Professional Documents

Culture Documents

Project Question

Uploaded by

subxaanalahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project Question

Uploaded by

subxaanalahCopyright:

Available Formats

An example of a Design

of small Gravity Dams

by Hailu Yemanu, Chief Engineer of the Awash Valley Authority and Lecturer of

Fluid Mechanics and Hydraulics at the Engineering College, Haile Selassie I University

1. Introduction

The purpose of this paper is to consider and

discuss the merits of the methods employed in the

consideration and design of a concrete diversion

dam designed by the writer with the purpose of

diverting a maximum flow of 1.5 m3/sec from the

Culfo River for the agricultural irrigation of approximately 1250 hectares at the Arba Minch Farm in

Gemu Gofa Province.

It is of course fully appreciated that there are

numerous and wide variations in the criteria which

can be employed to design such type of gravity dams

as carried out in various parts of the world and by

numerous engineers.

However, it is suggested that the criteria borne

in mind in the design of the small dam which is the

subject of the following notes may be of value in

considering the design of similar diversion or gravity

dams of varying sizes.

2. Hydrogeological data

According to the water tests carried out in the

abovementioned boreholes the permeability coefficient K is generally low from the seepage point of

view (order of 10-4 to 10-s cm/sec). Values of K

in the order of I 0-6 cm/sec often indicate that the

strata is practically impervious.

On the other hand the dissipation of excess

pore pressures produced by loading will be a short

term phenomenon, and therefore the stability analysis against shear failure may be performed in terms

of effective stresses, assuming an average value for

the internal angle of friction:

q> = 30

with no cohesion assumed.

3. Design data

On the basis of the limited hydrological observations of the river and the irrigation water requirement (Q max = 1.5 m3/sec) for the above mentioned

area of 1250 ha to be commanded the following

design data have been established:

Five investigation boreholes have been drilled

along the proposed axis of the dam to a depth ranging between 15 and 31.5m.

dam crest elevation

length of spillway

maximum head of spillway

On the left side of the Valley the soil consists

of basalt boulders with gravel sand and silt forming

a sort of soft conglomerate.

maximum estimated flood

On the right side sandy silty formations prevail,

occasionally including some gravel.

The frequent alternation of thin layers (sandy silts and silty - sands in general) did not suggest

the opportunity of laboratory tests of undisturbed

samples, but the visual inspection of the latter show

fairly good degree of relative density or consistency.

The intermediate borehole at the centre of the

axis of the dam has the same features as the boreholes on the left side of the valley down to Sm. depth,

while the underlying formations are similar to those

found on the right side.

108.70 m

33

m

m

1

(Elev. 109.70)

66 m3/sec

With the foregoing data the following was

proposed for the preliminary design of the dam:

foundation width of the dam 4.40 m

foundation depth

105.50 m elev.

107.00 m

upstream ground elevation

downstream ground elevation 106.65

(rock rip rap)

system of piles

5 ranges

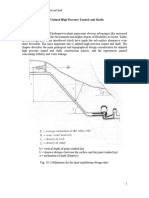

After obtaining the results of the geobydrological investigation of the dam site the preliminary

design of the diversion dam shown in Fig. 1 was

revised for safety against piping, shear failure,

excessive seepage and up lift under the dam and

also checked against over turning and sliding effects.

17

109 .70

M

.W

.L +

N.W.~

-108.70

"!:.

107

107

106.65

105 . 50

I.I

11. 10

I. 0

I. 0

1.

.1

4 . 40

Fig. 1 -

Preliminary Design of the Diversion Dam

4. Safety against Piping

_ a H

it Df

e -

The exit gradient generally provides the most

significant criterion design for the factor of safety

with respect to piping.

where:

H = hydraulic head loss

Df = Embedment depth of structure

a = coefficient to be determined according

to Harr as a function of the ratio Df/B

where B is the width of structure (Fig. 2).

For a depressed structure on a permeable base

of infinite extent the exit gradient may be analytically

calculated by Harr's expression:

I0

0.

I.00

!'.....

--

.............

0..

"

0 .4

--0

'\.

+I 0

r\

.'1'Q

lD

o"'-P> 0

+I

0. 2

0 .4

0 .6

0 .8

1.0

dr'

0 ::IV

0 .20

0

'\

/

_...... v

0 .20

\

0 .40

0.60

0.80

a

1:1

M IS

A CONS TANT FUNCTION OF

(AFTER PAVLOVSKY)

Fig. 2 18

0 .10

Ou..

'

~)

a: 0 .50

I \ -;o-

0.2

c0

J \

o"'- O--

!"....

(I)

i5

l)

OR

Determination of the Coefficient

1.00

The weighted-creep theory as developed by

Lane could also be employed as criteria for the

design of low concrete dams on pervious foundations

to be safe against piping and uplift pressures. Although this is an empirical method, considerable

confidence has been placed in it by many engineers

and it has been successfully used for the design of

many structures.

