Professional Documents

Culture Documents

12ME5DCDM2

Uploaded by

Abhyudaya SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

12ME5DCDM2

Uploaded by

Abhyudaya SinghCopyright:

Available Formats

U.S.N.

IIIIIIIIIII

BMS College of Engineering, Bangalore-560019

(Autonomous Institute, Affiliated to VTU, Belgaum)

July I August 2014 Supplementary Examinations

Course: Design Of Machine Elements-II

Course Code: 12MESDCDM2

Duration: 3 Hours

Max Marks: 100

Date: 06.08.2014

Instructions: Answer FIVE FULL questions, choosing one from each unit.

1.

UNIT -1

Derive expressions for stresses in extreme fibers of a curved beam subjected to

bending load with usual notations.

b) Differentiate between a curved beam and straight beam

c) Determine the force 'F' for the member shown in Fig. 1, such that the stress in the

member at section AB does not exceed 150 MPa with 'F' acting at the centroidal

axis point.

a)

07

03

10

Fig -1

2.

OR

a) Discuss the construction and design approach to a leaf spring. Hence obtain

expressions for stresses in full length and graduated length leaves of a leaf spring

assembly.

b) The valve spring of an IC engine is 60 mm long when the valve is open and 68

mm long when the valve is closed. The spring loads are 350 N when the valve is

closed and 500 N when the valve is open. The inside diameter of the spring is to

have a minimum value of 30 mm. Design the spring selecting a suitable material

and adopting a factor of safety of 3.

10

10

3.

UNIT-2

a) A cone clutch has a semi-cone angle of 120 to transmit 10 kW at 750 rpm. The

width of the face is one-fourth of the mean diameter of friction lining. If the

normal intensity of pressure between the contacting surfaces is not to exceed

0.085Mpa (0.85bar), assuming uniform wear and taking f=0.2, calculate

dimensions of clutch. Also find the axial force while running, i.e. at the beginning

of the engagement.

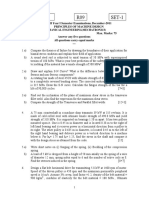

b) A 400 mm radius brake drum contacts a single shoe as shown in figure.2. and

sustains a torque of 200 Nm at 500 rpm. For a coefficient of friction 0.25,

determine;

(i) Normal force on the shoe

(ii) Required force F to apply brake for clockwise rotation.

(iii) Required force F to apply brake for counter clockwise rotation

(iv) The dimension 'c' required for self locking

(v) Heat generated

08

12

R400mm

b=350 mm

a

1000 mm

4.

5.

Fig- 2

UNIT-3

a) Derive the Lewis equation for tangential strength of the gear tooth.

b) Design a pair of spur gears to transmit a power of 20kW from a shaft running at

1OOOrpm to another shaft to be run at 400rpm. The allowable static strength of the

pinion is 191.3MPa and that ofthe gear is 137.34MPa. The pressure angle is 20

full depth involute. Use the shock factor as 1.25 and the gears are of carefully

cut gears. Check the design for dynamic and wear loads.

OR

a) Explain briefly the Formative number of teeth of Bevel gears.

b) A pair ofbevel gear wheels with 20 pressure angle consists of20 teeth pinion

meshing with 30 teeth gear. The module is 4 mm while the face width is 20mm,

the surface hardness of both pinion and gear is 400 BHN. The pinion rotates at 500

rpm and receives power from an electric motor. The starting torque of the motor is

150 percent of rated torque. Determine the safe power that can be transmitted

considering the dynamic load, wear strength and endurance strength. The

allowable bending stress may be taken as 240 MPa.

06

14

06

14

6.

