Professional Documents

Culture Documents

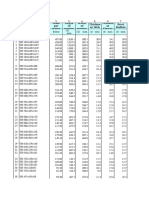

Pipe Rack Sizing and Loading Data

Uploaded by

apirakqCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Rack Sizing and Loading Data

Uploaded by

apirakqCopyright:

Available Formats

Pipe Rack Sizing and Loading Data

1 of 6

http://www.svlele.com/piping/pipe_rack.htm

HOME

lelepiping@gmail.com

Piping

Drawings

Piping

Pipe Rack Sizing and Loading Data

Isometrics

P&I Diagrams

Configuration: This is the selection of "fit-for-purpose." Each main run, minor 2D Piping

run and branch run must be looked at to determine its configuration. Will it be 3D Piping

an overhead rack or a sleeper way? Will each be single deck (layer) or multiple Models

deck? Will the support be a single column ("T") support or multi-column

support? How many columns? A second part of the configuration issue effects LISP Training

pipe racks in the process units themselves. This is the question of whether or not Piping Training

the pipe rack will support equipment such as Air Coolers (Fin Fans). Another

part of configuration is the issue of intersections. Poor planning on this issue can Design Info

cause problems later with the piping.

Tubular

Height: How high should each run of rack be? Should they be elevated or low Exchanger

sleepers. The sleepers are concrete with an imbedded steel plate on the top. For Agitator / Mixer

sleepers, they need to be off the ground to allow for maintenance and drainage

also to prevent corrosion. For elevated multi-level racks what should the Design &

separation be? For elevated racks you must plan the height and the separation of Drawings

the whole system together. A key element in the determination of separation is Tubular

Exchanger

the line sizes to be carried on the racks.

Width: This requires a detailed study of the total piping systems for the whole Agitator / Mixer

plant based on pipe rack routing. In the past, a study (called a "Transposition") Zero Hold up

was done to, as best you could, account for each line on each pipe rack. From Filter

this study, a berth sequence was established and the line spacing set. A Process Vessel

percentage was added as an error factor and then the clients "future" reserve Jib Crane

was added. This then constituted the minimum rack width. The final width

would be set after all racks were "sized" and then some might be rounded up in About Me

width for consistency, based on the materials of construction/fabrication My Resume

Contact Me

method.

Spacing: This issue can be addressed after the transposition has been

completed. The transposition identifies all the rack piping from the largest to the Cross Country

smallest From this the average line size for each leg of the rack system can be Piping

established. With the pipe size information (largest, smallest and average pipe

size) the number and spacing of the pipe support bents can be set. A cost

tradeoff is evaluated and made between more pipe supports spaced closer

together or fewer pipe supports and some sort of intermediate support system.

Pipe Rack and Structural form basic framework to hold equipments and Piping.

Pipe Rack work is done in 3 ways.

Concrete : In this case reinforced cement concrete structure is erected. The

reinforcement is provided by tensile strength of steel bars and compression

strength is provided by Cement. The columns and beams are provided with

insert plates, to weld steel members to it. It is time consuming as all work has to

be done on site and the concrete takes long time to cure.

Steel : This is based on steel structural members like Beams, Channels and

Angles. Most of the fitting and aligning work is done in shop and shipped to site.

It is then bolted on site. Design and Erection work is very fast. However,

periodic maintenance and painting is required, if environment is corrosive.

6/6/2559 21:57

Pipe Rack Sizing and Loading Data

2 of 6

http://www.svlele.com/piping/pipe_rack.htm

Steel covered by Concrete : The steel structure bears all the load while cement

cover protects it from corrosion. The steel structure does not melt in case of fire.

Most of the structure is made of vertical columns and horizontal beams, connected to

columns. The equipment and piping rests on beams. Sufficient gap is provided

between beams to lift the equipments and for passage of pipes. Columns are generally

5 meters away and height of beams is 4 meters above the floor level. Cross bracings

are provided to have stability to the structure. This is where anchor points are located,

especially in pipe racks. Most of the pipe supports are created from steel structural

members.

Modular Pipe rack: Sometimes clients look for modular pipe rack / modular structure

for their plants. Module is a series of standard units that function together. Structural

Frames completely fitted with pipes, Cable trays and miscellaneous equipment. If the

project site is at remote location, then it will be very difficult to get good local

contractor. Parallel construction activities are possible (foundation and module

fabrication) and gain in time schedule Controlled construction environment is possible

Controlled quality controlled.

In some countries, labor cost at site is more than labor cost at fabrication / module

assembly shop. So, if you fabricate and fit all the pipes, cable trays etc. at shop, then

you can save the project cost.

Data collection for pipe rack design: Pipe rack is the main artery of any plant. This

carries the pipes and cable trays (raceways) from one equipment to another equipment

within a process unit (called ISBL pipe rack) or carries the pipe and cable trays from

one unit to another unit (called OSBL pipe rack).

