Professional Documents

Culture Documents

Co Generation CHP

Uploaded by

Arya Bima Aji KusumaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Co Generation CHP

Uploaded by

Arya Bima Aji KusumaCopyright:

Available Formats

Cogeneration/Combined Heat and Power (CHP)

CLIMATE TECHBOOK

Quick Facts

Cogeneration, also known as combined heat and power (CHP), refers to a group of proven

technologies that operate together for the concurrent generation of electricity and useful heat in a

process that is generally much more energy-efficient than the separate generation of electricity and

useful heat.

The typical method of separate centralized electricity generation and on-site heat generation has a

combined efficiency of about 45 percent whereas cogeneration systems can reach efficiency levels

of 80 percent.

In the United States, cogeneration has a long history in the industrial sector. Globally, industry sites

in the chemicals, metal, oil refining, pulp and paper, and food processing sectors represent more

than 80 percent of total global electric CHP capacity.

Cogeneration is widely deployed outside the United States, with Denmark, the Netherlands, and

Finland leading the world in cogeneration deployment as a fraction of total national electricity

generation.

In 2008, cogeneration accounted for 9 percent of total U.S. electricity generating capacity. A recent

study by the Oak Ridge National Laboratory calculated that increasing that share to 20 percent by

2030 would lower U.S. greenhouse gas emissions by 600 million metric tons of CO2 (equivalent to

taking 109 million cars off the road) compared to business as usual.

Background

Cogeneration is a system of commercially available technologies that decrease total fuel consumption and

related GHG emissions by generating both electricity and useful heat from the same fuel input. Cogeneration

is often called combined heat and power (CHP), since most cogeneration systems are used to supply

electricity and useful heat. However, the heat energy from electricity production can also be used for cooling

and other non-heating purposes, so the term cogeneration is more inclusive. Cogeneration is a form of

local or distributed generation as heat and power production take place at or near the point of consumption.

For the same output of useful energy, cogeneration uses far less fuel than does traditional separate heat

and power production, which means lower greenhouse gas (GHG) emissions as fossil fuel use is reduced.

While this document focuses on the GHG emission reductions, cogeneration offers other benefits that

include:

Reducing other air pollutants (e.g., SO2, NOX, Hg)

Providing on-site electricity generation that is resilient in the face of grid outages thus providing

power for critical services in emergencies and avoiding economic losses

Avoiding or deferring investments in new electricity transmission and distribution infrastructure and

relieving congestion constraints on existing infrastructure.

Page | 1

March 2011

Cogeneration/Combined Heat and Power (CHP)

CLIMATE TECHBOOK

Using existing industrial and commercial sites for incremental power generation rather than building

new power plant capacity at greenfield sites

The largest potential for increased utilization of cogeneration is in the industrial sector. In the United States,

the industrial sector is responsible for approximately one third of the countrys total energy consumption.1

The industrial sectors direct GHG emissions account for 20 percent of the U.S. total, and an additional 9

percent of U.S. GHG emissions come from centrally generated electricity consumed in the industrial sector.2

Direct industrial emissions come from on-site combustion of fossil fuels and from non-energy related

process emissions.

While the greatest potential for increasing cogeneration is in the industrial sector, the technology is also

increasingly available for smaller-scale applications in residential and commercial facilities. Cogeneration

systems appeal to business operations requiring a continuous supply of reliable power such as data centers,

hospitals, universities, and industrial operations. District heating and cooling (DHC) in cities and large

institutions is one established use of cogeneration (and one widely employed in Europe) in the residential

and commercial sectors. District heating can meet low and medium temperature heat demands, such as

space heating and hot tap water preparation, by using waste heat from electricity generation to heat water

that is transported through insulated pipes. District cooling takes advantage of natural cooling from deep

water resources as well as the use of waste heat to cool water via absorption chillers. About 85 urban

utilities and 330 campuses in the United States use district energy to reduce costs and GHG emissions,

increase efficiency, and improve reliability.3

Description

Separate heat and power (SHP) refers to the widespread practice of centrally generating electricity at largescale power plants and separately generating useful heat onsite for applications such as industrial

processes or space and water heating. SHP leads to energy losses in both processes. In the United States,

conventional coal and natural gas power plants are, on average, 33 and 41 percent efficient, respectively, in

converting the energy in their fuel into electricity; although, the efficiency rates vary by technology with new

natural gas combined cycle plants capable of greater than 50 percent efficiency.4 Typical SHP has a

combined efficiency of about 45 percent while cogeneration systems that combine the power and heat

generation processes can be up to 80 percent efficient.5 Because cogeneration takes place on-site or close

to the facility it also results in less energy lost during the transmission and distribution process (usually

about 9 percent of net electricity generation).6

Figure 1 provides a helpful comparison of illustrative CHP and SHP systems and shows the energy inputs

each would require to ultimately produce the same amount of useful energy.

Page | 2

March 2011

Cogeneration/Combined Heat and Power (CHP)

CLIMATE TECHBOOK

Figure 1: CHP versus Separate Heat and Power (SHP) Production

Source: U.S. EPA: Combined Heat and Power Partnership, Efficiency Benefits.

Note: This figure shows an example where cogeneration uses only 100 units of fuel to produce an amount of electricity and

useful heat that would require 154 units of fuel via separate heat and power production.