7.

a)

UNIT-4

Explain with sketch the theory of hydrodynamic lubrication.

b) Derive Petroffs equation for coefficient of friction in journal bearings.

c) A 75mm long full journal bearing of diameter 75mm supports a radial load of

12kN at the shaft speed of 1800rpm. Assume the ratio of diameter to the

diametral clearance as 1000. The viscosity of oil is 0.01PaS at the operating

temperature. Determine the following

(i)

Sommerfeld number

(ii)

Coefficient of friction based on McKee equation

(iii) Amount of heat generated

UNIT-S

a) Select a V-belt drive to transmit a power of 6 kW from a shaft rotating at 1500

rpm to a parallel shaft to be run at 375rpm. The distance between the shaft centres

is 500mm. The pitch diameter of the smaller grooved pulley are to be taken

150mm. The factor of application is to be taken as 1.2.

b) A 25mm 6 x 37 steel wire rope is used in a mine of 80m deep. The velocity of the

cage is 2 m/sec, and the time required to accelerate the cage to the desired velocity

is 10 sees. The diameter of the drum is 1.25m. Determine the safe load that the

hoist can handle by assuming a factor of safety as 8. Neglect the impact load on

the rope.

*******

06

06

08

10

10

You might also like

- 12 Me 5dcdm2Document3 pages12 Me 5dcdm2Abhyudaya SinghNo ratings yet

- Question Bank All Units With VTU Old Questions With Front PageDocument11 pagesQuestion Bank All Units With VTU Old Questions With Front PageHareesha N GNo ratings yet

- Date: 29.09.2021 Marks: 50 Year/Sem: III/V Sub: ME8594 Dynamics of Machines Duration: 90 MinDocument2 pagesDate: 29.09.2021 Marks: 50 Year/Sem: III/V Sub: ME8594 Dynamics of Machines Duration: 90 MinsathishskymechNo ratings yet

- Previous Exam QuestionsDocument8 pagesPrevious Exam QuestionssallyreffatNo ratings yet

- 12ME5DCDM2Document3 pages12ME5DCDM2Abhyudaya SinghNo ratings yet

- Machine Design Exam QuestionsDocument2 pagesMachine Design Exam QuestionsSamNihalNo ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- DMM-2 3 1 Q&aDocument6 pagesDMM-2 3 1 Q&aAnand vinayNo ratings yet

- Sathyabama University: Register NumberDocument3 pagesSathyabama University: Register NumberSecret SecretNo ratings yet

- Tom I MT QB - 2022-23Document2 pagesTom I MT QB - 2022-23KirtanNo ratings yet

- BMS College of Engineering, Bangalore-560019: January 2015 Semester End Make Up ExaminationsDocument2 pagesBMS College of Engineering, Bangalore-560019: January 2015 Semester End Make Up ExaminationsAbhyudaya SinghNo ratings yet

- PMD ModelDocument8 pagesPMD ModelDamodara SatyaDeva MadhukarNo ratings yet

- Machine Design-II Question BankDocument32 pagesMachine Design-II Question BankAbhishek SakatNo ratings yet

- Be Summer 2022Document3 pagesBe Summer 2022Karan SheladiyaNo ratings yet

- 07a6ec05 Designofmachinemembers IIDocument11 pages07a6ec05 Designofmachinemembers IIzahid_polyNo ratings yet

- Dom QB Fina 1-5Document11 pagesDom QB Fina 1-5manipacetNo ratings yet

- DME Model QuesDocument3 pagesDME Model QuesSiva RamanNo ratings yet

- Mech 325 Tutorials (Questions Only)Document54 pagesMech 325 Tutorials (Questions Only)Shahriar Norouzi ZadehNo ratings yet

- Me1302 Dme 2Document4 pagesMe1302 Dme 2sumikannu100% (1)

- 181505-181902-MD - IiDocument2 pages181505-181902-MD - IiSiddharth PanchalNo ratings yet

- Design of Machine Members-II Feb 2022Document3 pagesDesign of Machine Members-II Feb 2022Anand KedhariNo ratings yet

- Valliammai Engineering College Department of Mechanical Engineering Question Bank Subject: Me 6505-Dynamics of Machines UNIT-I PART-A (2 Marks)Document15 pagesValliammai Engineering College Department of Mechanical Engineering Question Bank Subject: Me 6505-Dynamics of Machines UNIT-I PART-A (2 Marks)Johnson JohnsonNo ratings yet