Data Collection for different types of pipe rack:

1. Conventional / Continuous Pipe rack: Continuous Pipe racks (conventional

pipe rack) system: This is essentially a system where multiple 2-dimensional

(2D) frame assemblies (commonly called bents), comprised of two or more

columns with transverse beams, are tied together in the longitudinal direction

utilizing beam struts (for support of transverse pipe and raceway elements and

for longitudinal stability of the system) and vertical bracing to form a 3D space

frame arrangement. Pipe racks supporting equipment such as air-cooled heat

exchangers must utilize the continuous system approach.

Data collection for pipe rack design: Due to the fast track nature associated

with most of the projects, often the final piping, raceway, and equipment

information is not available at initiation of the pipe rack design. Therefore, as a

Civil/Structural Engineer, you should coordinate with the Piping group,

Electrical, Control Systems, and Mechanical groups to obtain as much

preliminary information as possible. When received, all design information

should be documented for future reference and verification. In the initial design,

the Engineer should use judgment when applying or allowing for loads that are

not known, justifying them in the design basis

Plot plans and equipment location plans.

3D model showing piping layout, cable tray layout, Pipe rack bent spacing

and elevation of support levels in the transverse direction , Elevation of

longitudinal beam struts and locations of vertical bracing. and location of

pipe bridge, if any.

Piping orthographic drawings.

Vendor prints of equipment located on the rack, e.g., air coolers and

exchangers. The vendor prints should include the equipment layout,

mounting locations and details, access and maintenance requirements, and

the magnitude and direction of loads being transmitted to the pipe rack.

Electrical and control systems drawings showing the routing and location

of electrical and instrumentation raceways and/or supports.

6/6/2559 21:57

Pipe Rack Sizing and Loading Data

3 of 6

http://www.svlele.com/piping/pipe_rack.htm

Underground drawings that show the locations of buried pipes, concrete

structures and foundations, duct banks, etc. in the area of the pipe rack.

Pipe rack construction material (Steel, Cast-in-situ concrete, Pre-cast

concrete) shall be as per project design criteria.

Design loads consideration:

Piping Gravity load (D): In the absence of defined piping loads and

locations, an assumed minimum uniform pipe load of 2.0 kPa should be

used for preliminary design of pipe racks. This corresponds to an

equivalent load of 6 in (150 mm) lines full of water covered with 2 in (50

mm) thick insulation, and spaced on 12 in (300 mm) centers. This

assumption should be verified based on coordination with the Piping

Group, and concentrated loads should also be applied for any anticipated

large pipes. When the actual loads and locations become known, as the

project develops, the structural design should be checked against these

assumed initial load parameters and revised as required. A concentrated

load should then be added for pipes that are 12 in (300 mm) and larger in

diameter. The concentrated load P should be:

P =(W - s x p x d), s = Spacing of pipe rack bent, p = pipe weight

considered (kPa), d = pipe diameter W = pipe concentrated load.

Where consideration of uplift or system stability due to wind or seismic

occurrences is required, use 60% of the design gravity loads as an "all

pipes empty" load condition.

Loading due to hydrostatic testing of lines should be considered in the

design if applicable. Coordinate the testing plan(s) with Construction,

Startup, and/or the Piping Group as necessary, in order to fully understand

how such loads will be applied to the pipe rack structure. Under most

normal conditions, multiple lines will not be simultaneously tested. The

hydro-test loads do not normally need to be considered concurrently with

the other non-permanent loads, such as live load, wind, earthquake, and

thermal. Typical practice is to permit an overstress of 15% for the

hydro-test condition. Because of these considerations, the hydro-test

condition will not normally govern except for very large diameter pipes.

Electrical Tray and Conduits (D): Electrical and control systems

drawings and/or the project 3D model should be reviewed to determine

the approximate weight and location of electrical trays, conduits, and

instrumentation commodities. Unless the weight of the loaded raceways

can be defined, an assumed minimum uniform load of 1.0 kPa should be

used for single tier raceways.

Self weight of Pipe rack (D): The weight of all structural members,

including fireproofing, should be considered in the design of the pipe rack.

Weight of Equipment on pipe rack (D): Equipment weights, including

erection, empty, operating, and test (if the equipment is to be hydro-tested

on the pipe rack), should be obtained from the vendor drawings. The

equipment weight should include the dead weight of all associated

platforms, ladders, and walkways, as applicable. Special Loads: Special

consideration should be given to unusual loads, such as large valves,

expansion loops, and unusual piping or electrical configurations.

Live Load (L): Live load (L) on access platforms and walkways and on

equipment platforms should be considered, as applicable.

Snow Load (S): Snow load to be considered on cable tray and on large

dia pipes. This load shall be calculated per project approved design code

and project design criteria. Generally, you need to consider 100% snow

load on top tier and 50% on other tier of pipe racks.

