Professional Documents

Culture Documents

Reiners Et Al. - 1994 - Decorative Optical Coatings

Uploaded by

chinuuu85brCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reiners Et Al. - 1994 - Decorative Optical Coatings

Uploaded by

chinuuu85brCopyright:

Available Formats

ELSEVIER

Thin Solid Films 253 (1994) 33 40

Decorative optical coatings

Georg Reiners a, Uwe Beck a, H e r m a n n A. Jehn b

aBAM (Bundesanstalt fiir Materialforsehung und-priifung), Unter den Eiehen 87, D-12200 Berlin, Germany

bForschungsinstitut fiir Edelmetalle und Metallehemie (FEM), Katharinenstrafle 17, D- 73525 Sehwiibisch-Gmiind, Germany

Abstract

The paper gives a survey of current research on decorative coatings. In the first part the main deposition techniques as well as

characterization techniques are discussed. The paper is restricted to decorative physically vapor deposited hard coatings with

electrochemically deposited barrier coatings. The influence of stoichiometry, structure, and surface roughness on the colour of

physically vapor deposited hard coatings is reviewed. In the last decades, a number of different coating deposition techniques have

been developed. The demand for environmental compatibility of low cost large-scale production techniques has resulted in the

development of combinations of physical vapor deposition and electroplating. Coating systems have been developed using NiPd

and CuSn(Zn) instead of Ni electroplated coatings as interlayers, strongly reducing the allergy risk. New industrial applications

demonstrate the increasing economic importance of decorative hard coatings.

Keywords: Nitrides; Optical properties; Physical vapour deposition; Structural properties

I. Introduction

Decorative coatings have a long tradition in jewellery, ritual objects and even objects of daily life. For

hundreds of years, for example, leaf gold has been used

to decorate works of art. In 1840, the first gold plating

made by electrochemical deposition (ECD) was produced [1]. The function of decorative coatings is

not restricted to giving a desired colour to the surface.

In many cases, the coating also has to protect the

substrate material against wear and/or corrosion. Normally, the substrate material takes over the "mechanical" function. By use of decorative coatings, expensive

substrate materials and/or expensive production techniques (e.g. machining of hard bulk materials) can be

substituted.

A number of different coating deposition techniques

have been developed: painting, anodizing, electroplating (ECD), diffusion coating, thermal spraying,

enamel coating, chemical and physical vapor deposition

(CVD and PVD). The present paper, however, is restricted to decorative hard coatings deposited by PVD

techniques.

The colour of PVD thin films, as many other properties, often differs from that of the bulk material because

the colour is mainly determined by the band structure

0040-6090/94/$7.00 1994 - - Elsevier Science S.A. All rights reserved

SSDI 0 0 4 0 - 6 0 9 0 ( 9 4 ) 0 4 6 5 7 - R

of the deposited layer which depends on both the

chemical composition and the crystal structure of the

film. The structure of PVD coatings can differ strongly

from that of undisturbed bulk structure depending on

the deposition technique and the substrate material.

Transition metal compounds, e.g. oxides, nitrides and

carbides, find increasing use as decorative coatings

combining intensive colours, high wear resistance and

good corrosion resistance [2-13]. The colour variation

of simple compounds such as the golden TiN and dark

gray TiC is limited. Oxidizing, nitriding and carburizing

of binary alloys or the addition of a second metalloid,

however, widen the spectrum of colours for decorative

applications. A typical example is (Ti, A1)N, changing

from silvery to gold and dark blue colour depending on

the A1 and N content [14].

PVD coatings are often combined with ECD coatings,

especially if cheap materials are used for jewellery parts,

watch cases and other objects of everyday life. In these

cases the electroplated layers mainly act as corrosionresistant interlayers because PVD films are not completely defect free and corrosive media can come in

contact with the substrate material. In addition, surface

leveling and special gloss effects can be obtained by the

deposition parameters of the ECD process. Conventional electroplated barrier layers are mostly based on

34

G. Reiners et al. / Thin Solid Films, 253 (1994) 33 40

Ni which are now having to be replaced because of

their allergy risk.

The first part of this paper deals with fundamentals

of colour generation and changes in colour along with

characterization techniques needed to study the correlation between color and other properties of the coatings.

The second part gives a comprehensive report of current research activities and recent applications of decorative hard coatings.

2. Economic aspects of decorative coatings

For many products, the design and finish fix the price

whereas the function is taken for granted. Colour is a

constitutive element of decorative design. Examples are

watches (watch cases). Even low-price watches show the

exact time with high accuracy but the prices of watches

differ by at least two orders of magnitude. Estimations

[15] show that the world market for thin film products

is about 32 billion US$ per year, decorative thin film

products contributing about 0.75 billion US$ per year.

Decorative parts are attacked in a very complex way

by wear and corrosion simultaneously. Again watches

are taken as an example. They combine all the tribological mechanisms which are typical of decorative coatings [16]. Hence, in addition to their decorative

functions, PVD coatings have to fulfil a wide range of

demands: good adhesion and resistance to wear and

corrosion as well as mechanical and chemical compatibility with the substrates or interlayers. Additionally,

reproducible deposition with respect to the decorative

properties of the coated parts is a prerequisite for any

successful application. The well known high sensitivity

of the human eye requires sensitive characterization

techniques for production quality control. Nevertheless,

the most important point is the price.

3. Deposition techniques of decorative coatings

In general, various techniques for the deposition of

decorative coatings are used in industry. In this paper,

we restrict ourselves to PVD coatings and the combination of PVD and ECD techniques for the deposition to

wear resistant coatings onto metallic substrates.

ECD coatings include noble metals (Au, Au alloys,

Pt, Ag, etc.), metals (e.g. Cr, Ni, Cu), and some binary

alloys (e.g. CuZn, CuSn, etc.). The surface roughness

can be reduced by ECD coatings. The wear resistance

of ECD coatings is sufficient for many applications and

the corrosion resistance is high in most cases. The

typical ECD coating thickness is more than 10 ~tm. The

deposition rates are much higher than 1 ~tm h-l.

The PVD technique has numerous possibilities for the

deposition of noble and other metals, binary, ternary

and multicomponent metal alloys, and especially reactively deposited hard coatings (nitrides, carbides, carbonitrides such as TiN, (Ti, A1)N, etc.). The roughness

of PVD coatings is normally the same as the roughness

of the substrate or greater. The corrosion resistance of

hard coatings is limited because of pin-holes in the

coating, whereas the wear resistance is extremely high.

The typical PVD coating thickness ranges between 1 and

5 ~tm. The deposition rates are often of the order of

1-5 ~tm h i. A more detailed comparison of ECD and

PVD coatings is given in Ref. [17].

A comparison of the properties of coatings deposited

by ECD and PVD has, for example, been made for gold

alloys [18] or ECD hard chrome and PVD CrN [19].

Comparison of different PVD techniques, however,

showed only slight differences with respect to colour

and gloss [20]. Combination of these techniques widens

the field of application for decorative purposes [21 23].