Cogeneration systems can be powered by a variety of fuels, including natural gas, coal, oil, and alternative

fuels such as biomass. In recent years, natural gas has been the predominant fuel for CHP systems, but

biomass and opportunity fuels (i.e., wastes or by-products from industrial processes, agriculture, or

commercial activities) are expected to gain a larger share with growing environmental and energy security

concerns.7,8 Some cogeneration technologies can operate with multiple fuel types, making the system less

vulnerable to fuel availability and volatile commodity prices.

Cogeneration is appropriate in situations where a facility has a continuous demand for heating or cooling as

well as demand for electrical or mechanical power. Cogeneration systems can provide electricity or

mechanical power (e.g., for driving rotating equipment like compressors, pumps, and fans) and heat energy

that can be used for: steam or hot water; process heating, cooling and refrigeration; and dehumidification.9

Cogeneration Process

There are two types of cogenerationtopping cycle and bottoming cycle. The most common type of

cogeneration is the topping cycle where fuel is first used to generate electricity or mechanical energy at the

facility and a portion of the waste heat from power generation is then used to provide useful thermal energy.

The less common bottoming cycle type of cogeneration systems first produce useful heat for a

manufacturing process via fuel combustion or another heat-generating chemical reaction and recover some

portion of the exhaust heat to generate electricity. Bottoming-cycle CHP applications are most common in

process industries, such as glass and steel, that use very high temperature furnaces that would otherwise

vent waste heat to the environment. The following description of cogeneration systems focus on topping

cycle applications.

Page | 3

March 2011

Cogeneration/Combined Heat and Power (CHP)

CLIMATE TECHBOOK

Each cogeneration system is adapted to meet the needs of an individual building or facility. System design is

modified based on the location, size, and energy requirements of the site. Cogeneration is not limited to any

specific type of facility but is generally used in operations with sustained heating requirements. Most CHP

systems are designed to meet the heat demand of the energy user since this leads to the most efficient

systems. Larger facilities generally use customized systems, while smaller-scale applications can use

prepackaged units.

Cogeneration systems are categorized according to their prime movers (the heat engines), though the

systems also include generators, heat recovery, and electrical interconnection components. The prime

mover consumes (via combustion, except in the case of fuel cells discussed below) fuel (such as coal,

natural gas, or biomass) to power a generator to produce electricity, or to drive rotating equipment. Prime

movers also produce thermal energy that can be captured and used for other on-site processes such as

generating steam or hot water, heating air for drying, or chilling water for cooling. There are currently five

primary, commercially available prime movers: gas turbines, steam turbines, reciprocating engines,

microturbines, and fuel cells.

Steam turbines and gas, or combustion, turbines are the prime movers (heat engines) best suited for

industrial processes due to their large capacity and ability to produce the medium- to high-temperature

steam typically needed in industrial processes.10

Gas Turbines

Gas turbines typically have capacities between 500 kilowatts (kW) and 250 megawatts (MW), can be used

for high-grade heat applications, and are highly reliable.11 Gas turbines operate similarly to jet engines

natural gas is combusted and used to turn the turbine blades and spin an electrical generator. The

cogeneration system then uses a heat recovery system to capture the heat from the gas turbines exhaust

stream. This exhaust heat can be used for heating (e.g., for generating steam for industrial processes) or

cooling (generating chilled water through an absorption chiller). About half of the CHP capacity in the United

States consists of large combined cycle systems that include two electricity generation steps (the

combustion turbine and a steam turbine powered by heat recovered from the gas turbine exhaust) that

supply steam to large industrial or commercial users and maximize power production for sale to the grid.

Figure 2 shows how a simple-cycle gas turbine cogeneration system recovers heat from the gas turbines hot

exhaust gases to produce useful thermal energy for the site.

Page | 4

March 2011

Cogeneration/Combined Heat and Power (CHP)

CLIMATE TECHBOOK

Figure 2: Gas Turbine or Engine with Heat Recovery Unit

Source: U.S. EPA Combined Heat and Power Partnership: Basic Information.

Note: Figure 2 shows a gas turbine cogeneration system, with the heat recovery unit capturing exhaust heat from the turbine,

and converting that to thermal energy for other uses.

Steam Turbines

Steam turbines systems can use a variety of fuels, including natural gas, solid waste, coal, wood, wood

waste, and agricultural by-products. Steam turbines are highly reliable and can meet multiple heat grade

requirements. Steam turbines typically have capacities between 50 kW and 250 MW and work by

combusting fuel in a boiler to heat water and create high-pressure steam, which turns a turbine to generate

electricity.12 The low-pressure steam that subsequently exits the steam turbine can then be used to provide

useful thermal energy, as shown in Figure 3. Ideal applications of steam turbine-based cogeneration

systems include medium- and large-scale industrial or institutional facilities with high thermal loads and

where solid or waste fuels are readily available for boiler use.

Figure 3: Steam Boiler with Steam Turbine

Source: US EPA Combined Heat and Power Partnership: Basic Information.

Note: Figure 3 shows how a cogeneration system that is primarily heat based, can also be used to generate electricity.

Reciprocating Engines

Page | 5

March 2011

Cogeneration/Combined Heat and Power (CHP)

CLIMATE TECHBOOK

In terms of the number of units, reciprocating internal combustion engines are the most widespread

technology for power generation, found in the form of small, portable generators as well as large industrial

engines that power generators of several megawatts; however, because of their small size, reciprocating

engines account for only a small share (about 2 percent) of total U.S CHP capacity.13 Spark ignition (SI)

engines are the most common types of reciprocating engines used for CHP in the United States. SI engines

(available in capacities up to 5 MW) are similar to gasoline-powered automobile engines, but they generally

run on natural gas, though they can also run on propane or landfill and biogas.