Wind Load (W): Transverse wind load on structural members, piping,

6/6/2559 21:57

Pipe Rack Sizing and Loading Data

4 of 6

http://www.svlele.com/piping/pipe_rack.htm

electrical trays, equipment, platforms, and ladders should be determined

in accordance with project approved design code. Longitudinal wind

should typically be applied to structural framing, cable tray vertical drop

(if any), large dia pipes vertical drop (if any) and equipment only. The

effects of longitudinal wind on piping and trays running parallel to the

wind direction should be neglected.

Earthquake Loads (E): Earthquake loads in the vertical, transverse, and

longitudinal directions should be determined in accordance with the

project design criteria. Vertical, transverse, and longitudinal seismic forces

generated by the pipes, raceways, supported equipment, and the pipe rack

structure should be considered and should be based on their operating

weights. Pipes must be evaluated for seismic loads under both full and

empty conditions and then combined with the corresponding gravity

loads.

Friction Loading (Tf): Friction forces caused by hot lines sliding across

the pipe support during startup and shutdown are assumed to be partially

resisted through friction by nearby cold lines. Therefore, in order to

provide for a nominal unbalance of friction forces acting on a pipe

support, a resultant longitudinal friction force equal to 7.5% of the total

pipe weight or 30% of any one or more lines known to act simultaneously

in the same direction, whichever is larger, is assumed for pipe rack design.

Friction between piping and supporting steel should not be relied upon to

resist wind or seismic loads.

Anchor and Guide Loads (Ta): Pipe racks should be checked for anchor

and guide loads as determined by the Pipe Stress Group. It may be

necessary to use horizontal bracing if large anchor forces are

encountered. For conventional pipe rack systems, it is normally preferred

to either have the anchors staggered along the pipe rack so that each

support has only one or two anchors, or to anchor most pipes on one

braced support. For initial design, when anchor and guide loads are not

known, use a longitudinal anchor force of 5.0 kN acting at mid span of

each bent transverse beam (refer project design criteria). Guide loads are

usually small and may be ignored until they are defined by the Pipe Stress

Engineer. For non-continuous pipe rack systems, piping may be

transversely guided or anchored at both cantilever frames and anchor

bays. Longitudinal anchors may be located only at anchor bays.

Framing of Continuous/Conventional Pipe rack:

Frames: Main pipe racks are usually designed as moment-resisting frames

in the transverse direction. In the longitudinal direction, there should be at

least one continuous level of beam struts on each side. For pipe racks with

more than one tier, the beam struts should be located at a level that is

usually equal to one-half tier spacing above or below the bottom tier.

Vertical bracing in the longitudinal direction should be provided to carry

the longitudinal forces, transmitted through the beam struts, to the base

plate / foundation level.

Transverse Beam: Transverse beams must be capable of resisting all

forces, moments, and shears produced by the load combinations.

Transverse beams are generally a moment-resisting frame, modeled and

analyzed as part of the frame system. The analysis model must reflect the

appropriate beam end conditions. In the design of beams, consideration

should be given to

Large pipes that are to be hydro-tested.

Anchor and friction load with large magnitude

Central Spine: For steel pipe racks with spans of more than 6 m, a center

6/6/2559 21:57

Pipe Rack Sizing and Loading Data

5 of 6

http://www.svlele.com/piping/pipe_rack.htm

spine consisting of a system of horizontal braces and struts located at mid

span of each level of piping should be considered . This additional light

horizontal framing greatly increases the capacity of the transverse pipe

support beams to resist friction and anchor forces, and also serves to

reduce the unbraced length of the beam compression flange in flexure and

to reduce the unbraced length of the beam about the weak-axis in axial

compression. This concept reduces the required beam sizes and provides a

mechanism for eliminating or minimizing design, fabrication, or field

modifications that could otherwise be required due to late receipt of

unanticipated large pipe anchor forces.

Longitudinal Beam Strut: For typical continuous pipe rack systems, the

longitudinal beam struts should be designed as axially loaded members

that are provided for longitudinal loads and stability. Additionally, the

longitudinal beam struts that support piping or raceway should be

designed for 50% of the gravity loading assumed for the transverse pipe

or raceway support beams, unless unusual loading is encountered. This

50% gravity loading will account for the usual piping and raceway

take-offs. Normally, the gravity loading carried by the beam struts should

not be added to the design loads for the columns or footings since pipes or

raceway contributing to the load on the beam struts would be relieving an

equivalent load on the transverse beams.

For any continuous pipe rack system where the anticipated piping and

raceway take-offs are minimal or none, the 50% loading criteria does not

apply. In such cases, the beam struts should be designed primarily as

axially loaded members. Do not provide beam struts if they are not

needed for piping or raceway support, or for system stability. Conversely,

the 3D model should be checked to verify that beam struts subjected to

unusually large loads (such as at expansion loops) have been given special

consideration. All longitudinal beam struts, including connections, should

be designed to resist the axial loads produced by the longitudinal forces.