We consider the following expressions for the

calcula tion of hydraulic gradient:

Bligh's equation

C = Fs le =

(2)

H

/JB + L. 1 Lane's equation

lcr

8.5

7.0

6.0

5.0

4.0

3.5

18

15

12

2 67

DJ

Fs

4.40

6.00

8.00

10.00

12.80

23.00

2.67

3.04

3.45

3.72

4.00

6.00

More advantage can be obtained by increasing

the depth DJ as shown by Table 3. In this case two

alternatives were considered:

B = 4.40 m

and B = 6.00 m

TABLE 3

2.5

4-6

3

2

1.8

1.6

1.15 m downstream side

4.40 m

2.70 m (max. upstream water elevation

109.70 m minus downstream

water level supposed at elevation

107.00 m).

_!!_H

B (m)

the preliminary design data (Fig. 1) we

1t

TABLE 2

Employing Harr's criteria from (1) and from

(Fig. 2) a = 0.5 and therefore:

c

1

0.374

Maintaining DJ constant and varying B we calculate Fs:

Safe Weighted Creep Ratio

Lane's Value Bligh's Value

of C = Fs

of C = Fs

Very fine sand or silt

Fine sand

Medium sand

Coarse sand

Fine gravel

Medium gravel

Gravel and sand

Coarse gravel including cobbles

Boulders with some cobbles &

gravel ...

Boulders, gravel & sand

Soft clay ...

Medium clay

Hard clay

Very hard clay or hard pan

From our preliminary design F:. is very low

and it was required to increase the safety factor.

An increase of F,) can be obtained by enlarging and

deepening the structure. The enlargement alone does

not bring obout convenient solution as shown

in Table 2.

Weighted-Creep Ratio

Type of Material

fer

le

This is too low for any type of pervious soil, compared with the minimum allowable value of 4 according to the criteria of Lane (Table 1.) When fine

sand is present, as in our case, Khosla, Bose and

Taylor recommend a safety factor of at least 6 and

it may be even raised to 10.

hydraulic head loss

Horizontal section of the line of creep

Vertical section of the line of creep

safe weighted creep ratio or expressed

as coefficient of safety factor Fs

critical gradient, as per Terzaghi = 1.

TABLE 1 -

From

have:

DJ =

B =

H =

Fs --

where:

H

B

t

C

The factor of safety in our case is:

0.5 x 2.70

3.14 x 1.15

0.374

B = 4.40 m

D1 (m)

Fs

1.15

l.65

2.15

2.65

3.15

2.67

3.56

4.24

4.95

5.82

B -= 6,00 m

Dr (m)

Fs

l.15

1.65

2.15

2.65

3.15

3.04

3.84

4.72

5.32

6.20

The above calculations refer to structures without cut-offs or sheet pilings but the result is not

likely to be much different when the width of the structure and the depth of vertical elements are not very

important; anyway the safety factor would be underestimated, if DJ represents the depth of vertical

elements.

In our case a sheet piling may meet with some

difficulty due to the presence of boulders, and the

execution of two cutoff walls (one upstream and one

downstream) will be more suitable.

19

cEL.108.70

--

L.105 .00

5

=3.15

'---~~uo~.J

- - --1-------8 / 2

----"I

'"'--- - - -- - - - B =6.00 - - - - - - - - - - - ,

CEL.109.70

....

Fig. 3 -

Stability Analysis Case A

~L.107.00

EL. to6.65

a

EL.105.00

- -- . _ ....._

[ EL.103.50

___,

i - . - - -- --

B I 2 ----

e

Fig. 4 -

= 6 .oo----------i

Stability Analysis Case B

On the basis of the results of the foregoing

analysis the following elements have been fixed

for the final design of the diversion dam (Figs. 3 & 4)

6.00 m

base width (b) =

base elevation =

105.00 m

Cutoff depth below downstream ground

3.15 m.

level (DJ) According to figures in Table 3. calculated following Harr's criteria, the factor of safety is 6.2 for the

most unfavourable case of maximum spillway head.

Ths can be considered satisfactory. Following Eligh 's

criteria the safety factor,

Fs =

15.05

2.70 -

5 57

.

CASE "A" (Fig. 3)

And according to Lane,

11.65

Fs =

_

= 4.3,

2 70

Both of these values are greater than four. Considering a = 0.51 when the water is at dam crest level:

le

0.510 X 2.05 = O.l06

n Dt = 3.14 x 3.15

fer

le =

Vertical resultant N including saturated weight

of soil between cutoff walls and full uplift force "U"

at cutoff base level (trapesoidal diagram with upstream presure of 5.20 ton/m2 and downstream value

of 3.15 ton/m2):

1

0.106 = 95

Fs rises to about 10.

