Professional Documents

Culture Documents

Recommended Busduct Installation

Uploaded by

Non Etabas Gadnatam0 ratings0% found this document useful (0 votes)

181 views3 pagesThanks

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThanks

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

181 views3 pagesRecommended Busduct Installation

Uploaded by

Non Etabas GadnatamThanks

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Recommended Busduct Installation, Inspection & Testing at Job Site

Before Busduct Installation at Job Site

Busduct delivered to job site shall be stored indoors and in a dry environment free from condensation. Extra

protection material shall be provided in addition to the packing of the busduct against any adverse

construction site conditions.

During Busduct Installation

In vertical busduct installation, busduct feeder which will be

supported by vertical hanger should be installed before other busduct

feeders in order to prevent a downward weight or load from

concentrating on the busduct at the lower floor

Flange end box must not be fixed permanently to the wall and floor.

However, Flange End Box can only be permanently secured provided

that all the busduct installation are completed (if unavoidable).

Vertical Hanger/Vertical

Spring Hanger must be

installed to the busduct

system to allow for busduct

elongation/expansion &

contraction as well as the

shrinkage of the building

Recommended Busduct Installation, Inspection & Testing at Job Site

Busduct Joint Section

Tightness Indication of Double Bolt Joint Design

Improper Installation of Brackets

Proper Installation of Brackets

X

Waterproof Curb

Busduct System

Curb

IP65 Busduct

IP54 Busduct

Floor

Floor

Fire Stop Material

Recommended Waterproof Curb

Waterproof Curb is recommended to be installed at each floor opening where busduct passes through.

It prevents water (caused by plumbing leaks, fire sprinker system leaks, fluid spills, etc) from seeping

into the busduct system. Besides, the floor opening will be sealed with fire stop material to prevent

smoke from passing through the floors in case of fire in the building.

Recommended Busduct Installation, Inspection & Testing at Job Site

Vertical Spring Hanger

Busduct feeder is

permanently fixed to the wall

End Cap is permanently

fixed to the wall

Busduct system bent due to

the improper installation

whereby both busduct ends

are fixed to the wall

Caution

Nut is fully tightened to the

bracket of Vertical Spring Hanger

Recommended installation method

of Vertical Spring Hanger

After Busduct Installation

Busduct Joint Connection

All phase and earth conductors shall be tested and inspected to ensure full clamping pressure is applied to all

contact surfaces and all joint bolt connection are securely carried out according to manufacturers recommendation

Insulation Resistance/Megger Test

It shall be measured with dc 500V or 1000V before busducts power turn-on at job site.

Contact Resistance Test

The contact resistance of each conductor shall be measured with dc 100A before busducts power turn-on at job

site.

Thermal Scanning Test

It shall be carried out for busduct metal housing, joint section and other connections to detect any abnormal heat or

hot spot.

You might also like

- WB Brush Seals Labyrinth - A4Document2 pagesWB Brush Seals Labyrinth - A4triplbingaziNo ratings yet

- Iris Power Condition Based Monitoring Turbo GuardII PDFDocument4 pagesIris Power Condition Based Monitoring Turbo GuardII PDFarthamonifanNo ratings yet

- Precondition For Turbine Box-UpDocument3 pagesPrecondition For Turbine Box-UpGopal RamalingamNo ratings yet

- 10090-Annexure-C-Scope of Work-Online UPSDocument3 pages10090-Annexure-C-Scope of Work-Online UPSenriqueramoscNo ratings yet

- 0962燃气管道布置qme 00 g 141b 000 Ei 172 en d Piping Arrangement Gas Turbine(121t7058)0962Document10 pages0962燃气管道布置qme 00 g 141b 000 Ei 172 en d Piping Arrangement Gas Turbine(121t7058)0962ALAMGIR HOSSAINNo ratings yet

- Tech Spec of PTR 33 11 KVDocument34 pagesTech Spec of PTR 33 11 KVAnonymous sAmJfcVNo ratings yet

- Pioneering Efficient Energy SolutionDocument36 pagesPioneering Efficient Energy Solutionatripathi2009No ratings yet

- Inspection Categorization PlanDocument6 pagesInspection Categorization Plankaruna346No ratings yet

- Erection Procedure For 6.6 KV Bus DuctDocument7 pagesErection Procedure For 6.6 KV Bus DuctAnmohieyNo ratings yet

