer.

a tubular base portion 12 and is interconnected with a

In the assembly of a slat-reinforced in?atable packer,

the welded \end portions of the slats are surrounded by

a high strength metal sleeve. The sleeve, in addition to

its function of protecting the welded end portions of the 60

coupling number 14 to a tubular string 16 extending to

the surface. It will be appreciated that the tubular string

16 can be formed by coupling individual sections of pipe

slats, acts as a mandrel around which the slats are bent

uous length of coiled tubing inserted into the wellbore

18 having a casing 20.

The packer element 10 generally comprises an in?at

upon in?ation expansion of the in?atable packer.

In the aforementioned US. Pat. No. 5,143,154, the

or, in a preferred embodiment of the invention, a contin

assembly of the packer requires the placement of the

able portion 22 with at least one and possibly two asso

high strength metal surrounding sleeve along the slats 65 ciated end ?ttings 24. It will be further understood that

prior to slat weldment. The sleeve can then be slid

longitudinally outwardly along the slats to cover the

end portions and to engage the retaining shoulder pro

the in?atable packer may be associated with one or

more downhole tools such as to effect the injection of

various ?uids into isolated portions of the wellbore 18.

5,363,542

greater than, that of cold-worked stainless steel which

has not been affected by welding.

The strength of the slats formed of the age-hardening

At the point desired in the wellbore, the in?atable

portion 22 of the packer element 10 is expanded through

the application of ?uid pressure to the interior of the

in?atable portion and expanded outwardly into engage

material can be elevated to an even greater degree by

ment with the casing 20 (FIG. 2). It will be understood

that while the use of the in?atable packer of the present

heat treating in accordance with practices familiar to

those skilled in the art.

invention is shown in conjunction with a cased bore

In accordance with the preferred embodiment of the

hole, the in?atable packer may also be used in an un

invention shown in FIG. 4, a plurality of slats 40 are

cased wellbore under appropriate conditions known to

welded to an end ?tting 42 at its end face 44 with a weld

10 bead 46. The outer surface of the end ?tting 42 includes

those skilled in the art.

As shown in FIG. 3, a plurality of overlapping slats

a threaded portion 48 in order to effect ?nal assembly of

30 are welded at their end portions to an end ?tting 32

the in?atable packer. In accordance with the invention,

with a weld bead 34. While the assembly is shown with

?nal assembly includes providing an outer sleeve 50

the slats 30 welded to an inner cylindrical surface of the

having an inner diameter greater than the outer diame

end ?tting 32, it will be appreciated that other arrange

ter of the assembly of the end ?tting 42 and the slats 40

ments are possible such as the welding of the slats 30 to

also including internal threads 52 for engagement with

the end face 16 of the end ?tting 32 or, possibly, the

the outer threads 48 of the end ?tting 42.

outer surface 38 of the end ?tting 32.

It can be clearly seen that welding and heat treatment

Typically the slat material is 301 % hard stainless steel.

of the end ?tting and slat assembly can be effected with

The yield strength of cold-worked material is 135 ksi 20 out involving the outer sleeve 50. After completion of

minimum. After welding, the heat affected zone adja

the welding and heat treatment operation with regard

cent the welded ends of the slats 30 has the properties of

to the end ?tting 42 and the slats 40, the outer sleeve 50

annealed material which has a yield strength of 40 ksi.

can be slipped over the end ?tting 42 and the slats 40

Thus, the slat in this heat affected area is 70% weaker

and the threads 52 of the outer sleeve 50 can be brought

25

than the rest of the slat.

into threaded engagement with the outer threads 48 of

In accordance with the invention, the slats 30 are

the end ?tting 42 effecting ?nal assembly.

formed of an age-hardening material which is welded in

While the invention has been described in the more

the annealed condition and then aged. Following age

limited aspects of the preferred embodiment thereof,

hardening, the slat has full age-hardened strength which

is equal to that of cold-worked stainless steel which has 30 other embodiments have been suggested and still others

will occur to those skilled in the art upon a reading and

not been affected by heat. Additionally, the weld mate

understanding of the foregoing speci?cation. It is in

rial can easily have a strength greater than that of the

tended

that all such embodiments be included within

slat.

the scope of this invention as limited only by the ap

In accordance with the invention, the slats 30 are

formed of an age-hardening material which is welded to 35 pended claims.