- Kinematics of MachinesDocument2 pagesKinematics of Machinessameer_m_daniNo ratings yet

- RT22352042019 PDFDocument2 pagesRT22352042019 PDFphani reddyNo ratings yet

- Dynamics of Machinery QuestionsDocument11 pagesDynamics of Machinery Questionslogeshboy0070% (1)

- 1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringDocument3 pages1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringChadaram JagadishNo ratings yet

- Assignment 1 (Unit 1 and 2)Document5 pagesAssignment 1 (Unit 1 and 2)Atharva ChoudhariNo ratings yet

- Makalah GTWDocument8 pagesMakalah GTWfaisalNo ratings yet

- rr320305 Design of Machine Members IIDocument8 pagesrr320305 Design of Machine Members IISrinivasa Rao GNo ratings yet

- Dme Model QPDocument3 pagesDme Model QPCody LeeNo ratings yet

- Machine Design - II Question Bank and Bearing CalculationsDocument2 pagesMachine Design - II Question Bank and Bearing CalculationsmaheshNo ratings yet

- NUEST Bachelor Engineering Design Applications ExamDocument4 pagesNUEST Bachelor Engineering Design Applications ExamPatrick NdlovuNo ratings yet

- Machine Design - LDocument2 pagesMachine Design - LNilesh Mistry (Nilesh Sharma)No ratings yet

- Mechanics of Machines Exam Questions and SolutionsDocument32 pagesMechanics of Machines Exam Questions and SolutionsSanjay CNo ratings yet

- Theory of Machines and MechanismsDocument3 pagesTheory of Machines and MechanismsineboluuNo ratings yet

- Dynamics of Machinary - Question BANKDocument17 pagesDynamics of Machinary - Question BANKS A ABDUL SUKKURNo ratings yet

- Design ExercisesDocument13 pagesDesign ExercisesBookieeNo ratings yet

- Design ProblemsDocument13 pagesDesign ProblemsAristotle RiveraNo ratings yet

- Assignment 01Document2 pagesAssignment 01Ratan Sadanandan O MNo ratings yet

- 3 Mech Me8594 Dom QBDocument29 pages3 Mech Me8594 Dom QBSurya SNo ratings yet

- MD2 Model QuestionsDocument2 pagesMD2 Model Questionsmanish sharmaNo ratings yet

- B.Tech Degree S8 (S, FE) / S6 (PT) (S, FE) Examination June 2023 (2015 Scheme)Document3 pagesB.Tech Degree S8 (S, FE) / S6 (PT) (S, FE) Examination June 2023 (2015 Scheme)Venkitaraj K PNo ratings yet

- Rr320304 Dynamics of MachinesDocument8 pagesRr320304 Dynamics of MachinesSrinivasa Rao GNo ratings yet

- KCE Mechanical Engineering Question BankDocument11 pagesKCE Mechanical Engineering Question BankkarthisanNo ratings yet

- Upto 2010 KomDocument36 pagesUpto 2010 KompsnasabariNo ratings yet

- End Term TOM 2020-2021Document3 pagesEnd Term TOM 2020-2021Nivash KumarNo ratings yet

- VSA Group of Institutions Dynamics of Machinery ExamDocument2 pagesVSA Group of Institutions Dynamics of Machinery ExamDmj Anbu RajNo ratings yet

- DME Chapter Three: or (Summer 15)Document7 pagesDME Chapter Three: or (Summer 15)honeyfunnyNo ratings yet

- WWW - Manaresults.co - In: (Mechanical Engineering)Document2 pagesWWW - Manaresults.co - In: (Mechanical Engineering)Mohammed SohailNo ratings yet

- Dynamics of Machinery Exam: Torque and Force AnalysisDocument8 pagesDynamics of Machinery Exam: Torque and Force AnalysisAkhil C KNo ratings yet