Reciprocating engines start quickly, follow load well, have good efficiencies even when operating at partial

load, and generally have high reliabilities.14 Reciprocating engines are well suited for CHP in commercial and

light industrial applications of less than 5 MW. Smaller engine systems produce hot water. Larger systems

can be designed to produce low-pressure steam. Multiple reciprocating engines can be used to increase

system capacity and enhance overall reliability.

Microturbines

Microturbines are small, compact, lightweight combustion turbines that typically have power outputs of 30 to

300 kW. A heat exchanger recovers thermal energy from the microturbine exhaust to produce hot water or

low-pressure steam. The thermal energy from the heat recovery system can be used for potable water

heating, absorption cooling, dessicant dehumidification, space heating, process heating, and other building

uses. Microturbines can burn a variety of fuels including natural gas and liquid fuels.

Fuel Cells

Fuel cells are an emerging technology with the potential to serve power and thermal needs with very low

emissions and with high electrical efficiency. Fuel cells use an electrochemical or battery-like process to

convert the chemical energy of hydrogen into water and electricity. The hydrogen can be obtained from

processing natural gas, coal, methanol, and other hydrocarbon fuels. As a less mature technology, fuel cells

have high capital costs, an immature support infrastructure, and technical risk for early adopters. However,

the advantages of fuel cells include low emissions and low noise, high power efficiency over a range of load

factors, and modular design. A variety of fuel cell technologies are under development, with some targeted

for small commercial markets, and other technologies focused on larger, industrial CHP applications.

Environmental Benefit / Emission Reduction Potential

Cogeneration offers multiple environmental benefits. Since less fuel is burned per unit of useful energy

output, cogeneration reduces GHG emissions and decreases air pollution compared to SHP systems.

Currently installed cogeneration systems avoid the equivalent of 1.8 percent of annual U.S. energy

consumption and annual CO2 emissions of 248 million metric tons (equal to 3.5 percent of total U.S. GHG

emissions in 2007).15,16 A recent study by the Oak Ridge National Laboratory (ORNL) calculated that

increasing cogenerations share of total U.S. electricity generation capacity to 20 percent by 2030 (which

ORNL estimated would require deploying 156 GW of new cogeneration capacity compared to about 85 GW

today) would lower U.S. GHG emissions by 600 million metric tons of CO2 (equivalent to taking 109 million

cars off the road) compared to business as usual.17

Page | 6

March 2011

Cogeneration/Combined Heat and Power (CHP)

CLIMATE TECHBOOK

While the ORNL analyzed an ambitious goal for expanding cogeneration by 2030, a 2009 study by McKinsey

& Company sought to estimate the cost-effective potential for expanding cogeneration by 2020 (i.e., the

potential to make NPV-positive investments in cogeneration).18 McKinsey estimated that the potential exists

in the United States for an additional 50.4 GW of cogeneration capacity by 2020, which would avoid an

estimated 100 million metric tons of CO2 per year compared to business as usual. McKinsey found that

the cost-effective incremental cogeneration capacity consisted primarily (70 percent) of large-scale (greater

than 50 MW) industrial cogeneration systems. Figure 4 shows McKinseys estimates of the composition of

cost-effective cogeneration potential for 2020.

Figure 4: McKinseys Estimates of Cost-Effective Cogeneration Potential for 2020 by Sector19

Education

7%

Healthcare

12%

Office

28%

Food

production

7%

Energyintensive

industries

31%

Non-energyintensive

industries

15%

Cost

Cogeneration systems are major investments. For example, the capital cost of a 50 MW gas turbine

cogeneration system might be on the order of $45 million, and such a cogeneration system might take 6-18

months to construct.20 A 1 MW reciprocating engine cogeneration system (e.g., for a hospital) might have a

capital cost of roughly $1.6 million.21 The cost of a cogeneration system depends on the level of complexity

of features beyond the basic prime mover such as the heat recovery or emissions monitoring systems (as

well as location, labor, and the financial carrying costs during construction). Generally, with the same fuel

and configuration, costs for cogeneration systems per kilowatt of capacity decrease as size increases. Given

the efficiency gains from cogeneration, some analysts estimate that GHG emission reductions can be

achieved at a negative cost via cogeneration in many instances since cost savings from reduced

expenditures on fuel (due to the higher efficiency of cogeneration compared to separate heat and power

generation) will outweigh the capital and other costs of cogeneration projects.22

Current Status of Cogeneration

Cogeneration currently accounts for roughly 12 percent of total U.S. electricity generation and comprises

about 9 percent (85 gigawatts at about 3,300 sites) of total generating capacity.23 Figures 5-8 show how

existing cogeneration capacity is distributed across different applications, system technology types, and fuel

Page | 7

March 2011

Cogeneration/Combined Heat and Power (CHP)

