Professional Documents

Culture Documents

FinalPaperTheoretical Analysis of Horizontal Axis Wind Turbine For Low Wind Velocity170328

Uploaded by

AwadeshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FinalPaperTheoretical Analysis of Horizontal Axis Wind Turbine For Low Wind Velocity170328

Uploaded by

AwadeshCopyright:

Available Formats

International Journal of Innovative and Emerging Research in Engineering

Volume 2, Special Issue 1 MEPCON 2015

Available online at www.ijiere.com

International Journal of Innovative and Emerging

Research in Engineering

e-ISSN: 2394 - 3343

p-ISSN: 2394 - 5494

Theoretical Analysis of Horizontal Axis Wind Turbine

for Low Wind Velocity

Shailesh P. Patankar1a, Samir J. Deshmukh2b, Rucha R. Kolhekar3c

a

Student of Thermal Engineering 1,Department of Mechanical Engineering, Prof. Ram Meghe Institute Of

Technology and Research, Badnera, Amravati, Maharashtra, India.

b

Associate Professor 2, Department of Mechanical Engineering , Prof. Ram Meghe Institute Of Technology and

Research, Badnera, Amravati, Maharashtra, India.

c

Assistant Professor 3, Department of Mechanical Engineering , Prof. Ram Meghe Institute Of Technology and

Research, Badnera, Amravati, Maharashtra, India.

ABSTRACT:

Wind energy is most of the promising renewable energy source. In general, Moderate to high-speed winds,

typically from 5m/s to about 25m/s are considered favorable for most wind turbines in India. But in rural

areas, wind speed is near about 3m/s to 6m/s. So, this wind turbine is applicable for low wind velocity. In wind

turbine technology, the turbine blades play an important role as it directly comes in contact with the wind.

The objective of this paper is to design the wind turbine blade and to study the various design parameters

affecting design of wind turbine. This design is used to develope small wind turbine used for low power

generation of 100kW at low wind speed of 3m/s to 6m/s. The design of wind turbine blade is done in CAD

Software as CREO 2.0. By Velocity triangle of single blade of wind turbine, velocity can be determined and

this can be implemented in design procedure to design wind turbine blade. By using the fixed blade

mechanism, on an average, 45% velocity rise can be obtained at the entry to the wind turbine blade.

Keywords: wind speed, fixed blade, angle of incidence, wind turbine blade.

I. INTRODUCTION

Wind energy is most of the promising renewable energy source. The wind energy is firstly used to produce

mechanical energy and the system used to change the kinetic energy of the wind into mechanical energy is called

windmill. The term wind turbine is the updated version of the term windmill. Wind turbine refers to the system which

converts the wind energy into electrical energy. Wind has considerable amount of kinetic energy when blowing at high

speeds. This kinetic energy when passing through the blades of the wind turbines is converted into mechanical energy

and rotates the wind blades and the connected generator, thereby producing electricity [6]. In general, Moderate to

high-speed winds, typically from 5m/s to about 25m/s are considered favourable for most wind turbines in India. But

in rural areas, wind speed is near about 3m/s to 6m/s. So, this wind turbine is applicable for low wind velocity.

With highly efficient, solid and reliable wind turbine, wind power offers a solution to meet energy needs and

environmental care. The blade is key element of micro wind turbines which converts the kinetic energy of the wind

and in electricity through generators [5]. Wind power represents one of the most promising sources of renewable

energy: currently wind is more economically feasible than solar or biomass for electricity generation [2]. Wind turbine

system that consists of a diffuser shroud with a broad-ring brim at the exit periphery and a wind turbine inside it. for

a given turbine diameter and wind speed. This is because a low-pressure region, due to a strong vortex formation

behind the broad brim, draws more mass flow to the wind turbine inside the diffuser shroud. Significant increase in

the output power of a micro-scale wind turbine was obtained [4]. Aerodynamic shape optimization is one of the main

research fields which is directly related to power production of a wind turbine [1]. In micro wind turbine, diffuser is

used to create pressure drop after rotation of blades so high velocity output can be obtained [7].

In wind turbine, fixed airfoil shaped blades are mounted on fixed shaft as stator and moving blades are mounted

on moving shaft. So, air impinged on fixed blades so moving blades are rotating. So, pressure reduction occurs in the

93

International Journal of Innovative and Emerging Research in Engineering

Volume 2, Special Issue 1 MEPCON 2015

diffuser and due to pressure drop air is sucked just like a exhaust nozzle of gas turbine and velocity of wind turbine is

increasing by increasing power output of system.

