Professional Documents

Culture Documents

Is 10096-1-1 (1983)

Uploaded by

slamienkaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Is 10096-1-1 (1983)

Uploaded by

slamienkaCopyright:

Available Formats

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

1 +, 1 +

01 ' 5

The Right to Information, The Right to Live

Step Out From the Old to the New

Mazdoor Kisan Shakti Sangathan

Jawaharlal Nehru

IS 10096-1-1 (1983): Recommendations for inspection,

testing and maintenance of radial gates and rope drum

hoists, Part 1: Inspection, testing and assembly at the

manufacturing stage, Section 1: Gates [WRD 12: Hydraulic

Gates and Valves]

! $ ' +-

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

! > 0 B

BharthariNtiatakam

Knowledge is such a treasure which cannot be stolen

IS : 141096 ( Part IjSec I )

(per

1_

lUll)

Indian Standard

RECOMMENDAnONS FOR

INSPECTION; TESTING AND MAINTENANCE OF

RADIAL GATES AND THEIR HOISTS

PART I

INSPECTION, TESTING AND ASSEMBLY AT

THE MANUFACTURING STAGE

Section I Gates

( First Reprinl SEPTEMBER 1993 )

UDC

626.422.23:620.1

BUREAU

CoPY,i.(ht 1984

OF INDIAN STANDARD S

MANAK SHAVAN. 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

Grl

F,DnuJry

198+

IS : 10096 ( Part 1 Sec 1 ) - 1983

Indian Standard

RECOMMENDATIONS FOR

INSPECTION, TESTING AND MAINTENANCE OF

RADIAL GATES AND THEIR HOISTS

PART I

INSPECTION, TESTING AND ASSEMBLY AT

THE MANUFACTURING STAGE

Section I

Gates

Hydraulic Gates and Valves Ser-uona l Co mnutte, HI)C 5(,

RCj)rrJCntln~

Chauman

SliRI Y. ADlNAR"'Y\~'" S . . s-ent

Tunaabhadra Steel Produc rs Lmutcd.

Dam ( Karnataka )

Memhers

G. S. A~NJnEnI ( Alternatt to

Shri Y Aclmarayana SaMrI )

CRIEF ENGr ..... Elm ( TDO )

Irrrganon

'V()r"~.

COVl rrunc nt

Chandrgarli

Drunca-ou ( Mj E ) ( Alternate )

Sam R. C. CHOPRA

TEXM.\CO Ltd, Calcutta

TUlll;,ILlj.ttL,~

SURr

SRRC

R.

BH-\TT\CHAIl.YA

SHIn H. C. DHINGHA

SImI

R.

CHAUll-\N (

(Alternale)

Haravana State Mmor l rrrganon

Corporauon Ltd, Chandrgarh

of

J'IIOJ.d)

(Tl1be~\f'lIs,

Alternate)

DIRECTOR

SHRI A. V GOPALA KRISHNA

RAG ( Alternate)

DIREOTOR ( G~TES DEEHON I )

Central Water &

POWf'J

Research

Stanon.

Punt'

Central Water Comr.nssion. New D{1I11

SHRI C L. VERM.l. ( Alternate)

SERI R. N. GUPTA

Nangal Work~hop~) Nanga! Township

SaRI N. S CUAWL.\ (Alternate)

SaRI K. K. jULKA

Beas Project, Bhahr.\ nea~ ~LlnJgl ment Brant

Nanga l Township

SURI V. P KACSHAL (Alternate)

MANAGlNQ Dtuzc'ron

Tarru l Nadu Pubhc Worb Engmecrmg Corporation

Ltd, Madras

WOR'K~ MANAGER ( Alternate)

SaRI K V. S MURTHY

Tr ivern Structurals Ltd. N,UOl

SHRI1\-1 K. V. S ..'\RMA (Alternate)

( Co,.lllIlUd on

/>4c' 2')

IS) O>P)'rlghJ 19Bf

BUREAU OF INDIAN STANDARDS

This publication is protected under the ["dlAn Copynght Ad (XIV of (957) and

reproduction In whole or in part by any means except With written permisston of the

pubHshec shall be dumed to ~ an Infriogement of COP} rIght under the tald Act.

: 10096 ( Part If Sec I ) - 1983

( Cvnhnued fllllll

!Iflr:~

1

R'!ITeSenflllg

Irr iaauon Depar rmout. Government

Pr adcsh, Lucknow

Bhar.u Heavy Elec rrrcals Ltd, Bhopal

of

Uttar

SHf-1 R \J Kt-:..f .... ll

SI.HIN Y N,ll\SlMI1\..,(Alltrnale)

Suur S K S'lIll\!