5. Stability against Shear Failure

The ultimate bearing capacity of a foundation

with inclined resultant load applied to a granular

subsoil, is given by the Erinch Hansen equation:*

q"

2

o.5yN,s { 1- 0.31 ) ( 1- i.5Z ) +

y DJ Nq ( 1+0.21 ] ( 1+ O.I

( 1- 1.5

z)

Upstream water elevation = 108.70 m (dam

crest),

Downstream water elevation = 106.65 m

(rock riprap top level).

Full water thrust is considered on both upstream

and downstream sides (Sw and Slw); earth pressures

compensating mutually.

= a H

_

Fs -

(4)

Bl= B - 2.e

where e represents the eccentricity.

Considering the final adopted design of the dam

(Section 4) and the nature of the soil (Section 2) we

arrive at:

Bl = 6.00 - 2e

L

= 33 m

DJ = 3.15 m

Nr = 20

=

300

(determined

in

Nq

= 22

<1>

y

Section 2)

= 1 ton/m3

The bearing capacity factors N, Nq are determined from Fig. 5.

As concerns the stress conditions, two cases

have been considered:

i-]

(3)

where:

B = width of foundation

L = length of foundation

H = horizontal forces acting on the soil

N = vertical forces acting on the soil

DJ = depth of foundation

y

= submerged density of soil

N,, Nq = bearing capacity factors,

functions of the internal angles of

friction of the soil ( q> ), according

to Terzaghi.

When the resultant, inclined force R = f(H,N)

is eccentric, B must be substituted with the reduced

effective width:

Total load (structure +soil

between cutoffs)

Uplift force at cutoffs base level

Resultant vertical force

Water thrust on upstream side

Water thrust on downstream

side

Resultant horizontal force

51.2

25.1

26.1

13.5

Sw

S 1w

5.0 ton

8.5 ton

ton

ton

ton

ton

Taking moment of forces about the upstream

cutoff wall toe, moment arm of the resultant inclined

force R:

a =

M1N

M2H = 3.20 m.

Eccentricity of the resultant inclined force R:

e =

a -

3.20 -

3.00

0.20 m.

According to equations, (3) and (4) and to the

magnitude and position of forces shown in (Fig. 3)

the following values of ultimate bearing capacity

have been obtained:

qu = 52.8 ton/m2/m.

from (3)

The applied average pressure to be compared

with qu is given by the expression:

Po

"' This is an extention of Terz.aghi formula:

qu ~ 0.5 y N, B + CNc + y Dr Nq,

where for cohesionless soil CNc = 0,

Ne being bearing capacity factor.

Bi

N

=

B- 2e

(5)

According to Equations (4) and (5), we have

Po = 4.65 ton/m2/ m.

21

The Motor anci Engineering Company of Ethiopia Ltci.

(Member of INCHCAPE Group)

Authorized dealers

for the Ethiopian Empire:

OPEL Cars & Trucks.

OLDSMOBILE

BEDFORD Trucks

FRIGIDAIRE

PONTIAC

ffi.~V'kJ'

V AUXHALL Cars

G. M. C. Trucks

G. M. Diesel

CADILLAC

DELCO-REMY - A.C.

DUPONT - FREON GAS

VREDESTEIN TIRES

: ftp>'f-C'i: fDD,h'}J;.()~:,-.

"'I ~ n C : IL 7. :,. 1.' I

Automotive Dept.

Pharmaceutical Dept.

Engineering Dept.

P. 0 . Box 1767

ADDIS ABABA

I. T. T. Corporation

ZANUSSI Products.

Cable 'MOENCO"

THOMAS DE LA RUE & Co.

INGERSOLL - RAND

HOBART - WELDERS.

ROGERS TRAILERS.

Telex: 1019

Telephones:

KOEHRING EXCAVATORS - CRANES - DRAGLINES

YALE FORK LIFTS & MACHINERY

Management

45708

POCLAIN EXCAVATORS.

Automotive Dept.

46440

BARBER - GREENE

Accounts

45674

CHEVRON ANGLE IRON

Pharmaceutical Department

45680

FORD TRACTORS & EQUIPMENT

Engineering Department

47557

TOYOTA VEHICLES & LAND CRUISERS.

WABACO - GRADERS - TOURNA TRACTORS

SCRAPERS ETC.

Garage and Spare Parts Dept. 46491

Custom Warehouse

46358

ALLIS-CHALMERS ENGINEERING PRODUCTS.

FAILING DRILLING RIGS (WABCO)

CONSTRUCTION EQUIPMENT, PUMPS, SILOS ETC.

Branch:

ASMARA

STONE CRUSHERS, IRRIGATION, ETC.

WATER TREATEMENT PLANTS

22

P. 0 . Box 842 -

Tel. 10384

Safety factor:

and the fo llowing safety factor is obtained:

Fs =

qi/

= 11.40

qu

Po

Po

N~

r-- i--

'

t-- i-..