II. AIRFOIL THEORY

An Airfoil is a streamlined body bounded principally by two flattened curves and whose length and width are very

large in comparison with the thickness. It has a thick, rounded leading edge and thin trailing edge. Its maximum

thickness occurs somewhere near the midpoint of the chord. The backbone line lying midway between the upper and

lower surfaces is camber line.[2]

An airfoil means two dimensional cross section shape of wing whose purpose is to either generate lift or minimizing

drag when exposed to wind.[4]

When such blade is suitably shaped and properly oriented in the flow, force acting on it normal to direction of flow

is considerably larger than force resisting its motion.

Figure 1. Basic Wind Turbine Blade Structure

Lift on body is force on body in a direction normal to flow direction. Drag on body is force on body in

direction parallel to flow direction. For operating efficient jet wind turbine, lift force should be high and drag force

should be low. [3]

Figure 2. Forces on Fixed Blade Airfoil

Aerodynamic lift is the force responsible for the power yield generated by the turbine and it is therefore

essential to maximize this force using appropriate design. A resistant drag force which opposes the motion of the blade

is also generated by friction which must be minimized.[6]

Lift To Drag Ratio = Coefficient of Lift/Coefficient of Drag=

Where,

III. METHODOLOGY OF DESIGN OF WIND TURBINE BLADE

Two primary parts of wind turbine are as

i)

ii)

Stator Nozzle

Rotor Blades

A. Analytical Method

94

International Journal of Innovative and Emerging Research in Engineering

Volume 2, Special Issue 1 MEPCON 2015

Most of turbines possess more than one stage which consists of ring of fixed nozzle blades followed by rotor blade

ring mounted on common shaft. Energy transformation occurs in both fixed as well as moving blades. Rotor

experiences both energy transfer as well as energy transformation. Figure shows a single stage turbine along with

pressure and velocity changes when wind passes through a turbine stage.

Figure 3. Turbine stage along with pressure and velocity change

The flow geometry at entry and exit of a turbo machine stage is described by the velocity triangles which

consist of following three components as

i)

ii)

iii)

the peripheral velocity (u) of rotor blades,

the absolute velocity (c) of fluid, and

the relative velocity (w) of fluid

The notation used here to draw velocity triangles corresponding to the x-y coordinate; the suffix (a) identifies

components in axial direction and the suffix (t) refers to tangential direction. Air angles in the absolute system are

denoted by alpha (), where as those in the relative system are represented by beta (). The velocity triangles at entry

and exit of wind turbine are shown in fig. 4. Since stage is axial, change in mean diameter between its entry and exit

can be neglected so, peripheral or tangential velocity (u) remains constant.

Figure. 4. Velocity triangles for a wind turbine

95

International Journal of Innovative and Emerging Research in Engineering

Volume 2, Special Issue 1 MEPCON 2015

It is often assumed that the axial velocity component remains constant through the stage. For such a conditions

So, By Inlet velocity and inlet blade angle 1 other parameters can be calculated.

B. Graphical Method

By calculating various parameters like inlet and outlet angles of fixed and rotor blades design the fixed as well

as rotor blades in CAD Software as CREO 1.0 as

Figure 5. Sectional view of fixed and rotor blade

Then by inlet casing, outer casing and diffuser design complete assembly of wind turbine can be completed.

96

International Journal of Innovative and Emerging Research in Engineering

Volume 2, Special Issue 1 MEPCON 2015

Figure 6. Sectional assembly view of complete showing fixed and rotor blade, inlet casing, outer casing and

diffuser

So, complete assembly of wind turbine can be

Figure 7. Complete assembly of jet wind turbine

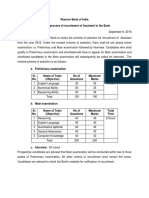

TABLE 1 theoretically calculated wind speed

SR

NO.

Inlet velocity in m/s

Outlet velocity in

m/s

Percentage

increase in

velocity in %

01

3 m/s

5.27 m/s

43.07%

02

4 m/s

6.056 m/s

43.31%

03

6 m/s

8.63 m/s

45.37%

04

8 m/s

10.43 m/s

47.63%

05

10 m/s

12.86 m/s

49.25%

06

12 m/s

14.61 m/s

51.36%

From table we observed that theoretically wind speed by using jet wind turbine can be increased 2-5% than

conventional wind turbine.

97

International Journal of Innovative and Emerging Research in Engineering

Volume 2, Special Issue 1 MEPCON 2015

IV. MATERIAL SELECTION

The present work demonstrates that PVC blades profile gives better power capacity with respect to increase in

rotational speed of rotor.[5]. So, PVC type material can be used to manufacture the prototype of jet wind turbine.