Having thus described my invention, I claim:

the end ?tting 42 in the annealed condition. The welded

1. In the method of assembly of an in?atable packer

assembly is solution annealed at approximately 1700 to

including attachment of a plurality of reinforcing slats

2000 F. for one hour to relieve residual stresses and to

to an end ?tting of said packer comprising the sequen

form a more uniform microstructure in weld heat affect

zone. The annealed assembly is aged to harden the slats 40 tial steps of forming slats of an age-hardening material

in annealed condition, welding said slats to said end

30, and ?tting 42, Many age-hardening treatments are

?tting, heat treating and age hardening the resultant

possible in accordance with practices familiar to those

welded slats and end ?tting, the improvement which

skilled in the art. One possible two stage age-hardening

comprises providing external threads on the end ?tting,

cycle is to age at 1400" F. for ten hours then furnace

cool to 1200" F. and hold for total aging time of twenty 45 slipping an overlying sleeve onto the end connector and

engaging internal threads on the sleeve with the exter

hours. It is important to hang the welded assembly

nal threads of the end ?tting.

during the annealing and aging treatments to prevent

distortion of the slats. Following age-hardening, the

*

welded slat assembly has a strength which is equal to, or

50

55

65

You might also like

- Inflatable Packer Reinforcement MethodDocument5 pagesInflatable Packer Reinforcement Methodmohammadreza91No ratings yet

- 11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555Document5 pages11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555mohammadreza91No ratings yet

- United States Patent (19) : Wood (45) Date of Patent: Jan. 8, 1985Document5 pagesUnited States Patent (19) : Wood (45) Date of Patent: Jan. 8, 1985mohammadreza91No ratings yet

- Segmented Sealing Lips Reduce Cracking in Turbine Disk SealsDocument4 pagesSegmented Sealing Lips Reduce Cracking in Turbine Disk SealsshamsNo ratings yet

- Tube Saport PDFDocument4 pagesTube Saport PDFjr110livecomNo ratings yet

- Unlted States Patent (191 1111 3,736,693: Koch 1451 June 5, 1973Document4 pagesUnlted States Patent (191 1111 3,736,693: Koch 1451 June 5, 1973fgrt45No ratings yet

- Tài liệu5Document12 pagesTài liệu5Hoàng ĐứcNo ratings yet

- Uhlted States Patent (19) (11) Patent Number: 4,579,373: Neal Et Al. (45) Date of Patent: Apr. 1, 1986Document5 pagesUhlted States Patent (19) (11) Patent Number: 4,579,373: Neal Et Al. (45) Date of Patent: Apr. 1, 1986daniel_iosif_glNo ratings yet

- LLLLLLLLLLL: United States Patent (191Document9 pagesLLLLLLLLLLL: United States Patent (191Mark EdowaiNo ratings yet

- US4753444Document5 pagesUS4753444Hadi KoraniNo ratings yet

- Us 6131519Document4 pagesUs 6131519dgfhjsdg hfsdhyjNo ratings yet

- United States Patent (19) : Anderson Et Al. 54 Yacht Mast 11) 4,072,121Document7 pagesUnited States Patent (19) : Anderson Et Al. 54 Yacht Mast 11) 4,072,12112348No ratings yet

- July 3, J 1923. ' 1,461,013: H. D. HodgeDocument4 pagesJuly 3, J 1923. ' 1,461,013: H. D. HodgeerwerNo ratings yet

- European Patent Specification F01D 11/00: Printed by Jouve, 75001 PARIS (FR)Document10 pagesEuropean Patent Specification F01D 11/00: Printed by Jouve, 75001 PARIS (FR)shamsNo ratings yet

- Us 5531545Document10 pagesUs 5531545Mark EdowaiNo ratings yet

- Us7201104 PDFDocument7 pagesUs7201104 PDFThamuze UlfrssonNo ratings yet

- H!!!!! - EEHHE) : Nonononononon Niinin 'Document4 pagesH!!!!! - EEHHE) : Nonononononon Niinin 'Hadi KoraniNo ratings yet

- Ullltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992Document7 pagesUllltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992mohammadreza91No ratings yet

