Professional Documents

Culture Documents

Msprimarygroutingrevisec 130804214254 Phpapp01

Uploaded by

Janaka DineshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Msprimarygroutingrevisec 130804214254 Phpapp01

Uploaded by

Janaka DineshCopyright:

Available Formats

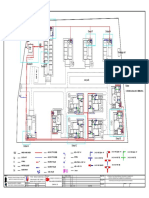

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

The Kingdom of Thailand

Ministry of Transport

MASS RAPID TRANSIT AUTHORITY OF THAILAND

MRT BLUE LINE EXTENSION PROJECT

CONTRACT 1: UNDERGROUND CIVIL WORKS

(HUA LAMPHONG SANAM CHAI SECTION)

METHOD STATEMENT

FOR

PRIMARY AND SECONDARY GROUTING

Document No. ITD/BE1/MS/T007, Rev. C

JULY 2013

PREPARED BY:

ITALIAN-THAI DEVELOPMENT PUBLIC COMPANY LIMITED

Italian-Thai Development PCL.

35

1 July 2013

Page 0 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

Document Title: Method Statement for Primary and Secondary Grouting

Document No: ITD/BE1/MS/T007

Document Amendment Record

Revision

Date

Amendment Record

15 February 2012

11 April 2012

1 July 2013

First submission for approval

Amend as per CSCBLs Letter Ref. CSCBL/C1/ITD/MST/0678,

Dated 14th March 2012

Improving some point of this method statement for making it

correct, practical and perfect: in item 4.1.2.3 page 6, 7 and item

4.2 page 9 and in checklist page 13, 15

Controlled Distribution List

Copy

No

Distribution

List

Type of

Issue

MRTA

PMC

CSC

Recipient

Copy

No

Distribution

List

Type of

Issue

Recipient

Type of Issue

A For Internal Review& Comment

B For ERs Approval

C For Acknowledgement or Information or Reference.

D For Use or Implementation or Construction

Type of Document

Where this page is over-stamped with the words C this means:

1. Distribution is centralized-in this case from the Quality Assurance Manager.

2. Each copy is issued to a particular person or organization. If no longer required it should be returned.

3. It is not to be photocopied either in whole or in part. Additional copies are available on request.

4. Copy holders will be automatically issued with any amendments. Responsibility for incorporating such

amendments rests with the copy holder.

Italian-Thai Development PCL.

35

1 July 2013

Page 1 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

Prepared by: __________________________

(Nopporn Rattanchayabun)

Section Manager (TBM Tunnel)

Reviewed by: _____________________________

(Prakin Arunotong)

Engineering and Project Control Manager

Date : ______________________

Reviewed by: _____________________________

(Thavesak Rungpiriyadech)

Tunnelling Works Manager

Date : ______________________

Approved by: _____________________________

(Pairach Supavivat)

Project Director

Date : ______________________

Date : ______________________

Table of Contents

1.

Scope........................................................................................................3

2.

Definitions and Abbreviations.....................................................................................3

3.

Specifications and Reference

Documents..................................................................4

4.

Working Procedures...................................................................4

5.

Inspection and Test Plan .........................................................12

6.

Quality Control Checklist for Primary and Secondary

Grouting.............................13

7.

Attachment A Grouting Material for shield Tunneling Work: Proposal for Mix Design

and Testing Method....................................................................................17

8.

Attachment B The Laboratory Test Program for Primary and Secondary Grouting

Works..27

9.

Attachment C ASTM C939-02 Standard Test Method for Preplaced-Aggregate

Concrete (Flow Cone Method)29

10.

Attachment D ASTM D4830-84 (Reapproved 2001) Standard Test Method for

Density of Bentonitic Slurries..33

Italian-Thai Development PCL.

35

1 July 2013

Page 2 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

1.

Scope

This method statement provides information for Primary Grouting and Secondary

Grouting in the MRT Blue Line Extension Project, Contract 1: Hua LamphongSanam Chai Section. The cavity between the segment outer surface and soil shall

be filled with grout material as soon as possible after TBM excavation. Therefore,

the cavity between segments extrados and surrounding ground will be grouted

immediately after TBM excavation suddenly after TBM move through segment hole 2

positions at shoulder left & right. This grouting shall be performed in two steps

namely primary grouting (concurrent with excavation) and later secondary grouting.

As the outline Construction Specifications Volume 6, Clause 9.8.3(C), Proprietary

grouts may be used, subject to the Employers Representatives consent. Therefore,

the thixotopical-gel type which consist of liquid A and liquid B was proposed for

Primary Grout.

The thixotopical-gel grouting was famous using in worldwide. The best benefit of

thixotopical-gel grouting is quick setting time. Comparison between thixotopical-gel

grout and single fluid grout with high water cement ratio, the thixotopical-gel grout

was more quicker setting time and best for protect road surface and building area.

Therefore ITD proposed the thixotopical-gel grouting for the MRT Blue Line

Extension Project.

The secondary grouting shall consist of cement liquid part A from the primary

grouting material which is prepared on ground surface batching plant and then

transported to tunnel.

2.

Definitions and Abbreviations

Inspection and Testing Plan (ITP) is a document made by ITD or manufacturer or

subcontractor to describe the minimum requirements of the quality control

activities, inspection and test items during fabrication, installation and/or

construction phase, reference documents, required acceptance criteria, certifying

or verifying documents, and inspection parties involved, its all for assure that the

work or product will be built in accordance with the project specification. Relevant

inspection levels contained in ITP is defined as follows:

Italian-Thai Development PCL.