When designing the longitudinal beam struts for flexural loads, the full

length of the beam should be considered as the unbraced length for the

compression flange.

Vertical Bracing: When moment-resisting frame design is not used in the

longitudinal direction, vertical bracing should be used to transmit the

longitudinal forces from the beam struts to the foundations. Knee-bracing

or K-bracing is most often used for this purpose. Unless precluded by

equipment arrangement or interferences, bracing should be placed

equidistant between two expansion joints. Design calculations and

drawings must reflect a break in the beam strut continuity between

adjacent braced sections through the use of slotted connections or by

eliminating the beam struts in the bays designated as free bays. The

maximum length of a braced section should be limited to 48m to 50m. If

the braced bay is not located equidistant from the free bays, the maximum

distance from the braced bay to a free bay should be limited such that the

maximum total longitudinal growth or shrinkage of the unrestrained

segment does not exceed 40 mm.

Column: The columns must be capable of resisting all loads, moments,

and shears produced by the load combinations. A moment-resisting frame

analysis should normally be used to determine the axial load, moment,

and shear at points along the columns. The frame analysis model should

be based on the following:

Consider column base as hinge.

Use 4 bolt connections for safety purpose.

6/6/2559 21:57

Pipe Rack Sizing and Loading Data

6 of 6

http://www.svlele.com/piping/pipe_rack.htm

For design of steel columns subjected to flexural loads, the distance

between the base and the first transverse beam or the knee brace

intersection should be considered as the compression flange unbraced

length.

to get all the information as a eBook

6/6/2559 21:57

You might also like

- Pipe Rack Sizing and Loading DataDocument7 pagesPipe Rack Sizing and Loading DatachantiramNo ratings yet

- Non-Continuous Piperacks System Modular Pipe RackDocument4 pagesNon-Continuous Piperacks System Modular Pipe RackMadhu GuptaNo ratings yet

- Primer on Pipe Supports FundamentalsDocument8 pagesPrimer on Pipe Supports FundamentalsSharun SureshNo ratings yet

- Pipe Rack Sizing and Loading DataDocument5 pagesPipe Rack Sizing and Loading DataAnand.5No ratings yet

- Pipe Rack Design Philosophy (Continuous Pipe Racks)Document17 pagesPipe Rack Design Philosophy (Continuous Pipe Racks)Umer AleemNo ratings yet

- Aspects of Piperack DesignDocument70 pagesAspects of Piperack Designdhdahanuwala100% (3)

- Piperack Planning GuideDocument4 pagesPiperack Planning GuideryncscNo ratings yet

- Pipe RackDocument25 pagesPipe RackVernie SorianoNo ratings yet

- Piperack Design PhiloshipyDocument10 pagesPiperack Design PhiloshipyJatinTankNo ratings yet

- Optimum Design of Steel Pipe RacksDocument17 pagesOptimum Design of Steel Pipe RacksRamesh PrabhakarNo ratings yet

- Connection DesignDocument33 pagesConnection DesignSri KalyanNo ratings yet

- Minimum Load For Empty Minimum Load For OperatingDocument6 pagesMinimum Load For Empty Minimum Load For OperatingjitendraNo ratings yet

- WWW - Civildesignhelp.info VV - HTMLDocument52 pagesWWW - Civildesignhelp.info VV - HTMLconsultor9010No ratings yet

- PipeDocument33 pagesPipeDhakshina K100% (1)

- Polaris Pipe Support Design StandardDocument5 pagesPolaris Pipe Support Design Standardsrinivas_j3166100% (1)

- Design Practice For Piping Arangement (Pipe Rack)Document53 pagesDesign Practice For Piping Arangement (Pipe Rack)Chairul Anwar100% (2)

- Techinical Specifications Welcome To NescoDocument54 pagesTechinical Specifications Welcome To NescotejzabNo ratings yet

- Pipe Rack & Rack PipingDocument23 pagesPipe Rack & Rack Pipingtrung652092100% (2)

- Design of Structural Steel Pipe RacksDocument1 pageDesign of Structural Steel Pipe RacksCharlie ChuNo ratings yet

- Sample Splice For Plate Girder DesignDocument7 pagesSample Splice For Plate Girder DesignChandan SinghNo ratings yet

- Bend Freq Beams Rods PipesDocument47 pagesBend Freq Beams Rods PipesAsur Cortes GNo ratings yet

- Anchor Design HILTIDocument14 pagesAnchor Design HILTIRohit GadekarNo ratings yet

- Piping Engineering Design Criteria Rev02Document15 pagesPiping Engineering Design Criteria Rev02swatkoolNo ratings yet