- Cement BasketDocument4 pagesCement Basketराजकुमार यादवNo ratings yet

- Pipe Sealing PATENTDocument23 pagesPipe Sealing PATENTDaniel InemughaNo ratings yet

- 915 9000 990 112 /// 325 Aaa 3002 295 022 225 464 710 965 150 DWWDocument15 pages915 9000 990 112 /// 325 Aaa 3002 295 022 225 464 710 965 150 DWWMetin MehelNo ratings yet

- Refinery Based Case Study of A Novel Gasket Designed For Use in Problematic Shell and Tube Heat Exchangers - Change GasketDocument19 pagesRefinery Based Case Study of A Novel Gasket Designed For Use in Problematic Shell and Tube Heat Exchangers - Change GasketAlbertoNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2002/0153034 A1Document25 pagesPatent Application Publication (10) Pub. No.: US 2002/0153034 A1Paballo MontleNo ratings yet

- Us 4394836Document4 pagesUs 4394836ererNo ratings yet

- TEPZZ - 4 885B - T: European Patent SpecificationDocument10 pagesTEPZZ - 4 885B - T: European Patent SpecificationshamsNo ratings yet

- United States Patent (19) : Patent Number: (45) Date of PatentDocument10 pagesUnited States Patent (19) : Patent Number: (45) Date of PatentMichael JordanNo ratings yet

- United States Patent (19) 11 4,023,782: Eifer (45) May 17, 1977Document16 pagesUnited States Patent (19) 11 4,023,782: Eifer (45) May 17, 1977liNo ratings yet

- United States Patent (191 (11) Patent Number: 5,259,288: Vatsvog (45) Date of Patent: Nov. 9, 1993Document13 pagesUnited States Patent (191 (11) Patent Number: 5,259,288: Vatsvog (45) Date of Patent: Nov. 9, 1993fghdfjerNo ratings yet

- 枪炮声抑制器 PDFDocument11 pages枪炮声抑制器 PDFJin SongNo ratings yet

- Chlorine CylinderDocument9 pagesChlorine Cylinderjoseph_mscNo ratings yet

- Us 5988287Document14 pagesUs 5988287mohammadreza91No ratings yet

- United States Patent: Noveske (10) Patent N0.: (45) Date of PatentDocument9 pagesUnited States Patent: Noveske (10) Patent N0.: (45) Date of Patentduffy5555No ratings yet

- Drilling constant curvature well boresDocument7 pagesDrilling constant curvature well boresandreNo ratings yet

- Dec. 22, 1953 R. T. Catlin Etal: AmmunitionDocument4 pagesDec. 22, 1953 R. T. Catlin Etal: Ammunitionkahj juliNo ratings yet

- Us 5610365Document5 pagesUs 5610365dgfhjsdg hfsdhyjNo ratings yet

- US5513743Document6 pagesUS5513743AdailsonNo ratings yet

- 06.damper Apparatus and Mounting Clip ToDocument4 pages06.damper Apparatus and Mounting Clip ToRohit BirajdarNo ratings yet

- United States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDocument7 pagesUnited States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDanister GladwinNo ratings yet

- Us8359722 PDFDocument8 pagesUs8359722 PDFaduwa64No ratings yet

- Dual split tubing hanger seal for oil and gas wellsDocument10 pagesDual split tubing hanger seal for oil and gas wellsabodolkuhaaNo ratings yet

- Concrete Mixer Drum ReinforcementDocument10 pagesConcrete Mixer Drum Reinforcementdaygo21No ratings yet

- Composite Bridge Plug System (US Patent 6796376)Document16 pagesComposite Bridge Plug System (US Patent 6796376)PriorSmartNo ratings yet

- References Cited Robiatiorlial Movergents. Pat Least One ElaitigallybexaatrlidDocument7 pagesReferences Cited Robiatiorlial Movergents. Pat Least One Elaitigallybexaatrlidmohammadreza91No ratings yet

- Vernier DesignDocument9 pagesVernier DesignRakeshNo ratings yet

- Umted States Patent (19) (11) Patent Number: 5,642,778: Gentry (45) Date of Patent: Jul. 1, 1997Document15 pagesUmted States Patent (19) (11) Patent Number: 5,642,778: Gentry (45) Date of Patent: Jul. 1, 1997aegosmithNo ratings yet

