Professional Documents

Culture Documents

Cabletrays Institute Technical Bulletin2

Uploaded by

ahmodahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cabletrays Institute Technical Bulletin2

Uploaded by

ahmodahCopyright:

Available Formats

Cabletrays Institute Technical Bulletin

1 of 2

Thermal Contraction and Expansion of Cable Tray

All materials expand and contract due to temperature changes. It is important that cable tray installations

incorporate features which provide adequate compensation for their thermal contraction and expansion.

1993 NEC Section 300-7 (b) states that "Raceways shall be provided with expansion joints where

necessary to compensate for the thermal expansion or contraction." In 1993 NEC Article 318 there are

no requirements for the handling of the thermal contraction and expansion of cable tray. This subject is

addressed in the NEMA Standards Publication No. VE 1 "Metallic Cable Tray Systems" Section 6.8.

There are expansion joint splice plates and bonding jumpers available from cable tray manufacturers. A

cable tray support should be located within 2 feet of each side of the expansion joint splice plates

position. The cable trays must not be clamped to each support so firmly that the cable tray cannot

expand without distortion. The cable tray needs to be anchored at the support closest to the midpoint

between the expansion joints with hold down clamps and secured by expansion guides at all other

support locations. The expansion guides allow the cable tray to slide back and forth as it contracts and

expands. If provisions for the thermal contraction and expansion of the cable trays are not provided for

where there are large summer to winter temperature extremes (example: roof top installations); there is

the potential for the cable trays to tear loose from their supports, for the cable trays to bend (snake), or

for bolt hole elongations at the splice plate areas.

Bridges and some other structures have expansion joints. Installing expansion joints in the cable tray

runs only at the structure expansion joint positions, does not normally provide a valid solution to

adequately compensate for the cable tray's thermal contraction and expansion. The materials of the

structures and the cable trays are different. They will have different values of thermal contraction and

expansion. They each require unique solutions for their thermal compensation and expansion.

In the NEMA Metallic Cable Tray Systems Standard VE 1, Section 6.8 Thermal Contraction and

Expansion. VE 1 Table 6-1

shows the allowable lengths of steel and aluminum cable tray between expansion joints for the

temperature differential values.

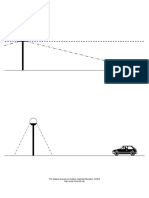

Figure 6-9

For a 100 F differential (winter to summer),

a steel cable tray will require an expansion

joint every 128 feet and an aluminum cable

tray every 65 feet. The temperature at the

time of installation will dictate the gap setting.

VE 1 Figure 6-9 is a nomograph from which

the required metal expansion gap setting

may be determined.

The Gap Setting of the Expansion Joint

Splice Plate Nomograph is used as follows

per the example indicated on VE 1 Figure

Cabletrays Institute Technical Bulletin

2 of 2

6-9.

Step 1. Plot the highest expected cable tray metal temperature on the maximum temperature vertical

axis. Example's Value = 100 F.

Step 2. Plot the lowest expected cable tray metal temperature on the minimum temperature vertical

axis. Example's Value: = -28 F.

Step 3. Draw a line between these maximum and minimum temperature points on the two vertical axis.

Step 4. To determine the required expansion joint gap setting: Plot the cable tray metal temperature at

the time of the cable tray installation on the Maximum temperature vertical axis (Example's

Value: 50 F). Project over from the 50 F point on the maximum temperature vertical axis to an

intersection with the line between the maximum and minimum cable tray metal temperatures.

From this intersection point, project down to the gap setting horizontal axis to find the correct

gap setting value (Example's Value: 3/8 inch gap setting). This is the length of the gap to be set

between the cable tray sections at the expansion joint splice plate location.

table 6-1

Table 6-1

For simplicity, the bonding jumpers around the expansion joint splice plates should be sized to match the

fault current capacity of the cable tray side rails or the cable tray cross section for one piece construction

cable trays. Following such a practice will not require that the bonding jumpers must be changed if

higher capacity circuits (that require increases in the protective device sizes or setting) are installed in

the cable tray at a later date. If it is known that there will not be any additions of higher rated circuits and

that the rating of the protective devices will not be increased, the bonding jumpers may be sized as per