- Pipe Rack LAYOUTDocument25 pagesPipe Rack LAYOUTSAMI UR RAHMANNo ratings yet

- A Good Question Considering Shipping Container StructuresDocument4 pagesA Good Question Considering Shipping Container StructuresJohn Rheynor Mayo100% (1)

- Guide To The Design of Diaphragms, Chords and Collectors Based On The 2006 IBC and ASCE/SEI 7-05Document22 pagesGuide To The Design of Diaphragms, Chords and Collectors Based On The 2006 IBC and ASCE/SEI 7-05Daniel SilvaNo ratings yet

- Pipe Rack Design PhilosophyDocument5 pagesPipe Rack Design PhilosophyMUTHUKKUMARAMNo ratings yet

- Loaded Flat PlatesDocument8 pagesLoaded Flat Platessloane01No ratings yet

- Design of AnchorsDocument27 pagesDesign of AnchorsKarikalan JayNo ratings yet

- Pile Footing Connections A Survey of State PracticeDocument5 pagesPile Footing Connections A Survey of State PracticeNadgee Gonzalez100% (1)

- Truss Support Connection Design T5-S1Document11 pagesTruss Support Connection Design T5-S1rajedmaglinteNo ratings yet

- P/R Design Tips For Steel Design (IFC)Document17 pagesP/R Design Tips For Steel Design (IFC)apara_jitNo ratings yet

- Foundation 3 DDocument4 pagesFoundation 3 Djakeer7No ratings yet

- Anchorage and Development LengthsDocument2 pagesAnchorage and Development LengthsSimo AliNo ratings yet

- Structures Repair Guidelines: Engineering (Track & Civil) GuidelineDocument79 pagesStructures Repair Guidelines: Engineering (Track & Civil) GuidelinekanosriNo ratings yet

- Design of Piping SupportsDocument15 pagesDesign of Piping SupportsPedro Luis Choque MamaniNo ratings yet

- RCC14 Crack Width PDFDocument1 pageRCC14 Crack Width PDFmdelacua2No ratings yet

- Structural Steelwork Connections: Bolted Gusset Plate Connection For Truss B.S. 5950 Part 1 Calculations & ScketchesDocument4 pagesStructural Steelwork Connections: Bolted Gusset Plate Connection For Truss B.S. 5950 Part 1 Calculations & ScketchessitheeqNo ratings yet

- Structural Beam Deflection and Stress FormulaDocument14 pagesStructural Beam Deflection and Stress FormulaKeith AdminNo ratings yet

- Seismic Analysis of High-Rise BuildingDocument66 pagesSeismic Analysis of High-Rise BuildinglefratodriNo ratings yet

- Two-Tier Pipe Rack Connection DesignDocument4 pagesTwo-Tier Pipe Rack Connection DesignNicoleta cristianNo ratings yet

- Report PDFDocument108 pagesReport PDFNavneeth Kumar KorleparaNo ratings yet

- Hanger Support Spacing and Rod Size For Horizontal PipesDocument8 pagesHanger Support Spacing and Rod Size For Horizontal Pipesyarzar17No ratings yet

- A Comparative Study On Wind Loads Between Design Standards For The Design of Pipe-Rack StructuresDocument8 pagesA Comparative Study On Wind Loads Between Design Standards For The Design of Pipe-Rack Structuresvirat_daveNo ratings yet

- EG 1905 Pipe RacksDocument35 pagesEG 1905 Pipe RacksAnonymous h87K4sT100% (1)

- General Pipe Rack Configuration 0 DivDocument2 pagesGeneral Pipe Rack Configuration 0 DivhumshkhNo ratings yet

- s0!00!05 - Concrete Reinforcing Lap LengthsDocument1 pages0!00!05 - Concrete Reinforcing Lap LengthshuyxpkissNo ratings yet

- ENGINEERING GUIDELINES THESIS FORMATDocument13 pagesENGINEERING GUIDELINES THESIS FORMATShubham PawarNo ratings yet

- Pipe Support2of 5Document1 pagePipe Support2of 5Anonymous fLgaidVBhz100% (1)

- 1.1 Design of Pipe Racks Writeup PDFDocument5 pages1.1 Design of Pipe Racks Writeup PDFCarlosAlbertoGrimaldoBarajasNo ratings yet

- Pipe Rack Design Philosophy GuideDocument13 pagesPipe Rack Design Philosophy Guideप्रभु नाथ सिंहNo ratings yet

- Pipe Rack Design PhilosophyDocument18 pagesPipe Rack Design PhilosophyselvakumarNo ratings yet

- Pipe Rack Design Philosophy GuideDocument8 pagesPipe Rack Design Philosophy Guidegk80823100% (1)

- Non-Continuous Piperacks System Modular Pipe RackDocument4 pagesNon-Continuous Piperacks System Modular Pipe RackReld DavidNo ratings yet

- Pipe Rack Design PhilosophyDocument6 pagesPipe Rack Design PhilosophyLogesh PerumalNo ratings yet