- Wellheads, Flow Control Eqpmt N FlowlinesDocument131 pagesWellheads, Flow Control Eqpmt N FlowlinesEbenezer Amoah-KyeiNo ratings yet

- United States Patent: Sultan Et Al. (45) Date of Patent: Apr. 29, 2008Document7 pagesUnited States Patent: Sultan Et Al. (45) Date of Patent: Apr. 29, 2008aqil_shamsiNo ratings yet

- US4483464Document6 pagesUS4483464Joao LemesNo ratings yet

- Fabrication of Steel PipeworkDocument10 pagesFabrication of Steel PipeworkjoseritoNo ratings yet

- Connecting Rod Cracker: Rigid Support and Floating Die Crack Connecting RodsDocument12 pagesConnecting Rod Cracker: Rigid Support and Floating Die Crack Connecting RodsOkta Pariantoro Budi SetiawanNo ratings yet

- Cloth Tow Target Sleeve (1992)Document26 pagesCloth Tow Target Sleeve (1992)CAP History LibraryNo ratings yet

- United States Patent: (45) July 4, 1972Document4 pagesUnited States Patent: (45) July 4, 1972Lidya SimatupangNo ratings yet

- Polish Top LinerDocument12 pagesPolish Top LinerLenis CeronNo ratings yet

- United States Patent: (12) (10) Patent N0.: US 7,213,519 B2 Wiley Et Al. (45) Date of Patent: May 8, 2007Document26 pagesUnited States Patent: (12) (10) Patent N0.: US 7,213,519 B2 Wiley Et Al. (45) Date of Patent: May 8, 2007fghdfjerNo ratings yet

- O/65ézá / /zzáez: Ozzezz67Document4 pagesO/65ézá / /zzáez: Ozzezz67TECUMCE GOMEZ PEREZNo ratings yet

- Mosler Safe & Lock Co. v. Mosler, 127 U.S. 354 (1888)Document6 pagesMosler Safe & Lock Co. v. Mosler, 127 U.S. 354 (1888)Scribd Government DocsNo ratings yet

- Deç. 7, 1948. F, A, Gaspar ' - 2,455,469: Filed Oct. 1, 1946Document3 pagesDeç. 7, 1948. F, A, Gaspar ' - 2,455,469: Filed Oct. 1, 1946david19775891No ratings yet

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- Us 20050077053Document16 pagesUs 20050077053mohammadreza91No ratings yet

- Us 5988287Document14 pagesUs 5988287mohammadreza91No ratings yet

- Viii/Ii/Ii": United States Patent (191 (11) Patent Number: 4,708,208Document9 pagesViii/Ii/Ii": United States Patent (191 (11) Patent Number: 4,708,208mohammadreza91No ratings yet

- Ullltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992Document7 pagesUllltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992mohammadreza91No ratings yet

- US5439053 Thickness PDFDocument6 pagesUS5439053 Thickness PDFmohammadreza91No ratings yet

- Packer Sealing Element With Shape Memory MaterialDocument8 pagesPacker Sealing Element With Shape Memory Materialmohammadreza91No ratings yet

- United States Patent: (10) Patent N0.: Hoifman Et Al. (45) Date 0f PatentDocument10 pagesUnited States Patent: (10) Patent N0.: Hoifman Et Al. (45) Date 0f Patentmohammadreza91No ratings yet

- Us 2843208Document7 pagesUs 2843208mohammadreza91No ratings yet

- References Cited Robiatiorlial Movergents. Pat Least One ElaitigallybexaatrlidDocument7 pagesReferences Cited Robiatiorlial Movergents. Pat Least One Elaitigallybexaatrlidmohammadreza91No ratings yet

- Us 4406461Document5 pagesUs 4406461mohammadreza91No ratings yet

- Us5353871 PDFDocument4 pagesUs5353871 PDFmohammadreza91No ratings yet

- 0 - Rank One Convexification Approach For The Modeling of Magnetic Shape Memory Response PDFDocument2 pages0 - Rank One Convexification Approach For The Modeling of Magnetic Shape Memory Response PDFmohammadreza91No ratings yet