- Design of Transmission Systems Model ExamDocument3 pagesDesign of Transmission Systems Model ExamrajkumardotcomNo ratings yet

- MECHANICAL ENGINEERING DYNAMICS OF MACHINERY MODEL QUESTION PAPERDocument4 pagesMECHANICAL ENGINEERING DYNAMICS OF MACHINERY MODEL QUESTION PAPERNirman ParasharNo ratings yet

- Dmm2 Mar2006Document8 pagesDmm2 Mar2006Abdul Saleem MohammedNo ratings yet

- Dynamics Question Bank PDFDocument21 pagesDynamics Question Bank PDFbejumohanNo ratings yet

- 05-04 Machine Design & Cad-II (Me)Document2 pages05-04 Machine Design & Cad-II (Me)Abdul AhadNo ratings yet

- Design of Machine Elements - IIDocument8 pagesDesign of Machine Elements - IIprasaad26No ratings yet

- Design of Machine Element-IIDocument53 pagesDesign of Machine Element-IIPramod R Bidve100% (1)

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityDhruvNo ratings yet

- Me 7 Sem Subject Design of Mechanical Drives Jun 2017Document2 pagesMe 7 Sem Subject Design of Mechanical Drives Jun 2017djniksthehearteditorNo ratings yet

- Belt, Rope & Chain Drives - PDF PDFDocument36 pagesBelt, Rope & Chain Drives - PDF PDFabhisar100% (3)

- 12ME5DCDM2Document3 pages12ME5DCDM2Abhyudaya SinghNo ratings yet

- List of Public Sector Companies in IndiaDocument39 pagesList of Public Sector Companies in IndiaAbhyudaya SinghNo ratings yet

- Curved BeamDocument85 pagesCurved Beampoojasmita14100% (3)

- 12ME5DCDM2Document3 pages12ME5DCDM2Abhyudaya SinghNo ratings yet

- BMS College of Engineering, Bangalore-560019: January 2015 Semester End Make Up ExaminationsDocument2 pagesBMS College of Engineering, Bangalore-560019: January 2015 Semester End Make Up ExaminationsAbhyudaya SinghNo ratings yet

- ClutchDocument41 pagesClutchJyoten Panditpautra100% (1)

- DESIGN OF SPRINGSDocument112 pagesDESIGN OF SPRINGSchshbt80% (5)

- DVGDocument53 pagesDVGbalajigandhirajanNo ratings yet

- 12ME5DCDM2Document3 pages12ME5DCDM2Abhyudaya SinghNo ratings yet

- BMS College of Engineering, Bangalore-560019: January 2015 Semester End Make Up ExaminationsDocument2 pagesBMS College of Engineering, Bangalore-560019: January 2015 Semester End Make Up ExaminationsAbhyudaya SinghNo ratings yet

- 11ME5DCDM2Document3 pages11ME5DCDM2Abhyudaya SinghNo ratings yet

- BMS College of Engineering, Bangalore-560019: January 2015 Semester End Make Up ExaminationsDocument2 pagesBMS College of Engineering, Bangalore-560019: January 2015 Semester End Make Up ExaminationsAbhyudaya SinghNo ratings yet

- 12ME5DCDM2Document4 pages12ME5DCDM2Abhyudaya SinghNo ratings yet

- 11ME5DCDM2Document3 pages11ME5DCDM2Abhyudaya SinghNo ratings yet

- 12ME5DCDM2Document3 pages12ME5DCDM2Abhyudaya SinghNo ratings yet

- 11ME5DCDM2Document3 pages11ME5DCDM2Abhyudaya SinghNo ratings yet

- Cable Installation Manual For Power and Control Cables: Global ReachDocument100 pagesCable Installation Manual For Power and Control Cables: Global Reacharjmandquest100% (1)

- Bhagvender Singh XII-A Physics Project PDFDocument15 pagesBhagvender Singh XII-A Physics Project PDFvoid50% (4)