4. Colour

Colour and gloss are the most important properties

of decorative parts and hence also of decorative coatings. The visual perception of colour is well described

by the CIE L*a*b* coordinates L*, a* and b* [24],

which allow better quantification of colour differences

as perceived. The parameters are the lightness L*

(black = 0 , white = I00), the red-green value a* and

the yellow-blue value b* (a*, b * = 0-100).

4. I. Colours ~[ bulk materials

Illuminated by white light a material can generate

colors by dispersion (prisms), interference (filter),

diffraction (grids), scattering (granules), or absorption

(atomic, molecular, solids). For decorative hard coatings the generation of colour is restricted to absorption,

i.e. the response of matter to the incident light. In order

to obtain coloured coatings the colors of bulk materials

can be considered. Some natural colours are given in

Table 1 together with the substances. The composition

of the Swiss gold standards, which are important for

decorative applications, are given in Table 2.

Additional information on nitrides, carbides, and

borides can be found in Ref. [18] and Refs. [25] and

[26]. Colour standards used to calibrate colour measuring equipment can be found in Ref. [27].

Bulk colours generated by absorption processes (e.g.

pigments in a dispersed state) depend on the crystal

structure and the chemical composition of the compound. These dependences are the reason why standard

materials are unsuccessful as PVD coatings. PVD hard

coatings are highly disordered microcrystalline thin

films. Their electronic properties differ from the bulk

values and consequently the colour differs too.

35

G. Reiners et al. / Thin Solid Films, 253 (1994) 33-40

Table 1

Colours of bulk materials [16]

Common

name

Base

Addition

Colour

Ruby

Ruby

Ruby

Sapphire

Sapphire

Sapphire

Topaz

AI203

AI203

AI203

AI203

A1203

AI203

A1203

A1203

A1203

AI203

TiO 2

TiO 2

TiO 2

TiO 2

TiO 2

2"/0_3% Cr2O3

Scarlet

Pink

Blue

Violet

Blue

Yellow

Gold

Sky blue

Marine blue

Blue violet

White

Lantern red

Yellow

Blue

Canary

0.01%-0.5% Cr203

2%-3% V203

0.5% TiO 2 + 1.5% Fe203 + 0.1% Cr203

0.5% TiO 2 + 1.5% Fe203

0.5%- 1% NiO

0.5% NiO + 0.01%-0.05% Cr203

MgO + 0.1%-0.5% CoO

MgO + 0.5%-1% CoO

MgO + 1.5% CoO

0.5% Cr203

0.01% Cr203

1.5% Fe203

0.05% NiO

Table 2

Swiss gold standards (ISO 8654)

ISO notation

ON

1N

2N

3N

4N

5N

Composition (atoms per 1000)

Au

Ag

Cu

585

585

750

750

750

750

300-340

240-265

150-160

120-130

85-95

45-55

Rest

Rest

Rest

Rest

Rest

Rest

Colour

Yellow green

Pale yellow

Bright yellow

Yellow

Ros6

Red

Absorption-flee interference layers generate colours

on a highly reflecting substrate according to the length

of the optical path within the layer. Consequently, the

impression of colour depends on the angle of view.

Multilayers may reduce this dependence.

The colours of hard coatings presently produced by

PVD techniques on an industrial scale are summarized

in Table 3 together with typical hardness values. A

more detailed collection of thin film colours prepared

on a laboratory scale can be found in Ref. [31].

The colours depend additionally on the stoichiometry

and the roughness of the substrate and thin film as well

as the coating thickness [32].

4.2. Colours of thin films

5. Characterization techniques

In general, there are two possible ways of varying the

colour of thin films, i.e. changes in structure and stoichiometry which both influence the electronic structure

of the deposited film resulting in changes in the selective

absorption. Consequently, a shift in the optical gap

results in changes in reflectivity over the visible wavelength range. TiN is an example of stoichiometric dominated colour generation [14, 28] whereas ZrN is an

example of microstructure dominated colour changes

[29, 30]. A very straightforward common example of

the exclusive influence of structure on colour is graphite

and diamond layers.

In principal one has also to consider second order of

magnitude effects for colour changes: surface and volume scattering. This is all the more important for

semitransparent coatings (e.g. Ti inclusions in TiO2 on

a highly reflecting substrate). According to the penetration depth of the incident light wave, the fraction of

surface to volume scattering changes or even in-layer

reflection takes place.

Research into the correlation between colour, stoichiometry and the crystal structure of decorative PVD

coatings requires the typical spectrum of techniques to

chatacterize, in addition to colour, the composition

(glow discharge optical spectroscopy GDOS, Auger

electron spectroscopy AES, electron spectroscopy for

chemical analysis ESCA) structure (X-ray diffraction

XRD), hardness (universal hardness test), adhesion

(scratch test, bending tests) and roughness. Testing of

the corrosion and wear behavior of decorative coated

components requires adapted test conditions which take

into account the specific tribological and corrosion

conditions of the used component. Again, watches are a

good example. All types of wear and corrosion attack

take place. For industrial and laboratory wear and

corrosion test for decorative coatings see for example

Refs. [33, 34].

The optical properties are usually measured by three

techniques to verify the impression of colour both

36

G. Reiners et al. / Thin Solid Films, 253 (1994) 33-40

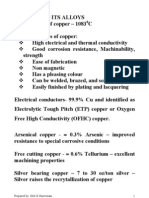

Table 3

Thin film colours from Ref. [31]

Type

Compound

Colour

Hardness (Hv)"

Nitrides

TiN~

ZrN

Cr2N, CrN

TaN

(Ti, A1)N

(Ti, AI)ON

(Ti, Zr)N

Golden ~ brown-yellow

Yellow-green

Metallic --, brown

Blue-grey

Gold --+dark blue

Transparent --, black

Golden

2400

2600

2500

Carbides

TiC

TiC/WC

TaC.,.

SiC

Bright gray

Dark gray

Yellow~ brown

Black

1500-2900

1400

1800

Carbonitrides

TiC,N>,

ZrC.~N>,

Red golden--, violet

Silver--*gold --. violet

2700

2400-2900

~Different test conditions; parameters not always mentioned in the literature.

physically and physiologically. Integrating sphere measurements (ISM), which uses standared industrial

equipment, and angular dependent measurements obtained by goniospectroscopy (GS) describe the physiological colour perception due to directly and diffuse

reflected parts of light by means of the CIE L * a * b *

coordinates. Both systems refer to the ideal mat white

surface (require a white reference) and measure the

spectral reflectance factor R~[x]. The influences of the

measuring system used, the white reference sample

used, and whether the measurement was taken with or

without gloss trap are discussed in Ref. [35].

Using polarized light in spectroscopic ellipsometry

(SE) allows determination of the complex refractive

index N =n(~o)+ik(~o) and the dielectric function

8 = 8)(o)+ i82(c0) of the layer. As this technique uses

directly reflected light, a smooth surface is required for

measurement [35]. There is no reference to white light

needed and the geometric influences of illumination and

measurement are negligible, but the visual impression is

not correctly described. However, it is possible to describe optical properties more physically, to separate

interference effects and to detect changes in stoichiometry. SE can be used to investigate changes in the optical

constants of the deposited layers as a function of both

stoichiometry (target material composition, reactive

gas flow rate) and structure (film thickness, substrate

temperature).