35

1 July 2013

Page 3 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

(Hold Point)

Signify an important inspection point. This is used for special tests or inspections

which shall be witnessed, signed and dated by the authorized inspector and/or the

Employer and/or the Employers Representative.

W

(Witness Point)

Signify an important inspection point to be witnessed by the authorized inspector.

W/O

(Witness Point-Optional)

Signify an inspection point to be witnessed or optional point not to be witnessed by

the authorized inspector and/or Employer and/or the Employers Representative.

(Surveillance Point)

Signify an inspection point which may be carried out on a random basis.

Notification of these points are normally not specified (ITD will review the

frequency of inspection results).

X

(Sub-contractor Inspection)

ITPs for sub-contract works shall contain the nominated inspection points and

inspectors.

D

(Documentation Required)

Signify that a test report, material certificate or the like shall be supplied, or that

the particular inspection activity must be verified by a document signed and dated.

It may be in the form of a QA traveler document attached to, or moving through the

process with the products.

R

(Review Point)

Review and verify of quality system documentation and final quality records. This

may vary from a spot review to a full quality audit and may include verification by

ITD that a final report or manufacturers data report has been compiled and is a

complete and accurate record. ITPs shall be reviewed by ITD and at the same time

marked up to indicate ITDs surveillance inspection activities. As previously stated,

all ITPs shall be reviewed and approved by responsible Manager(s) prior to the

commencement of manufacture or construction.

3. Specifications and Reference Documents

Related specification contained in OCS Volume 6 Section 9.8.1 - 9.8.12.

4.

Working Procedures

Italian-Thai Development PCL.

35

1 July 2013

Page 4 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

4.1

Primary Grouting Method

4.1.1

General

This Section provides the information for performing the primary

grouting with the Thixotopical - gel type grout material

The major activities in primary grouting are:

a) Grout Material Quality Control.

b) Grouting, the grout pressure is measured, monitored and

recorded by the tunnel driving monitoring system on the TBM

working platform number 2 and record with print out by ENZAN

software.

c) Tunnel Segment Movement Monitoring, we have two surrey teams

both on ground and in the tunnel to monitoring ground

displacement and segment deformation by check TBM clearance

to segment for diameter result.

The details for each activity are described in following sections.

4.1.2

Grout Material Mixing and Quality Control

In order to ensure that the proposed quality of the thixotropical-gel

type grout material is achieved the quality testing procedure shall be

applied.

Although the testing methods for quality control are described in the

Grouting Material for Shield Tunneling Work: Proposal of Mix Design

and Testing Method, the details method shall be referred to as

follows:

4.1.2.1

Grout Mix

The proposed grout mix is shown in Table 1.

Table 1: Grout Mix for Primary Grout

Solution

Material

Design Quantity

(per 1 m3 mixed grout)

Liquid A

Cement

240 kg

Bentonite

30 kg

Water

830 kg

Stabiliser

2.4 kg

Special Sodium Silicate

80 litre

Liquid B

Italian-Thai Development PCL.

35

1 July 2013

Page 5 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

This final mix design is subject to laboratory test before actual carried out.

4.1.2.2 Instrument and Equipment to be used

The following instruments and equipment shall be used for

the primary grouting mixing and quality control:

4.1.2.3

Unconfined compression apparatus.

ii

Graduated cylinder (1 litter).

iii

Beaker (3 litter).

iv

Stop Watch.

Specimen Mould (5 cm cube).

vi

50 cm cubic case for water measuring.

vii

Grout Mixing Plant and Associated Equipment.

viii

Weight Meter.

Calibration on weight scales of grout mixing plant and check

density of stabilizer and sodium silicate

In order to ensure that the accuracy of weight material

components, mixing ratio, injection flow rate and injection

pressure, the following calibration activities will be

performed every 4 months.

a)

b)

Italian-Thai Development PCL.

35

Calibration on weight scales of grout mixing plant

i.

Remove any object from the top of mixer and make

no load on the mixer.

ii

Confirm that 0 kg (No load) on the mixer.

iii

Put each weight (20kg) on the mixer and add each

weight until 1300 kg (weight 20 kg = 65

block):record the weight displays each step.

iv

Then, lift each weight down from the mixer and

record the weight display each step until weight

display is 0 kg.

Repeat process item (I. to IV.) again.

Total weight shall be measured to an accuracy of

(+ -) 1%.

Check specific gravity of stabilizer.

1 July 2013

Page 6 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

c)

d)

Pour stabilizer 500 cc. in the beaker.

ii

Use specific gravity meter to measure and record

the specific gravity of stabilizer 3 times, then

average the value.

The specific gravity of stabilizer shall be

measured in the range 1.095 to 1.115 g/cm 3.

Check specific gravity of sodium silicate.

i

Pour sodium silicate 500 cc. in the beaker.

ii

Use specific gravity meter to measure and record

the specific gravity of sodium silicate 3 times, then

average the value.

The specific gravity of sodium silicate shall be

measured in the range 1.394 to 1.422 g/cm3.

Check stabilizer pump feed test.

i

line.

ii

e)

Operate the pump and set the flow for the feed

After flow volume stable, take a sample for one

minute.