JI'SSOP & Co Ltd, Calcutta

Suru S N \1, ( .1JI,molt)

l..,uPFfllN'rl':'J:'I\ '.::1'

l-..... (.INm;1l Irrrgation & PU\'\Ier Department, Government of

( PH I ( CDo )

Mohar eshua, Na<sik

Snur R ~\, vn urCentral Indra Machmer y Manufacturing Co Ltd,

Bh;,rarpul

";1I111 K C H \ 111"'\ Y ( A[lerltlllt )

Snm M. C "J, \\' \F'

Himachal Pradesh State Elccrnc ity Board, Simla

~Hl(':oJ VI...\A -, A! J( \:-1'

Nauona l

Hvdr oek ctrrc

Power

Corporation,

Nt'w ntJill

Smu G. R \),J \S,

Dn cc t or Genetal , lSI ( E.l.~OffiCiO Member)

Director ( elV Lngg )

.\certfar)1

Snur l-h,\1\NT Ku~rAll

A\sist.\nt Drrecror

Crv Engg ), lSI

Panel for Inspecuon, Testing and Maintenance of Radial Gates,

BDC 56: P8

CO'lt'rn~r

Suru M. 1\

~ll Hu.I \

Irrrganon works,

Charuhgarh

Government

of

Punjab,

J[embers

Tungabhadra Steel Products Ltd. Tungabhadra

D.im < Karn.'i:taka r

Central Water Ccmrmssron, New Delhi

N.mg ..d Workshops, Nangal Township

SHnJ G S ANNIl" HI

Dl1n~( TOil ( GA.'Il'>, DI':... tcxe I )

~11J1! R. N (;.t1I'j \

S'l!'l:,\ S Cn \\\L \ < .1ilernatc)

SHUI Y R K \\,It....

"'IWf

SIH

r '\

R "\i

Me

BSL

Project, Bhakta Bcas

'vundc magar ( H P. )

Management Board,

AGt:AI.\\ \L (Ahrnat~)

kHE/t lJ';I:

St'pnll.:s'r"<JIJ'f:

( G \ I! ... ) ( CDO )

R S\\ \ll\ P

SUHl

SHin!l.L C TrW,wI

E=.-.C:INl-:EIl,

J<"s,op Co Ltd, Calcutta

l rrig ation Department, Government of Maharashtra,

ltombav

Ce-ntra! India Machinery Manufacturmg Co Ltd,

Bh ..ratpur

HImachal Pradesh

Srate

Electrrcny

Board,

Government of Himachal Pradesh, SImla

AMENDMENT NO. I JANUARY 1993

TO

IS 10096 ( Part l/See 1) : 1983 RECOMMENDATIONS

FOR INSPECTION, TESTING AND MAINTENANCE OF

RADIAL GATES AND THEIR HOISTS

PART 1 INSPECTION, TESTING AND ASSEMBLY AT THE

MANUFACTURING STAGE

Section 1 Gates

( Cover page, page 1 lind page 3, tule ) THEIR'

Substuute 'ROPE DRUM' [or

(RVD 12)

Reprography URI I, BlS, New DeII1J..lodla

IS : 10096 ( Part I/Sec I ) 1983

Indian Standard

RECOMMENDATIONS FOR

INSPECTION, TESTING AND MAINTENANCE OF

RADIAL GATES AND THEIR HOISTS

PART'

INSPECTION. TESTING AND ASSEMBLY AT

THE MANUFACTURING STAGE

Section I

O.

Gates

FOREWORD

0.1 This Indian Standard (Part llSec I ) was adopted by the Indian

Standards Instituuon on 25 November 1083, after the draft finahzed by

the Hydraulic Gates and Valves Sectional Committee had been approved

by the Civil Engmeering Division Council.

0.2 The gates are used not only to pass large floods but also to ,egulate

the reservoir level during minor variations in flow. The gate, in general

is a structural steel frame consisting of end vertical girders with properly

spaced horizontal girder between them. The spacing depends on the

design water pressure and on dimensions of the gate. The frame is held

apiece by secure welding or riveting.