- Electroanalytical Techniques for Studying Redox ReactionsDocument3 pagesElectroanalytical Techniques for Studying Redox Reactionsjayapandis83No ratings yet

- Methods of Test For Cables: Indian StandardDocument2 pagesMethods of Test For Cables: Indian StandardARUN BNo ratings yet

- Spe 131758 Ms - GL and EspDocument11 pagesSpe 131758 Ms - GL and EspSamuel VmNo ratings yet

- Effect of Water Absorption in Polymers at Low and High TemperaturesDocument9 pagesEffect of Water Absorption in Polymers at Low and High TemperaturesGeotamNo ratings yet

- Carter Auto Water Pump Components 072420Document2 pagesCarter Auto Water Pump Components 072420geniusNo ratings yet

- SYSMEDOCSeries Oxygen Concentrator User ManualDocument24 pagesSYSMEDOCSeries Oxygen Concentrator User ManualHakimNo ratings yet

- Pneumatic Maneuvering SystemDocument65 pagesPneumatic Maneuvering Systemminhankyaw100% (3)

- Ingersoll Rand VR-843CDocument2 pagesIngersoll Rand VR-843CMontSB100% (1)

- Electrocardiograf Ym412i Service ManualDocument14 pagesElectrocardiograf Ym412i Service ManualramarservmedNo ratings yet

- Ce2039 MSW NotesDocument659 pagesCe2039 MSW NotesMuthu Praveen SarwanNo ratings yet

- World Jet Fuel Specifications 2005Document51 pagesWorld Jet Fuel Specifications 2005Richo Crb100% (2)

- Accident Radio Logic GOIANIADocument157 pagesAccident Radio Logic GOIANIACatalin CuraliucNo ratings yet

- 450 Kva Diesel Generator Set Model HG 450Document1 page450 Kva Diesel Generator Set Model HG 450ghostshotNo ratings yet

- BIOGAS 5000 Operating ManualDocument107 pagesBIOGAS 5000 Operating ManualmjsampaioNo ratings yet

- Auto ElectricianDocument3 pagesAuto Electricianmnrao62No ratings yet

- Business Graduation ProjectDocument26 pagesBusiness Graduation ProjectSanket ThoratNo ratings yet

- Analisis Comparativo Cat® 992G Vs - Cat 993KDocument14 pagesAnalisis Comparativo Cat® 992G Vs - Cat 993KMónica Rada Urbina100% (1)

- Iptc-19474-Ms A Strategic and Flexible Approach To Through Tubing Electrical Submersible PumpDocument15 pagesIptc-19474-Ms A Strategic and Flexible Approach To Through Tubing Electrical Submersible PumpGilbert OmittaNo ratings yet

- Microprocessor Engine/Generator Controller: Model MEC 20Document4 pagesMicroprocessor Engine/Generator Controller: Model MEC 20Gerardo OrtizNo ratings yet

- MATE 280 Characterization of Powders and Porous MaterialsDocument65 pagesMATE 280 Characterization of Powders and Porous MaterialsAnissa Adiwena100% (1)

- Field Joint CoatingDocument7 pagesField Joint CoatingTeodor EzaruNo ratings yet

- Response of Water Resources Systems To Climate ChangeDocument355 pagesResponse of Water Resources Systems To Climate ChangePat Prodanovic100% (5)

- InternationalDocument11 pagesInternationalheeral patelNo ratings yet

- Encore 22 lb. Capacity Front Load DryerDocument2 pagesEncore 22 lb. Capacity Front Load Dryermairimsp2003No ratings yet

- ASME - Middle-East-Training-Brochure PDFDocument32 pagesASME - Middle-East-Training-Brochure PDFMohamed F MorsyNo ratings yet

- GreenTech EC Technology enDocument44 pagesGreenTech EC Technology enspscribd1No ratings yet

- Error Codes Special Modes: Yes Yes YesDocument2 pagesError Codes Special Modes: Yes Yes YesJorge SaavedraNo ratings yet