6. Current research activities

Current research is foccused on three main fields: (i)

the search for new colours of PVD hard coatings, (ii)

demonstration of the applicability of cheap materials

used as substrates for decorative hard coatings, and (iii)

scaling-up of the optimized deposition processes to

produce decorative hard coatings on large and threedimensional parts under industrial conditions. The investigations, however, cover not only these fields (new

hard coatings, selection and coating of substrate materials and equipment construction) but also substrate pretreatment and cleaning procedures, interlayer and top

layer selection and deposition as well as wear and

corrosion tests of coating/substrate systems. In the following, standard and new films and procedures are

discussed with special emphasis on coating development

and system design. Scaling-up as a technical problem is

not treated here in more detail. In principal, hard

coatings are usually deposited by magnetron sputtering, and also by arc ion plating and combined

techniques [ 13].

6.1. Decorative hard coatings

6.1. I. Standard colours

The colour variation of simple compounds such as

the golden TiN and the dark gray TiC is limited.

Oxidizing, nitriding and carburizing of binary alloys or

the addition of a second metalloid, however, widen the

spectrum of colours for decorative applications. A typical example is (Ti,A1)N changing from silvery to gold

and dark blue colour depending on the A1 and N

content [ 14].

The reactive deposition of ZrN coatings with varying

nitrogen contents allows tuning of the colour to match

the colour of brass which is needed for decorative

coatings for bathroom furnishings [36, 37]. The reactive

deposition of CrN results in a coating colour quite

similar to ECD hard chrome coatings which are also

needed for decorative coatings for bathroom furnishings [ 19].

G. Reiners et al. / Thin Solid Films, 253 (1994) 3 3 - 4 0

Table 4

C o m p o s i t i o n o f t a r g e t m a t e r i a l s ( a t . % ) [35, 36]

Base

Cr

AI

Ti

Ti

30

50

---

50

--

---

Zr

10

10

20

Zr

Zr

20

--

10

40

20

--

---

&O

.~""

30

".~

~..".". . . . . .

"*-.

",~

......

-.

10

*~,

',.,

;./

sooOS=

o

.....'"

- .~:.C~,.

-10

-t,

I

-2

.....

.........

I

0

I

+2

I

t,

1

6

I

8

I

10

ZrV 80:20

----

Zr

ZrAI 8 0 : 2 0

.....

ZrY 80:20

Zrln 80:20

Fig. 1. T h e c o l o u r o f nitrides o f Z r - b a s e d alloys as a function o f

different alloying elements [38].

6.1.2. New colours

The addition of a second metal or a metalloid (Table

4) to produce ternary nitrides results in a reduction in

hue [29, 35]. Fig. 1 shows the colour of nitrides of

Zr-based alloys depending on different alloying elements [38]. Nevertheless only limited success allows

(Zr,V)N colours to be tuned to match different Swiss

gold standards [39]. In general, the lightness L* decreases with increasing flow rates for these coatings, see

also Ref. [29]. The surface roughness can change not

only the brilliance of a coating but also its chromatic

value. This was demonstrated by depositing TiN coatings onto substrates with different well defined surface

roughness [32].

Typical examples illustrate some dependences. ZrN

coatings of different thickness deposited under constant

conditions show a nearly constant atomic concentration

ratio Zr:N of about 0.47-0.48 but remarkably different

L*, a*, b* values. The change in colour of these

coatings are accompanied by changes in the XRD

spectra. The reason for this colour variation is therefore

mainly structural. (Zr,Y)N coatings deposited with increasing nitrogen flow rates exhibit strong changes in

both stoichiometry and structure in the lower flow

37

regime [29]. For higher flow rates the main effect on

colour change is again structural.

Comparing the effect of the addition of a second or

third metal, only the addition of yttrium as a third

metal (quaternary nitrides such as (Zr,Y,A1)N) broadens the spectrum of colours depending on the nitrogen

flow rate (e.g. (Zr,Y,A1)N [40]).

The reactive deposition of (Ti,A1)ON [41] with very

low oxygen flow rates results in promising coating

colours, but the coating structure, composition, and

chemical binding stage are not stable. After hours or

days the coating colour changes normally to metallic

gray. Studies are in progress to understand the mechanisms involved.

In part, additional colours are observed for high

reactive gas flow rates which are caused by interference

effects. Target poisoning takes place which results in a

lower deposition rate. The layers are transparent or at

least semitransparent. The measured ellipsometric data

tan(tk) and cos(~) consequently show a modulation

according to an interference effect [35].

Intensive studies on sputter deposition of ZrB 2,

ZrBt~, ZrBN, LaBN coatings were reported in Refs.

[42] and [43]. The first applications are expected soon

because of promising results with anthracite and dark

blue and black colours.

A completely different approach was described in

Ref. [44]. The authors tried to incorporate pigments in

transparent hard coatings such as SIO2. The pigment

material was evaporated onto the substrate prior to

deposition of the hard coating.

A very simple process comparable with CVD

deposition is described in Ref. [45]. A variety of metal

chlorides can be deposited for example by painting

onto Ti substrates. Ti has a thin intrinsic oxide layer.

The coated parts were tempered at 450-650C

in air. During this tempering process a metal oxide

layer of up to 21am thickness grows on the TiO2

layer. Many different colours have been found using

different noble and ignoble metal chlorides as

precursors.

6.2. Decorative coating systems

As already mentioned, in technical applications of

decorative coatings the hard compound films are often

combined with top layers to improve the optical impression or with interlayers to improve adhesion or

corrosion resistance.

6.2.1. Noble metal top coatings

For gold coloured consumer goods it is state of the

art to deposit at least a thin gold flash ( ~ 100 nm) on

top of the hard coatings to obtain the brilliance of gold

alloys. Better adaptation of the colour to the different

G. Reiners et al. / Thin Solid Films, 253 (1994) 33-40

38

Swiss gold standards (see Table 2) is normally achieved

using different expensive gold sputter targets. The reactive deposition of for example AuV alloys allows the

deposition of coatings with different gold colours using

a single target [19].

A new nickel-free gold alloy target (AuV 7.5 at.%)

for the deposition of colour adjustable gold coatings by

reactive sputtering is described in Ref. [46]. A wear

resistance three times better than that of ECD gold

coatings was found.

6.2.2. Interlayer systems ECD, standard or allergy-free

Nickel or nickel-containing alloys have so far been

state of the art for ECD deposition. However, nickel

causes considerable problems with respect to allergy

risk. A nickel proof test according to a Danish standard

of 1988 [47] or a German standard in artificial sweat

solution shows that nickel can penetrate gold layers as

they are removed from the surface over time. However,

even with a PVD hard coating on top of nickel the

problem is not solved because of pin-holes. An improvement in quality can be achieved by the introduction of an NiPd layer [30]. However, this is not suitable

for applications which are in direct contact with human

skin.