Conduct the test for three time, compare the

volume which the deviation of volume shall be in

the range (+ -) 3%.

Grout liquid flow rate.

To ensure an accurate mixing rate at the injection point,

each flow rate of liquid A and B shall be checked the

flow rate at the injection point.

f)

Italian-Thai Development PCL.

35

Prepare a container to pour grout liquid near an

injection point.

ii

Start pumping liquid A into a container. Calculate

the flow rate of liquid A upon the time for pumping

and the actual volume of the liquid A shall be in the

range (+-) 3%.

iii

Repeat the same procedure above for liquid B.

iv

Confirm that the flow rate ratio shall be 11.5 (Liquid

A): 1 (Liquid B).

Grout Pressure.

1 July 2013

Page 7 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

To ensure an accurate of grout pressure gauge, the

pressure gauge should be calibrated and has the

calibration certificate by an external and independent

party.

4.1.2.4

Testing Frequency

The frequency of the quality test of the grout material is

shown in Table 3. A summary report shall be submitted

upon the test result of the first 30 rings.

Table 3 The Frequency of the Quality Test of the Grout Material

Period

Frequency

First 30 rings

Every ring

After 30 rings in Initial Drive and in whole Main Drive

Every 5 rings at Batching Plant (on ground)

4.1.2.5

Quality Testing Items

The following tests shall be performed in accordance with

the testing frequency as specified in Table 3. Table 4

shows the testing items and the acceptance criteria for

each test.

Table 4: Testing Item and the Acceptance Criteria for Each Test

Item

Specification

Test Method

Test Standard

Specific Gravity

1.20 + 0.02 g/cm 3

Mud Balance

ASTM D 4380-84

(Reapproved

2001)

Liquid A

Bleeding

0-5% (1 hour after

Liquid A mixing)

Bleeding Test

ASTM C940-98A

Liquid A

Consistency

< 11 seconds

Flow Test

ASTM C939-02

Gel Time

4-12 seconds

Mix Test

N/A

1 Hour

0.03 N/mm 2

ASTM C109M-02

Frequency

Every Shift

Remark

Liquid A

Liquid A+B

Every Ring for

Compressive

Italian-Thai Development PCL.

35

1 July 2013

Page 8 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

Strength

24 Hours

0.4 N/mm 2

first 30 rings

7 Days

0.8 N/mm 2

Every 5 rings

28 Days

1.5 N/mm 2

During

maindrive

4.1.2.6

Mixed

Grout

Deterioration test

In order to ensure that the pot life of liquid A, a

deterioration test shall be performed. All testing as shown

in Table 4 shall be performed both immediately and also

24 hours after mixing Liquid A.

If the test results are within the specified tolerance as per

Table 4, then Liquid A shall be judged to have had no

deterioration.

4.1.3

Grouting

The injection of the grout material shall be performed as the method

statement for tunnel excavation specifies.

The grout pressure and the volume shall be monitored and recorded

by the tunnel driving monitoring system.

The filling rate against the theoretical cavity volume shall be

calculated and recorded by the tunnel driving monitoring system.

4.2

Secondary Grouting Method

4.2.1

Introduction

Secondary grouting will be completed in correlation with deformation

measurement within 10 day after ring completion and not move than

30 meters behind the TBM face. Secondary grouting shall be at a

pressure not greater than 4 bars, consistent with completely filling all

voids.

The mix design are tabulated as below:

Italian-Thai Development PCL.

35

Materials

Proportion

Cement

500 kg

Water

850 litre

Bentonite

50 kg

1 July 2013

Page 9 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

4.2.2 Testing Frequency

The frequencies of the quality test of the grout material are random

checking by 1 sample per time of grouting in tunnel.

4.2.3 Quality Testing Items

The following tests shall be performed in accordance with the testing

frequency. Table of specified requirements shows the testing items

and the acceptance criteria for each test.

Table 5: Specified Requirements of Secondary Grouting Material.

Item

Specification

Test Method

Test Standard

Specific Gravity

1.35 + 0.02 g/cm 3

Mud Balance

ASTM D 4380-84

(Reapproved

2001)

Bleeding

0-5% (1 hour after

Liquid A mixing)

Bleeding Test

ASTM C940-98A

Consistency

N/A

Flow Test

ASTM C939-02

Compressive

Strength Test

1.5 N/mm 2

at 49 days

4.2.4

ASTM C109M-02

Frequency

Remark

Liquid A

Every internal

5 No rings

Liquid A

Random check

Liquid A

Liquid A

Deterioration test

In order to ensure that the pot life of liquid A, deterioration test shall be

performed. All testing as shown in Table 5 of specified requirement

shall be performed both immediately and also 24 hours after mixing

Liquid A.

If the test results are within the specified tolerance as per the above

Table 5, then Liquid A shall be judged to have had no deterioration.

4.2.5

Work Sequence for secondary grout

The injection of the grout material shall be performed after primary

grouting completed. During each shift secondary grouting shall be

performed at the back up on the working stage of TBM. The

secondary grouting shall use the mobile pump order to control the

pressure to 3.5 kg/cm2. The position of grouting shall be located at

existing drill holes at every interval of 5 No rings with wet hole. Any

Italian-Thai Development PCL.

