Professional Documents

Culture Documents

Chapter 3 Measurement Methods and Control Strategies 2010 Instrumentation Reference Book Fourth Edition

Uploaded by

Motasim_mCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 3 Measurement Methods and Control Strategies 2010 Instrumentation Reference Book Fourth Edition

Uploaded by

Motasim_mCopyright:

Available Formats

Chapter 3

Measurement Methods and Control

Strategies

W. Boyes

3.1 Introduction

3.3 Process control strategies

Measurement methods for automation are somewhat different from those designed for use in laboratories and test

centers.

Specific to automation, measurement methods that work

well in a laboratory might not work at all in a process or

factory-floor environment. It might not be possible to know

all the variables acting on a measurement to determine the

degree of error (uncertainty) of that measurement. For example, a flowmeter may be calibrated at the factory with an accuracy of 0.05% of actual flow. Yet in the field, once installed,

an automation professional might be lucky to be able to

calibrate the flowmeter to 10% of actual flow because of

the conditions of installation. Because control strategies are

often continuous, it is often impossible to remove the sensor

from the line for calibration.

Basic process control strategies include on/off control;

deadband control; proportional, integral, derivative (PID)

control; and its derivatives.

On/off control is simple and effective but may not be

able to respond to rapid changes in the measured variable

(known as PV, or process variable). The next iteration is a

type of on/off control called deadband, or hysteresis control.

In this method, either the on or the off action is delayed

until a prescribed limit set point is reached, either ascending

or descending. Often multiple limit set points are defined,

such as a level application with high level, high-high

level, and high-overflow level set points. Each of the set

points is defined as requiring a specific action.

Feedback control is used with a desired set point from

which deviation is not desired. When the measured variable

deviates from the set point, the controller output drives the

measured variable back toward the set point. Most of the

feedback control algorithms in use are some form of PID

algorithm, of which there are three basic types: the standard,

or ideal, form, sometimes called the ISA form; the interactive form, which was the predominant form for analog

controllers; and the parallel form, which is rarely found in

industrial process control.

In the PID algorithm, the proportional term provides

most of the control while the integral function and the derivative function provide additional correction. In practice, the

proportional and integral terms do most of the control; the

derivative term is often set to 0.

PID loops contain one measured variable, one controller, and one final control element. This is the basic control

3.2 Measurement and field

calibration methodology

In many cases, then, field calibration methods are expedients designed to determine not the absolute accuracy of

the measurement but the repeatability of the measurement.

Especially in process applications, repeatability is far more

critical to the control scheme than absolute accuracy. It is

often not possible to do more than one or two calibration

runs in situ in a process application. It often means that the

calibration and statistical repeatability of the transmitter is

what is checked in the field, rather than the accuracy of the

entire sensor element.

2010 Elsevier Inc. All rights reserved.

doi: 10.1016/B978-0-7506-8308-1.00003-6

23

24

PART | I The Automation Knowledge Base

loop in automation. PID loops need to be tuned; there

are several tuning algorithms, such as Ziegler-Nichols and

others, that allow the loop to be tuned. Many vendors today

provide automatic loop-tuning products in their control

software offerings.

PID feedback controllers work well when there are few

process disturbances. When the process is upset or is regularly discontinuous, it is necessary to look at other types of

controllers. Some of these include ratio, feed forward, and

cascade control. In ratio control, which is most often found

in blending of two process streams, the basic process stream

provides the pacing for the process while the flow rates for

the other streams are modulated to make sure that they are

in a specific ratio to the basic process stream. Feed forward

control, or open loop control, uses the rate of fall-off from

the set point (a disturbance in the process) to manipulate the

controlled variable. An example is the use of a flowmeter to

control the injection of a chemical additive downstream of

the flowmeter. There must be some model of the process so

that the effect of the flow change can be used to induce the

correct effect on the process downstream.