""'-

Nq .

i'-... ~

'~

.,

~~

\ ~

!'-.. ~""

.... \ \

I\

40

Values of Nr

Fig. 5 -

20

30

la.I

\~

'

, '

50

/ nNr

\\

60

' ,.Ne ' \330 I /

........

4.27

The stability against shear failure is also ample

in the above indicated Case ( B).

The stability against shear failure is then ample

even in the most unfavourable conditions.

,_ ....

...

..........

9J =44 =Nr = 260

=4g>=Nr=78D

.o"

-

11

10 000

20

I'- 0

and Nq

'-"""" Nr

40

50

60

Values of ~

I() -

Chart showing relation between <!> and bearing capacity factors

Loaded strip, width B

Total load per unit length of footing

General shear failure: Qd = B (CNc + y DJ Nq

Local shear failure:

Q'd = B

(~

CN'c

y DJ N'q

+t

+

y BNr}

t yBN'r)

..j

-.J

llOutH-1

u u

Square footing, width B

II

po

j._

q)#ll:\ w.

UNIT

W!tGtlT OF IAltTH ' (

Total critical load:

Qds = B2 (l.3 CNc + y DJ Nq + 0.4 y BNr)

Unit shear resistance, S - c + o tan <!>

6. Seepage

CASE "B'' (Fig. 4)

Upstream water elevation = 109.70 m

(maximum spillway head),

Downstream water elevation = 107.00 m

(0.35m above riprap top).

Horizontal water thrust is calculated according

to the new conditions and Vertical resultant force

N as in case (A).

It is very unlikely that the maximum head condition may last for such a long time to produce

uplift pressure worse than that considered in case (A).

Therefore U is taken as in case (A).

Vertical forces

Horizontal forces

l

l

Sw

S'w

H

51.2 ton

25.1 ton

26.1 ton

18.8 ton

5.0 ton

12.7 ton

Proceeding as in the previous Case (A)

Eccentricity of resultant force R:

e = 0.68 m

Applied pressure at cutoffs base level:

N

P0 = B _

e = 5.63 ton/m1 .

2

According to the results of permeability tests

the quantity of seepage under the dam is likely to

be low, on condition that the passage of water along

or near the soil structure contacts is prevented.

The contacts between soil and structure which

may have been disturbed or lessened by excavations

would require treatment up to certain depth.

Grouting might solve the problem but for such

a small dam this solution was considered to be expensive.

Since the permeability tests indicate low seepage loss and the cutoff walls also reduce this loss,

it was considered that the seepage would not be a

serious problem. However, in order to seal the contacts between soil and structure, it was proposed

to substitute the disturbed natural soil at the upstream cutoff wall by compacted mixture of clay,

sand and gravel. The downstream cutoff wall side

was provided with inverted filter as shown in Fig. 6.

Measures taken to minimize seepage losses also

reduce considerably the uplift effect. The cutoff

walls, the compacted mixture of clay, sand and

gravel at the upstream face of the structure would

increase greatly the "creep length". This together with

the inverted filters at the downstream face of the

cutoff wall reduces considerably the uplift effect under

the dam.

23

7.

Overturning

H

N

Since the resultant of vertical forces is much

higher than the resultant of horizontal forces in

both cases A & B (Section 5) the structure is safe

against overturning.

Case B:

120

12.7

"!" - 26.1

HO

"!"

8.5

- 0.325

26.l

Case A: "/"

Taking moment about of the downstream cutoff wall toe:

. equal to or 1ess t h an

1s

0.485

I 2 PIPE

PflClrU OIF DAiii TO 9E P&VEO

[ L IOI 15

WITH THICll llOCK (50 Clll WITH

EL IOG 6$

CtMlNT llOUAR

:.. ~.

..I

no

10

-~~ .~

G Allo.tS T08E 'tLLED

WITH THICK STOIE AllO

PLACEJ> tN T...U:

llOW$

1$o I

100

SECTION

8- 8

SCllL E I 50

Fig. 6 -

MH

MN

Fs -

Case A

2.15 x 8.5

3.50 x 26.l

Final design of the Diversion Dam

0.2, less than 1

Case B

MN

2.40 x 12.7

= 0.33, less than 1

Fs = - - MH

3.50 x 26.l

The factor of safety against overturning is sometimes defined as the ratio of the tightening moments

to the overturning moments about the toe of the

dam. When so defined all excepting the direct foundation reaction are deemed active. Ordinarily the factor

of safety against over-turning is between 2 and 3.

Case A: Fs -

MN

MH = 5, greater than 3

Case B: Fs -

MN

MH = 3,3, greater than 3

Our case represents for permissible "/" - concrete

against gravel, coarse sand and boulders.