35

1 July 2013

Page 10 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

grout holes showing evidence of water leakage shall also be

secondary grouted, as will those nearest to any wet joints. However,

the most important issue to concern is the surface displacement which

should be considered together between the surface monitoring

instrument result and the tunnel driving monitoring system. If one

both systems can detect the settlement or heave, engineer have to

stop secondary grouting at that point and re-consider grout pressure

before processing the secondary grout.

The procedure for injection of the secondary grout shall be as follows:

a

Open grout hole plug.

Each segment grout hole plug shall be carefully removed in order

to prevent any inflow of ground water or soil through the hole.

Drill hole through the non-return valve in segment grout hole

(never key segment). The 28 mm electric drill (400 mm. length)

shall be inserted into the position of the abandoned non-return

valve.

Installation of injection pipe at grout hole.

The injection pipe shall be installed as soon as possible after

removing grout hole plug.

4.2.6

Connect grout hose to injection pipe.

Carry out the grouting until the pressure achieved 3.0-3.5 kg/cm 2.

(Automatic shut down of pump pressure of 3.0-3.5 kg/cm 2).

Grouting volume shall be measured by measurement liquid

volume using in mixing tank.

Change injection point once the grout pressure has achieved 3.03.5 kg/cm2 and leave the grout injection pipe in the hole until the

grout has set. The grout hole plug shall be replaced and fully

tightened once the grout pipe has been removed.

The compressive strength test specification is required grout

strength 1.5 N/mm2. @ 49 days.

Use new injection pipe for installation into the next grouting

position.

Change grouting hose to next position and continue.

Facilities to be prepared

a

Grouting pump with pressure limiter.

Electric Hand Drill whole size 28 mm. x 400 mm. length

Italian-Thai Development PCL.

35

1 July 2013

Page 11 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

4.2.7

Tank of agitator installed in TBM back up unit.

Injection pipe with ball valve 2 inch dia. same threading with the

grout hole in segment.

Grout hose, size 1 inch.

Quality Control

Following items as the quality control checklist shall be checked and

monitored during the works.

Italian-Thai Development PCL.

35

1 July 2013

Page 12 of

MRT Blue Line Extension Project

Works

Contract 1: Underground Civil

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007,

Rev. C

INSPECTION AND TEST PLAN

PROJECT : MRT Blue Line Extension

Contract : Underground Civil Work

(Hua Lamphong Sanam Chai Section)

Location/Area : Tunnel at Hua Lamphong to Sanam Chai Station

Quality System : ISO 9001

Document Type : Controlled

For : Method Statement Primary and Secondary Grouting

Inspection Responsibilities

No.

Main Activity

Relevant

Specification

Acceptance Criteria

Document

ITD

Frequency of Inspection/Test

Verification/Acceptance

sign off by

Form Checklist

Subcontractor

Vendor

Site

Engineer

QC

Every Day

N/A

W/O

Every Day

N/A

W/O

Every Day

N/A

Every Day

N/A

ER

No.

Rev.

W/O

MS/T007/1

Site Engineer

W/O

MS/T007/2

Site Engineer

W/O

W/O

MS/T007/3

Site Engineer

W/O

W/O

MS/T007/3

Site Engineer

Primary Grouting

Primary Grout Material Test

OCS Volume 6

Section 9.8

Primary Grouting Shift

Report

OCS Volume 6

Section 9.8

Secondary Grouting

Secondary Grout Material

Test

OCS Volume 6

Section 9.8

Secondary Grouting Shift

Report

OCS Volume 6

Section 9.8

Italian-Thai Development PCL.

ASTM D 4380-84

(Reapproved 2001),

ASTM C940-98A

ASTM C939-02

ASTM C109-02

ASTM D 4380-84

(Reapproved 2001),

ASTM C940-98A

ASTM C939-02

ASTM C109-02

ASTM D 4380-84

(Reapproved 2001),

ASTM C940-98A

ASTM C939-02

ASTM C109-02

ASTM D 4380-84

(Reapproved 2001),

ASTM C940-98A

ASTM C939-02

ASTM C109-02

1 July 2013

Page 12 of 35

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev. C

Mandatory Hold Point Until Approved

Surveillance Point Random ITP/Each Quantity

Witness Point

Subcontract Inspection

Witness Point-Optional

Document or Record Required

W/O

Italian-Thai Development PCL.

1 July 2013

Page 13 of 35

R

N/A

Review Point

Not Applicable

MRT Blue Line Extension Project

Works

Contract 1: Underground Civil

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

Primary Grout Material Test

(Form No. MS/T007/1, Rev. C)

Time:

No

Test ltem

Specification

Specific Gravity

Set ting

Consistency

Gel time

Tunnel : WB / EB

Test Result

Ring No________

Judgment

Test Standard

Remark

Yes / No

ASTM D 4380-84

(Reapproved 2001),

Liquid A

Yes / No

ASTM C 940-98A

Liquid A

Yes / No

ASTM C939 62

Liquid A

Yes / No

N/A

Liquid (A+B)

1.20

0.02g/cm 3

0-5% (After

1 hour)

< 11

seconds

4 ~ 12

seconds

1 hour

1.

2.

3.

Avg.

0.03 N/mm 2

Yes / No

0.4 N/mm 2

Yes / No

0.8 N/mm 2

Yes / No

1.5 N/mm. 2

Yes / No

See note

1.

24 hour

Compressive Strength Test

Mixing Date:

2.

3.

Avg.