D.3 Reference to the following Indiafj Standards ,..;11 be found useful

lB

implementation of this standard:

IS: 210-1978 Grey iron castings (third retnsion )

IS : 226-1975 Structural steel ( standard quality) (fifth revision)

IS : 306-1968 Tin bronze ingots and castings ( second revision)

IS: 318-1981 Leaded tin bronze ingots and castings (second revlSlon)

IS: 823-1964 Code of procedure for manual metal arc welding of

mild steel

IS : 1030-1974 Carbon steel castings for general engineering purposes

( second revision )

IS : 1570-1961 Schedules for wrought steels for general engineering

purposes

3

IS : 10096 ( P"rt I/Sec I ) 1983

IS

2004-1 'l78 Carbon steel forgings for general engineering purposes

( second "VlSIon )

IS: 2062-1980 Structural isteel (fusion welding quality) (secona

tension )

IS : 25%-1978 Code of practice for

rmision )

radiographic testing (first

IS . 3648-l966 Hexagon fit bolts

IS: 3658-1981 Code of practice for liquid penetrant flaw detection

(first "visIon)

IS 3664-1'l81 Code of practice for ultrasonic pulse echo testing by

contact and Immersion methods (jirst remsion)

IS: 3703-1980 Code of practice for magnetic particle flaw detection

(first "v'SlOn )

IS

T.~

7307 (Part I )-1974 Approval tests for welding procedure"

Part I FUSIOn welding of steel

7~1O

( Part I )-1974 Approval testing of welders working to

pl {11(1(f procedures: Part I Fusion welding of steel

b . iJ18 ( Part I )-1 114 Approval tests for welders when welding

procedure approval is not required: Part I Fusion welding of steel

0.4 This standard is being pubhshed in three parts.

Part I deals with

mspec.tion, testing and. assembly at manufacturing stage, Part .2 deals

with inspection and tesnng at the time of erection, and Part 3 deals with

inspection, tesung and maintenance after erection.

0.4.1 Part ] i_ being published in two sections.

part

WIn

Other section of this

cover the hoists ( under preparation ).

0.5 For the purpose of deciding whether a particular requirement of this

srandar d

IS

exprc"sm~

complied with, the final value, observed or calculated,

the result of a test, shall be rounded off in accordance

WIth IS : 2-1960'. The number of significant places retained in the

rounded off value should be the same as that of the specified value in

rlus standard.

I. SCOPE

1.1 ThIS standard ( Part IISec I ) lay, down the recommendations for

mspection, tesnnc and assembly of radial gates at the manufacturing

stage.

It does not cover hoisting equipment.

"Rules for roundmg off numerical values ("vlSed).

IS : 10096 ( Part ItSec 1 ) 1983

2. GENERAL

2.1 All materials and components used for the work shall be new and

free from defects and subject to the tolerances specified under this

standard.

2.2 Complete inspection shall be made at the place of manufacture prior

to despatch.

3. MATERIALS

3.1 All materials and components supplied by the manufacturer shall

conform to the requirements of the latest relevant Indian Standards. In

the absence of Indian Standard for any particular material or component, other specification mutually agreed to between the purchaser and

the supplier may be used.

3.2 All materials used shall be of tested quality. Original manufacturer', test certificates for bought out Items such as castings, forgings and

seals, shall be furnished by the gate manufacturer to the purchaser on

demand.

3.3 Castings

3.3.1 All castings shall conform to the relevant Indian Standards.

3.3.2 Visual examination shall be done to find out the general

soundness of the castings and if required, non-destructive tests shaIl be

conducted on the castings.

3.3.3 Repairs of major defects in castings by welding shall not

generally be allowed, but if the strength aud machinability of the

casting can be ensured, the repairing may be undertaken with the

approval of the purchaser.

3.3.4 Defective castings as permitted under 3.3.3 shall be heat-treated

after repairs by welding, where deemed essential.

3.4 Forgings

3.4.1 All

Standards

forgings

shall conform to the latest relevant Indian

3.4.2 All forgings shall be suitably heat-treated according to relevant

Indian Standards

3.4.3 VISual inspection of forgings shall be done and the finished

surface shall be smooth and free from defects, If required, non-destrucrive tests shaIl be conducted on the forgings.

IS : 10096 ( Part 1;Sec 1 ) 1983

4. WELDING

4.1 All weldings shall conform to the relevant Indian Standards and

approved electrodes shall be used.

4.2 Welding procedure for all major welds shall be dr awn-up and cart red

out and if required by the purchaser, test pieces may be made to ensure

the soundness of the welding.

4.3 Only tested welders shall be employed for the welding work.

4.4 Visual exammation shall be carried out of all welded joints to ensure

that welding is free from:

a) cracks on the surfaces of the joints or parent metals located near

the heat affected zones,

b) undercuts in the parent metals,

c) non-uniform width of fillet joints,

d) misalignment and distortion

or the

welded member, and

e) irregular reinforcing beads of welds.

4.4.1 Welds found to be defective shall be subjected to non-destructive

tests to ensure soundness of welding.