1993 NEC Table 250-95.

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Thermal Expansion and Contraction of Trays PDFDocument3 pagesThermal Expansion and Contraction of Trays PDFAditya VuthaNo ratings yet

- Electric Heat Tracing: Installation ProceduresDocument10 pagesElectric Heat Tracing: Installation ProceduresrajNo ratings yet

- Flat End PlatesDocument4 pagesFlat End Platesb_wooNo ratings yet

- SecVIII Div1 UW40Document2 pagesSecVIII Div1 UW40arianaseriNo ratings yet

- TafirifezaDocument2 pagesTafirifezazafrikhan875No ratings yet

- Optimization of Tubesheet Thickness of Shell and Tube Heat ExchangerDocument6 pagesOptimization of Tubesheet Thickness of Shell and Tube Heat Exchangersagar1503No ratings yet

- PWHT Procedure For Petrol Steel - CoreDocument9 pagesPWHT Procedure For Petrol Steel - CoreSuleyman HaliciogluNo ratings yet

- Cable Tray Load Factor and Spec PDFDocument7 pagesCable Tray Load Factor and Spec PDFÖmer EmelNo ratings yet

- Shrinkage and Temperature ReinforcementDocument5 pagesShrinkage and Temperature ReinforcementMustafaNo ratings yet

- Refinery Based Case Study of A Novel Gasket Designed For Use in Problematic Shell and Tube Heat Exchangers - Change GasketDocument19 pagesRefinery Based Case Study of A Novel Gasket Designed For Use in Problematic Shell and Tube Heat Exchangers - Change GasketAlbertoNo ratings yet

- Trace Heating Thermon Trace Heating Trace Heating CableDocument8 pagesTrace Heating Thermon Trace Heating Trace Heating Cablemajid8080No ratings yet

- General Guidelines On Installation of ThermocouplesDocument15 pagesGeneral Guidelines On Installation of ThermocouplesCharu ChhabraNo ratings yet

- Bandejas Fibra de VidrioDocument5 pagesBandejas Fibra de VidrioCristhJuliangNo ratings yet

- Expansion Joints: Raison EtreDocument2 pagesExpansion Joints: Raison EtreTAHIR MAHMOODNo ratings yet

- A Transient Hot-Wire Cell For Thermal Conductivity Measurements Over A Wide Temperature RangeDocument5 pagesA Transient Hot-Wire Cell For Thermal Conductivity Measurements Over A Wide Temperature RangeGeetha PookatNo ratings yet

- Flange Closure Design Spreadsheet-11 AmerivenDocument27 pagesFlange Closure Design Spreadsheet-11 AmerivenWilmer FigueraNo ratings yet

- Pvp1996-Vol336 3Document4 pagesPvp1996-Vol336 3dogusNo ratings yet

- Shell & Tube Heat Exchanger Part 1Document4 pagesShell & Tube Heat Exchanger Part 1NAMONo ratings yet

- Above Ground Pipeline DesignDocument15 pagesAbove Ground Pipeline DesigndilimgeNo ratings yet

- Intercomparison Procedures: For Gage Blocks Using Electromechanical ComparatorsDocument21 pagesIntercomparison Procedures: For Gage Blocks Using Electromechanical ComparatorsRonny AndalasNo ratings yet

- Transformer Bushings, Type GOE and GOE (2) : Technical GuideDocument24 pagesTransformer Bushings, Type GOE and GOE (2) : Technical GuideTxavitoNo ratings yet

- Electric Heat Tracing Rev1.0Document12 pagesElectric Heat Tracing Rev1.0draftingisincNo ratings yet

- Asme Section II A Sa-249 Sa-249mDocument10 pagesAsme Section II A Sa-249 Sa-249mAnonymous GhPzn1xNo ratings yet

- Thermal Considerations For QFN Packaged Integrated CircuitsDocument12 pagesThermal Considerations For QFN Packaged Integrated CircuitspadrititaNo ratings yet

- Investigation and Repair of H (1) - E.R Flange LeakDocument19 pagesInvestigation and Repair of H (1) - E.R Flange LeakriysallNo ratings yet

- Asme Section II A Sa-358 Sa-358mDocument10 pagesAsme Section II A Sa-358 Sa-358mAnonymous GhPzn1xNo ratings yet