A standard layer system on brass consists of a 7 tam

thick electroplated nickel layer on a brass substrate

with a 0.4 lam thick PVD coating on top. An advanced

system was patented in Germany [21, 22]. On top of the

first ECD nickel layer a second ECD NiPd coating

(1-1.5 ~tm thick) was deposited. Coated with a decorative PVD layer, such systems protect brass and aluminum alloys much better against corrosion attack.

Fig. 2 shows such an advanced layer system [35] in 3 '~

angled cross-sections on a brass substrate. Fig. 3 shows

the depth profile of this coating system measured by

GDOS. Applying the same system to substrates made

from die cast zinc one finds severe problems with pores

beneath the coating of the cast. Only high quality die

cast substrates can fulfil the demands for decorative

hard coatings.

lS58

Geatzl

20~1

Fig. 2. 3 angled cross-section of the coating system TiN/Ti/CuSn on

a brass substrate.

I0

JT~

I

6

~2

0

Pb

~\

10

20

,

,

30

~0

50

sputter time [see]

~

60

',

BO

70

,

90

I

100

~-

Fig. 3. Depth profile of a coating system TiN/Ti/CuSn on a brass

substrate measured by GDOS.

As ECD CuSn and CuSn(Zn) layers have no known

allergy risk, they can be used as a substitute for nickelcontaining barrier layers. The adhesion of these layers

to the substrate is good, while the adhesion of PVD

coatings deposited directly onto CuSn or CuSn(Zn) has

yet to be optimized.

The corrosion behavior of P V D - E C D coating systems has been studied by electrochemical methods aswell as short-term technical test (see e.g. Refs. [33] and

[48]). Such studies are of high importance for coating

system development.

6.2.3. Interlayer systems (PVD)

A new barrier coating (NiFeCrPB, analog to

Metglass "' 2826A) deposited by magnetron sputtering

is described in Ref. [46]. A modified sputter deposited

titanium barrier layer was tested in Ref. [49].

6.3. Substrate selection and pretreatment

The suitability of machinable brass alloy (CuZn39

Pb2) and an aluminum alloy (A1MgSi0.5) as substrate

materials for decorative hard coatings was successfully

demonstrated in Ref. [30]. The use of ignoble substrate

materials requires the combination of an ECD layer for

corrosion protection with a PVD decorative thin film.

Brass substrates were cleaned using a five- to seven-step

cleaning procedure without fluorinated or chlorinated

hydrocarbons, for some applications preceded by grinding and polishing of the substrate surface. Most of the

multicomponent coatings discussed in Section 6.1.2

were deposited onto polished SUS 304 stainless steel

sheets.

In the past fluorinated or chlorinated hydrocarbons

were frequently used in cleaning and drying processes

prior to deposition. Now it has become normal on an

industrial as well as on a laboratory scale to use CFCfree processes. Detailed information on the development of pretreatment and drying processes without

using fluorinated or chlorinated hydrocarbons is given

in Ref. [50].

G. Reiners et al. / Thin Solid Films, 253 (1994) 33-40

Advances in three-dimensional decorative coatings

were reported in Ref. [50]. Larger parts can be coated

using a new on-line production coater equipped with

new magnetron sputter sources.

7. Applications of decorative hard coatings

Scanning the literature reporting decorative coatings,

more than 100 articles have been published in the last 5

years. In the following some of the major present and

promising future applications are summarized.

The most important applications in the field of consumer goods are still eye-glass frames, eye glasses,

writing utensils, pens, watch cases and bands, lighters,

custom jewellery, and cuttlery [51-53]. A few reports

also mentioned bicoloured coatings [54] which may be

too expensive for most applications.

An increasing number of papers reports on new

applications for fittings and furnishings (e.g. Ref. [34]),

which demonstrates the progress of industrial coating

technologies for three-dimensional parts [13, 50] and

successful corrosion resistance by interlayers.

Architectural glass coating is mainly done to obtain

special optical functions such as IR reflection. Many of

these coatings have intrinsic colours. Therefore the

demand for homogeneity and reproducibility of the

window colour is very high and requires sophisticated

process quality control. During the last few years an

increasing number of papers has dealt with decorative

coatings on steel sheets for possible applications in

architecture [55-63].

8. Advanced coating systems

Future applications as for example hot plates and

microwave barriers require thermal resistant decorative

coatings on glass. The work until now has not been

successful because of delamination of the coatings at

higher temperatures.

Thin film systems for so-called smart windows (automobile windshields, architectural glass) with adjustable

reflectance and transmission coefficients (e.g. electrochromic systems) also have intrinsic colours. For

large-area application similar demands on the homogeneity and reproducibility of the window colour also

requires sophisticated process quality and control.

9. Conclusions

Many coatings can act as decorative hard coatings.

This paper has reviewed optimized standard decorative

PVD coatings as well as coating systems with advanced

39

corrosion resistance and new colours. Coating systems

have been developed with NiPd and CuSn(Zn) instead

of Ni electroplated coatings acting as interlayers, thus

strongly reducing the allergy risk. The colour of PVD

hard coatings is influenced by stoichiometry, structure

and surface roughness. New industrial applications

demonstrate the increasing economic importance of

decorative hard coatings.

Acknowledgement

A part of the reviewed work (Refs. 8, 11, 12, 18, 23,

29, 30, 32, 33, 35, 36, 39, 41, 48, 50) were supported by

the Federal Ministry of Research and Technology

(BMFT # 13N5834-37). In this joint project "Decorative

PVD coatings--Basic Properties and Performance",

Leybold AG (Hanau, Germany), METALEUROP

Coating Technology GmbH, (Hohenlockstedt, Germany), BAM (Berlin, Germany), and FEM (Schw/ibischGmiind, Germany) are working together. The authors

thank many coworkers for their assistance and

DEMETRON GmbH (Schw/ibisch-Gmfind, Germany)

for cooperation.

References

[1] F. Simon, 5th Leybold Syrup. on Decorative Coatings, 28 30

April, 1993 Steinheim Leybold, Hanau, Germany.

[2] A. J. Perry, J. Vae. Sci. Technol A, 4 (6) (1986) 2670.

[3] A. J. Perry, M. Georgson and C. G. Ribbing, J. Vae. Sci.

Technol. A, 4 (1986) 2674.

[4] Y. Fukui, T. Miono and T. Kittaka, Curr. Adv. Mater. Process.,

2 (5) (1989) 1638-1639.

[5] H. Randhawa, Surf. Coat. Teehnol., 36 (1988) 829-836.

[6] G. Hakansson, J. E. Sundgren, D. Mclntyre, J. E. Greene and

W. D. Mtinz, Thin Solid Films, 153 (1987) 55.

[7] I. Musil, S. Kodlec, J. Vyskocil and L. Valvoda, Thin Solid

Films, 167(1988) 107 119.

[8] U. Kopacz and S. Schulz, Asia Pacific lnterfinish 90, Singapore,

19-22 November 1990, Australasian Institute of Metal Finishing,

Parkville, Victoria, 1990, pp. 8.1 8.37.