CLIMATE TECHBOOK

inputs. Only about 12 percent of existing cogeneration capacity is deployed at commercial or institutional

facilities (as opposed to industrial or manufacturing facilities). Nearly three quarters of cogeneration capacity

uses natural gas for fuel, and gas-fired combustion turbines and combined cycle systems dominate

cogeneration capacity even though nearly half of all cogeneration sites use reciprocating engines (the

reciprocating engines are much smaller in terms of capacity than the other systems). Large cogeneration

systems (100 megawatts or more in capacity) account for roughly 65 percent of total cogeneration

capacity.24

Figure 5: Existing Cogeneration Capacity by Application25

Primary

Metals

5%

Other Manufacturing

8%

Food

8%

Commercial

/Institutional

12%

Paper

14%

Other

Industrial

6%

Figure 6: Existing Cogeneration Sites by System Type26

Combustion

Turbine

12%

Combined

Cycle

7%

Petroleum

Refining

17%

Chemical

30%

Boiler /

Steam

Turbine

23%

Figure 7: Existing Cogeneration Capacity by System

Type27

Other

16%

Figure 8: Existing Cogeneration Capacity by Fuel Type28

Combined

Cycle

53%

Coal

14%

Combustion

Turbine

13%

Boiler /

Steam

Turbine

32%

Reciprocating

Engine

42%

Reciprocating

Engine

2%

Natural

Gas

73%

Waste

8%

Wood

2%

Biomass

1%

Oil

Other

1%

1%

Current U.S. cogeneration capacity is largely concentrated in states with large industrial heat consumption

(see Table 1), such as for petrochemical and petroleum refining operations. Texas alone has one fifth of the

total U.S. cogeneration installed capacity, and the top five states in terms of installed capacity account for

half of the U.S. total.29 State air pollution regulations that use output-based standards and state-level

incentives for cogeneration also promote cogeneration in certain states.

Cogeneration projects multiplied in the United States following the passage of the Public Utilities Regulatory

Policies Act (PURPA) in 1978. PURPA required utilities to interconnect with and purchase electricity from

Page | 8

March 2011

Cogeneration/Combined Heat and Power (CHP)

CLIMATE TECHBOOK

qualified facilities like cogeneration systems thus giving industrial and institutional users access to the grid

and the ability to sell back excess electricity. Shortly after enactment of PURPA, Congress also created

federal tax credits for CHP investments. Following the enactment of PURPA and the CHP tax credits,

cogeneration grew dramatically with capacity increasing more than three-fold in two decades (from about 20

gigawatts in 1978).30 2006 through 2009 saw much lower levels of cogeneration deployment than historical

growth rates owing in part to higher natural gas prices and economic uncertainty.31 One factor affecting the

growth of CHP was the change to PURPA regulations that resulted from the Energy Policy Act of 2005. As

instructed by the act, the Federal Energy Regulatory Commission (FERC) issued new rules that no longer

required utilities to buy electricity from larger qualified facilities when those facilities have access to

competitive electricity markets, and FERC issued rules to ensure that new CHP qualified facilities were not

mainly electricity-generating facilities taking advantage of the incentives offered to CHP facilities (so-called

PURPA machines).32

Table 1: Cogeneration Installed Capacity by State, 200633

Rank

1

2

3

4

5

6

7

8

9

10

State

TX

CA

LA

NY

FL

NJ

AL

PA

MI

OR

Rest of U.S.

Total Capacity

(MW)

17,240

9,220

6,959

5,789

3,545

3,493

3,362

3,242

3,104

2,523

26,523

% of U.S.

Total

20%

11%

8%

7%

4%

4%

4%

4%

4%

3%

31%

Recent federal legislation, including the Energy Improvement and Extension Act of2008 (EIEA) and the

American Recovery and Reinvestment Act of 2009 (ARRA), encourages wider deployment of cogeneration

with tax incentives for cogeneration projects (the CHP investment tax credit and accelerated depreciation)

and substantial funding for select CHP projects.34

Globally, cogeneration is in widespread use, especially in the European Union (EU). Five EU countries rely on

cogeneration for between 30 to 50 percent of their total power generation, and cogeneration has

contributed to 57 million metric tons of CO2e, or 15 percent, of Europes overall GHG emission reductions

from 1990 to 2005.35,36 Globally, industry sites in the chemicals, metal, oil refining, pulp and paper, and

food processing sectors represent more than 80 percent of total global CHP capacity.37 Cogeneration

currently accounts for approximately 13 and 5 percent of total electricity generation capacity in China and

India, respectively.38 The International Energy Agency (IEA) projects that by 2030, Chinese and Indian

cogeneration penetration could rise to 28 and 26 percent, respectively, with adequate policy and market

incentives.39 In China, cogeneration has significant growth potential given the countrys large industrial base.

IEA projected that under aggressive international efforts to reduce GHG emissions, global industrial

Page | 9

March 2011

Cogeneration/Combined Heat and Power (CHP)

CLIMATE TECHBOOK

cogeneration could quadruple from 2005 to 2050 as compared to merely doubling under business as

usual.40

Obstacles to Further Development or Deployment of Cogeneration

Capital Constraints

Cogeneration systems are large capital investments. Firms may be unwilling to undertake such

significant capital investments even when they may offer positive returns. Another cost consideration

for firms is business uncertainty. If a firm is not confident that it will continue operations for many

years at a given facility, it may not invest in the high upfront costs of cogeneration since a projects

economic viability can depend on cost savings realized over several years. In addition, there can be

costs associated with manufacturing downtime and siting and permitting issues. Also, seamless

integration of components beyond the basic equipment can necessitate specialized parts and

increase the cost of a cogeneration system.41

Utility Business Practices

Many cogeneration systems maintain their connection to the utility grid for supplemental power

needs beyond their self generation capacity and/or for standby and back-up service during routine

maintenance or unplanned outages. Utility charges for these services (standby rates) can

significantly reduce the money-saving potential of cogeneration.42 However, cogeneration and other

types of distributed energy allow the grid to function more efficiently by reducing baseload and peak

demand, as well as reducing the need for transmission and distribution upgrades and construction.