4.5 Proper sequence of welding shall be followed for welding of heavy

structural parts in order to minimize distortion.

4.6 Defective welds after testing shall be removed and rewelded.

4.7 All major stress carrying welded joints shall be subjected to suitable

non-destructive testing, as specified by the purchaser.

4.8 Any item or part may be stress- relieved according to the requirements and procedure laid down in IS : 28251969*. Generally following

items require stress-relieving.

a) Yoke/trunnion girders, anchor girders and trunnion brackets

where heavy welding is involved; and

b) Trunnion hub if part of the arm ( structural portion) is welded

to the casting.

5. MANUFACTURING TOLERANCES

5.1 The gates and embedded parts shall be manufactured to such

accuracy and tolerances as are required for the safe and efficient operation of the gates. Unless otherwise specified, the tolerances given in 5.2

and 5.3 may be used as a general guide.

Code for unfired pressure vessels.

IS : 10096 ( Part IjSec 1 ) 1983

5.2 Embedded Parts

5.2.1 Deviation of any point on the face of seal seat from 2 m machined

straight edge held against it shall not exceed 0'5 rnrn.

5.2.2 Deviation from straightness of the wall plate shall not be more

than 2 mm in 2 metre length.

5.2.3 Offsets and gaps at any adjoining joints between seal :seats,

guides, etc, shall not exceed 0'5 mm.

5.3 Gates

5.3.1 The gate leaves with stiffeners shall generally be manufactured On

a jIg and fixture.

of radius or

The tolerance on the radius of gate leaf shall be I

r:oo

lO mm whichever is less.

5.3.2 The drsta nce between the side guide rollerjguide shoes on one

side of the gate to the corresponding guide roller/guide shoes on the other

side shall not vary from dimension shown in the drawing' by more than

0'00 mm to - 2'00 mm.

5.3.3 Parallel distance of centre line of both the trunnion bearings

from upstream bottom edge of skin plate shall not vary more than

3'0 mm,

5.3.4 The horizontal distance between the centre to centre of trunnions

shall not vary from the dimension shown in the drawings by more than

3'0 mm.

5.4 Connections -- At all sphces, the holes shall be match drilled.

fit bolts are provided, holes shall be reamed at assembly.

If

6. SHOP ASSEMBLY AND TESTING

6.1 Gates and Embedded Parts -

The anchor girder together with

the tre bars of convenient length for testing and yoke girder shall be loadtested equivalent to 1'5 times the design load before erection. The load

shall be applied gl adually by means of hydraulic Jacks and the assembly

shall remain under load to enable all the observations required by the

test procedure to be made.

6.1.1 Assembly of wall plates and sill beams shall be done at shop.

6.1.2 Gates shall be assembled complete WIth guide rollers and trunnions for proper alignrnenr and inspection. AU the dimensions specified

in 5.2 and 5.3 and other central dimensions shall be checked on

assembly.

IS 10096 ( Part l{Sec 1 ) - 1983

6.1.3 Side guide rollers may be shnnrncd , if necessary, to maintain the

required tolerances as specified in 5.3.2.

6.2 Seals - Seals may be assembled either at shop or during erection

according to the convenience of the manufacturer. The holes in sea"

shall be match drilled with seals base and clamps.

6.3 Ballast - Ballast if required, can be provided either at shop or at

site.

6.4 Marking

6.4.1 All erection marks shall be hard-punched.

6.4.2 All the components shall be match-marked before dismanthng.

7. CLEANING AND PAINTING

7.1 Surface 'hall be cleaned thoroughly, preferably by sand.shot blasting.

7.2 Painting shall be as specified by the purchaser and the application

procedure shall be as recommended by the paint manu facturer

BUREAU

OF

INDIAN

STANDARDS

HHdqua,tan :

M....... Bhavan. 9 Bahodur Sh.h Zalar Marg. NEW DELHI 110002

ralepho_ : 331 01 31

T.legraml : ManakunSlllI

331 13 76

(Common 10 all 01f1C88)

RallionalOfficN:

ra/aphon.

Central

. M.nak Bhavan. 9. Bahadur Shah Zalar Marg

l331 01 31

NEw DELHI 110002

l3311376

Eastern

: 1114C.I.T. SchameVII M.

st 88 82

V.I.P. Road. Manlklola. CALCUTIA 700064

21843

Nanharn

: seo 445-446. Sector 35-C. CHANDIGARH 160036

41 2918

Soulhern . C.I.T. Campu IV Cross Road. MADRAS 600113

8329295

tWeotern

: Manakalaya. E9 MIDC. Marol, Andha" (East).