- WWW SefindiaDocument11 pagesWWW SefindiaSUSHANTBIJAMNo ratings yet

- Piping Engineering - Piping Layout Procedure and Pipe Rack - XyntechDocument14 pagesPiping Engineering - Piping Layout Procedure and Pipe Rack - XyntechKeiko DavilaNo ratings yet

- Pipe Rack and Rack Piping Considerations With Online Course With PDFDocument5 pagesPipe Rack and Rack Piping Considerations With Online Course With PDFSaidFerdjallahNo ratings yet

- Pipe Rack PresentationDocument19 pagesPipe Rack Presentationkaushalacharya67% (3)

- Pipe Rack and Rack Piping Considerations With Online Course With PDFDocument5 pagesPipe Rack and Rack Piping Considerations With Online Course With PDFAmjadali ChoudhariNo ratings yet

- Unrestrained Beam Design - Ii PDFDocument24 pagesUnrestrained Beam Design - Ii PDFapirakqNo ratings yet

- CAD Forum - Random Lines Are Displayed Over My AutoCAD DrawingDocument2 pagesCAD Forum - Random Lines Are Displayed Over My AutoCAD DrawingapirakqNo ratings yet

- Procedure To Calculate Deflections of Curved BeamsDocument11 pagesProcedure To Calculate Deflections of Curved BeamsapirakqNo ratings yet

- Ten Hag - Man Utd Style Criticism 'Too Strong' - The AthleticDocument14 pagesTen Hag - Man Utd Style Criticism 'Too Strong' - The AthleticapirakqNo ratings yet

- Structural Strengthening Concept For Analysis and DesignDocument13 pagesStructural Strengthening Concept For Analysis and DesignapirakqNo ratings yet

- Lateral Forces Structures Ch14Document32 pagesLateral Forces Structures Ch14apirakq100% (1)

- Dhammapāda StoriesDocument126 pagesDhammapāda StoriesapirakqNo ratings yet

- Yield Line Analysis of Column Webs With Welded Bem ConnectionsDocument6 pagesYield Line Analysis of Column Webs With Welded Bem ConnectionsapirakqNo ratings yet

- Response Analysis of Multi-Storey RC Buildings-437Document10 pagesResponse Analysis of Multi-Storey RC Buildings-437Joseph GuzmanNo ratings yet

- Section 05 PrakashDocument61 pagesSection 05 PrakashapirakqNo ratings yet

- L5 SystemsDocument79 pagesL5 SystemsapirakqNo ratings yet

- Most Common Errors in Seismic DesignDocument3 pagesMost Common Errors in Seismic DesignAnkush JainNo ratings yet

- Advanced Structures and Construction: Historical Evolution of Tall Vertical StructuresDocument69 pagesAdvanced Structures and Construction: Historical Evolution of Tall Vertical StructuresapirakqNo ratings yet

- L3 Lateral ForceDocument75 pagesL3 Lateral Forceapirakq100% (1)

- Two Pile GroupDocument12 pagesTwo Pile GroupJammy KingNo ratings yet

- Az in E: Codes & StandardsDocument3 pagesAz in E: Codes & StandardsapirakqNo ratings yet

- FFS - Masterfund - KF-HEALTHD Class JPM Global Healthcare A (Dist) USD PDFDocument2 pagesFFS - Masterfund - KF-HEALTHD Class JPM Global Healthcare A (Dist) USD PDFapirakqNo ratings yet

- Report - Cu Cas 00 13Document18 pagesReport - Cu Cas 00 13Silver Olguín CamachoNo ratings yet

- 06 Eurocodes Steel Workshop WALDDocument136 pages06 Eurocodes Steel Workshop WALDIonut SavaNo ratings yet

- Astm 1157Document4 pagesAstm 1157Saeed HassaniNo ratings yet

- ASTMC595 and C1157RecentChangesDocument8 pagesASTMC595 and C1157RecentChangesapirakqNo ratings yet

- CE474 - Additional Stiffness ProblemsDocument14 pagesCE474 - Additional Stiffness ProblemsapirakqNo ratings yet

- Etabs Trainingnew1Document11 pagesEtabs Trainingnew1apirakqNo ratings yet

- Analysis and Design of Reinforced Concrete Structures With Spring Base IsolationDocument13 pagesAnalysis and Design of Reinforced Concrete Structures With Spring Base IsolationapirakqNo ratings yet

- fx-FD10 Pro: User's GuideDocument222 pagesfx-FD10 Pro: User's GuideLouis AndrewsNo ratings yet

- 2012 IBC Serviceability Requirements Under Wind LoadingDocument1 page2012 IBC Serviceability Requirements Under Wind LoadingapirakqNo ratings yet

- Design Shear WallDocument26 pagesDesign Shear WallCaoTrungThành100% (2)