- Electrical Heat Tracing ProcedureDocument8 pagesElectrical Heat Tracing Proceduretndeshmukh100% (1)

- Wiring HarnessDocument23 pagesWiring HarnessRichard Andrianjaka LuckyNo ratings yet

- Cable Tray SystemDocument26 pagesCable Tray SystemAldrien CabinteNo ratings yet

- The Basic of Electric Process HeatingDocument8 pagesThe Basic of Electric Process HeatingAmir AmkaNo ratings yet

- Tubesheets For U-Tube Heat ExchangersDocument2 pagesTubesheets For U-Tube Heat Exchangerskinjalpatel12345No ratings yet

- Astm b280 1997 PDFDocument10 pagesAstm b280 1997 PDFvaradha184100% (1)

- Heat Exchanger Handbook - Heat Exchangers PDFDocument66 pagesHeat Exchanger Handbook - Heat Exchangers PDFhonghai_dl100% (3)

- Heat Pipe ThesisDocument7 pagesHeat Pipe Thesisbrookelordmanchester100% (2)

- Underground Cable Ampacity With Neher McGrathDocument7 pagesUnderground Cable Ampacity With Neher McGrathJesus RodriguezNo ratings yet

- PWHTDocument13 pagesPWHTcv100% (2)

- PWHT ProcedureDocument6 pagesPWHT ProcedurevictorbirlanNo ratings yet

- Investigation and Repair of Heat Exchanger Flange LeakDocument11 pagesInvestigation and Repair of Heat Exchanger Flange Leaksagar1503No ratings yet

- Carbon Steel Forgings For Pressure Vessel ComponentsDocument4 pagesCarbon Steel Forgings For Pressure Vessel Componentsraghav248No ratings yet

- Research PaperDocument9 pagesResearch Paperirfan ashrafNo ratings yet

- T-Zone Installation GuideDocument24 pagesT-Zone Installation GuidethermaltechnologiesNo ratings yet

- OTC 5049 MS Paper PDFDocument10 pagesOTC 5049 MS Paper PDFwizard120986No ratings yet

- C StructDesign Bendapudi Feb10 (1) Part 1Document0 pagesC StructDesign Bendapudi Feb10 (1) Part 1Rubén MenaNo ratings yet

- Design, Development and Testing of Electrically Isolated Helium Feeds For Forced Flow Cooled Super-Conducting Magnet at 4.5 KDocument8 pagesDesign, Development and Testing of Electrically Isolated Helium Feeds For Forced Flow Cooled Super-Conducting Magnet at 4.5 KVinit MhatreNo ratings yet

- Jpghrsghrb-905 (PWHT Procedure, Asme) Rev.0Document9 pagesJpghrsghrb-905 (PWHT Procedure, Asme) Rev.0Anoop N Kutty100% (1)

- API660 Heat ExchanerDocument2 pagesAPI660 Heat ExchanerTristan Irvin AsiNo ratings yet

- Ea 10 08Document16 pagesEa 10 08Armando_84No ratings yet

- Better Piping and Expansion Joint DesignDocument3 pagesBetter Piping and Expansion Joint DesignSeungmin PaekNo ratings yet

- Air Cooler Piping Stress Analysis Using Caesar IIDocument5 pagesAir Cooler Piping Stress Analysis Using Caesar IIsemin prsesNo ratings yet

- Expansion Joint Technical Specification and Data SheetDocument9 pagesExpansion Joint Technical Specification and Data SheetAhmad Dzulfiqar RahmanNo ratings yet

- Installation, Operating and Maintenance Instructions For Indeeco Electric Duct HeatersDocument2 pagesInstallation, Operating and Maintenance Instructions For Indeeco Electric Duct HeatersJed DavidNo ratings yet

- AN101 TO220 GuidelinesDocument4 pagesAN101 TO220 GuidelinesBayangan MautNo ratings yet

- Cabletrays Institute Technical Bulletin14Document5 pagesCabletrays Institute Technical Bulletin14MENELADONo ratings yet

- Construction Therm RefrigeratorDocument8 pagesConstruction Therm RefrigeratorKiran KumarNo ratings yet

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysFrom EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNo ratings yet