- GEI-100547-EX2100 and EX2100e ExcitationControl Factory Testsand Demonstrations Instruction GuideDocument12 pagesGEI-100547-EX2100 and EX2100e ExcitationControl Factory Testsand Demonstrations Instruction GuideLê Trung DũngNo ratings yet

- Lightning Protection System Installation Works Inspection ChecklistDocument1 pageLightning Protection System Installation Works Inspection ChecklistReda HamedNo ratings yet

- Medium Voltage Cable Inspection Digital PDFDocument4 pagesMedium Voltage Cable Inspection Digital PDFAnonymous VNu3ODGavNo ratings yet

- EDG TestDocument6 pagesEDG Testyogacruise100% (1)

- TFR CommissioningDocument24 pagesTFR CommissioningKrishna DNo ratings yet

- Geh 6721 - Vol - IiDocument1,009 pagesGeh 6721 - Vol - Iialaa fadhelNo ratings yet

- Scope of Supply GEF9Document144 pagesScope of Supply GEF9Her Phy ToNo ratings yet

- HTTP WWW - Trenchgroup.com Ps Tools Download - PHP File Docudb Psfile Doc 83 Import4cd7ff1c2563f.pdf&Name Transformer Bushings COTA 25kV To 765kvDocument12 pagesHTTP WWW - Trenchgroup.com Ps Tools Download - PHP File Docudb Psfile Doc 83 Import4cd7ff1c2563f.pdf&Name Transformer Bushings COTA 25kV To 765kvhenny_el3306No ratings yet

- Himatrix: Cpu 03 ManualDocument40 pagesHimatrix: Cpu 03 ManualFrancisco Javier Pinto EscalonaNo ratings yet

- QCS 2010 Section 28 Part 2Document38 pagesQCS 2010 Section 28 Part 2Saif Abdulla0% (1)

- Hyundai Electric BrochureDocument36 pagesHyundai Electric BrochurebadbenzationNo ratings yet

- MDB Specs PDFDocument9 pagesMDB Specs PDFAbdElrahman AhmedNo ratings yet

- RFA of Method Statement For MV Cable Termination WorkDocument2 pagesRFA of Method Statement For MV Cable Termination Workquynhanh2603No ratings yet

- User Manual - Online Wiring Certificates-Rev3Document12 pagesUser Manual - Online Wiring Certificates-Rev3Tony Ras Mwangi100% (1)

- INSPECTION SHEET FOR EX DDocument2 pagesINSPECTION SHEET FOR EX DAlinaIordache100% (1)

- Preventing and Identifying Potential Failures of Dead Break Elbows in Wind Farm Application - Brian - Peyres PDFDocument6 pagesPreventing and Identifying Potential Failures of Dead Break Elbows in Wind Farm Application - Brian - Peyres PDFSatadal DashNo ratings yet

- Certificate of Compliance Under The Electricity (Electrical Installations) Regulations 2002Document2 pagesCertificate of Compliance Under The Electricity (Electrical Installations) Regulations 2002Zhu Qi WangNo ratings yet

- Scope of Work For Gas TurbineDocument47 pagesScope of Work For Gas TurbinePhong le100% (1)

- 36kv Indoor VCB & GCBDocument2 pages36kv Indoor VCB & GCBRamesh AnanthanarayananNo ratings yet

- Spec LV MV CABLESDocument5 pagesSpec LV MV CABLESFor AppsNo ratings yet

- Scope of WorkDocument75 pagesScope of WorkPhong leNo ratings yet

- Commercial Checklist-Print - 2008 Nec - 08-28-08Document23 pagesCommercial Checklist-Print - 2008 Nec - 08-28-08akiferindrariskyNo ratings yet

- LPS Testing Method StatementDocument2 pagesLPS Testing Method StatementkanthaNo ratings yet

- Oil Leak Job Competion ReportDocument8 pagesOil Leak Job Competion Reportwinston11No ratings yet

- Condensate Pot For Steam Applications - Swagelok Energy Advisors, IncDocument2 pagesCondensate Pot For Steam Applications - Swagelok Energy Advisors, Incjanaisha_bai7170100% (1)

- Abb Cable AccessoriesDocument131 pagesAbb Cable Accessoriesaamir_janjua_3No ratings yet

- Factory Acceptance Test Procedure For DCS - Page 5Document2 pagesFactory Acceptance Test Procedure For DCS - Page 5kapsarcNo ratings yet