V. CONCLUSIONS

From design of wind turbine, due to arranging of fixed blade before moving blades velocity of wind at outlet may be

increased. Due to pressure reduction occurs in the diffuser and due to pressure drop air is sucked just like an exhaust

nozzle of gas turbine and velocity of wind turbine is increasing by increasing power output of system. By using this

type of wind turbine 2-5% velocity can be increased other than conventional wind turbine. By numerically, maximum

wind velocity can be 10.43m/s which is 47.63% increase in velocity output.

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

REFERENCES

Sandip. A. Kale and Ravindra N. Varma, Aerodynamic Design of a Horizontal Axis Micro Wind Turbine Blade

Using NACA 4412 Profile, International Journal Of Renewable Energy Research Vol. 4, No. 1(2014) pp. 1-4.

Monir Chandrala, Abhishek Choubey and Bharat Gupta, Aerodynamic Analysis Of Horizontal Axis Wind

Turbine Blade, International Journal of Engineering Research and Applications (IJERA) ISSN: 2248-9622 Vol.

2, Issue 6, November- December 2012, pp.1244-1248.

Chris Kaminsky, Austin Filush, Paul Kasprzak and Wael Mokhtar, A CFD Study of Wind Turbine

Aerodynamics, Proceedings of the 2012 ASEE North Central Section Conference, 2012, pp.1-18.

Yuji Ohya and Takashi Karasudani, A Shrouded Wind Turbine Generating High Output Power with Wind-lens

Technology, Energies journal ISSN 1996-1073 Vol. 3,( 2010) pp.634-649.

H.S.Patil, Experimental Work on Horizontal Axis PVC Turbine Blade of Power Wind Mill, International

Journal of Mechanical Engineering Vol. 2, Issue 2 (2013) pp.1-11.

John McCosker, Design and Optimization of a Small Wind Turbine, Rensselaer Polytechnic Institute Hartford,

Connecticut vol. 3, (2012) pp.456-495.

Vernica Cabanillas Snchez, Blade Performance Analysis And Design Improvement Of A Small Wind Turbine

For Rural Areas, Proceedings of International Conference on renewable energy resources Vol. 3,(2013) pp.364395.

HoSeong Ji, JoonHo Baek, Rinus Mieremet and Kyung Chun Kim, Aerodynamic characteristics of an

Archimedes spiral wind turbine blade according to the angle of attack change, Europes Premier Wind Energy

Event EWEA 2014, Barcelona, Spain Vol. 2, 2014.

M.C. Robinson, M.M. Hand, D.A. Simms and S.J. Schreck, Horizontal Axis Wind Turbine Aerodynamics:

Three-Dimensional, Unsteady, and Separated Flow Influences, Proceedings of FEDSM99 3rd ASME/JSME

Joint Fluids Engineering Conference San Francisco, Vol.1 July 18-23, 1999 pp.1-13

98

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- QP PatternDocument2 pagesQP PatternSarika AggarwalNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Latest Updates RBI Revised Process of Recruitment of Assistant in The Bank PDFDocument1 pageLatest Updates RBI Revised Process of Recruitment of Assistant in The Bank PDFAwadeshNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- AEn PDFDocument15 pagesAEn PDFrupali goyalNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Detailed Advt For Recruitment of CWE RRBs V Proforma-B 160317Document50 pagesDetailed Advt For Recruitment of CWE RRBs V Proforma-B 160317prembiharisaranNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Transient Vibrations ReportDocument12 pagesTransient Vibrations ReportMohammed ImranNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- SSC Online Applicationdsd SD DDVDocument1 pageSSC Online Applicationdsd SD DDVAwadeshNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Study The Following Information Carefully and Answer The Questions Given BelowDocument1 pageStudy The Following Information Carefully and Answer The Questions Given BelowAwadeshNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- AEn PDFDocument15 pagesAEn PDFrupali goyalNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Detailed Advt For Recruitment of CWE RRBs V Proforma-B 160317Document50 pagesDetailed Advt For Recruitment of CWE RRBs V Proforma-B 160317prembiharisaranNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Aerodynamic Method of The Archimedes Windturbine Abeko Site PDFDocument9 pagesThe Aerodynamic Method of The Archimedes Windturbine Abeko Site PDFhola123456789jgNo ratings yet

- QP PatternDocument2 pagesQP PatternSarika AggarwalNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Format of Application: For Official Use Only SL - No. of Application Year Course Whether ApprovedDocument8 pagesFormat of Application: For Official Use Only SL - No. of Application Year Course Whether Approvedabhishek123hitNo ratings yet