Furthermore the cutoff walls prevent displacement as could be observed from Figs. 3, 4 and 6.

Exact values for coefficients of static friction

cannot be determined without the benefit of laboratory tests, but the allowable sliding factors given

below which include ample factors of safety for

concrete against sliding on the various foundation

materials may be used as a general guide:

Material

Sound rock, clean and irregular surface

Rock, some jointing and laminations

Gravel and coarse sand

Sand

Shale

Silt and clay

testing

f

0.8

0.7

0.4

0.3

0.3

required

8. Sliding

The allowable sliding factor is the coefficient

of static friction between two sliding surfaces reduced

by an appropriate factor of safety. If "/" represents

the allowable sliding factor, a dam is considered

safe against sliding when

24

9. Conclusions

The final design of the diversion dam is safe

against piping, shear failure, excessive seepage,

uplift, overturning and sliding effects.

Piles are not necessary for stability against

sliding or shear failure as discussed in section 5.

The presence of a double cutoff wall and an

adequate compacted mixture of clay, sand and gravel

at the upstream side of the cutoff wall and the

graded inverted filter at the downstream side of the

cutoff wall will prevent piping, excessive seepage

and uplift effect under the dam.

The downstream rock riprap must be sufficiently thick and long in order to pr~vent erosion

near the dam by the over flowing water and for the

purpose gabions have been recommended. But ero

sion may still take place beyond the protected zone.

I in this case the toe of the valley slopes should also

be protected by rockfills and periodically repaird as

necessary.

REFERENCES:

(1) Geotechnical Report L Sp.A., Italy, 1966.

1748, Ing. Giovanni Rodio,

(2) Design of Small Dams - Bureau of Reclamation, U.S.A..

1965.

(3) Soil Mechanics in Engineering Practice -Terzaghi &

Peck, U.S.A., 1962.

(4) A General Formula for Bearing Capacity - J. Brinch

Hansen, Technical University of Denmark, 1962.

(5) Foundations of Structures - General Subjects and

Foundations Other Than Piled Foundations - Proceedings of the Fourth International Conference on Soil

Mechanics and Foundation Engineering, London, 1957.

(6) Ground Water and Seepage - Harr, Milton E., U.S.A.,

1962.

J\. E. G.

Jlngemeine

Berlin (West)

Frankfurt (Main)

West Germany

E1ektricitats

Gesellschaft

Agents for the Ethiopian Empire

SEFERIAN & Co. (Ethiopia) Ltd., S.C.

P. 0. Box 64 - Tel. Nos. 48100-1-2, 44719 - ADDIS ABABA

25

You might also like

- Manual Cropwat 8Document16 pagesManual Cropwat 8subxaanalah91% (11)

- Chapter 4 PART 2Document14 pagesChapter 4 PART 2Fetene Nigussie75% (8)

- Head and Cross RegulatorsDocument14 pagesHead and Cross RegulatorsSaphal Lamichhane78% (9)

- (COMSOL) Models - Geomech.slope - Stability PDFDocument22 pages(COMSOL) Models - Geomech.slope - Stability PDFjorgeNo ratings yet

- 51CDocument6 pages51Cjhacademyhyd100% (5)

- Stress Analysis Methods For Underground Pipe Lines Part 2 - Soil-Pipe InteractionDocument5 pagesStress Analysis Methods For Underground Pipe Lines Part 2 - Soil-Pipe Interactionsateesh chand100% (1)

- Abid Ali SAP Resume (Experience)Document3 pagesAbid Ali SAP Resume (Experience)Abid AliNo ratings yet

- AC DC AcDocument3 pagesAC DC AcPhani KumarNo ratings yet

- Head and Cross RegulatorsDocument19 pagesHead and Cross RegulatorsEng Shakir H100% (1)

- CE404 03 Stilling BasinsDocument10 pagesCE404 03 Stilling BasinsAbhishek Shah100% (1)

- LF RD Retaining WallDocument37 pagesLF RD Retaining Wallsadik268No ratings yet

- Hydraulics of Weirs: Design of Irrigation StructuresDocument8 pagesHydraulics of Weirs: Design of Irrigation StructuresAmr KhaterNo ratings yet

- CIVE 413 Environmental River Mechanic Camp Hale ProjectDocument10 pagesCIVE 413 Environmental River Mechanic Camp Hale ProjectNeil AndikaNo ratings yet

- Quay Walls DesignDocument12 pagesQuay Walls DesignAdrian Frantescu100% (1)

- 10 Unlined HP Tunnel and ShaftDocument4 pages10 Unlined HP Tunnel and ShaftSubash PoudelNo ratings yet

- 5 Seepage TheoriesDocument30 pages5 Seepage TheoriesSushil Mundel100% (1)