BOMBAY 400093

B,anch Offica. :

28348

Puahpak. Nurmohamad ShaIkh Marg. Khanpur. AHMADABAD 380001

39 49 66

P.."ya Indus'nal Araa. 1st Stage. Bangalo,e-Tumkur Road.

BANGALORE 560068

554021

Gango'" Complex. 51A Floor. Bhldbhada Road. T.T. Nagar.

BHOPAL 462003

53827

Plo, No. 82/83.

Road. BHUBANESHWAR 751002

Kala, K.lhir BUIldIng. 6/48-A Avana.. Road. COIMBATORE 641037

28705

Quality Mark'ng Canlre. N.H. IV. NI.T-, FARIDA8AD 121001

8-71 1998

Sovltrl Complex. 116 G. T. Road. GHAZIABAD 201001

33177

63/6 Ward No. 29. R.G. BaNa Road. 61h Bylana.

GUWAHA TI 781003

231083

6-8-66C L. N. Gup,a Ma,g. ( Nampally S'allon Road)

HYDERABAD 500001

R14 Yudhos'a, Marg. C Scheme. JAIPUR 302005

83471

21 8B 78

117/418 B Sarvodayl Nagar. KANPUR 208005

55507

Pial No A-9. Hauss No 561/63, Sindhu Nagar. Kanpur Roao.

LUCKNOW 226005

62306

Pethpuna Industrial Estate, PATNA 800013

District Industries Centre Complsx. Bagh-e-All Mlldan.

SRINAGAR 190011

82104

T. C. No 14(1421. umver.. ty P. D.. Palavam.

THIRUVANANTHAPURAM 695034

In.paction Office. (With Sala Pomt)

52 51 71

PUlhpan,alr, Forll Floor. 206A Wesl H,gh Court Road

Shankar Naga, Square. NAGPUR 440010

52435

Insututlon of Engineers (India) Buildll"g. 1332 Shlvall Naga,.

PUNE 411006

Lew'"

'Sala. OffICe Calcutta II a, 6 Chownnghae Approach.

P. O. Pnncep Sir..t, CALCUTIA

t Sales Off,ce I. at Nov.lty Chambars. Granl Road. 80MBAY

J:

$lIes

ena

II

at Unity BUilding, NaraslmharsJ8 Square.

276800

898528

223971

BANGALORE

Reprography Unit, 8IS. New Delhi, India

You might also like

- Beginning Android DevelopmentDocument721 pagesBeginning Android DevelopmentNikola Johnny Popadic67% (3)

- Is 10028 3 1981Document27 pagesIs 10028 3 1981sasikumarNo ratings yet

- Maximum Pressure Rating Schedule 160, Schedule 40 and Schedule 80 - Engineers EdgeDocument5 pagesMaximum Pressure Rating Schedule 160, Schedule 40 and Schedule 80 - Engineers EdgeDevanshu KrNo ratings yet

- Organic Rankine CycleDocument11 pagesOrganic Rankine CycleslamienkaNo ratings yet

- Is 15466 (2004)Document16 pagesIs 15466 (2004)slamienkaNo ratings yet

- Selden Keel Boat v1 LmarineriggingDocument72 pagesSelden Keel Boat v1 LmarinerigginglmarinegroupNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Is 4736 1986Document15 pagesIs 4736 1986Vineeth BalakrishnanNo ratings yet

- Bms & Hvac SystemDocument41 pagesBms & Hvac SystemHirushan Menuka100% (2)

- Slide Gate Indian CodeDocument26 pagesSlide Gate Indian CodeRolando Alvarado100% (1)

- Is.9921.2.1982 IsolatorsDocument30 pagesIs.9921.2.1982 IsolatorspramitbaulNo ratings yet

- Mosquito RepellentDocument6 pagesMosquito RepellentJai MurugeshNo ratings yet

- Is 2974 1 1982Document27 pagesIs 2974 1 1982ersivarajNo ratings yet

- Visualization of Cavitation in Water TurbinesDocument10 pagesVisualization of Cavitation in Water TurbinesslamienkaNo ratings yet

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysFrom EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysRating: 1 out of 5 stars1/5 (1)

- Failure Analysis in Engineering ApplicationsFrom EverandFailure Analysis in Engineering ApplicationsRating: 1 out of 5 stars1/5 (1)

- Rcs454: Python Language Programming LAB: Write A Python Program ToDocument39 pagesRcs454: Python Language Programming LAB: Write A Python Program ToShikha AryaNo ratings yet