[9] P. Seserko, U. Kopacz and S. Schulz, Galvanotechnik, 80 (12)

(1989) 4274 4277.

[10] R. Riedl, Galvano-Organo Trait. Surf., 617 (June-July 1991)

699 704.

[11] U. Kopacz and R. Riedl, Z. Metallkd., 83 (7) (1992) 492-499.

[12] S. Schulz, Diinne Schicten, 3 (1) (March 1992) 7-11.

[13] W. D. Miinz, Annu. Tech. Conf., Society of Vacuum Coaters,

Society of Vacuum Coaters, Albuqerque, NM, 1993, pp. 411418.

[14] H. A. Jehn, S. Hofmann and V.-E. Rfickborn, J. Vac. Sci.

Technol. A, 4 (6) (1986) 701.

[15] Programmevaluation Diinnschichttechnologien,

August 1993

(VDI-Technologeizentrum Physikalische Technologien, Diisseldorf, im Auftrag des BMFT).

[16] R. Riedl, Moderne Verfahren zur dekorativen Oberfliichenveredelung, 27-28 September 1993, Diisseldorf, VDI-TZ VDI-W,

Bl-19.

[17] S. Grainger, Engineering Coatings Design and Application,

Woodhead, Cambridge, 1993.

4(1

G. Reiners et al. / Thin Solid Films, 253 (1994) 33-40

[18] S. Kunkel, U. Kopacz and M. Bfihr, Proc. 13th. Int. Plansee

Seminar 24-28 May 1993, Reutte, Austria, 1993, Vol. 4, pp.

274 281.

[19] U. Kopacz and S. Schulz, Sac. Vac. Coat., 34th Annu. Technol.

Conj. Proc., 1991, pp. 48-61.

[20] W. D~ Mfinz, J. Schroeder, H. Petersein, G. Hakansson, L.

Hultman and J. -E. Sundgren, Proe. SURTEC '89 Berlin, 11 13

October 1989, pp. 61-76.

[21] H. Erhart, Metalloberfl6che, 44 (2) (19901 59-62.

[22] H. Erhart, Galvanotechnik, 81 (1990) 1216-1218~

[23] U. Kopacz, C. Daube and S. Schulz, Galvanotechnik, 83 (1992)

844 848.

[24] Recommendations on uniform colour spaces, colour-difference

equations, psychometric colour terms, CIE Publ. 15, Suppl. 2-70

CIE, Paris, 1978.

[25] CRC Handbook of Chemistry and Physics, CRC Press, Boca

Raton, FL, 1982 1983, 63rd edn.

[26] G. V. Samsonov and I. M. Vinitskii (eds.), Handbook of Refractory Compounds, IFI/Plenum, New York, 1985.

[27] Calibration of Spectrometers, Technical Instruction, Labsphere,

Inc., North Sutton, NH 03260, USA

[28] H. G. Tompkins, R. Gregory and B. Boeck, Surf InterJace

Anal., 17(1) (19921 22 24.

[29] G. Reiners, H. Hantsche, H. A. Jehn, U. Kopacs and A. Rack,

Sur]~ Coat. Technol., 54-55 (103) (1992) 273 278.

[30] U. Beck, G. Reiners, I. Urban, H. A. Jehn, U. Kopacz and H.

Schack, Surf. Coat. Technol., 61 (1993) 215-222.

[31] U. Kopacz, Moderne Verfahren zur dekorativen Oberfliichenveredelung, DiisseldorJ~ 27 28 September 1993, VI)I-TZ, VDI-W,

Al-19.

[32] U. Beck, G. Reiners and K. Witt, Thin Solid Films, 236 (1993)

184-190.

[33] H. A. Jehn and M. E. Baumg~rtner, SurJl Coat. Technol., 54 55

(1992) 108-114.

[34] M. Kathrein, C. Mitterer and R. Riedl, in H. Grewe (ed.), Proe.

Symp. Reibung und Versehleifl, Bad Nauheim, 29-30 October

1992, DGM Informationsgesellschaft, Oberursel, 1992, pp, 383

390.

[35] U. Beck, G. Reiners, I. Urban and K. Witt, Thin Solid Films,

220 (1992) 234-240.

[36] U. Kopacz, Products-Finishing (Cincinnati), 56 (8) (1992) 72

73.

[37] U. Kopacz, Met. Finish. 90 (12)(1992)7-14.

[38] U. Kopacz, 4th Leybold Symp. on Decorative Coatings, 8 10

April 1992, Riidesheim Leybold, Hanau, Germany.

[39] U. Beck. G. Reiners, U. Kopacz and H. A. Jehn, Surf Coat.

Technol., 60 (1993) 389-395.

[40] U. Kopacz, 5th Leybold Syrup. on Decorative Coatings, 8-10

April 1993, Steinheim Leybold, Hanau, Germany.

[41] U. Beck and Th. Gross, Proc. 4th Int. Conf. on Plasma Surface

Engineering, Garmisch-Parterkirchen, 1994, in press.

[42] C. Mitterer, P. Losbichler, W. S. M. Werner, H. St6ri and J.

Barounig, SurJ~ Coat. Technol., 54-55 (1992) 329-334.

[43] J. Stallmaier, C. Mitterer and J. Barounig, Proc. Ilth lnt. Con[~

on Vacuum Metallurgy, Antibes, 11-14 May 1992 in Vide,

Couches Minces, Suppl. au 261 (1992) 265 267.

[44] H. Dirnigen, Tiitigkeitsbericht 1991-92 (Fraunhofer-Institut fiir

Schicht- und Oberflfichentechnik), p. 24.

[45] F. Beck and W. Kaiser, Galvanotechnik, 83 (2) (1992) 454-461.

[46] M. Weigert, 5th Leybold Symp. on Decorative Coatings, 28 30

April 1993, Steinheim Leybold, Hanau, Germany.

[47] Diinisches Gesetzbhztt Nr. 472, 27 June 1989 pp. 1689- 1690.

[48] H. A. Jehn and I. Pfeiffer-Schfiller, Galvanotechnik, 84 (1993)

3283-3288, 3669 3675, 4059 4064.

[49] Ch. Daube, Dissertation, 13 December 1990, RWTH Aachen.

[50] U. Kopacz, P. Ballhause and J. Snyder, Annu. Tech. Conj.

Society of Vacuum Coaters, Society of Vacuum Coaters, Albuquerque, NM, 1993, pp. 419-422.

[51] F. Aubert, Galvanotechnik, 82 (19911 4193 4196.

[52] N.N., ETA SA Fabriques d'Ebauches, Grenchen, CH., oberfl.

surf., 31 (1 2) (1990) 29.

[53] R. Reidl, Galvanotechnik, 80 (101 (1989) 3391 3397.

[54] H. F. Fehse, Galvanotechnik, 81 (10) (1990) 3514 3518.

[55] M. Hashimoto, S. Miyajiima, W. Ito, S. Ito and T. Murata,

SurJ~ Coat. Technol., 36 (1988)837 845.