- Gen Air TestDocument14 pagesGen Air TestPRINCE SHARMANo ratings yet

- Livening Up NotesDocument1 pageLivening Up NotesAceel FitchNo ratings yet

- Mew TransformerDocument2 pagesMew TransformerAbin MeetuNo ratings yet

- Space Requirements For Electrical RoomsDocument2 pagesSpace Requirements For Electrical Roomsnetsavy71100% (1)

- SECTION 16450 Grounding Part 1 - GeneralDocument8 pagesSECTION 16450 Grounding Part 1 - Generalno nameNo ratings yet

- Supervisor de Actuador PDFDocument2 pagesSupervisor de Actuador PDFAob AprilNo ratings yet

- BS 7671 TemplateDocument1 pageBS 7671 TemplateKarim AmerNo ratings yet

- Neutral Grounding Resistors: Installation and Maintenance InstructionsDocument7 pagesNeutral Grounding Resistors: Installation and Maintenance Instructionsks_ramachandra7017No ratings yet

- Ground ResistorDocument2 pagesGround Resistorashoksince2005No ratings yet

- Scope GeneralDocument22 pagesScope Generalالمهندس اشرف الزيديNo ratings yet

- Evonik Thermal Analysis For MAHAGENCO TurbinesDocument56 pagesEvonik Thermal Analysis For MAHAGENCO Turbinesramnadh803181No ratings yet

- GE's TM2500+ Solution Offers Fast, Mobile and Flexible PowerDocument6 pagesGE's TM2500+ Solution Offers Fast, Mobile and Flexible PowerJorge Armando Acevedo Pinel100% (1)

- 22kV-Cable-Termination-Failure (Chapter 6) PDFDocument6 pages22kV-Cable-Termination-Failure (Chapter 6) PDFTarikfaraj100% (1)

- GE Induction and Synchronous MotorsDocument8 pagesGE Induction and Synchronous MotorsidontlikeebooksNo ratings yet

- SAER 10537 - ConXtech Overview Experience and Deployment PDFDocument52 pagesSAER 10537 - ConXtech Overview Experience and Deployment PDFAyman AlradiNo ratings yet

- CKE ITP 01 32 00 2012-Borang-IRCDocument1 pageCKE ITP 01 32 00 2012-Borang-IRCNUR FATEHA MOHAMMEDNo ratings yet

- Steam TurbinesDocument5 pagesSteam Turbinesavsrao123No ratings yet

- D 100017 X 012Document24 pagesD 100017 X 012ErnestoNo ratings yet

- CH - 1Document62 pagesCH - 1ISHAN MEHROTRANo ratings yet

- Method Statement For InstallationDocument5 pagesMethod Statement For Installationsamsul maarifNo ratings yet

- Fixing of Non Swell Type Water Stop in Sub Structure Concrete WorksDocument8 pagesFixing of Non Swell Type Water Stop in Sub Structure Concrete WorksKaram MoatasemNo ratings yet

- Federation of Piling Specialists Testing Datasheet No. 1: Guidance For The Principal ContractorDocument27 pagesFederation of Piling Specialists Testing Datasheet No. 1: Guidance For The Principal ContractorHemant YadavNo ratings yet

- Waterline NetworkDocument23 pagesWaterline NetworkRobin Oidem CaniedoNo ratings yet

- HR Form 11 - Request To Avail Work From Home OptionDocument1 pageHR Form 11 - Request To Avail Work From Home OptionNon Etabas GadnatamNo ratings yet

- The Dow Chemical Company: Concrete Details Detail 101 Detail 101Document1 pageThe Dow Chemical Company: Concrete Details Detail 101 Detail 101Non Etabas GadnatamNo ratings yet

- A554 D 455 PM Lis Doc 004Document3 pagesA554 D 455 PM Lis Doc 004Non Etabas GadnatamNo ratings yet

- A554 D 455 CV Sow Con 021Document4 pagesA554 D 455 CV Sow Con 021Non Etabas GadnatamNo ratings yet

- A554 D 455 PM Sow Con 005Document4 pagesA554 D 455 PM Sow Con 005Non Etabas GadnatamNo ratings yet

- A554 D 455 CV Lis Doc 021Document7 pagesA554 D 455 CV Lis Doc 021Non Etabas GadnatamNo ratings yet

- 1065 Electronic Safety Security Comprehensive Quality Plan SampleDocument20 pages1065 Electronic Safety Security Comprehensive Quality Plan SampleNon Etabas GadnatamNo ratings yet