Pricing arrangements between utilities and cogeneration system operators that fairly account for

utilities obligation to supply backup power as well as the benefits to the grid of cogeneration (e.g.,

avoided costs of building new generation and transmission capacity) can encourage cogeneration

investments.

Utility Interconnection

The economic viability of cogeneration systems depends on their ability to safely, reliably, and

economically interconnect with the existing grid. Interconnection standards, including technical

specifications as well as application processes and fees, between utilities and cogeneration systems

are often state mandated and vary regionally. This lack of uniformity makes it difficult for

manufacturers of cogeneration technologies to produce modular components and can make

cogeneration system deployment more complicated and expensive. Improved interconnection

policies could increase deployment of cogeneration systems.43,44

Environmental Permitting Regulations

By generating both electricity and heat onsite, cogeneration can increase a facilitys onsite air

emissions even as it reduces total emissions associated with the facilities heat and electricity

consumption. Current environmental permitting regulations do not always recognize this overall

emissions reduction benefit. For example, the Clean Air Acts New Source Review (NSR) requires

large, stationary sources to install best available pollution control equipment during construction or

Page | 10

March 2011

Cogeneration/Combined Heat and Power (CHP)

CLIMATE TECHBOOK

major modifications that increase onsite emissions. In some circumstances NSR requirements can

discourage installation of CHP systems even when they would improve environmental outcomes.45

The adoption of output-based emission standards, which allows cogeneration systems to benefit

from their increased efficiency, is one way to encourage more cogeneration systems.

Need for Further Research, Development, and Demonstration (RD&D)

To improve the performance of cogeneration technologies and reduce investment costs, further

RD&D is warranted, specifically in the areas of: high-temperature CHP, small-scale systems (e.g.,

improving the efficiency of micro-turbines and their cost through improved manufacturing

techniques), fuel cell research, heat & cold storage system optimization and integration, and

medium-scale systems (e.g., increased demonstration of medium-scale turbines in various industrial

settings).46

Policy Options to Help Promote Cogeneration

Price on Carbon

Policies that set a price on GHG emissions, such as a GHG cap-and-trade program (see Climate

Change 101: Cap and Trade), can encourage investment in energy-efficient technology such as

cogeneration. Carbon pricing policies (e.g., cap and trade allowance allocation) can be designed so

as not to create disincentives for cogeneration.47

Renewable Portfolio and Energy Efficiency Resource Standards

Renewable Portfolio Standards and Energy Efficiency Standards require that energy providers meet a

specific portion of their electricity demand through renewable energy and/or energy efficiency

measures. Such policies specify eligible energy sources and technologies that count towards the

requirements. More than a dozen states allow cogeneration to count toward renewable/alternative

energy and efficiency standards.48

Financial Incentives for Cogeneration

Certain states already offer investment tax credits (ITC), which are a form of subsidy to help offset

the upfront capital cost of investments, for cogeneration, and the federal government also offers a

10 percent ITC for cogeneration (enacted in 2008) and accelerated depreciation.49 Some states

offer production incentives, which provide a financial benefit based upon the annual useful energy

output of the cogeneration system.

Interconnection Standards

Coordination among state and federal regulators, utilizes, and stakeholder groups regarding best

practices in cogeneration interconnection with the electric grid can help ensure cogeneration

interconnection contributes to a safe and reliable grid and minimize the cost and complexity facing

cogeneration technology providers and users designing and deploying systems for interconnection.

Environmental Permitting

Page | 11

March 2011

Cogeneration/Combined Heat and Power (CHP)

CLIMATE TECHBOOK

Cogeneration is more readily deployed when environmental regulations do not penalize cogeneration

systems that increase onsite air emissions (by using more fuel onsite to generate both electricity and

heat) while also decreasing net air emissions by having higher efficiency (and thus less total fuel

use) than separate heat and power generation.50

Research, Development, and Demonstration (RD&D)

Continued and increased funding for programs such as the Department of Energys Industrial

Technologies Program (ITP)51 would support RD&D for cogeneration technologies to improve

reliability and efficiency and reduce costs. ITPs public-private partnerships help future deployment of

both integrated energy systems and component technologies (for upgrading and retrofits).

Technical Assistance for Potential Cogeneration Users

Many companies (especially small and medium-sized businesses) that would benefit from

cogeneration systems are not aware of their financial or technical options. Expanding programs that

work with companies such as the U.S. Environmental Protection Agencys Combined Heat and Power

Partnership,52 the National Institute of Standards Manufacturing Extension Partnership,53 and

DOEs Industrial Assessment Centers and CHP Regional Application Centers54 would help further

promote cogeneration.

Related Business Environmental Leadership Council (BELC) Company Activities

ABB

Air Products

Alstom

Baxter Healthcare

Cummins

Dow Chemical Company

GE

PG&E

Weyerhaeuser

Related Pew Center Resources

The U.S. Electric Power Sector and Climate Change Mitigation, 2005

Corporate Energy Efficiency Project

Further Reading / Additional Resources

American Council for an Energy Efficient Economy (ACEEE), Combined Heat and Power (CHP)

Page | 12

March 2011

Cogeneration/Combined Heat and Power (CHP)

CLIMATE TECHBOOK

Gas Technology Institute (GTI)

Hedman, Bruce, ICF International, CHP: The State of the Market, presentation to the U.S. EPA Combined

Heat and Power Partnership 2009 Partners Meeting, 1 October 2009.