- Hydraulic Design of Energy Tors For Culverts and ChannelsDocument15 pagesHydraulic Design of Energy Tors For Culverts and ChannelsCharles S. MeehanNo ratings yet

- Unlined High Pressure Tunnel and ShaftsDocument4 pagesUnlined High Pressure Tunnel and Shaftsbiplov nepalNo ratings yet

- Evaluation of The Load On A Shield Tunnel Lining in GravelDocument6 pagesEvaluation of The Load On A Shield Tunnel Lining in GravelLevent KurtulduNo ratings yet

- Exercise-Design of Weir-Option 1Document6 pagesExercise-Design of Weir-Option 1ale hopeju2009No ratings yet

- Breakwater DesignDocument11 pagesBreakwater Designyanu13100% (1)

- Notes On Flood Routing Through Reservoirs and ChannelsDocument12 pagesNotes On Flood Routing Through Reservoirs and ChannelsIVANAYALANo ratings yet

- Head Losses in TunnelDocument18 pagesHead Losses in TunnelmuazeemK67% (3)

- Design of HP HT Pipelines Against Lateral BucklingDocument20 pagesDesign of HP HT Pipelines Against Lateral BucklingHarmoni Andreas100% (1)

- V H V P U: Fig.5.1 Estimation of Built-Up Pore-Water PressureDocument15 pagesV H V P U: Fig.5.1 Estimation of Built-Up Pore-Water PressureTaqudas AhmedNo ratings yet

- Experimental Study For Sequent Depth Ratio of Hydraulic Jump in Horizontal Expanding ChannelDocument9 pagesExperimental Study For Sequent Depth Ratio of Hydraulic Jump in Horizontal Expanding ChannelAtiqur Rahman MishuNo ratings yet

- Vertical Drop WeirDocument39 pagesVertical Drop WeirSYED FAROOK100% (1)

- Hydraulic Heave Safety at Excavations With Surcharge FiltersDocument8 pagesHydraulic Heave Safety at Excavations With Surcharge Filterslyes geotNo ratings yet

- Stability of Braced CutsDocument14 pagesStability of Braced CutsDariush Galebi0% (2)

- Engineering MekaDocument28 pagesEngineering MekaAbdi DebelaNo ratings yet

- Geotechnical Engineering Capillarity in SeepageDocument5 pagesGeotechnical Engineering Capillarity in SeepageNicole CruzNo ratings yet

- DrahmedsoilMechanicsnoteschapter5 PDFDocument61 pagesDrahmedsoilMechanicsnoteschapter5 PDFRavaliNo ratings yet

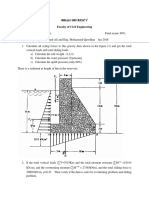

- Tut2004 G4HDocument3 pagesTut2004 G4HAbdiwali Y. Dhoof93% (14)

- Dodo 123456489Document21 pagesDodo 123456489omarrgb97No ratings yet

- Hydraulic Design of Upstream Scouring Sluice: 99.05 M 95.64 M 96.75 M 100.65 MDocument8 pagesHydraulic Design of Upstream Scouring Sluice: 99.05 M 95.64 M 96.75 M 100.65 MIlman AdlyNo ratings yet

- Tank Foundation DesignDocument5 pagesTank Foundation DesignAlonzo1586100% (8)

- Free Flow Below Skew Sluice Gate: Talib MansoorDocument9 pagesFree Flow Below Skew Sluice Gate: Talib MansoorIJERDNo ratings yet

- Addis Ababa Institute of Technology School of Civil and Environmental Engineering CENG 6606 - Hydraulic Structures IIDocument11 pagesAddis Ababa Institute of Technology School of Civil and Environmental Engineering CENG 6606 - Hydraulic Structures IIKenenisa BultiNo ratings yet

- Open Channel Hydraulics Chapter Three: 3. Rapidly Varied Flow (RVF)Document17 pagesOpen Channel Hydraulics Chapter Three: 3. Rapidly Varied Flow (RVF)mustefa kelilNo ratings yet

- Design Principles For Aqueduct and Siphon AqueductDocument16 pagesDesign Principles For Aqueduct and Siphon AqueductartiNo ratings yet

- ECK Rainage Esign: B D A - O 2006Document20 pagesECK Rainage Esign: B D A - O 2006HundeejireenyaNo ratings yet

- Quay Wall Bottom Protection PDFDocument12 pagesQuay Wall Bottom Protection PDFdndudcNo ratings yet

- Section 6: Gutter and Inlet EquationsDocument20 pagesSection 6: Gutter and Inlet EquationsAl Patrick Dela CalzadaNo ratings yet

- Analysis of The Stand UpDocument6 pagesAnalysis of The Stand UpSafar Al InseNo ratings yet

- 240 Toe Rock StabilityDocument13 pages240 Toe Rock StabilityFoong Tong WengNo ratings yet