ASTM C109-62

See note

7 days

1.

2.

3.

Avg.

28 days

1.

2.

3.

Avg.

Completed by Site Engineer

Agreed by QC

Name :___________________

(

Date : _____________________

ER

Name :___________________

)

Engineer

See note

)

Engineer

Witnessed Point-Optional by :

__________

(

)

Date : _____________________

Date : ___________________________

Italian-Thai Development PCL.

35

July 2013

Page 13 of

MRT Blue Line Extension Project

Works

Contract 1: Underground Civil

Hua Lamphong Sanam Chai

Section

Rev. C

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007,

Note: 1 Div. = (Div. x 2.3942 + 0.9710) x 9.81 N; Calibrated Date May 23, 2013.

Italian-Thai Development PCL.

14 of 35

1 July 2013

Page

MRT Blue Line Extension Project

Works

Contract 1: Underground Civil

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

Completed by Site Engineer

Agreed by QC

Name :__________________________________

ER

Name :_______________________________

Witnessed Point-Optional by : __________________

)

Engineer

)

Engineer

Date : __________________________________

Date : _______________________________

Date : _____________________________________

Primary Grouting Shift Report

Location: West Bound / East Bound

Previous Ring Excavation

Date: .

Grouting Time

Ring

No.

Ring No.

Time Finished

Italian-Thai Development PCL.

35

Start

Finished

Day Shift / Night Shift

Inspector:

Position of

Injection hole

Grouting Pressure

(2-3.5 kgf/cm 2)

1

1 July 2013

Visual Observation

hole Position

6

Taking Sample

Remark

Page 14 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev. C

(Form No. MS/T007/2, Rev. C)

Italian-Thai Development PCL.

1 July 2013

Page 15 of 35

MRT Blue Line Extension Project

Works

Contract 1: Underground Civil

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

Secondary Grout Material Test

(Form No. MS/T007/3, Rev. C)

Mixing Date:

Time:

Tunnel : WB / EB

No

Test ltem

Specification

Specific Gravity

Set ting

Consistency

Test Result

Ring No________

Judgment

Test Standard

Remark

Yes / No

ASTM D 4380-84

(Reapproved 2001),

Liquid A

Yes / No

ASTM C 940-98 A

Liquid A

Yes / No

ASTM C939 02

Liquid A

1.35

0.02g/cm 3

0-5% (After

1 hour)

< 15

seconds

1 hour

1.

2.

3.

Avg.

Yes / No

Yes / No

2.

3.

Avg.

35 days

1.

2.

ASTM C 109-02

3.

Avg.

Yes / No

Yes / No

1.5 N/mm. 2

Yes / No

1.

42 days

Compressive Strength Test

24 hour

1.

2.

3.

Avg.

49 days

1.

2.

3.

Avg.

Completed by Site Engineer

Italian-Thai Development PCL.

35

Agreed by QC

1 July 2013

See note

ER

Page 16 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

A

Name :___________________

(

Name :___________________

)

Engineer

Date : _____________________

)

Engineer

Witnessed Point-Optional by :

__________

(

)

Date : _____________________

Date : ___________________________

Note: 1 Div. = (Div. x 2.3942 + 0.9710) x 9.81 N Calibrated Date May 23, 2013.

Italian-Thai Development PCL.

35

1 July 2013

Page 17 of

MRT Blue Line Extension Project

Works

Contract 1: Underground Civil

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

Secondary Grouting Shift Report

Location: West Bound / East Bound

Date: .

Day Shift / Night Shift

Inspector:

(Form No. MS/T007/4, Rev. C)

No.

Ring No.

Grout Hole No.

Max Pressure

Grout Volume

Start Time

Finish Time

Remarks

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Italian-Thai Development PCL.

1 July 2013

Page 16 of 35

MRT Blue Line Extension Project

Works

Contract 1: Underground Civil

Hua Lamphong Sanam Chai

Section

C

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

Completed by Site Engineer

Name :__________________________________

Agreed by QC

Name :_______________________________

Witnessed Point-Optional b

)

Engineer

Date : __________________________________

)

Engineer

Date : _______________________________

Date : _________________

Attachment A

Grouting Material for shield Tunneling Work: Proposal

for Mix Design and Testing Method

Italian-Thai Development PCL.

35

1 July 2013

Page 17 of

MRT Blue Line Extension Project

Works

Contract 1: Underground Civil

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

1.

Introduction

This document was prepared to present the design approach and the testing

method of the grouting material that will be used for shield tunneling Hua lamphong

- Sanam Chai Section In order to secure the maximum effect of filling in the void

between the excavated profile and the permanent linings to the underground

works, thyrotrophic -gel grouting material is proposed. A thyrotrophic-gel grouting

material provides enough strength against the ground pressure and the recovery of

fluidity of the grouting material within one hour after grouting this ensuring a

continuous and impermeable void filling. The required properties of thyrotrophic

-gel grouting material are:

1.1

Non shrinkage after grouting void.

1.2

High resistance to underground water before setting.

1.3

High controllability of grout flow.

1.4

Suitability for along distance pumping.

1.5

No separation of solid material from solution during storing and

pumping.

Specification

Following are the specifications of properties of the thyrotrophic-gel grouting

material for Tunnel Works to secure the maximum effects.