Combining feed forward and feedback control in one

integrated control loop is called cascade control. In this

scheme, the major correction is done by feed forward control, and the minor correction (sometimes called trim) is

done by the feedback loop. An example is the use of flow

to control the feed of a chemical additive while using an

analyzer downstream of the addition point to modulate the

set point of the flow controller.

multiple fuzzy logic sets appear to be able to learn, they are

often regarded as a crude form of artificial intelligence. In

process automation, only four rules are required for a fuzzy

logic controller:2

3.4Advanced control strategies

Suggested Reading

Since the 1960s, advances in modeling the behavior of

processes have permitted a wholly new class of control

strategies, called advanced process control, or APC. These

control strategies are almost always layered over the basic

PID algorithm and the standard control loop. These APC

strategies include fuzzy logic, adaptive control, and model

predictive control.

Conceived in 1964 by University of California at Berkeley

scientist Lotfi Zadeh, fuzzy logic is based on the concept of

fuzzy sets, where membership in the set is based on probabilities or degrees of truth rather than yes or no.1 Because

Dieck, Ronald H., Measurement Uncertainty, Methods and Applications,

4th ed., ISA Press, Research Triangle Park, NC, 2007.

Trevathan, Vernon L., editor, A Guide to the Automation Body of Know

ledge, 2nd ed., ISA Press, Research Triangle Park, NC, 2006.

Blevins, Terry, and McMillan, Gregory, et al., Advanced Control

Unleashed: Plant Performance Management for Optimum Benefit,

ISA Press, Research Triangle Park, NC, 2003.

1. Britannica Concise Encyclopedia, quoted in www.answers.com

Rule 1: If the error is negative and the change in error is

negative, the change in output is positive.

Rule 2: If the error is negative and the change in error is

positive, the change in output is zero.

Rule 3: If the error is positive and the change in error is

negative, the change in output is zero.

Rule 4: If the error is positive and the change in error is

positive, the change in output is negative.

Adaptive control is somewhat loosely defined as any algorithm in which the controllers tuning has been altered. Another

term for adaptive controllers is self-tuning controllers.

Model predictive control uses historicized incremental

models of the process to be controlled where the change in

a variable can be predicted. When the MPC controller is initialized, the model parameters are set to match the actual

performance of the plant. According to Gregory McMillan,

MPC sees future trajectory based on past moves of manipulated variables and present changes in disturbance variables

as inputs to a linear model. It provides an integral-only type

of control.3

These advanced control strategies can often improve

loop performance but, beyond that, they are also useful in

optimizing performance of whole groups of loops, entire

processes, and even entire plants themselves.

2. McMillan, Gregory K., Advanced Process Control, in A Guide to the

Automation Body of Knowledge, 2nd ed., ISA Press, Research Triangle

Park, NC, 2006

3. Ibid

You might also like

- Chapter 26 Chemical Analysis Moisture Measurement 2010 Instrumentation Reference Book Fourth EditionDocument8 pagesChapter 26 Chemical Analysis Moisture Measurement 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- Chapter 34 Advanced Control For The Plant Floor 2010 Instrumentation Reference Book Fourth EditionDocument10 pagesChapter 34 Advanced Control For The Plant Floor 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- Chapter 38 Instrument Installation and Commissioning 2010 Instrumentation Reference Book Fourth EditionDocument6 pagesChapter 38 Instrument Installation and Commissioning 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- Copyright 2010 Instrumentation Reference Book Fourth EditionDocument1 pageCopyright 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- Avatar Upgrade Program PDFDocument33 pagesAvatar Upgrade Program PDFMotasim_mNo ratings yet

- Programming With MatLabDocument23 pagesProgramming With MatLabZia SilverNo ratings yet

- Prepare For IELTSDocument169 pagesPrepare For IELTSapi-3818413100% (2)

- Chapter 35 Batch Process Control 2010 Instrumentation Reference Book Fourth EditionDocument2 pagesChapter 35 Batch Process Control 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- Introduction 2010 Instrumentation Reference Book Fourth EditionDocument2 pagesIntroduction 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- Contributors 2010 Instrumentation Reference Book Fourth EditionDocument2 pagesContributors 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- 90 Days of ActionDocument92 pages90 Days of ActionPaula StanwyckNo ratings yet

- ISO 9000 Quality Assurance AcknowledgementsDocument1 pageISO 9000 Quality Assurance AcknowledgementsMotasim_mNo ratings yet