- Technical Bulletin: Depth of Burial For PVC PipeDocument2 pagesTechnical Bulletin: Depth of Burial For PVC PipeLava SatNo ratings yet

- Canal Syphon ProgrammeDocument29 pagesCanal Syphon Programmechitransh200289% (9)

- On Stability Analysis of Slurry-Wall Trenches: Plaxis PracticeDocument6 pagesOn Stability Analysis of Slurry-Wall Trenches: Plaxis PracticeVetriselvan ArumugamNo ratings yet

- Final ExamDocument5 pagesFinal ExamNarcisa RudnicNo ratings yet

- Diseño Óptimo de Forma de Una Presa de Tierra, Utilizando El Algoritmo Artificial de Colonia de AbejasDocument8 pagesDiseño Óptimo de Forma de Una Presa de Tierra, Utilizando El Algoritmo Artificial de Colonia de AbejasJames KenobiNo ratings yet

- AMCRPS Impervious enDocument64 pagesAMCRPS Impervious enonin007No ratings yet

- Tablaestacas PDFDocument18 pagesTablaestacas PDFPaulaNo ratings yet

- Spillway DesignDocument18 pagesSpillway DesignFrancisco Alves100% (2)

- The Mechanics of Water-Wheels - A Guide to the Physics at Work in Water-Wheels with a Horizontal AxisFrom EverandThe Mechanics of Water-Wheels - A Guide to the Physics at Work in Water-Wheels with a Horizontal AxisNo ratings yet

- Soils as a Key Component of the Critical Zone 3: Soils and Water CirculationFrom EverandSoils as a Key Component of the Critical Zone 3: Soils and Water CirculationGuilhem BourrieNo ratings yet

- Fluid Dynamics in Complex Fractured-Porous SystemsFrom EverandFluid Dynamics in Complex Fractured-Porous SystemsBoris FaybishenkoNo ratings yet

- In Mind Assistance With Administration of Logistics Operations)Document1 pageIn Mind Assistance With Administration of Logistics Operations)subxaanalahNo ratings yet

- Excutive SummaryDocument11 pagesExcutive SummarysubxaanalahNo ratings yet

- QGIS Training 1Document77 pagesQGIS Training 1subxaanalahNo ratings yet

- Final Exam Hydraulic StructuresDocument2 pagesFinal Exam Hydraulic Structuressubxaanalah80% (5)

- LUP Annex 1 GlossaryDocument2 pagesLUP Annex 1 Glossarysubxaanalah100% (1)

- SoilDocument182 pagesSoilsubxaanalahNo ratings yet

- Mesfen DamtewDocument114 pagesMesfen DamtewsubxaanalahNo ratings yet

- TOR - Distribution of Cooking StovesDocument4 pagesTOR - Distribution of Cooking StovessubxaanalahNo ratings yet

- Soil Water Characteristics-EquationsDocument52 pagesSoil Water Characteristics-EquationsakbelNo ratings yet

- Based Farming. in The Bases of Assessing Potentiality of Project Are On Runoff Farming and Also Establishing Hydro-Meteorological NetworkDocument2 pagesBased Farming. in The Bases of Assessing Potentiality of Project Are On Runoff Farming and Also Establishing Hydro-Meteorological NetworksubxaanalahNo ratings yet

- 1 5-Irrigation PDFDocument60 pages1 5-Irrigation PDFjoemarNo ratings yet

- Exercise 5Document1 pageExercise 5subxaanalahNo ratings yet

- Course ScheduleDocument3 pagesCourse SchedulesubxaanalahNo ratings yet

- IrrigationDocument28 pagesIrrigationArmando BasocNo ratings yet

- 1.1 The Role and Purpose of IrrigationDocument11 pages1.1 The Role and Purpose of IrrigationsubxaanalahNo ratings yet

- SWHISAWatershedstrategicpaper 18 Oct 08Document10 pagesSWHISAWatershedstrategicpaper 18 Oct 08subxaanalahNo ratings yet

- 4 Dolenqie Watershed Planning Report English FinalDocument64 pages4 Dolenqie Watershed Planning Report English FinalsubxaanalahNo ratings yet

- Mid Exam WRMDocument2 pagesMid Exam WRMsubxaanalahNo ratings yet

- Data of Site HarafDocument1 pageData of Site HarafsubxaanalahNo ratings yet

- Minara WSDocument120 pagesMinara WSsubxaanalahNo ratings yet

- ToR SoilbundDocument1 pageToR SoilbundsubxaanalahNo ratings yet

- 1 - Kurie Watershed Planning Report DRAFT by WMG 31aug09Document73 pages1 - Kurie Watershed Planning Report DRAFT by WMG 31aug09subxaanalahNo ratings yet