2.1

Gel (Setting) Time of Liquid A and Liquid B

Gel Time is specified between 4 and 12 seconds

Grouting material will be exposed to ground water during grouting while it

has fluidity. If the gel time is too long, the grouting material will be diluted

and lose the expected properties. Conversely, if the gel time is too short,

the void will not be fully filled because the grouting material can not be

flown from the grouting point to the whole void. The resulting insufficient

grouting cause round settlement and poor water tightness.

From the above points, the most appropriate gel time is specified between 4

and 12 seconds.

2.2

Bleeding Rate of Liquid A

The bleeding rate shall be less than 5% at 1 hour after mixing

Grouting material with high bleeding rate does not have long usable life

because much bleeding cause separation of grouting material and blockage

of Liquid A in the pipeline from the grouting plant to tunneling face.

Italian-Thai Development PCL.

35

1 July 2013

Page 18 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

12.3

Consistency (Flow Rate) of Liquid A in P-Type Funnel Test

Consistency of Liquid A shall not be greater than 11 seconds If Liquid A has

high consistency, it may cause a blockage. The maximum value of the

consistency of Liquid A in P-Type funnel is specified as 11 second.

2.4

Compressive Strength

The designed compressive strength is shown as below:

Table-1 Required compressive Strength

2.5

Curing Time

Compressive Strength

Mixing after 1 hour

0.03 N/mm 2

Mixing after 1 day

0.4 N/mm 2

Mixing after 7 days

0.8 N/mm 2

Mixing after 28 days

1.5 N/mm 2

Usable Life of Liquid A

Usable life of Liquid A shall be minimum 24 hours for long distance pumping

from the mixing plant on ground to tunneling face.

3.

Proposed Mix Design

The mix proportion of the thyrotrophic-gel grouting material for Tunnel Westbound

and Eastbound is proposed as below.

Table Mix Design

Solution

Material

Quantity (per 1 m 3 mixed grout)

Liquid A

Cement

240 kg

Bentonite

30 kg

Water

830 liter

Stabiliser

2.4 kg

Special Sodium Silicate

80 liter

Liquid B

This final mix design is subject to laboratory test before actual carried out.

Italian-Thai Development PCL.

35

1 July 2013

Page 19 of

MRT Blue Line Extension Project

Works

Contract 1: Underground Civil

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

4.

Testing Method

Trial mixing and the grouting mix tests for the grouting material to be used for

Tunnel Works are carried out as follows.

4.1

Liquid A mixing procedure

We were separated liquid of cavity grouting to 2 parts, one part is Liquid A

component, betonies, stabilizer and water, another part is Liquid B. It is

accelerator. The density of Liquid A will be measured by volume of weight,

actual measured density and theoretical density should be compared.

4.1.1

4.1.2

4.2

Equipment

4.1.1.1

Electric Balance.

4.1.1.2

Hand Mixer.

4.1.1.3

Bucket of 20 litre.

Procedure

4.1.2.1

Put water in bucket 20 litre amount according to design

mixed.

4.1.2.2

Put betonies in bucket mix by hand mixing, start stop

watch.

4.1.2.3

At time 1.30 minutes put cement in bucket.

4.1.2.4

At time 2.30 minutes put cement in bucket .

4.1.2.5

Mix grout until 3 minutes stop mixing and used Liquid A in

other testing.

Measurement of Liquid A bleeding

Due to keep good pump ability of grout, bleeding of grout material is

unavoidable. Bleeding seams a kind of segregation of mixed grout material.

4.2.1 Equipment

4.2.1.1

Mess cylinder 500 ml.

4.2.1.2

Hand Mixer.

4.2.1.3

Bucket of 20 liter.

4.2.1.4

Stop watch.

Italian-Thai Development PCL.

35

1 July 2013

Page 20 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

4.2.2

Procedure

4.2.2.1

Mixed liquid A in bucket.

4.2.2.2

4.2.2.3

Put Liquid A in mess cylinder 500 ml.

Measure the bled water quantity at one hour later.

4.2.2.4

Bleeding procedure formula is Bleeding percentage = (Bled

water volume (m1.)/500 ml.) *100

Remark

4.3

Limit of Bleeding is defined as 5% and for laboratory

test 2%.

In air entraining type grout the bleeding is less than

ordinary grout.

Measurement of Consistency

4.3.1 Equipment

4.3.2

4.4

4.3.1.1

Bucket of 20 litre.

4.3.1.2

Hand Mixer.

4.3.1.3

Pre pact flow cone.

4.3.1.4

Stop watch.

Procedure

4.3.2.1

Mixed Liquid A in bucket of 20 litre

4.3.2.2

Fill Liquid A in bucket.

4.3.2.3

Discharge grout, stop watch until the grout was empty

record time by sec.

Measurement of gel time

Gel time check is related to the performance of accelerator. It is defined by a

time (see) since start mix liquid A and Liquid B until it become harden (no flow

ability). Gel time is measured by Two cup met hid.

4.4.1 Equipment

4.4.1.1

Beaker of 2000 cc made of plastic w/side hand 2 pieces.

4.4.1.2

Stop watch.

4.4.2 Procedure

Italian-Thai Development PCL.

35

1 July 2013

Page 21 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

4.5

4.4.2.1

Prepare Liquid A (850 cc-950 cc) and Liquid B (50 cc-150

cc) in the beaker.