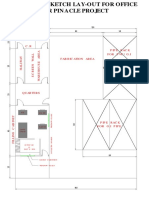

- Proposed Office For Pinacle ProjectDocument1 pageProposed Office For Pinacle ProjectNon Etabas GadnatamNo ratings yet

- General Comprehensive Quality Plan & Manual Sample: Selected Pages Sample IncludesDocument28 pagesGeneral Comprehensive Quality Plan & Manual Sample: Selected Pages Sample IncludesJesseNo ratings yet

- PLDM Plumbing FCD PlanDocument34 pagesPLDM Plumbing FCD PlanNon Etabas GadnatamNo ratings yet

- Work Proposal - PLDM - SanDocument2 pagesWork Proposal - PLDM - SanNon Etabas GadnatamNo ratings yet

- 1 Gala Bronze Gate Nrs Valve Fig 3152Document1 page1 Gala Bronze Gate Nrs Valve Fig 3152Non Etabas GadnatamNo ratings yet

- 633559-M-E-D010-Stage 4 Pavilion-IFC SetDocument7 pages633559-M-E-D010-Stage 4 Pavilion-IFC SetNon Etabas GadnatamNo ratings yet

- PLV Pav Lasc 100DDDocument25 pagesPLV Pav Lasc 100DDNon Etabas GadnatamNo ratings yet

- 1 Gala CI Y-Strainer Cast Iron Fig 7101Document1 page1 Gala CI Y-Strainer Cast Iron Fig 7101Non Etabas GadnatamNo ratings yet

- 24 Vibration IsolatorDocument22 pages24 Vibration IsolatorNon Etabas Gadnatam100% (1)

- 1067 Fire Suppression Comprehensive Quality Plan SampleDocument20 pages1067 Fire Suppression Comprehensive Quality Plan SampleNon Etabas GadnatamNo ratings yet

- 9 PT-LSDocument11 pages9 PT-LSNon Etabas GadnatamNo ratings yet

- 1st Partial Round DuctDocument1 page1st Partial Round DuctNon Etabas GadnatamNo ratings yet

- 2TR Portable SpecsDocument1 page2TR Portable SpecsNon Etabas GadnatamNo ratings yet

- 1 Gala Ci Gate Valve Resilient Seated Nrs NRGV 3243Document1 page1 Gala Ci Gate Valve Resilient Seated Nrs NRGV 3243Non Etabas GadnatamNo ratings yet

- (FDA) - Progef Standard PPDocument1 page(FDA) - Progef Standard PPNon Etabas GadnatamNo ratings yet

- 1 Gala Bronze Y-Strainer Fig 7654 SMDocument1 page1 Gala Bronze Y-Strainer Fig 7654 SMNon Etabas GadnatamNo ratings yet

- 39CQ Iom 06302014Document20 pages39CQ Iom 06302014Non Etabas GadnatamNo ratings yet

- 1 Gala Rubber Flexible Connector Flange Double Bellows GFLEX-F2 FlangeDocument3 pages1 Gala Rubber Flexible Connector Flange Double Bellows GFLEX-F2 FlangeNon Etabas GadnatamNo ratings yet

- 1 FT Gala Rubber Flexible Connector Double Bellows GFLEX-GS THREADEDDocument2 pages1 FT Gala Rubber Flexible Connector Double Bellows GFLEX-GS THREADEDNon Etabas GadnatamNo ratings yet

- 1 Gala Balancing Valve Variable Orifice FT Fig DRVF 1210-Df Pn16 65mm To 450mmDocument1 page1 Gala Balancing Valve Variable Orifice FT Fig DRVF 1210-Df Pn16 65mm To 450mmNon Etabas GadnatamNo ratings yet

- CoverDocument1 pageCoverNon Etabas GadnatamNo ratings yet

- 1 Balancing Valve Bronze GALA-smDocument1 page1 Balancing Valve Bronze GALA-smNon Etabas GadnatamNo ratings yet

- Equipment Schedule & Technical Summary Ests 1 PE-11 & PE-12 Passenger ElevatorsDocument5 pagesEquipment Schedule & Technical Summary Ests 1 PE-11 & PE-12 Passenger ElevatorsNon Etabas GadnatamNo ratings yet

- Avamar-4.1-Technical-Addendum. Avamar Commandspdf PDFDocument537 pagesAvamar-4.1-Technical-Addendum. Avamar Commandspdf PDFdanilaix50% (2)

- Cerebrum - Product Sheet + Protocol List V2.2Document10 pagesCerebrum - Product Sheet + Protocol List V2.2Tony PerezNo ratings yet