- ASCE 7 Drift Check For Seismic and Wind LoadingDocument1 pageASCE 7 Drift Check For Seismic and Wind LoadingapirakqNo ratings yet

- Some Aspect of The Design and Analysis..Document8 pagesSome Aspect of The Design and Analysis..apirakqNo ratings yet

- Horizontal Construction JointsDocument96 pagesHorizontal Construction JointsapirakqNo ratings yet

- Cobi Spec GuideDocument10 pagesCobi Spec Guideharry HendersonNo ratings yet

- Industrial Strainers Filters Y StrainerDocument1 pageIndustrial Strainers Filters Y StrainerEi Ei PhyoNo ratings yet

- PDF High Performance Diaphragm Liquid End HPD Low Flow Installation Operation and Maintenance Manual - CompressDocument40 pagesPDF High Performance Diaphragm Liquid End HPD Low Flow Installation Operation and Maintenance Manual - CompressVũ Văn QuangNo ratings yet

- Chemrite - 540Document2 pagesChemrite - 540ghazanfarNo ratings yet

- VbeDocument2 pagesVbeAniket PatilNo ratings yet

- Method Statement For PEB WorkDocument27 pagesMethod Statement For PEB WorkVIJAY BAHADUR YADAV100% (2)

- Voyager II IOM Cooling - Gas FiredDocument64 pagesVoyager II IOM Cooling - Gas FiredSadiq AmeerNo ratings yet

- 56r 08Document21 pages56r 08manojsingh4allNo ratings yet

- Minor Losses in Piping SystemsDocument19 pagesMinor Losses in Piping Systemsphanirajinish100% (1)

- Introduction Portable ToiletsDocument1 pageIntroduction Portable ToiletsShrestha Hem100% (1)

- Carrier Infinity Control Owners ManualDocument35 pagesCarrier Infinity Control Owners ManualsunshineorthodocNo ratings yet

- SAP 2000 Manual Water Tank DesignDocument20 pagesSAP 2000 Manual Water Tank DesignSyner Qxz100% (1)

- Data File PHJDDocument43 pagesData File PHJDtamrinNo ratings yet

- 224 enDocument1 page224 encvijo31No ratings yet

- Lattice Towers and Masts IntroductionDocument17 pagesLattice Towers and Masts IntroductionPankaj_Taneja_9684No ratings yet

- 1.01D21A Post perp-TYPE - II B1 (UC152x152X37) Tob2 (UC203X46)Document49 pages1.01D21A Post perp-TYPE - II B1 (UC152x152X37) Tob2 (UC203X46)balaNo ratings yet

- Catalogo NovumDocument72 pagesCatalogo NovumrodgutieNo ratings yet

- Aplus CompactorDocument8 pagesAplus CompactorAlex ChewNo ratings yet

- City of Redwood City Supervising Civil EngineerDocument3 pagesCity of Redwood City Supervising Civil EngineerhamadaNo ratings yet

- Barriers to Quality Management in Small Building ConstructionDocument16 pagesBarriers to Quality Management in Small Building ConstructionAcharya RabinNo ratings yet

- ECOBA Statistic 2004Document1 pageECOBA Statistic 2004dungnv2733No ratings yet

- Tile Adhesives, Tile Grouts and Plastering SkimDocument30 pagesTile Adhesives, Tile Grouts and Plastering SkimNykha Alenton100% (1)

- Addis Ababa University (Eiabc) : Research ProposalDocument20 pagesAddis Ababa University (Eiabc) : Research ProposalLemlem MamoNo ratings yet

- Emile - Warre.people - Hive.plans - Engl. .11pDocument0 pagesEmile - Warre.people - Hive.plans - Engl. .11ptewngomNo ratings yet

- 370 The Red Book - Basics of Foundation Design Fellenius 2017 PDFDocument468 pages370 The Red Book - Basics of Foundation Design Fellenius 2017 PDFTomasz Cz100% (1)

- WaterproofingDocument2 pagesWaterproofinghoney4747No ratings yet

- GC Guy Wire (US) Catalog Sheet FinalDocument1 pageGC Guy Wire (US) Catalog Sheet FinalAde 'aiyie' SasmitaNo ratings yet

- Polycarbonate Glazing SystemDocument16 pagesPolycarbonate Glazing SystemGirish DhawanNo ratings yet

- 18 Silbond and SilaidDocument4 pages18 Silbond and SilaidsviruindiaNo ratings yet

- HMO Property and Management StandardsDocument60 pagesHMO Property and Management StandardsFemi AdeosunNo ratings yet

- Horse Training 101: Key Techniques for Every Horse OwnerFrom EverandHorse Training 101: Key Techniques for Every Horse OwnerRating: 4.5 out of 5 stars4.5/5 (27)

- Life Is Not an Accident: A Memoir of ReinventionFrom EverandLife Is Not an Accident: A Memoir of ReinventionRating: 3.5 out of 5 stars3.5/5 (7)