4.4.2.2

Liquid A pour to Liquid B, start watch and Liquid B pour to

Liquid A repeat this until no flow ability is observed and

measure this time.

4.4.2.3

Record gel time.

Measurement of Compressive Strength

Test cube (5 cm.* 5 cm.) are normally used for this test, 3 test cube are

tested and water curing method is used.

4.5.1 Equipment

4.5.2

4.5.1.1

Beaker of 200 cc. made of plastic w/side hand 2 pieces.

4.5.1.2

Test piece mould for mortar.

4.5.1.3

Compressive strength machine (small capacity 20 kg. More

or less).

4.5.1.4

Electronic balance.

Procedure

4.5.2.1

Prepare Liquid A and Liquid B same quantity as gel time

check.

4.5.2.2

Liquid A pour to Liquid B and Liquid B to Liquid A repeat 2

time and pour Liquid A+B in test piece mould for mortar

before it hardens.

4.5.2.3

Check compressive strength at time 1 hr, 1 day, 7 days, 28

days.

Italian-Thai Development PCL.

35

1 July 2013

Page 22 of

MRT Blue Line Extension Project

Works

Contract 1: Underground Civil

Hua Lamphong Sanam Chai

Section

C

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

Italian-Thai Development PCL.

35

1 July 2013

Page 23 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

Measurement of Bleeding

Measurement of Consistency

Italian-Thai Development PCL.

35

1 July 2013

Page 24 of

MRT Blue Line Extension Project

Works

Contract 1: Underground Civil

Hua Lamphong Sanam Chai

Section

C

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

Measurement of Specific Gravity

Italian-Thai Development PCL.

35

1 July 2013

Page 25 of

MRT Blue Line Extension Project

Works

Contract 1: Underground Civil

Hua Lamphong Sanam Chai

Section

C

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

Measurement of Gel Time

Italian-Thai Development PCL.

35

1 July 2013

Page 26 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

Attachment B

The Laboratory Test Program for Primary and Secondary

Grouting Works

Italian-Thai Development PCL.

35

1 July 2013

Page 27 of

MRT Blue Line Extension Project

Works

Contract 1: Underground Civil

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

Item

Specification

Test Method

Date

Specific Gravity

1.200.02 g/cm 3

Mud Balance

12 June 2012

Bleeding

0.5% (1 hour

after Liquid

A mixing)

Bleeding Test

12 June 2012

Consistency

< 11 seconds

Flow Test

12 June 2012

Gel Time

4.12 seconds

Mix Test

12 June 2012

Compressive

12 June 2012

Compressive

Strength

1 Hour

0.03 N/mm 2

24 Hours

0.4 N/mm 2

7 Days

0.8 N/mm 2

28 Days

1.5 N/mm 2

Strength Test

Place

At the institute

which be inform

and submit at

least 1 month

before test date.

At the institute

which be inform

and submit at

least 1 month

before test date.

At the institute

which be inform

and submit at

least 1 month

before test date.

The Laboratory test Program for Primary and Secondary Grouting Works.

Italian-Thai Development PCL.

35

1 July 2013

Page 28 of

Remark

Liquid A

Liquid A

Liquid A

Liquid A+B

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

Attachment C

ASTM C939-02 Standard Test Method for PreplacedAggregate Concrete (Flow Cone Method)

Italian-Thai Development PCL.

35

1 July 2013

Page 29 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

Italian-Thai Development PCL.

35

1 July 2013

Page 30 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

Italian-Thai Development PCL.

35

1 July 2013

Page 31 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

Italian-Thai Development PCL.

35

1 July 2013

Page 32 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

Italian-Thai Development PCL.

35

1 July 2013

Page 33 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

Italian-Thai Development PCL.

35

1 July 2013

Page 34 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

Italian-Thai Development PCL.

35

1 July 2013

Page 35 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

Attachment D

ASTM D4830-84 (Reapproved 2001) Standard Test

Method for Density of Bentonitic Slurries

Italian-Thai Development PCL.

35

1 July 2013

Page 36 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

Italian-Thai Development PCL.

35

1 July 2013

Page 37 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

Italian-Thai Development PCL.

35

1 July 2013

Page 38 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

Italian-Thai Development PCL.

35

1 July 2013

Page 39 of

MRT Blue Line Extension Project

Contract 1: Underground Civil Works

Hua Lamphong Sanam Chai

Section

Method Statement for Primary and Secondary Grouting Doc No. ITD/BE1/MS/T007, Rev.

C

Italian-Thai Development PCL.

35

1 July 2013

Page 40 of

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Soil Qty CBR15Document12 pagesSoil Qty CBR15Janaka DineshNo ratings yet

- Pure Water2Document1 pagePure Water2Janaka DineshNo ratings yet

- Pavement Layer Progress Up To December 2018Document8 pagesPavement Layer Progress Up To December 2018Janaka DineshNo ratings yet

- AL Economics Model Paper PDFDocument4 pagesAL Economics Model Paper PDFJanaka Dinesh100% (2)

- Kitchen ItemsDocument2 pagesKitchen ItemsJanaka DineshNo ratings yet

- Tree Removal Measurement FormatDocument2 pagesTree Removal Measurement FormatJanaka DineshNo ratings yet

- Stair CaseDocument13 pagesStair CaseJanaka DineshNo ratings yet

- Sure Inject J56Document2 pagesSure Inject J56Janaka DineshNo ratings yet

- Bored Piling Records - Section BDocument40 pagesBored Piling Records - Section BJanaka DineshNo ratings yet