- Us 4406461Document5 pagesUs 4406461mohammadreza91No ratings yet

- 1286 - Giant Magnetic-field-Induced Strain in NiMnGa Seven-Layered Martensitic PhaseDocument3 pages1286 - Giant Magnetic-field-Induced Strain in NiMnGa Seven-Layered Martensitic Phasemohammadreza91No ratings yet

- Ullltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992Document7 pagesUllltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992mohammadreza91No ratings yet

- Unlted States Patent (10) Patent No.: US 7,621,322 B2Document9 pagesUnlted States Patent (10) Patent No.: US 7,621,322 B2mohammadreza91No ratings yet

- 79 - Magnetic - Eld-Induced Superelasticity of Ferromagnetic Thermoelastic Martensites Experiment and Modeling PDFDocument8 pages79 - Magnetic - Eld-Induced Superelasticity of Ferromagnetic Thermoelastic Martensites Experiment and Modeling PDFmohammadreza91No ratings yet

- 268-Giant Field-Induced Reversible Strain in Magnetic Shape Memory NiMnGa Alloy PDFDocument3 pages268-Giant Field-Induced Reversible Strain in Magnetic Shape Memory NiMnGa Alloy PDFmohammadreza91No ratings yet

- 86 - Voltage Generation Induced by Mechanical Straining in Magnetic Shape Memory Materials PDFDocument5 pages86 - Voltage Generation Induced by Mechanical Straining in Magnetic Shape Memory Materials PDFmohammadreza91No ratings yet

- 55 - Stress-And Magnetic-Field-Induced Variant Rearrangement in Ni-Mn-Ga Single Crystals With Seven-Layered Martensitic Structure PDFDocument4 pages55 - Stress-And Magnetic-Field-Induced Variant Rearrangement in Ni-Mn-Ga Single Crystals With Seven-Layered Martensitic Structure PDFmohammadreza91No ratings yet

- 75 - Modelling Detwinning of Martensite Platelets Under Magnetic and (Or) Stress Actions On Ni-Mn-Ga Alloys PDFDocument3 pages75 - Modelling Detwinning of Martensite Platelets Under Magnetic and (Or) Stress Actions On Ni-Mn-Ga Alloys PDFmohammadreza91No ratings yet

- 142 - Quantitative Model of Large Magnetostrain Effect in Ferromagnetic Shape Memory Alloys PDFDocument10 pages142 - Quantitative Model of Large Magnetostrain Effect in Ferromagnetic Shape Memory Alloys PDFmohammadreza91No ratings yet

- 1577 - Energy Harvesting Vibration Sources For Microsystems ApplicationsDocument21 pages1577 - Energy Harvesting Vibration Sources For Microsystems Applicationsmohammadreza91No ratings yet

- 18 - A Three Dimensional Phenomenological Model For Magnetic Shape Memory AlloysDocument7 pages18 - A Three Dimensional Phenomenological Model For Magnetic Shape Memory Alloysmohammadreza91No ratings yet

- 967 - 6% Magnetic-Field-Induced Strain by Twin-Boundary Motion in Ferromagnetic Ni-Mn-GaDocument4 pages967 - 6% Magnetic-Field-Induced Strain by Twin-Boundary Motion in Ferromagnetic Ni-Mn-Gamohammadreza91No ratings yet

- 1286 - Giant Magnetic-field-Induced Strain in NiMnGa Seven-Layered Martensitic PhaseDocument3 pages1286 - Giant Magnetic-field-Induced Strain in NiMnGa Seven-Layered Martensitic Phasemohammadreza91No ratings yet

- 02-Plant Morphology (Exercise)Document5 pages02-Plant Morphology (Exercise)varshavishuNo ratings yet

- Jurnal ResinDocument8 pagesJurnal ResinRizky Febrian SatrianiNo ratings yet

- Lab Report 1Document3 pagesLab Report 1CarlEspantoNo ratings yet

- English Based On Latest PatternDocument13 pagesEnglish Based On Latest PatternAtish ToppoNo ratings yet

- Specifications of TES-593Document2 pagesSpecifications of TES-593symasiNo ratings yet

- Boiler BlowdownDocument2 pagesBoiler BlowdownbaratheonNo ratings yet

- Schematic 1280 - So Do Nokia 1 PDFDocument18 pagesSchematic 1280 - So Do Nokia 1 PDFanh3saigon0% (1)