[56] Y. Fukui, M. Tadaaki, T. Kittaka, Nisshin Steel Tech. Rep.

61 December 1989, Nisshin Steel Co., Tokyo, Japan, pp. 3343.

[57] I. ltoh, Y. Oikawa, M. Hashimoto, S. Saita, T. Komori, M.

Onoyama, S. Itoh and T. Murata, Nippon Steel Tech. Rep., (43)

October 1989, Nippon Steel Co., Chiba, Japan, pp. 8 15.

[58] G. J. Smith and R. A. Innes, US Patent 5135262, 20 June 1990.

[59] I. Itoh, Y. Oikawa, M. Hasimoto, T. Komori, M. Onoyama and

M. Ueshima, Nippon Steel Tech. Rep., 46, July 1990 (Nippon

Steel), pp. 8 12.

[60] K. Nakamoto, S. Mori, T. Kuwano, Y. Tomohara and M.

Makimoto, Nisshin Steel Tech. Rep., 64, June 1991 (Nisshin

Steel), pp. 66 75.

[61] T. Komori, Y. Oikawa and I. Ira. Stainless Steels "91, Chiba,

10 13 June 1991, Iron and Steel Institute of Japan, Tokyo, 1991.

pp. 985 991.

[62] K. ltoh, Alutopia (Japan), 21 (6) (1991) 54 59.

[63] T. Takahash, Y. Oikawa, T. Komori, I. Ito and M. Hashimoto,

Surf Coat. Technol., 51 (1 3) (19921 522 528.

You might also like

- Effect of Coatings on Corrosion of SteelDocument6 pagesEffect of Coatings on Corrosion of SteelLuthfi Ady100% (1)

- PVD Coating Technology for ToolingDocument6 pagesPVD Coating Technology for ToolingNorman IskandarNo ratings yet

- Hard and Superhard Nanocomposite CoatingsDocument9 pagesHard and Superhard Nanocomposite CoatingsAnonymous HdETOphR5No ratings yet

- Effects of Nano Pigments On The Corrosion Resistance of Alkyd CoatingDocument8 pagesEffects of Nano Pigments On The Corrosion Resistance of Alkyd Coatingdvega1981No ratings yet

- Influence of Paint On Steel Corrosion For Marine ApplicationsDocument8 pagesInfluence of Paint On Steel Corrosion For Marine ApplicationsHose Gamaliel100% (1)

- Erdemir 1 - Tribological and Solid Lubrificant Coatings PDFDocument9 pagesErdemir 1 - Tribological and Solid Lubrificant Coatings PDFMÔNICA SUEDE S. SILVANo ratings yet

- Coating 2Document7 pagesCoating 2Chirlly UlaiNo ratings yet

- Adhesion Testing of Thermally Sprayed and Laser Deposited Coatings 2004 Surface and Coatings TechnologyDocument11 pagesAdhesion Testing of Thermally Sprayed and Laser Deposited Coatings 2004 Surface and Coatings TechnologyMeneer TierNo ratings yet

- Surface Treatments and CoatingsDocument4 pagesSurface Treatments and Coatingsmightym85No ratings yet

- Improving Piston Ring Wear Resistance Through Coated SurfacesDocument47 pagesImproving Piston Ring Wear Resistance Through Coated SurfaceseshuNo ratings yet

- Corrosion Behaviour of Sol-Gel Treated and Painted AA2024 Aluminium AlloyDocument10 pagesCorrosion Behaviour of Sol-Gel Treated and Painted AA2024 Aluminium AlloyAdrian OrtizNo ratings yet

- IMO Performance Standard For Protective Coating and IACS Common Structural RulesDocument76 pagesIMO Performance Standard For Protective Coating and IACS Common Structural Rulesheobukon100% (2)

- Zinc-Rich Primers-Test Performance and Electrochemical PropertiesDocument6 pagesZinc-Rich Primers-Test Performance and Electrochemical PropertiesSyaiful Arif WicaksonoNo ratings yet

- CorrosionDocument13 pagesCorrosionbourneremembersNo ratings yet

- Articles +doll2010 Article ChemicalVaporDepositionAndAtomDocument7 pagesArticles +doll2010 Article ChemicalVaporDepositionAndAtomRAHUL SINGHNo ratings yet

- 2Document13 pages2VNSAramakiNo ratings yet

- Physical Vapor Deposition of Thin Film Hard Wear Resistant CoatingsDocument2 pagesPhysical Vapor Deposition of Thin Film Hard Wear Resistant Coatingsmajid khan yousafzaiNo ratings yet

- Drodten 2008Document34 pagesDrodten 2008Alexis Cruz ZabaleguiNo ratings yet

- HFOVDocument9 pagesHFOVscribd_anjirNo ratings yet

- Metallic Coatings For Corrosion PreventionDocument9 pagesMetallic Coatings For Corrosion PreventionDevashish JoshiNo ratings yet

- Effects of Pigments and FillersDocument12 pagesEffects of Pigments and Fillersvipin1222100% (2)

- EMI Shielding Design GuideDocument15 pagesEMI Shielding Design Guidemax_schofieldNo ratings yet

- Research Progress in Organic Zinc Rich Primer Coatings For Cathodic Protection of MetalsDocument18 pagesResearch Progress in Organic Zinc Rich Primer Coatings For Cathodic Protection of MetalsJorge Suarez100% (1)

- Project Proposal: 1. AbstractDocument4 pagesProject Proposal: 1. Abstractgilberto herreraNo ratings yet

- An Experimental Investigation of Metallurgical Properties of Thermally Coated Stainless Steel: A ReviewDocument3 pagesAn Experimental Investigation of Metallurgical Properties of Thermally Coated Stainless Steel: A ReviewIJSTENo ratings yet

- Oxidation CorrosionDocument17 pagesOxidation CorrosionGise GSNo ratings yet

- Foundry Coating Technology - A ReviewDocument18 pagesFoundry Coating Technology - A ReviewIvyNo ratings yet

- Hybrid Silica Sol-Gel Coatings On Austempered Ductile Iron (ADI)Document4 pagesHybrid Silica Sol-Gel Coatings On Austempered Ductile Iron (ADI)Hatem RagabNo ratings yet

- Mee4001-Tool Design Latest Developments On Cutting Tools and Coatings Name:Shrey S Jain REGNO:18BME1225 Faculty:Dr. Umasankar Slot:F1Document13 pagesMee4001-Tool Design Latest Developments On Cutting Tools and Coatings Name:Shrey S Jain REGNO:18BME1225 Faculty:Dr. Umasankar Slot:F1Shrey JainNo ratings yet

- Coating Inhibitors MonitoringDocument23 pagesCoating Inhibitors Monitoringdip_maan100% (1)

- Deniss ProjectDocument24 pagesDeniss Projectreuben simiyuNo ratings yet

- Surface & Coatings Technology: Vijay Krishna, R. Padmapreetha, S.B. Chandrasekhar, K. Murugan, Roy Johnson TDocument8 pagesSurface & Coatings Technology: Vijay Krishna, R. Padmapreetha, S.B. Chandrasekhar, K. Murugan, Roy Johnson THarun AydınNo ratings yet