International Energy Agency, Combined Heat and Power: Evaluating the Benefits of Greater Global

Investment, 2008.

McKinsey & Company

Reducing U.S. Greenhouse Gas Emissions: How Much at What Cost?, 2007

Unlocking Energy Efficiency in the U.S. Economy, 2009

New York State Energy Research and Development Authority (NYSERDA), Combined Heat and Power

Program Guide.

Oak Ridge National Laboratory, Combined Heat & Power: Effective Energy Solutions for a Sustainable

Future, 2008

U.S. Combined Heat and Power Association (USCHPA)

U.S. Department of Energy

Case Studies Database

Combined Heat and Power (CHP) Regional Application Centers (RACs)

Industrial Distributed Energy

U.S. Environmental Protection Agency

Catalog of CHP Technologies

CHP Partnership Program

U.S. Energy Information Administration (EIA), Annual Energy Review 2009, Table 1.2a: Energy Consumption by Sector, Selected

years 1949 2008.

1

U.S. Environmental Protection Agency (EPA), Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990-2007, Table ES-7,

2009.

2

Environmental and Energy Study Institute, The Role of District Energy/Combined Heat and Power in Energy and Climate Policy

Solutions, 2009.

3

EIA, Electric Power Annual, 2010, see Table 5.3 and Table 5.4. New natural gas combined cycle plant efficiency estimate comes

from EIAs Assumptions to the Annual Energy Outlook 2010 (see table 8.2).

4

Oak Ridge National Laboratory (ORNL), Combined Heat & Power: Effective Energy Solutions for a Sustainable Future, 2008.

IEA, Combined Heat and Power: Evaluating the Benefits of Greater Global Investment, 2008.

ORNL, 2008.

For more information on opportunity fuels, see Resource Dynamics Corporation, 2004, Combined Heat and Power Market

Page | 13

March 2011

Cogeneration/Combined Heat and Power (CHP)

CLIMATE TECHBOOK

Potential for Opportunity Fuels, prepared for the Department of Energy.

9

ORNL, 2008.

10

EPA, Catalog of CHP Technologies.

11

EPA, Catalog of CHP Technologies: Gas Turbines.

12

EPA, Catalog of CHP Technologies: Steam Turbines.

13ORNL,

2008.

14

Part-load efficiency refers to the efficiency when equipment is running below its rated level of output.

15

DOE, Powering Progress in Combined Heat and Power (CHP).

16

EPA, Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990-2007.

17

DOE, Powering Progress in Combined Heat and Power (CHP).

McKinsey & Company, Unlocking Energy Efficiency in the U.S. Economy, 2009. NPV refers to net present value, which, for a

cogeneration project in McKinseys analysis, is the discounted value of future cost savings (e.g., from avoided electricity generation

by utilities) net of incremental costs associated with cogeneration (e.g., up-front capital and installation costs, ongoing maintenance

costs, and fuel costs).

18

19

McKinsey & Company, Unlocking Energy Efficiency in the U.S. Economy, 2009.

20

EPA, Catalog of CHP Technologies: Gas Turbines, 2008, see Table 3.

21

EPA, Catalog of CHP Technologies: Reciprocating Engines, 2008, see Table 3.

22

McKinsey & Company, Reducing U.S. Greenhouse Gas Emissions: How Much at What Cost?, 2007.

23

ORNL, 2008.

24

ORNL, 2008.

25

ORNL, 2008.

26

ORNL, 2008.

27

ORNL, 2008.

28

ORNL, 2008.

29

ORNL, 2008.

30

ORNL, 2008.

Hedman, Bruce, ICF International, CHP: The State of the Market, presentation to the U.S. EPA Combined Heat and Power

Partnership 2009 Partners Meeting, 1 October 2009.

31

32

Stoel Rives LLP, Energy Law Alert: New FERC Order Weakens PURPAs QF Must Buy Provisions, 23 October 2006.

33

ORNL, 2008.

34

EPA, Federal Incentives for Developing Combined Heat and Power Projects.

35

Denmark, Finland, Russia, Latvia, and the Netherlands, IEA, Combined Heat and Power, 2008.

36

IEA, Combined Heat and Power: Evaluating the Benefits of Greater Global Investment, 2008.

37

IEA, Energy Technology Perspectives 2008: Scenarios & Strategies to 2050, 2008.

38

IEA, Combined Heat and Power: Evaluating the Benefits of Greater Global Investment, 2008.

39

IEA, Cogeneration and District Energy Sustainable Energy Technologies for Today and Tomorrow

40

IEA, Energy Technology Perspectives 2008: Scenarios & Strategies to 2050, 2008.

The necessitated tailoring of cogeneration systems due to a lack of factory-integrated components requires extensive project

engineering, which adds to the costs and increases risk of assimilation errors. Site-specific priorities determine the design-basis for

sizing a CHP system. NYSERDA, Public Policy Issues and Hurdles to Implementing CHP in NYS.

41

Page | 14

March 2011

Cogeneration/Combined Heat and Power (CHP)

CLIMATE TECHBOOK

42

ACEEE, Standby Rates.

43

California Energy Commission (CEC), Exploring Feed-in Tariffs for California.

44

The Economist, Building the Smart Grid, 4 June 2009.

45

ORNL, 2008.