- Settlement X Y Farms Sub Catchment New Soil Bund Reh Soil BundDocument8 pagesSettlement X Y Farms Sub Catchment New Soil Bund Reh Soil BundsubxaanalahNo ratings yet

- Selected Pages WMODocument41 pagesSelected Pages WMOsubxaanalahNo ratings yet

- Chapter One Final DraftDocument14 pagesChapter One Final DraftsubxaanalahNo ratings yet

- 7135 PLB Level 1 Guide Trainers Review 5.42pmDocument68 pages7135 PLB Level 1 Guide Trainers Review 5.42pmsubxaanalahNo ratings yet

- Community Dam DesignDocument34 pagesCommunity Dam DesignsubxaanalahNo ratings yet

- Chapter Two EditedDocument7 pagesChapter Two EditedsubxaanalahNo ratings yet

- 7135 PLB Level 1 Guide Trainers Review 5.42pmDocument68 pages7135 PLB Level 1 Guide Trainers Review 5.42pmsubxaanalahNo ratings yet

- CV - Pramod For Store & Logistics..Document2 pagesCV - Pramod For Store & Logistics..Anuj sainiNo ratings yet

- Trouble Shooting Dewatering PumpDocument136 pagesTrouble Shooting Dewatering PumpMuhammad NoorNo ratings yet

- Re-Measurement Sheet FOR UNIT 148 Interconnecting Piperack M44-Pr3Document6 pagesRe-Measurement Sheet FOR UNIT 148 Interconnecting Piperack M44-Pr3Vasilica BarbarasaNo ratings yet

- Scania Jenerator DC1372A - 438-487kW PDFDocument2 pagesScania Jenerator DC1372A - 438-487kW PDFMehmet ErenNo ratings yet

- Finals DSP WithMinimalErrors PDFDocument64 pagesFinals DSP WithMinimalErrors PDFanembam putobungbongNo ratings yet

- Wireless Selection GuideDocument50 pagesWireless Selection GuideShailesh KshatriyaNo ratings yet

- Classification Matter Flow ChartDocument1 pageClassification Matter Flow ChartKiera CeelyNo ratings yet

- West Virginia Transporter 2017Document16 pagesWest Virginia Transporter 2017Kyle LangsleyNo ratings yet

- Conveyor Belt: Heavy Duty RubberDocument5 pagesConveyor Belt: Heavy Duty RubberHeidrahNo ratings yet

- MS XLSXDocument290 pagesMS XLSXAlvaro S. AcejoNo ratings yet

- LY IR9000 BGA Rework Station User GuideDocument4 pagesLY IR9000 BGA Rework Station User GuidemariabaccaroNo ratings yet

- Listprice 07 11Document1,797 pagesListprice 07 11Tejano RockNo ratings yet

- Date Code - Osram - 1994-PresentDocument2 pagesDate Code - Osram - 1994-PresentMuzeul LampilorNo ratings yet

- DDC Brochure 2021 - DigitalDocument4 pagesDDC Brochure 2021 - DigitalJonathan MooreNo ratings yet

- Pre Accion PDFDocument8 pagesPre Accion PDFjhoger2012No ratings yet

- Owatch VR Games Quotation - 2017!4!24Document3 pagesOwatch VR Games Quotation - 2017!4!24ali4957270No ratings yet

- Textile Shop Management SystemDocument6 pagesTextile Shop Management SystemVedha TechnologiesNo ratings yet

- K 1020189523hfjfjDocument3 pagesK 1020189523hfjfjCarlos Angel Vilcapaza CaceresNo ratings yet

- FRP Fish TanksDocument33 pagesFRP Fish TanksA.Subin DasNo ratings yet

- Pacom S72724+PDR32-RMT-HYB+ManualDocument130 pagesPacom S72724+PDR32-RMT-HYB+ManualDavidChisholmNo ratings yet

- Instrument and Control Designer Rev01Document5 pagesInstrument and Control Designer Rev01masilamaniNo ratings yet

- Grinding Polishing: Kiesow Dr. BrinkmannDocument36 pagesGrinding Polishing: Kiesow Dr. BrinkmannChoice OrganoNo ratings yet

- Makalah Program PDFDocument10 pagesMakalah Program PDFIvanFolkNo ratings yet

- Kata Loge 128Document312 pagesKata Loge 128Anonymous O5F8rZYuboNo ratings yet

- Imeko TC5 2010 009Document4 pagesImeko TC5 2010 009FSNo ratings yet

- Maryland Institute of Technology and Management, Jamshedpur Theory of Machine-Module: IIIDocument12 pagesMaryland Institute of Technology and Management, Jamshedpur Theory of Machine-Module: IIISourabh PradhanNo ratings yet

- Pds Microstran LTR en LRDocument2 pagesPds Microstran LTR en LRthaoNo ratings yet

- 20v4000enDocument266 pages20v4000enMario MartinezNo ratings yet