- Switches ExplainedDocument3 pagesSwitches ExplainedMotasim_mNo ratings yet

- Simulation, Modeling, and Performance Analysis of IEEE 802.16e OFDMA Systems For Urban and Rural EnvironmentsDocument4 pagesSimulation, Modeling, and Performance Analysis of IEEE 802.16e OFDMA Systems For Urban and Rural EnvironmentsMotasim_mNo ratings yet

- 1001 Vocabulary and Spelling QuestionsDocument160 pages1001 Vocabulary and Spelling Questionssashi01092% (12)

- Appendix 2 TH Venin S Theorem 2001 Measurement and Instrumentation Principles Third EditionDocument6 pagesAppendix 2 TH Venin S Theorem 2001 Measurement and Instrumentation Principles Third EditionMotasim_mNo ratings yet

- Appendix 4 Solutions To Self Test Questions 2001 Measurement and Instrumentation Principles Third EditionDocument4 pagesAppendix 4 Solutions To Self Test Questions 2001 Measurement and Instrumentation Principles Third EditionMotasim_mNo ratings yet

- Appendix 1 Imperial Metric SI Conversion Tables 2001 Measurement and Instrumentation Principles Third EditionDocument7 pagesAppendix 1 Imperial Metric SI Conversion Tables 2001 Measurement and Instrumentation Principles Third EditionMotasim_mNo ratings yet

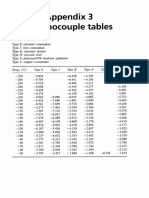

- Appendix 3 Thermocouple Tables 2001 Measurement and Instrumentation Principles Third EditionDocument6 pagesAppendix 3 Thermocouple Tables 2001 Measurement and Instrumentation Principles Third EditionMotasim_mNo ratings yet

- Index 2001 Measurement and Instrumentation Principles Third EditionDocument7 pagesIndex 2001 Measurement and Instrumentation Principles Third EditionMotasim_mNo ratings yet

- Appendix 4 Solutions To Self Test Questions 2001 Measurement and Instrumentation Principles Third EditionDocument4 pagesAppendix 4 Solutions To Self Test Questions 2001 Measurement and Instrumentation Principles Third EditionMotasim_mNo ratings yet

- Appendix 3 Thermocouple Tables 2001 Measurement and Instrumentation Principles Third EditionDocument6 pagesAppendix 3 Thermocouple Tables 2001 Measurement and Instrumentation Principles Third EditionMotasim_mNo ratings yet

- Hsu 4 Information and Control Systems AbDocument43 pagesHsu 4 Information and Control Systems AbMotasim_mNo ratings yet

- Preface 2001 Measurement and Instrumentation Principles Third EditionDocument3 pagesPreface 2001 Measurement and Instrumentation Principles Third EditionMotasim_mNo ratings yet

- Appendix D International Society of Automation Formerly Instrument Society of America 2010 Instrumentation Reference Book Fourth EditionDocument2 pagesAppendix D International Society of Automation Formerly Instrument Society of America 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- Chapter 4 Simulation and Design Software1 2010 Instrumentation Reference Book Fourth EditionDocument2 pagesChapter 4 Simulation and Design Software1 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- 1081app A 1 PDFDocument11 pages1081app A 1 PDFMotasim_mNo ratings yet

- Chapter 5 Security For Industrial Automation1 2010 Instrumentation Reference Book Fourth EditionDocument2 pagesChapter 5 Security For Industrial Automation1 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- Appendix C The Institute of Measurement and Control 2010 Instrumentation Reference Book Fourth EditionDocument4 pagesAppendix C The Institute of Measurement and Control 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Ethics, Assignment 2Document2 pagesEthics, Assignment 2Myles Ninon LazoNo ratings yet

- Teaching Materials and Teaching Aids - IIDocument15 pagesTeaching Materials and Teaching Aids - IIrohityadavalldNo ratings yet

- اللون - عبد الكريم محسنDocument38 pagesاللون - عبد الكريم محسنNagham AhasanNo ratings yet