46

IEA, Combined Heat and Power: Evaluating the Benefits of Greater Global Investment, 2008.

For example, investing in cogeneration will increase a facilitys direct GHG emissions even though it will reduce total emissions

due to the improved efficiency of cogeneration. For a discussion of how to avoid creating disincentives for cogeneration under cap

and trade, see Colvin, Michael, Combined Heat and Power and Cap & Trade, California Public Utilities Commission, presentation

materials for ARB public meetings, 9 September 2009.

47

48

For more information on such state policies, see the Pew Centers Renewable and Alternative Energy Portfolio Standards.

For more information on the federal ITC for cogeneration and relevant state incentives, see the Database of State Incentives for

Renewables and Efficiency (DSIRE).

49

50

For more information on this topic, see EPAs Output-Based Regulations: A Handbook for Air Regulators, 2004.

51

DOE, Industrial Technologies Program web site.

52

EPA, Combined Heat and Power Partnership web site.

53

Manufacturing Extension Partnership web site.

54

See the CHP Regional Application Centers web site.

Page | 15

March 2011

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Tugas Oret2anDocument18 pagesTugas Oret2anArya Bima Aji KusumaNo ratings yet

- Man Hoursummary No Departemen Total Manhour Est. Manpower: Date SummaryDocument33 pagesMan Hoursummary No Departemen Total Manhour Est. Manpower: Date SummaryArya Bima Aji KusumaNo ratings yet

- Service Worldwide: Comprehensive Service For AUMA ActuatorsDocument8 pagesService Worldwide: Comprehensive Service For AUMA ActuatorsArya Bima Aji KusumaNo ratings yet

- Reff WrappingDocument3 pagesReff WrappingArya Bima Aji KusumaNo ratings yet

- Gra Divepc Ag Ms 136 CoverDocument1 pageGra Divepc Ag Ms 136 CoverArya Bima Aji KusumaNo ratings yet

- Citric Acid SafetyDocument6 pagesCitric Acid SafetyArya Bima Aji KusumaNo ratings yet

- Chemical Cleaning ChecklistDocument8 pagesChemical Cleaning ChecklistArya Bima Aji KusumaNo ratings yet

- Epc Division: Engineering DepartmentDocument4 pagesEpc Division: Engineering DepartmentArya Bima Aji KusumaNo ratings yet

- GRT DN02 Chemical CleaningDocument5 pagesGRT DN02 Chemical CleaningArya Bima Aji KusumaNo ratings yet

- Scema Lay Out Chemical Cleaning Edit BaruDocument1 pageScema Lay Out Chemical Cleaning Edit BaruArya Bima Aji KusumaNo ratings yet

- Ways To Avoid Boiler Tube CorrosionDocument8 pagesWays To Avoid Boiler Tube CorrosionTiu TonNo ratings yet

- Pipping Layout Temp Cooling SystemDocument1 pagePipping Layout Temp Cooling SystemArya Bima Aji KusumaNo ratings yet

- Attachment-1 Attachment-3 Attachment-2Document4 pagesAttachment-1 Attachment-3 Attachment-2Arya Bima Aji KusumaNo ratings yet

- High Pressure Boilers Need Very Clean Internal SurfacesDocument2 pagesHigh Pressure Boilers Need Very Clean Internal SurfacesArya Bima Aji KusumaNo ratings yet

- To: PT Pembangunan Perumahan (Persero) : Submittal FormDocument1 pageTo: PT Pembangunan Perumahan (Persero) : Submittal FormArya Bima Aji KusumaNo ratings yet

- 1083fm PDFDocument46 pages1083fm PDFMohamed NaserNo ratings yet

- Gas TurbinesDocument31 pagesGas TurbinesShahril Anuar100% (2)

- To: PT Pembangunan Perumahan (Persero) : Submittal FormDocument1 pageTo: PT Pembangunan Perumahan (Persero) : Submittal FormArya Bima Aji KusumaNo ratings yet

- Holiday Test Procedure Wasit GasDocument6 pagesHoliday Test Procedure Wasit GasAehtasham Ul Haq100% (2)

- Dino FavaDocument1 pageDino FavaArya Bima Aji KusumaNo ratings yet

- SC13003-C9001-U10-0002-Commissioning Plan Procedure For MBOP - 24-08-2015 PDFDocument70 pagesSC13003-C9001-U10-0002-Commissioning Plan Procedure For MBOP - 24-08-2015 PDFArya Bima Aji KusumaNo ratings yet

- Improve manufacturing performance through loop checkingDocument8 pagesImprove manufacturing performance through loop checkingOhaneje Uzoma67% (3)

- Project Specification - Gresik Gas Cogeneration Plant Vendor ListDocument1 pageProject Specification - Gresik Gas Cogeneration Plant Vendor ListArya Bima Aji KusumaNo ratings yet

- HRSG Handbook BrochureDocument2 pagesHRSG Handbook Brochuremahmoud_allam3No ratings yet

- Fire FightingDocument1 pageFire FightingArya Bima Aji KusumaNo ratings yet

- Co Generation CHPDocument15 pagesCo Generation CHPArya Bima Aji KusumaNo ratings yet

- iNsTrucTioN-BACA DULU!Document1 pageiNsTrucTioN-BACA DULU!Arya Bima Aji KusumaNo ratings yet

- Application For Motor Solo Run / No Load RunDocument3 pagesApplication For Motor Solo Run / No Load RunArya Bima Aji KusumaNo ratings yet