- Final Project Template V2 1Document46 pagesFinal Project Template V2 1HUY NGUYEN QUOCNo ratings yet

- Organization TheoryDocument131 pagesOrganization TheoryElii ManNo ratings yet

- SABA Migration RunBook v1.0 20210913xlsxDocument54 pagesSABA Migration RunBook v1.0 20210913xlsxZakaria AlmamariNo ratings yet

- Seminar3 enDocument7 pagesSeminar3 enandreiNo ratings yet

- AE 321 - Module 07 - FinalDocument14 pagesAE 321 - Module 07 - FinalJohn Client Aclan RanisNo ratings yet

- Terminal Parking Spaces + 30% Open Space As Required by National Building CodeDocument3 pagesTerminal Parking Spaces + 30% Open Space As Required by National Building CodeDyra Angelique CamposanoNo ratings yet

- Java DL 2023Document16 pagesJava DL 2023Sktr BhanuNo ratings yet

- SWFP66D Series Fine-Grinding Hammer Mill: Operation ManualDocument65 pagesSWFP66D Series Fine-Grinding Hammer Mill: Operation ManualDanielDeFrancescoNo ratings yet

- Lesson 12&13Document4 pagesLesson 12&13Jhynes RenomeronNo ratings yet

- Dynapac Mini Roller - CC125Document14 pagesDynapac Mini Roller - CC125Iftequar Rizwan KhanNo ratings yet

- Cryptography and Its Types - GeeksforGeeksDocument2 pagesCryptography and Its Types - GeeksforGeeksGirgio Moratti CullenNo ratings yet

- Soil Classification and Crop Recommendation SystemDocument4 pagesSoil Classification and Crop Recommendation SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 2Kv Hdfpc-Dlo, Rhh/Rhw-2 & Rw90: Flexible Stranded Rope-Lay Class I Tinned Copper Per ASTM B33 and B172Document3 pages2Kv Hdfpc-Dlo, Rhh/Rhw-2 & Rw90: Flexible Stranded Rope-Lay Class I Tinned Copper Per ASTM B33 and B172gerrzen64No ratings yet

- Delivery Certificate ID: 153586587 Page 1/ 3: VehicleDocument3 pagesDelivery Certificate ID: 153586587 Page 1/ 3: VehicleJhay SevillaNo ratings yet

- An Experimental Study On Airborne Landmine DetectiDocument7 pagesAn Experimental Study On Airborne Landmine Detecticlinton ruleNo ratings yet

- Elektor Electronics 1998-10Document54 pagesElektor Electronics 1998-10Adrian_Andrei_4433No ratings yet

- Mgo Los Banos Laguna-Community Affairs Officer IIDocument1 pageMgo Los Banos Laguna-Community Affairs Officer IICESHNo ratings yet

- Dx225lca-2 InglesDocument12 pagesDx225lca-2 InglesredwiolNo ratings yet

- Sop SampleDocument2 pagesSop Samplearshpreet bhatiaNo ratings yet

- PDF N Fcom Sek TF N Eu 20190311 DSC PLP LeduDocument600 pagesPDF N Fcom Sek TF N Eu 20190311 DSC PLP Leduhussein mohklisNo ratings yet

- RouterOS by Example Stephen Discher PDFDocument236 pagesRouterOS by Example Stephen Discher PDFAntonioNo ratings yet

- ECIL Technical Officer Recruitment 2023 NotificationDocument3 pagesECIL Technical Officer Recruitment 2023 NotificationLucasNo ratings yet

- Arduino Nano DHT11 Temperature and Humidity VisualDocument12 pagesArduino Nano DHT11 Temperature and Humidity Visualpower systemNo ratings yet

- Fs Project ReportDocument50 pagesFs Project Reportfizzy thingsNo ratings yet

- Condition: 21 Engine Difficult To Start, Turbocharger Damaged, V8 4.0TFSIDocument7 pagesCondition: 21 Engine Difficult To Start, Turbocharger Damaged, V8 4.0TFSITommy D. SalamiNo ratings yet

- Purposive Communication AssignmentDocument2 pagesPurposive Communication AssignmentJohn Warren MestiolaNo ratings yet

- EENG226 Lab1 PDFDocument5 pagesEENG226 Lab1 PDFSaif HassanNo ratings yet

- Lesson 2Document10 pagesLesson 2Anore James IvanNo ratings yet