- The Elements of A Radio DramaDocument13 pagesThe Elements of A Radio Dramadinejedidah0% (1)

- Teacher Candidate Evaluation Rubric - CT ObservationsDocument30 pagesTeacher Candidate Evaluation Rubric - CT Observationsapi-253290620No ratings yet

- Non Duality Western Phil - Greg GoodeDocument35 pagesNon Duality Western Phil - Greg GoodewaynefergusonNo ratings yet

- Tumpuan Insan: Person Centered Therapy/CounselingDocument22 pagesTumpuan Insan: Person Centered Therapy/CounselingMASIRAHNo ratings yet

- Introspection Method: Wundt's Role in Developing the TechniqueDocument11 pagesIntrospection Method: Wundt's Role in Developing the TechniqueMannan Bansal100% (1)

- Applied Linguistics 1990 MCLAUGHLIN 113 28Document16 pagesApplied Linguistics 1990 MCLAUGHLIN 113 28Charles Cornelius100% (2)

- Five Levels CompetencyDocument2 pagesFive Levels CompetencyYasmin SingaporewalaNo ratings yet

- Social Work Group Practice: Models, Stages, SettingsDocument22 pagesSocial Work Group Practice: Models, Stages, SettingsZahoor Ahmad100% (2)

- Top Down and Bottom UpDocument5 pagesTop Down and Bottom UpMher Ghazarian100% (1)

- Design of Indirect MRAS-based Adaptive Control SystemsDocument5 pagesDesign of Indirect MRAS-based Adaptive Control SystemsThiện DũngNo ratings yet

- 04chapter3 PDFDocument38 pages04chapter3 PDFMegz OkadaNo ratings yet

- The Book of Pleasure and Different Religions as Means to FreedomDocument27 pagesThe Book of Pleasure and Different Religions as Means to FreedomIsaac Christou100% (1)

- Ujala SupremeDocument22 pagesUjala SupremeNamit KewatNo ratings yet

- Pavon Cuellar Marxismo y PsicoanálisisDocument21 pagesPavon Cuellar Marxismo y PsicoanálisisrdelafaNo ratings yet

- Perception, Attribution, and The Management of Diversity: Understanding and Managing Organizational BehaviorDocument31 pagesPerception, Attribution, and The Management of Diversity: Understanding and Managing Organizational BehavioradaNo ratings yet

- Importance of Emotional Intelligence in Negotiation and MediationDocument6 pagesImportance of Emotional Intelligence in Negotiation and MediationsimplecobraNo ratings yet

- The Self and The Development of The Social WorldDocument5 pagesThe Self and The Development of The Social Worldhandyoklos50% (2)

- Project Management Decision Support ToolsDocument3 pagesProject Management Decision Support ToolsSiddharth JhalaNo ratings yet

- Enabling A Positive Working LifeDocument31 pagesEnabling A Positive Working Lifemohamed abdukadir100% (5)

- CAMP TINIO NATIONAL HIGH SCHOOL DAILY LESSON LOGDocument28 pagesCAMP TINIO NATIONAL HIGH SCHOOL DAILY LESSON LOGMariel San PedroNo ratings yet

- Neo Classical Theory and Hawthorne StudiesDocument10 pagesNeo Classical Theory and Hawthorne StudiesJoehad Said100% (1)

- End of Ir Theory Final-5!6!2013Document30 pagesEnd of Ir Theory Final-5!6!2013Callie TompkinsNo ratings yet

- Child Centered Treatment Planning FormDocument5 pagesChild Centered Treatment Planning FormCurieNo ratings yet

- NLP for Project Managers: Make Things HappenDocument2 pagesNLP for Project Managers: Make Things HappenSimone WinnyNo ratings yet

- Conflict and AttitudeDocument9 pagesConflict and AttitudesheqarayzanNo ratings yet

- Understanding The Self Learning Program 18-19Document5 pagesUnderstanding The Self Learning Program 18-19St. Anthony of PaduaNo ratings yet

- Meta NLP Full Text PDFDocument199 pagesMeta NLP Full Text PDFGODEANU FLORIN100% (3)