- Performance Evaluation of Alkyd Coatings For Corrosion Protection in Urban and Industrial EnvironmentsDocument6 pagesPerformance Evaluation of Alkyd Coatings For Corrosion Protection in Urban and Industrial Environmentsguayoyito100% (1)

- DevashishDocument43 pagesDevashishDevashish JoshiNo ratings yet

- CH 29Document5 pagesCH 29Cesar BandaNo ratings yet

- Jarak SprayDocument6 pagesJarak SprayIhsanulfajar MulyantoNo ratings yet

- Silver Paste For DSCC Solar CellDocument30 pagesSilver Paste For DSCC Solar CellAkshay BhavsarNo ratings yet

- TN 25Document8 pagesTN 25paulo_linanNo ratings yet

- Coatings: DLC and Dlc-Ws Coatings For Machining of Aluminium AlloysDocument15 pagesCoatings: DLC and Dlc-Ws Coatings For Machining of Aluminium Alloysxmen norNo ratings yet

- Intelligent Self-Healing Corrosion Resistant Vanadia Coating For AA2024Document11 pagesIntelligent Self-Healing Corrosion Resistant Vanadia Coating For AA2024saleh90No ratings yet

- Mechanical Properties of Multilayer Coatings Deposited by PVD Techniques Onto The Brass SubstrateDocument6 pagesMechanical Properties of Multilayer Coatings Deposited by PVD Techniques Onto The Brass SubstrateBharath Achary T SNo ratings yet

- Coating materials for thin filmsDocument26 pagesCoating materials for thin filmsamitrameshwardayal0% (1)

- The Impact of Bias and Nitrogen Pressure on TiNbN CoatingsDocument18 pagesThe Impact of Bias and Nitrogen Pressure on TiNbN CoatingsFernando Spanholi TelesNo ratings yet

- Ronak Mehta ContentDocument12 pagesRonak Mehta ContentDevashish JoshiNo ratings yet

- Physical Vapor DepositionDocument20 pagesPhysical Vapor DepositionPraveen KumarNo ratings yet

- Coatings For Corrosion Protection: An: 1. Mechanisms of Coating FunctionDocument5 pagesCoatings For Corrosion Protection: An: 1. Mechanisms of Coating FunctionGnneth Milln RamrezNo ratings yet

- Cutting Ability Improvement of Coated Tool MaterialsDocument4 pagesCutting Ability Improvement of Coated Tool MaterialsjacqulinegeorgeNo ratings yet

- 2008-Investigation On Wear and Adhesion of Graded Si - SiC.DLC Coatings Deposited byDocument4 pages2008-Investigation On Wear and Adhesion of Graded Si - SiC.DLC Coatings Deposited byPing-Yen HsiehNo ratings yet

- Surface & Coatings TechnologyDocument12 pagesSurface & Coatings TechnologyAdam StewartNo ratings yet

- Coating For The Protection of Steel StructureDocument17 pagesCoating For The Protection of Steel StructureMohamed Abdel SamieNo ratings yet

- Coatings: Corrosion Behavior and Surface Properties of PVD Coatings For Mold Technology ApplicationsDocument12 pagesCoatings: Corrosion Behavior and Surface Properties of PVD Coatings For Mold Technology ApplicationsFINNING CATNo ratings yet

- Coating As An Ideal Prevention For Corrosion in Manufacture and Infrastructure IndustryDocument43 pagesCoating As An Ideal Prevention For Corrosion in Manufacture and Infrastructure IndustryLarasanto Larasanto100% (1)

- Polymeric Coating For Prevention of Hydrogen Permeation - Science Direct ArticleDocument11 pagesPolymeric Coating For Prevention of Hydrogen Permeation - Science Direct ArticleSAUGAT DUTTANo ratings yet

- New Development of Anodic Electrocatalysts for Chlor-Alkali IndustryDocument11 pagesNew Development of Anodic Electrocatalysts for Chlor-Alkali Industryfaisal58650No ratings yet

- Corrosion: Corrosion ControlFrom EverandCorrosion: Corrosion ControlL L ShreirRating: 5 out of 5 stars5/5 (1)

- Role of Thermal Spray Coatings On Wear, Erosion and Corrosion Behavior: A ReviewDocument8 pagesRole of Thermal Spray Coatings On Wear, Erosion and Corrosion Behavior: A ReviewVijay KaushikNo ratings yet

- Anti-Corrosion Coatings For Different Service Exposures: Shivananda PrabhuDocument10 pagesAnti-Corrosion Coatings For Different Service Exposures: Shivananda Prabhurohit yadavNo ratings yet

- Durability of Acrylic Cataphoretic Coatings AdditiDocument21 pagesDurability of Acrylic Cataphoretic Coatings AdditiemptyNo ratings yet

- High-manganese cast steel coatingsDocument6 pagesHigh-manganese cast steel coatingssushmaxNo ratings yet

- Effect of Rhenium on Oxidation Resistance of Aluminide CoatingsDocument8 pagesEffect of Rhenium on Oxidation Resistance of Aluminide CoatingsEngels OchoaNo ratings yet

- List of Documentaries On North KoreaDocument3 pagesList of Documentaries On North Koreachinuuu85brNo ratings yet

- North KoreaDocument23 pagesNorth Koreachinuuu85brNo ratings yet

- Masatoshi KoshibaDocument2 pagesMasatoshi Koshibachinuuu85brNo ratings yet

- Sam WaltonDocument3 pagesSam Waltonchinuuu85brNo ratings yet

- Rayko DaskalovDocument3 pagesRayko Daskalovchinuuu85brNo ratings yet

- Bill GatesDocument10 pagesBill Gateschinuuu85brNo ratings yet

- Fraunhofer LinesDocument2 pagesFraunhofer Lineschinuuu85brNo ratings yet

- Hurrican HarveyDocument10 pagesHurrican Harveychinuuu85brNo ratings yet

- Fifa World CupDocument8 pagesFifa World Cupchinuuu85brNo ratings yet

- University of London: History and Overview of Major Research InstitutionDocument3 pagesUniversity of London: History and Overview of Major Research Institutionchinuuu85brNo ratings yet

- LPG SubsidyDocument2 pagesLPG Subsidychinuuu85brNo ratings yet

- Takaaki KatijaDocument2 pagesTakaaki Katijachinuuu85brNo ratings yet

- Pretorius - 1990 - Phase Sequence of Silicide Formation at Metal-SiliDocument5 pagesPretorius - 1990 - Phase Sequence of Silicide Formation at Metal-Silichinuuu85brNo ratings yet

- Names of IndiaDocument6 pagesNames of Indiachinuuu85brNo ratings yet

- Hinkel Et Al. - 1987 - Evidence For Si Diffusion Through Epitaxial NiSi2Document4 pagesHinkel Et Al. - 1987 - Evidence For Si Diffusion Through Epitaxial NiSi2chinuuu85brNo ratings yet