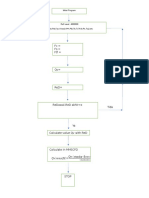

- Algoritma Aga 3Document1 pageAlgoritma Aga 3Arya Bima Aji KusumaNo ratings yet

- Algoritma Aga 3Document1 pageAlgoritma Aga 3Arya Bima Aji KusumaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Earthing of Zenner BarrierDocument4 pagesThe Earthing of Zenner BarrierFatholla SalehiNo ratings yet

- DS 20230629 SG3300UD-MV SG4400UD-MV Datasheet V16 ENDocument2 pagesDS 20230629 SG3300UD-MV SG4400UD-MV Datasheet V16 ENDragana SkipinaNo ratings yet

- Coa - Ofx-8040a (H078K5G018)Document2 pagesCoa - Ofx-8040a (H078K5G018)Jaleel AhmedNo ratings yet

- BC Specialty Foods DirectoryDocument249 pagesBC Specialty Foods Directoryjcl_da_costa6894No ratings yet

- MTS Material Testing SolutionsDocument34 pagesMTS Material Testing SolutionskarthegreNo ratings yet

- S0231689H02-B01-0001 Rev 02 Code 1 General Arrangement Drawing For 44 Kva Diesel Generator PDFDocument6 pagesS0231689H02-B01-0001 Rev 02 Code 1 General Arrangement Drawing For 44 Kva Diesel Generator PDFAnonymous AfjzJdnNo ratings yet

- Alexander Lee ResumeDocument2 pagesAlexander Lee Resumeapi-352375940No ratings yet

- 63db2cf62042802 Budget Eco SurveyDocument125 pages63db2cf62042802 Budget Eco SurveyNehaNo ratings yet

- Sampling Fundamentals ModifiedDocument45 pagesSampling Fundamentals ModifiedArjun KhoslaNo ratings yet

- Perbandingan Sistem Pemerintahan Dalam Hal Pemilihan Kepala Negara Di Indonesia Dan SingapuraDocument9 pagesPerbandingan Sistem Pemerintahan Dalam Hal Pemilihan Kepala Negara Di Indonesia Dan SingapuraRendy SuryaNo ratings yet

- Anomaly Sell Out Remap December 2019 S SUMATRA & JAMBIDocument143 pagesAnomaly Sell Out Remap December 2019 S SUMATRA & JAMBITeteh Nha' DwieNo ratings yet

- Lecture7 PDFDocument5 pagesLecture7 PDFrashidNo ratings yet

- Maximizing Revenue of IT Project DevelopmentDocument4 pagesMaximizing Revenue of IT Project DevelopmentJulius Mark CerrudoNo ratings yet

- A Dream Takes FlightDocument3 pagesA Dream Takes FlightHafiq AmsyarNo ratings yet

- Itec 3100 Student Response Lesson PlanDocument3 pagesItec 3100 Student Response Lesson Planapi-346174835No ratings yet

- Tps65070X Power Management Ic (Pmic) With Battery Charger, 3 Step-Down Converters, and 2 LdosDocument98 pagesTps65070X Power Management Ic (Pmic) With Battery Charger, 3 Step-Down Converters, and 2 Ldosmok waneNo ratings yet

- Product Data: Airstream™ 42BHC, BVC System Fan CoilsDocument40 pagesProduct Data: Airstream™ 42BHC, BVC System Fan CoilsMaxmore KarumamupiyoNo ratings yet

- Mesa de Trabajo 1Document1 pageMesa de Trabajo 1iamtheonionboiNo ratings yet

- IBM TS3500 Command Line Interface (CLI) ExamplesDocument6 pagesIBM TS3500 Command Line Interface (CLI) ExamplesMustafa BenmaghaNo ratings yet

- Using The Marketing Mix Reading Comprenhension TaskDocument17 pagesUsing The Marketing Mix Reading Comprenhension TaskMonica GalvisNo ratings yet

- Merlin Gerin Medium VoltageDocument10 pagesMerlin Gerin Medium VoltagekjfenNo ratings yet

- Parasim CADENCEDocument166 pagesParasim CADENCEvpsampathNo ratings yet

- Serras Tilted Arc Art and Non Art Senie in Art Journal 1989Document6 pagesSerras Tilted Arc Art and Non Art Senie in Art Journal 1989api-275667500No ratings yet

- LeasingDocument2 pagesLeasingfollow_da_great100% (2)

- Specialized Government BanksDocument5 pagesSpecialized Government BanksCarazelli AysonNo ratings yet

- Research Design Elements for ScenariosDocument25 pagesResearch Design Elements for Scenariosrohizal ibrahimNo ratings yet

- Technical Skills:: Surabhi SrivastavaDocument3 pagesTechnical Skills:: Surabhi SrivastavaPrasad JoshiNo ratings yet

- Blum2020 Book RationalCybersecurityForBusineDocument349 pagesBlum2020 Book RationalCybersecurityForBusineJulio Garcia GarciaNo ratings yet

- Joint Memorandum Circular (JMC) No. 2021Document49 pagesJoint Memorandum Circular (JMC) No. 2021Nicey RubioNo ratings yet

- Virgilio S. Delima V. Susan Mercaida Gois GR NO. 178352 - June 17, 2008 FactsDocument6 pagesVirgilio S. Delima V. Susan Mercaida Gois GR NO. 178352 - June 17, 2008 FactsNikki BarenaNo ratings yet