- Building RegulationsDocument2 pagesBuilding RegulationsMomtaz MoniNo ratings yet

- Cabletrays Institute Technical Bulletin9Document4 pagesCabletrays Institute Technical Bulletin9ahmodahNo ratings yet

- Cabletrays Institute Technical Bulletin7Document1 pageCabletrays Institute Technical Bulletin7ahmodahNo ratings yet

- EarthDocument9 pagesEarth0b0biyd,u,uNo ratings yet

- Chapter 5 Contents: 5 - Electrical Design 5 - 3 - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . .Document2 pagesChapter 5 Contents: 5 - Electrical Design 5 - 3 - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . .ahmodahNo ratings yet

- Letter Qena - Cairomatic PDFDocument1 pageLetter Qena - Cairomatic PDFIsmael KhalilNo ratings yet

- Fire Alarm DefinitionsDocument3 pagesFire Alarm DefinitionsMomtaz MoniNo ratings yet

- Cabletrays Institute Technical Bulletin14Document4 pagesCabletrays Institute Technical Bulletin14ahmodahNo ratings yet

- Cabletrays Institute Technical Bulletin4Document2 pagesCabletrays Institute Technical Bulletin4ahmodahNo ratings yet

- CCCof CCDocument1 pageCCCof CCDamodharan ChandranNo ratings yet

- Induction MotorDocument6 pagesInduction Motorbalaji1986No ratings yet

- Life Time - DR ShadyDocument1 pageLife Time - DR ShadyahmodahNo ratings yet

- Fuseology Bussmann PDFDocument3 pagesFuseology Bussmann PDFIsmael KhalilNo ratings yet

- Classificação IPDocument1 pageClassificação IPDanLorenaNo ratings yet

- Emergency Lighting DefinitionsDocument3 pagesEmergency Lighting DefinitionsMomtaz MoniNo ratings yet

- Prkglot Ped GraphicDocument1 pagePrkglot Ped GraphicahmodahNo ratings yet

- Abstract PDFDocument1 pageAbstract PDFIsmael KhalilNo ratings yet

- Cabletrays Institute Technical BulletinDocument3 pagesCabletrays Institute Technical BulletinahmodahNo ratings yet

- Field Tests: File: F-1 10/2/96Document2 pagesField Tests: File: F-1 10/2/96aljameelNo ratings yet

- Cabletrays Institute Technical Bulletin8Document2 pagesCabletrays Institute Technical Bulletin8ahmodahNo ratings yet

- Hot-Dip Galvanized vs. Aluminum: Design and InstallationDocument2 pagesHot-Dip Galvanized vs. Aluminum: Design and InstallationahmodahNo ratings yet

- Mains Lighting DefinitionsDocument3 pagesMains Lighting DefinitionsMomtaz Moni100% (1)

- Cabletrays Institute Technical Bulletin5Document2 pagesCabletrays Institute Technical Bulletin5ahmodahNo ratings yet

- 16670Document4 pages16670momtazaliNo ratings yet

- Cramolin Urethane Red (Lacquer) : Technical Data SheetDocument2 pagesCramolin Urethane Red (Lacquer) : Technical Data SheetahmodahNo ratings yet

- Inverter Battery Sizing FaqDocument2 pagesInverter Battery Sizing Faqmaven3No ratings yet

- Gland Chart For BS5308Document1 pageGland Chart For BS5308ahmodahNo ratings yet

- Cabletrays Institute Technical Bulletin3Document2 pagesCabletrays Institute Technical Bulletin3ahmodahNo ratings yet

- Distrbtn GraphicDocument1 pageDistrbtn GraphicahmodahNo ratings yet

- 5 PercentVoltageDropDocument2 pages5 PercentVoltageDropArafat BauntoNo ratings yet

- Joint Design For Concrete Structures - 4Document10 pagesJoint Design For Concrete Structures - 4tonyNo ratings yet

- Mold DesignDocument9 pagesMold DesignA MahmoodNo ratings yet

- Using Specialty Sand Blends To Reduce Veining DefectsDocument2 pagesUsing Specialty Sand Blends To Reduce Veining DefectsJohn VoNo ratings yet