- CODE OF PRACrrICE FOR DESIGN AND CONSTRUCTION OF MACHINE FOUNDATIONS PART II FOUNDATIONS FOR IMPACT TYPE MACHINES (HAMMER FOUNDATIONS)Document21 pagesCODE OF PRACrrICE FOR DESIGN AND CONSTRUCTION OF MACHINE FOUNDATIONS PART II FOUNDATIONS FOR IMPACT TYPE MACHINES (HAMMER FOUNDATIONS)Mohamed MamdohNo ratings yet

- Is 1838 1 1983 PDFDocument14 pagesIs 1838 1 1983 PDFrgscribd61No ratings yet

- Boiler FormulasDocument5 pagesBoiler FormulasAnonymous 6Mb7PZjNo ratings yet

- Applied Metrology for Manufacturing EngineeringFrom EverandApplied Metrology for Manufacturing EngineeringRating: 5 out of 5 stars5/5 (1)

- Hager Protection Devices TechnicalDocument70 pagesHager Protection Devices TechnicalerreagaaNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Young, A.D. - Boundary LayersDocument146 pagesYoung, A.D. - Boundary Layersslamienka67% (3)

- Is 10096-2 (1983)Document17 pagesIs 10096-2 (1983)slamienkaNo ratings yet

- Disclosure To Promote The Right To InformationDocument15 pagesDisclosure To Promote The Right To InformationgovimanoNo ratings yet

- Disclosure To Promote The Right To InformationDocument59 pagesDisclosure To Promote The Right To InformationDebarati BhattacharjeeNo ratings yet

- Disclosure To Promote The Right To InformationDocument20 pagesDisclosure To Promote The Right To InformationSanje1024No ratings yet

- Disclosure To Promote The Right To InformationDocument14 pagesDisclosure To Promote The Right To InformationgovimanoNo ratings yet

- Disclosure To Promote The Right To InformationDocument27 pagesDisclosure To Promote The Right To InformationgovimanoNo ratings yet

- 6280Document13 pages6280sanbarunNo ratings yet

- Is 818 Code of Practice For Safety and Health For Welding and Gas CuttingDocument50 pagesIs 818 Code of Practice For Safety and Health For Welding and Gas CuttingPULSEMURALI100% (3)

- Disclosure To Promote The Right To InformationDocument21 pagesDisclosure To Promote The Right To InformationJaisree Balu PydiNo ratings yet

- Indian Standard: Rules For Rounding Off Numerical ValuesDocument18 pagesIndian Standard: Rules For Rounding Off Numerical ValuesSumeet PrajapatiNo ratings yet

- IS 460 Part 1Document19 pagesIS 460 Part 1Muhammed NoufalNo ratings yet

- Indian Standard: Recommended Practice Straight Beam Ultrasonic of Steel Plates (FOR TestingDocument10 pagesIndian Standard: Recommended Practice Straight Beam Ultrasonic of Steel Plates (FOR TestingAMITaXWINo ratings yet

- IS 802 Part-2:1978Document13 pagesIS 802 Part-2:1978Sardar. Vikramjit Singh RandhawaNo ratings yet

- Conduit SpecificationDocument22 pagesConduit Specificationamijetomar08No ratings yet

- Indian Standard: Recommendations For Inspection, Testing and Maintenance of Radial Gates and Rope Drum HoistsDocument10 pagesIndian Standard: Recommendations For Inspection, Testing and Maintenance of Radial Gates and Rope Drum HoistsRAMESH PANDARINo ratings yet

- 4853 1982Document20 pages4853 1982govimanoNo ratings yet

- Is 802 Part-III Code of Practice Use of Structural Steel I.183132521Document10 pagesIs 802 Part-III Code of Practice Use of Structural Steel I.183132521Kapil VatsNo ratings yet

- Is 2386 4 1963Document37 pagesIs 2386 4 1963mssantNo ratings yet

- Is 7332 1 1991Document15 pagesIs 7332 1 1991NitinNo ratings yet

- Is 7332 1 1991Document15 pagesIs 7332 1 1991chhetrim21No ratings yet

- Is 2720.8.1983Document14 pagesIs 2720.8.1983Elumalai Srinivasan100% (2)

- Disclosure To Promote The Right To InformationDocument13 pagesDisclosure To Promote The Right To InformationVijayKatariaNo ratings yet

- Is 9259 1979 PDFDocument15 pagesIs 9259 1979 PDFsagarNo ratings yet

- Reaffirmed 1995Document10 pagesReaffirmed 1995mondianeerajNo ratings yet

- Is 9295 - 2002 - Steel Tubes For Idlers For Belt ConveyorsDocument14 pagesIs 9295 - 2002 - Steel Tubes For Idlers For Belt ConveyorsavijayakumarsamyNo ratings yet