- Tree Removal Measurement FormatDocument2 pagesTree Removal Measurement FormatJanaka DineshNo ratings yet

- X-Roc Epoxybond: Technical Data SheetDocument2 pagesX-Roc Epoxybond: Technical Data SheetJanaka Dinesh100% (1)

- Slab6-Ch 3 Cal SLB MomentsDocument7 pagesSlab6-Ch 3 Cal SLB MomentsJanaka DineshNo ratings yet

- AL Economics Model PaperDocument4 pagesAL Economics Model PaperJanaka DineshNo ratings yet

- Ki NG Do M o F Thai L And: EDI CT OF GovernmentDocument12 pagesKi NG Do M o F Thai L And: EDI CT OF GovernmentJanaka DineshNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Effect of Glass Fiber On M25 Concrete: B.Tech Major ProjectDocument64 pagesEffect of Glass Fiber On M25 Concrete: B.Tech Major ProjectSuraj KumarNo ratings yet

- Concrete Mix Design of M-15 (PCC)Document141 pagesConcrete Mix Design of M-15 (PCC)Abhishek SinghNo ratings yet

- Hot Mix Asphalt TestingDocument21 pagesHot Mix Asphalt TestingBhuiyan1No ratings yet

- Tutorial On Flowmeters Nov17Document2 pagesTutorial On Flowmeters Nov17Ranjan Kumar100% (1)

- D2395-14 Standard Test Methods For Density and Specific Gravity (Relative Density) of Wood and Wood-Based MaterialsDocument13 pagesD2395-14 Standard Test Methods For Density and Specific Gravity (Relative Density) of Wood and Wood-Based MaterialsHussein BeqaiNo ratings yet

- Comparison of The Physical Characteristics and GC/MS of The Essential Oils of Ocimum Basilicum and Ocimum SanctumDocument10 pagesComparison of The Physical Characteristics and GC/MS of The Essential Oils of Ocimum Basilicum and Ocimum SanctumAmin MojiriNo ratings yet

- Marshall Mix DesignDocument27 pagesMarshall Mix DesignSAQAR ALGHAMDI100% (5)

- Uncompacted Void Content of Fine Aggregate Fop For Aashto T 304 ScopeDocument7 pagesUncompacted Void Content of Fine Aggregate Fop For Aashto T 304 ScopeRodolfo RodriguezNo ratings yet

- PRT193 - Final ExamDocument31 pagesPRT193 - Final ExamJovvin HermoginoNo ratings yet

- Commissioning of DC & UPS SystemsDocument61 pagesCommissioning of DC & UPS Systemshajimak100% (2)

- Unit 1-SKP PDFDocument23 pagesUnit 1-SKP PDFSmr Only100% (1)

- Hypro Housing Fa-Mf3Document4 pagesHypro Housing Fa-Mf3Roberto Torres ArancibiaNo ratings yet

- Slope Protection. RMDocument32 pagesSlope Protection. RMjas roveloNo ratings yet

- Aashto T - 283Document6 pagesAashto T - 283Anonymous sSNLqweXgNo ratings yet

- Poultry Science: Percentage Shell As A Function of Shell Thickness, Egg Volume, and Egg ShapeDocument6 pagesPoultry Science: Percentage Shell As A Function of Shell Thickness, Egg Volume, and Egg ShapesibieNo ratings yet

- Exp 10 Relative Density ApplicationDocument2 pagesExp 10 Relative Density ApplicationLaarni Villalon Ventigan0% (1)

- C135Document2 pagesC135Sabila IhsaniNo ratings yet

- Collection and Preparation of Coke Samples For Laboratory AnalysisDocument4 pagesCollection and Preparation of Coke Samples For Laboratory Analysisharrison_sNo ratings yet

- Viscosity of Sulphuric Acid PDFDocument13 pagesViscosity of Sulphuric Acid PDFSanthosh MohanNo ratings yet

- Battery Specific Gravity Test: Battery Hydrometer TestDocument2 pagesBattery Specific Gravity Test: Battery Hydrometer TestHenry PalNo ratings yet

- Basic Characteristics of Soil-4Document34 pagesBasic Characteristics of Soil-4yoi82No ratings yet

- Methanol SpecificationsDocument69 pagesMethanol SpecificationsShreepathi AdigaNo ratings yet

- Mix Design Method For Asphalt Concrete PavementDocument16 pagesMix Design Method For Asphalt Concrete PavementElumalai Srinivasan100% (1)

- Composition of Crude OilDocument2 pagesComposition of Crude Oilzapspaz100% (1)

- 16t-67-Chromite Sand and FlourDocument3 pages16t-67-Chromite Sand and FlourCharlie ChongNo ratings yet

- D121-09 Standard Terminology of Coal and CokeDocument14 pagesD121-09 Standard Terminology of Coal and CokedcardonasterNo ratings yet

- My ProjectDocument56 pagesMy ProjectAnusuiya ThankapazhamNo ratings yet

- Chapter 3 Marshall SpecimenDocument35 pagesChapter 3 Marshall SpecimenHanaNo ratings yet

- Pressure Vessel Design Without Seismic Loads PDFDocument21 pagesPressure Vessel Design Without Seismic Loads PDFMas afjalNo ratings yet