- Becky Lynch: The Man: Not Your Average Average GirlFrom EverandBecky Lynch: The Man: Not Your Average Average GirlRating: 4.5 out of 5 stars4.5/5 (12)

- Elevate and Dominate: 21 Ways to Win On and Off the FieldFrom EverandElevate and Dominate: 21 Ways to Win On and Off the FieldRating: 5 out of 5 stars5/5 (4)

- Endure: How to Work Hard, Outlast, and Keep HammeringFrom EverandEndure: How to Work Hard, Outlast, and Keep HammeringRating: 4.5 out of 5 stars4.5/5 (284)

- What Winners Won't Tell You: Lessons from a Legendary DefenderFrom EverandWhat Winners Won't Tell You: Lessons from a Legendary DefenderRating: 4.5 out of 5 stars4.5/5 (7)

- Crazy for the Storm: A Memoir of SurvivalFrom EverandCrazy for the Storm: A Memoir of SurvivalRating: 3.5 out of 5 stars3.5/5 (217)

- The Arm: Inside the Billion-Dollar Mystery of the Most Valuable Commodity in SportsFrom EverandThe Arm: Inside the Billion-Dollar Mystery of the Most Valuable Commodity in SportsRating: 4 out of 5 stars4/5 (49)

- Sprawlball: A Visual Tour of the New Era of the NBAFrom EverandSprawlball: A Visual Tour of the New Era of the NBARating: 4 out of 5 stars4/5 (11)

- I Never Had It Made: An AutobiographyFrom EverandI Never Had It Made: An AutobiographyRating: 3.5 out of 5 stars3.5/5 (38)

- House of Nails: A Memoir of Life on the EdgeFrom EverandHouse of Nails: A Memoir of Life on the EdgeRating: 3 out of 5 stars3/5 (4)

- Bloodlines: The True Story of a Drug Cartel, the FBI, and the Battle for a Horse-Racing DynastyFrom EverandBloodlines: The True Story of a Drug Cartel, the FBI, and the Battle for a Horse-Racing DynastyRating: 4 out of 5 stars4/5 (8)

- The Teen’s Living Guide: Unlocking Your Potential for a Remarkable JourneyFrom EverandThe Teen’s Living Guide: Unlocking Your Potential for a Remarkable JourneyRating: 5 out of 5 stars5/5 (76)

- Body Confidence: Venice Nutrition's 3 Step System That Unlocks Your Body's Full PotentialFrom EverandBody Confidence: Venice Nutrition's 3 Step System That Unlocks Your Body's Full PotentialRating: 4 out of 5 stars4/5 (2)

- The Perfect Mile: Three Athletes, One Goal, and Less Than Four Minutes to Achieve ItFrom EverandThe Perfect Mile: Three Athletes, One Goal, and Less Than Four Minutes to Achieve ItNo ratings yet

- The Inside Game: Bad Calls, Strange Moves, and What Baseball Behavior Teaches Us About OurselvesFrom EverandThe Inside Game: Bad Calls, Strange Moves, and What Baseball Behavior Teaches Us About OurselvesRating: 4 out of 5 stars4/5 (7)

- Summary: Range: Why Generalists Triumph in a Specialized World by David Epstein: Key Takeaways, Summary & Analysis IncludedFrom EverandSummary: Range: Why Generalists Triumph in a Specialized World by David Epstein: Key Takeaways, Summary & Analysis IncludedRating: 4.5 out of 5 stars4.5/5 (6)

- Patriot Reign: Bill Belichick, the Coaches, and the Players Who Built a ChampionFrom EverandPatriot Reign: Bill Belichick, the Coaches, and the Players Who Built a ChampionRating: 3.5 out of 5 stars3.5/5 (30)

- The Truth About Aaron: My Journey to Understand My BrotherFrom EverandThe Truth About Aaron: My Journey to Understand My BrotherNo ratings yet

- Badasses: The Legend of Snake, Foo, Dr. Death, and John Madden's Oakland RaidersFrom EverandBadasses: The Legend of Snake, Foo, Dr. Death, and John Madden's Oakland RaidersRating: 4 out of 5 stars4/5 (15)

- The Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsFrom EverandThe Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsNo ratings yet

- Last Child in the Woods: Saving Our Children From Nature-Deficit DisorderFrom EverandLast Child in the Woods: Saving Our Children From Nature-Deficit DisorderRating: 4 out of 5 stars4/5 (283)

- The Mindful Athlete: Secrets to Pure PerformanceFrom EverandThe Mindful Athlete: Secrets to Pure PerformanceRating: 4.5 out of 5 stars4.5/5 (278)

- Earnhardt Nation: The Full-Throttle Saga of NASCAR's First FamilyFrom EverandEarnhardt Nation: The Full-Throttle Saga of NASCAR's First FamilyRating: 3.5 out of 5 stars3.5/5 (7)