- asset-v1-CornellX+ENGR2000X+2T2016+type@asset+block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Document42 pagesasset-v1-CornellX+ENGR2000X+2T2016+type@asset+block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Axel DominiqueNo ratings yet

- 3Document5 pages3Sifa RahmaniaNo ratings yet

- (Eng Total) Seungjin PDFDocument70 pages(Eng Total) Seungjin PDFDavidNo ratings yet

- Taller 1-2 PDFDocument3 pagesTaller 1-2 PDFSergio Raul DelgadoNo ratings yet

- Evaluation of Measurement Uncertainty in Volumetric Operations The Tolerance-Based Approach and The Actual Performance-Based ApproachDocument7 pagesEvaluation of Measurement Uncertainty in Volumetric Operations The Tolerance-Based Approach and The Actual Performance-Based Approachrtorrez79No ratings yet

- Astm E228-22Document10 pagesAstm E228-22zairaNo ratings yet

- Lectures 1 and 2 Temp SHC and ExpansionDocument23 pagesLectures 1 and 2 Temp SHC and ExpansionChrise RajNo ratings yet

- TylekI MechanicalProperties PDFDocument22 pagesTylekI MechanicalProperties PDFAldin AlicNo ratings yet

- Flat Glass System Gi Ard in ADocument32 pagesFlat Glass System Gi Ard in AvirkedNo ratings yet

- SP 00 01Document58 pagesSP 00 01alirezafalcon_793007No ratings yet

- Physics Past Paper Common Questions by Vasumitra Gajbhiye-2Document35 pagesPhysics Past Paper Common Questions by Vasumitra Gajbhiye-2anxietyNo ratings yet

- Heat PDFDocument20 pagesHeat PDFRaman GoyalNo ratings yet

- Volume DilatometryDocument12 pagesVolume DilatometryengroniyideNo ratings yet

- Sterling - JEE - Physics - (Elasticity Thermal Exp, Calorimetry & Heat Transfer) - EngDocument51 pagesSterling - JEE - Physics - (Elasticity Thermal Exp, Calorimetry & Heat Transfer) - EngRamJiPandeyNo ratings yet

- Policarbonat Celular Sunlite Ghid-TehnicDocument18 pagesPolicarbonat Celular Sunlite Ghid-TehnicVasile TomoiagaNo ratings yet

- Lecture 1 - Intro To CMT & Considerations in Material SelectionDocument41 pagesLecture 1 - Intro To CMT & Considerations in Material SelectionKier Lorenz FernandezNo ratings yet

- TR67 PDFDocument91 pagesTR67 PDFHemantha BalasuriyaNo ratings yet

- Chapter 7 Mechanical PropertiesDocument29 pagesChapter 7 Mechanical Propertiesapi-269630671No ratings yet

- Kullie StrainGageManualDigitalDocument67 pagesKullie StrainGageManualDigitalDizzixxNo ratings yet

- Advantages and Limitations of Ceramic Packaging Technologies in Harsh Applications.Document6 pagesAdvantages and Limitations of Ceramic Packaging Technologies in Harsh Applications.ALTHEA JANINE MACAPUNDAGNo ratings yet

- Ptfe Datasheet CurbellDocument1 pagePtfe Datasheet CurbellAbohicham AbhNo ratings yet

- Tigris Gas Manual en FinalDocument14 pagesTigris Gas Manual en FinalLuis13956353No ratings yet

- Acoustics in Plumbing Systems: Continuing Education From The American Society of Plumbing EngineersDocument18 pagesAcoustics in Plumbing Systems: Continuing Education From The American Society of Plumbing Engineersmech_sahilNo ratings yet

- 5.dental Waxes 14Document14 pages5.dental Waxes 14Chandra Babu0% (1)

- Advanced Piping Stress AnalysisDocument6 pagesAdvanced Piping Stress Analysisanurag7878100% (1)

- (A. Paul (Auth.) ) Chemistry of Glasses (B-Ok - Xyz) PDFDocument300 pages(A. Paul (Auth.) ) Chemistry of Glasses (B-Ok - Xyz) PDFLuciano100% (1)

- T3 - Fluid Mechanics - CH2Document24 pagesT3 - Fluid Mechanics - CH2roi constantineNo ratings yet