- Navier-Stokes Equations - Wikipedia, The Free EncyclopediaDocument13 pagesNavier-Stokes Equations - Wikipedia, The Free EncyclopediaAwadeshNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Science Based Open ElectivesDocument16 pagesScience Based Open ElectivesAj AmanNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 1990 Classification of Expansive Soils by Sediment Volume MethodDocument6 pages1990 Classification of Expansive Soils by Sediment Volume MethodS R Kumar KonathalaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- DRRR Reviewer: A Comprehensive Plan ShouldDocument3 pagesDRRR Reviewer: A Comprehensive Plan ShouldJames BastesNo ratings yet

- Fundamentals of Heat Exchanger DesignDocument972 pagesFundamentals of Heat Exchanger DesignNgô Linh Đan80% (5)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Company Profile 公司及项目简介完成版-英文-打印版 PDFDocument53 pagesCompany Profile 公司及项目简介完成版-英文-打印版 PDFDigendra Singh RathoreNo ratings yet

- Hamon Press Release en 200112Document1 pageHamon Press Release en 200112chatuusumitavaNo ratings yet

- Geography Grade 7Document126 pagesGeography Grade 7hidilip1975No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 019 Icges2012 S10007Document5 pages019 Icges2012 S10007Aditya PratamaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- 1st Quarter Examination in ELS April DocsDocument2 pages1st Quarter Examination in ELS April DocsCindy PalenNo ratings yet

- Core BooksDocument3 pagesCore Booksemmanuelsimati49No ratings yet

- TE. Toefl Reading 2Document5 pagesTE. Toefl Reading 2beatriceNo ratings yet

- Evaporation: Types of EvaporatorsDocument9 pagesEvaporation: Types of EvaporatorsDr-Khalid Al-ShemmariNo ratings yet

- Born-Haber Cycles: AQA Chemistry A2 Stretch and Challenge © Nelson Thornes LTD 2009 1Document2 pagesBorn-Haber Cycles: AQA Chemistry A2 Stretch and Challenge © Nelson Thornes LTD 2009 1Paul MurrayNo ratings yet

- 2.3.5 Practice - Atomic Structure (Practice)Document11 pages2.3.5 Practice - Atomic Structure (Practice)damarionbryant46No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Updated Final THRM Module Engr. CM GualbertoDocument116 pagesUpdated Final THRM Module Engr. CM GualbertoVon Eric DamirezNo ratings yet

- 2017 11 Sample Paper Chemistry 01 QPDocument3 pages2017 11 Sample Paper Chemistry 01 QPpanav.u25No ratings yet

- Biodiversity and Conservation PDFDocument7 pagesBiodiversity and Conservation PDFDeepikaNo ratings yet

- Proposal "Air Pollution by PT. Wilmar Nabati Gresik East Java"Document4 pagesProposal "Air Pollution by PT. Wilmar Nabati Gresik East Java"Imtikhana KhofifahNo ratings yet

- Model Test-2 Class: IX (EV) Subject: Chemistry Creative SectionDocument2 pagesModel Test-2 Class: IX (EV) Subject: Chemistry Creative SectionLUBNA AKTERNo ratings yet

- Research Overview Context Guillen.Document3 pagesResearch Overview Context Guillen.andreagassiNo ratings yet

- Interference and DiffractionDocument30 pagesInterference and DiffractionSweeha PanwarNo ratings yet

- Brown To Green Report 2019Document65 pagesBrown To Green Report 2019humejraNo ratings yet

- Selection of Industrial DryerDocument7 pagesSelection of Industrial DryerGizem ErdoğanNo ratings yet

- Lab: Newton's Second Law InvestigationDocument5 pagesLab: Newton's Second Law InvestigationRoshan Jawad ZafirNo ratings yet

- Chapter 6Document14 pagesChapter 6naumanNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chapter 3 MineralsDocument7 pagesChapter 3 MineralsJamie Ann ManalastasNo ratings yet

- Permazyme 11XDocument6 pagesPermazyme 11XMaria Esperanza SantanderNo ratings yet

- Thixotropy of ClaysDocument2 pagesThixotropy of ClaysKrishan Pandya100% (1)

- P Xe 120 C Um 5 XSixe 2 Yz G6Document58 pagesP Xe 120 C Um 5 XSixe 2 Yz G6vaibhav dhamaleNo ratings yet

- 4.5 M SBCDocument3 pages4.5 M SBCvivekNo ratings yet

- Mathematical Model and Characterization of The Transient Behavior of A PEM Fuel CellDocument8 pagesMathematical Model and Characterization of The Transient Behavior of A PEM Fuel CellDEVA NAIKNo ratings yet