- Is 2720 Part-13 Methods of Test For Soils Direct Shear Te.182160738Document14 pagesIs 2720 Part-13 Methods of Test For Soils Direct Shear Te.182160738Vinod JogurNo ratings yet

- Indian Standard: Specification For Bridge Insulations Testers (Magneto Generator Type)Document17 pagesIndian Standard: Specification For Bridge Insulations Testers (Magneto Generator Type)Frank StephensNo ratings yet

- 2016 - Plain Washer PDFDocument16 pages2016 - Plain Washer PDFNagesh Chopade100% (2)

- Is 432 2 1982 PDFDocument14 pagesIs 432 2 1982 PDFAnil Daniel HansNo ratings yet

- Is.1598.1977 IzodDocument16 pagesIs.1598.1977 Izodbhavin178No ratings yet

- Disclosure To Promote The Right To InformationDocument26 pagesDisclosure To Promote The Right To InformationgovimanoNo ratings yet

- IS4736.1986 - Galvanizing On Tubes PDFDocument15 pagesIS4736.1986 - Galvanizing On Tubes PDFdombipin100% (1)

- 1200 - Part 7 - Measurement of Bldgs & Civil Engg WoDocument8 pages1200 - Part 7 - Measurement of Bldgs & Civil Engg WoSenthil KumarNo ratings yet

- Is 9459Document13 pagesIs 9459Anonymous mcHqIfbnV1No ratings yet

- Disclosure To Promote The Right To InformationDocument22 pagesDisclosure To Promote The Right To InformationSandeep ReddyNo ratings yet

- Disclosure To Promote The Right To InformationDocument23 pagesDisclosure To Promote The Right To InformationjamilvoraNo ratings yet

- Disclosure To Promote The Right To InformationDocument16 pagesDisclosure To Promote The Right To InformationCristian WalkerNo ratings yet

- Is 7326-3 (1976)Document11 pagesIs 7326-3 (1976)slamienkaNo ratings yet

- Is 8081 Specification For Slotted SectionsDocument16 pagesIs 8081 Specification For Slotted Sectionsbantyrock9671No ratings yet

- Disclosure To Promote The Right To InformationDocument31 pagesDisclosure To Promote The Right To InformationEr Chandra BoseNo ratings yet

- Reaffirmed 1997Document18 pagesReaffirmed 1997Prachita RautNo ratings yet

- Automation in Mining, Mineral and Metal Processing: Proceedings of The 3Rd Ifac Symposium, Montreal, Canada 18-20 August 1980From EverandAutomation in Mining, Mineral and Metal Processing: Proceedings of The 3Rd Ifac Symposium, Montreal, Canada 18-20 August 1980J. O'SheaNo ratings yet

- WWW - Ckdblansko.cz: Creative Blue PowerDocument10 pagesWWW - Ckdblansko.cz: Creative Blue PowerslamienkaNo ratings yet

- Design of A Small Hydro Kaplan Turbine With A Self-Sealing RotorDocument36 pagesDesign of A Small Hydro Kaplan Turbine With A Self-Sealing RotorslamienkaNo ratings yet

- Energies 07 07067Document27 pagesEnergies 07 07067Roozbeh PNo ratings yet

- Cavitation of Hydraulic MachineryDocument26 pagesCavitation of Hydraulic Machineryslamienka0% (1)

- Solving The Unit Commitment Problem of Hydropower Plants... (01v24n3)Document25 pagesSolving The Unit Commitment Problem of Hydropower Plants... (01v24n3)slamienkaNo ratings yet

- Is 13041 (1991)Document9 pagesIs 13041 (1991)slamienkaNo ratings yet

- Is 13591 1992 PDFDocument13 pagesIs 13591 1992 PDFslamienkaNo ratings yet

- Wind Tunnel Measurements of Low Speed ... 3608Document59 pagesWind Tunnel Measurements of Low Speed ... 3608slamienkaNo ratings yet

- Is 11793 (1986)Document26 pagesIs 11793 (1986)slamienkaNo ratings yet

- Is 14177 1994Document11 pagesIs 14177 1994Subhash SharmaNo ratings yet

- CFD and CAD in Ship DesignDocument57 pagesCFD and CAD in Ship DesignslamienkaNo ratings yet