- CSIR-UGC NET Physical Sciences Exam GuideDocument3 pagesCSIR-UGC NET Physical Sciences Exam GuideMaruthiNo ratings yet

- Disorder and The Optical-Absorption Edge of Hydrogenated Amorphous SiliconDocument4 pagesDisorder and The Optical-Absorption Edge of Hydrogenated Amorphous Siliconchinuuu85brNo ratings yet

- Spip Brochure PDFDocument40 pagesSpip Brochure PDFchinuuu85brNo ratings yet

- Innes and Sambles - 1987 - Optical Characterisation of Gold Using Surface PlasmonsDocument12 pagesInnes and Sambles - 1987 - Optical Characterisation of Gold Using Surface Plasmonschinuuu85brNo ratings yet

- Kurtz and Gordon - 1986 - Chemical Vapor Deposition of Titanium Nitride at LDocument14 pagesKurtz and Gordon - 1986 - Chemical Vapor Deposition of Titanium Nitride at Lchinuuu85brNo ratings yet

- Wittmer Et Al. - 1981 - Electrical Characteristics of TiN Contacts To N SiDocument6 pagesWittmer Et Al. - 1981 - Electrical Characteristics of TiN Contacts To N Sichinuuu85brNo ratings yet

- LNM 1Document42 pagesLNM 1KANHIYA78100% (1)

- Grün - 1979 - The Crystal Structure of Β-Si3N4 Structural and sDocument5 pagesGrün - 1979 - The Crystal Structure of Β-Si3N4 Structural and schinuuu85brNo ratings yet

- Ece656 L01Document21 pagesEce656 L01chinuuu85brNo ratings yet

- Gate PHYSICS 2013 UnsolvedDocument13 pagesGate PHYSICS 2013 Unsolvedchinuuu85brNo ratings yet

- SimranDocument1 pageSimranchinuuu85brNo ratings yet

- S 2Document1 pageS 2Mridul GroverNo ratings yet

- India's 2016 demonetisation of Rs 500 and Rs 1000 banknotesDocument9 pagesIndia's 2016 demonetisation of Rs 500 and Rs 1000 banknoteschinuuu85br0% (1)

- Welding Consumable Nominal Chemical Composition, Wt. Pct. Other Designation SystemsDocument1 pageWelding Consumable Nominal Chemical Composition, Wt. Pct. Other Designation SystemsLLNo ratings yet

- Keur 00824-401 201505Document4 pagesKeur 00824-401 201505erik0007No ratings yet

- AOCS Recommended Practice Ca 12-55 Phosphorus PDFDocument2 pagesAOCS Recommended Practice Ca 12-55 Phosphorus PDFMaximino Alvarez100% (1)

- Astm C361M-14Document26 pagesAstm C361M-14diego rodriguez100% (1)

- Styrene Acrylic FTIRDocument9 pagesStyrene Acrylic FTIRDesi Rahma PrihandiniNo ratings yet

- Healthcare WasteDocument32 pagesHealthcare WasteEddiemtongaNo ratings yet

- Villanova Torsion Test ReportDocument19 pagesVillanova Torsion Test ReportwaleedkhalillahmedNo ratings yet

- k3) Luxatherm5600 7954Document2 pagesk3) Luxatherm5600 7954Syed FaridNo ratings yet

- Critical Chloride Content in Reinforced ConcreteDocument7 pagesCritical Chloride Content in Reinforced ConcreteAshrafNo ratings yet

- Gyproc Plasters: Product CatalogueDocument24 pagesGyproc Plasters: Product CatalogueFariz AbdullaNo ratings yet

- TemperatureDocument6 pagesTemperatureNur Khairiah Daimah SanupinNo ratings yet

- DBR Cvs AuditoriumDocument9 pagesDBR Cvs AuditoriumJohn JacksonNo ratings yet

- Defense Technology 1082 - Riot Control Grenade CS MSDSDocument7 pagesDefense Technology 1082 - Riot Control Grenade CS MSDSCenangau DaunkariNo ratings yet

- Dyeing Process of Cotton Fabric With Reactive DyesDocument6 pagesDyeing Process of Cotton Fabric With Reactive DyesMianAbrarAnjumNo ratings yet

- CH 4034 Comprehensive Design Project II Interim Report 1: Production of Ammonia From NaphthaDocument21 pagesCH 4034 Comprehensive Design Project II Interim Report 1: Production of Ammonia From NaphthaAlfonso BlancoNo ratings yet

- Copper and It's AlloysDocument5 pagesCopper and It's AlloysReza MortazaviNo ratings yet

- Fan - 2009 - 8 - ECTC 2009 - 2 RahimDocument5 pagesFan - 2009 - 8 - ECTC 2009 - 2 RahimkraidonNo ratings yet

- Masterlife Ci 220 v5Document2 pagesMasterlife Ci 220 v5Tech BoyNo ratings yet

- Mahaa One RMC: Er - Nanthakumar Boomi Textile MillsDocument19 pagesMahaa One RMC: Er - Nanthakumar Boomi Textile MillsMAHAA ONE RMC RAMASAMY MNo ratings yet

- LNG Light Hydrocarbon Separation with Cryogenic Energy UtilizationDocument4 pagesLNG Light Hydrocarbon Separation with Cryogenic Energy UtilizationphantanthanhNo ratings yet

- SOP On LMO Tank 20210401 - USAID RISEDocument25 pagesSOP On LMO Tank 20210401 - USAID RISEBoke BelayNo ratings yet

- ASME IIA SA29 SA29M Steel Bars, Carbon and Alloy, Hot-Wrought and Cold-FinishedDocument1 pageASME IIA SA29 SA29M Steel Bars, Carbon and Alloy, Hot-Wrought and Cold-FinishedAmanda Ariesta ApriliaNo ratings yet

- Introduction To Mass TransferDocument44 pagesIntroduction To Mass TransferGhazanferAliNo ratings yet

- GC6000-2-4 Selection of Bearing SizeDocument5 pagesGC6000-2-4 Selection of Bearing SizeFrancisco AlessandriNo ratings yet

- WS1000-EN Table of ContentsDocument3 pagesWS1000-EN Table of ContentsNeesonNo ratings yet

- Liquid Penetrant Testing Chapter 4: Emulsification, Penetrant Removal and Developer ApplicationDocument11 pagesLiquid Penetrant Testing Chapter 4: Emulsification, Penetrant Removal and Developer ApplicationRajendrasinh PuvarNo ratings yet

- Sika Lightcrete I-500: Admixture For Lightweight ConcreteDocument3 pagesSika Lightcrete I-500: Admixture For Lightweight ConcreteAmmar A. AliNo ratings yet

- Simplified Plumbing Design NPC Philippines PDFDocument168 pagesSimplified Plumbing Design NPC Philippines PDFClimaco EdwinNo ratings yet

- The Optical Properties of Magnesium Oxide ContainiDocument6 pagesThe Optical Properties of Magnesium Oxide ContainiAbdulbar kelilNo ratings yet

- Ds Oil and Grease TypesDocument2 pagesDs Oil and Grease TypesIsaias BarbaNo ratings yet