- Duties and Responsibilities of Housekeeping Staff:-1) Executive Housekeeper/Director of HousekeepingDocument8 pagesDuties and Responsibilities of Housekeeping Staff:-1) Executive Housekeeper/Director of HousekeepingsachinNo ratings yet

- Intellectual Property: Impact of Exhaustion of Intellectual Property Right On Pharmaceutical Industry in VietnamDocument26 pagesIntellectual Property: Impact of Exhaustion of Intellectual Property Right On Pharmaceutical Industry in VietnamSơn BadGuyNo ratings yet

- Comparative Analysis of Mineral Constituents of Ethanol Leaf and SeedDocument9 pagesComparative Analysis of Mineral Constituents of Ethanol Leaf and SeedKIU PUBLICATION AND EXTENSIONNo ratings yet

- 08-05-2021 JR - Super60 ActP (In Coming) Jee-Main WTM-01 Question PaperDocument14 pages08-05-2021 JR - Super60 ActP (In Coming) Jee-Main WTM-01 Question Paperpurandar puneetNo ratings yet

- Hydrocele: CausesDocument7 pagesHydrocele: CauseslanaNo ratings yet

- 20K-S100 - CK20S10 - 21MK50-Chasis SN-80 SharpDocument26 pages20K-S100 - CK20S10 - 21MK50-Chasis SN-80 SharpAmadou FallNo ratings yet

- (UNISIM (BEHAS) - Introduction To Aerospace) EAS105 - Lab4Document33 pages(UNISIM (BEHAS) - Introduction To Aerospace) EAS105 - Lab4Mohd Ashraf Mohd IsmailNo ratings yet

- Msae Msae2018-Arwm012 Full Dronespraying 2Document4 pagesMsae Msae2018-Arwm012 Full Dronespraying 2Muhammad Huzaifah Mohd RoslimNo ratings yet

- Full Test 14 (Key) PDFDocument4 pagesFull Test 14 (Key) PDFhoang lichNo ratings yet

- Typhoid FeverDocument9 pagesTyphoid FeverAli Al.JuffairiNo ratings yet

- Star T: Flowchart "Physical Fitness Test"Document1 pageStar T: Flowchart "Physical Fitness Test"Eller-Jed Manalac MendozaNo ratings yet

- ICH Topic Q 3 B (R2) Impurities in New Drug Products: European Medicines AgencyDocument14 pagesICH Topic Q 3 B (R2) Impurities in New Drug Products: European Medicines AgencyJesus Barcenas HernandezNo ratings yet

- 700 - 900 Error Codes PDFDocument1 page700 - 900 Error Codes PDFIsai Lara OsoriaNo ratings yet

- Redraw Rod For Multiwire DrawingDocument6 pagesRedraw Rod For Multiwire DrawingWajeeh BitarNo ratings yet

- Establishment of Retirement PlanDocument3 pagesEstablishment of Retirement PlanVioleta StancuNo ratings yet

- SF 9 - ES Learners Progress Report CardDocument3 pagesSF 9 - ES Learners Progress Report Cardroxanne50% (2)

- ITC's diverse businesses: cigarettes, packaging, hotels, paperboards, stationery, matches, incense sticks, retail, food, exportsDocument1 pageITC's diverse businesses: cigarettes, packaging, hotels, paperboards, stationery, matches, incense sticks, retail, food, exportsShashank JainNo ratings yet

- List of Job Specific Safety PPE Used On Site.Document2 pagesList of Job Specific Safety PPE Used On Site.Aejaz MujawarNo ratings yet

- Red Velvet Cake RecipeDocument6 pagesRed Velvet Cake RecipeRuminto SubektiNo ratings yet

- Effects of Climate Change and Global WarmingDocument14 pagesEffects of Climate Change and Global WarmingSwetal SosaNo ratings yet

- Tan Trok Tam Devi Suk TamDocument4 pagesTan Trok Tam Devi Suk Tamtejasg82No ratings yet

- 02AdvancedThinkAhead1 Term3 TL2Document4 pages02AdvancedThinkAhead1 Term3 TL2marina dominguez sanchezNo ratings yet

- Viscometer Toki Sangyo - TV25 - 35Document12 pagesViscometer Toki Sangyo - TV25 - 35Eddy CurrentNo ratings yet