- Is 13623 (1993)Document9 pagesIs 13623 (1993)slamienkaNo ratings yet

- Is 10210 1993Document19 pagesIs 10210 1993AMIAMINo ratings yet

- Is 7326-3 (1976)Document11 pagesIs 7326-3 (1976)slamienkaNo ratings yet

- Is 11855 (2004)Document11 pagesIs 11855 (2004)slamienkaNo ratings yet

- Is 10096-3 (2002)Document13 pagesIs 10096-3 (2002)slamienkaNo ratings yet

- Is 7332 1 1991 PDFDocument15 pagesIs 7332 1 1991 PDFslamienkaNo ratings yet

- Is 11228 1985Document20 pagesIs 11228 1985teklador123456No ratings yet

- Is 10021 (2000)Document13 pagesIs 10021 (2000)slamienkaNo ratings yet

- Is 7718 (1991)Document14 pagesIs 7718 (1991)slamienka100% (1)

- Is 7326-2 (1992)Document9 pagesIs 7326-2 (1992)slamienkaNo ratings yet

- Is 7332-3 (1994)Document9 pagesIs 7332-3 (1994)slamienkaNo ratings yet

- Naval Arch - Incline TestDocument11 pagesNaval Arch - Incline TestDheerajKaushalNo ratings yet

- Slump and Compacting Factor Test Values and Uses in Concrete WorkabilityDocument2 pagesSlump and Compacting Factor Test Values and Uses in Concrete WorkabilityNick GeneseNo ratings yet

- Actividad 5 TermodinamicaDocument4 pagesActividad 5 TermodinamicaAngel EncastinNo ratings yet

- Multiple Stiffened Cold-Formed Steel Profiles For Cylindrical Vault Roofing SystemsDocument24 pagesMultiple Stiffened Cold-Formed Steel Profiles For Cylindrical Vault Roofing SystemsTiago LopesNo ratings yet

- Monarch Industrial Products (I) Pvt. Ltd. Decorative Floor Toppings Supply Order Price ListDocument1 pageMonarch Industrial Products (I) Pvt. Ltd. Decorative Floor Toppings Supply Order Price ListgangadevimgmNo ratings yet

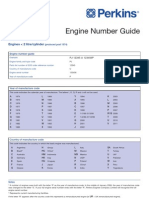

- Perkins Engine Number Guide PP827Document6 pagesPerkins Engine Number Guide PP827Muthu Manikandan100% (1)

- Efecto de La Temperatura Del Hipoclorito de SodioDocument4 pagesEfecto de La Temperatura Del Hipoclorito de SodioMarriano DarinoNo ratings yet

- Prescolite Akt4 WH Specsheet 13Document2 pagesPrescolite Akt4 WH Specsheet 13James HohensteinNo ratings yet

- Industrial Hose Products - DAYCODocument200 pagesIndustrial Hose Products - DAYCOHebert CcahuanaNo ratings yet

- Ccsviiid1 2029-3Document2 pagesCcsviiid1 2029-3DieguitoOmarMoralesNo ratings yet

- Silent Sound TechnologyDocument22 pagesSilent Sound TechnologyPurnima K100% (2)

- Main Engine Fuel Pump Drive Roller Damage: Return To TOCDocument2 pagesMain Engine Fuel Pump Drive Roller Damage: Return To TOCTunaNo ratings yet

- Unit One: Wind LoadsDocument67 pagesUnit One: Wind Loadsabdu yimerNo ratings yet

- Um String Code 2 0 eDocument46 pagesUm String Code 2 0 ehydrasearchNo ratings yet

- Physics 110A: Electromagnetism: 1 Introduction and OverviewDocument4 pagesPhysics 110A: Electromagnetism: 1 Introduction and OverviewJoshua LinNo ratings yet

- Everyday Vocabulary Telephone TestDocument3 pagesEveryday Vocabulary Telephone TestzdravkamajkicNo ratings yet

- Lars Part Ix - Safety Managment System Requirements-SmsDocument24 pagesLars Part Ix - Safety Managment System Requirements-SmssebastienNo ratings yet

- Solar Mosquito DestroyerDocument2 pagesSolar Mosquito DestroyerNIKITA KANGRALKARNo ratings yet

- Frame RelayDocument33 pagesFrame RelayDilsha AshrafNo ratings yet

- Bulb Flat Sizes, Dimensions and Weight - Steel Bulb Flats - Weight Table - Rushmore Enterprises IncDocument3 pagesBulb Flat Sizes, Dimensions and Weight - Steel Bulb Flats - Weight Table - Rushmore Enterprises IncHerlambang Miracle YudhianNo ratings yet

- Emergency Braking SystemDocument4 pagesEmergency Braking Systemieee4mybusinessonlyNo ratings yet

- P28 and P128 Series Lube Oil Controls With Built-In Time Delay RelayDocument8 pagesP28 and P128 Series Lube Oil Controls With Built-In Time Delay RelayFreddy de los SantosNo ratings yet