Professional Documents

Culture Documents

Enhancing Value of Slit Housing Using Value Engineering A Case Study

Uploaded by

singh1984_09Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Enhancing Value of Slit Housing Using Value Engineering A Case Study

Uploaded by

singh1984_09Copyright:

Available Formats

International Journal of Scientific & Engineering Research Volume 3, Issue 5, May-2012

ISSN 2229-5518

Enhancing Value of Slit Housing using Value

Engineering A Case Study

Amit Sharma, Dr. R.M. Belokar

Abstract This paper presents the concept of Value Engineering in a well articulated manner which can be easily perceived. The model of

Value Engineering and its different phases are explained in brief which can be implemented for the optimization of any product. Each part

of the Value Engineering job plan is discussed and executed to get the detailed information about the product. A case study h as been

discussed and an analysis has been carried out by this process to achieve the product optimization. Various tools are used for t he analysis

of the product while evaluating the product at the functional level. With the systematic approach and critical analysis , the final product turns

out to be a successful showcase of Value Engineering.

Index Terms Case Study, Creative Worksheet, Decision Matrix, Functional Analysis, Job Plan, Value Engineering (VE).

1 INTRODUCTION

alue Engineering (VE) which is a professionally applied,

function-oriented, systematic team approach used to analyze and improve value in a product, design, system or

service and process a methodology for solving problems and/or reducing costs while improving

performance/quality requirements. VE can be understood also as a

systematic method to improve the value and optimize the life

cycle cost of a function or a facility [1], [3]. This paper outlines

the basic frameworks of Value engineering and presents a case

study showing the merits of Value Engineering in a company

manufacturing medical instruments.

The Society of American Value Engineers International, or

SAVE, uses the broad term Value Methodology, defined as

the systematic application of recognized techniques which

identify the functions of the product or service, establish the

worth of those functions, and provide the necessary functions

to meet the required performance at the lowest overall cost.

The paper is organized in several stages. The first stage defines the concept of value engineering. Several definition are

given making the concept more cohesive and explaining the

need of VE in the present scenario where cost optimization has

become a critical need for every industry to survive in this

competitive environment. Second stage defines the VE job

plan which should be followed for analyzing any product. In

the third stage a case study has been presented which helps us

reach to a concrete solution of the problem discussed here and

in the last stage the conclusion and future scope of Value engineering have been provided.

Amit Sharma is a Research Scholar and is currently pursuing his PhD

program in Production Engineering from PEC University of Technoiogy,

Chandigarh, India, PH-+919041293477. E-mail:amiter84@gmail.com

Dr. R.M.Belokar is currently working as an Associate Professor in PEC

University of Technoiogy, Chandigarh, India, PH-01722753287. E-mail:

rmbelokar@pec.ac.in

2 DEFINITION

Value Engineering is the systematic application of recognized techniques by multi-disciplined team(s) that identifies

the function of a product or service; establishes a worth for

that function; generates alternatives through the use of creative thinking; and provides the needed functions, reliably, at

the lowest overall cost. Value Engineering may be defined in

other ways, as long as the definition contains the following

three basic precepts:

a. An organized review to improve value by using multidisciplined teams of specialists knowing various aspects of the problem being studied.

b. A function oriented approach to identify the essential

functions of the system, product, or service being studied, and the cost associated with those functions.

c. Creative thinking using recognized techniques to explore alternative ways of performing the functions at a

lower cost, or to otherwise improve the design.

It involves an objective appraisal of functions performed

by parts, components, products, equipment, procedures, and

services; and so on anything that costs money [2].

3 VALUE ENGNIEERING AS A PROCESS

VE process consists of three main phases that are: pre-study,

value study and post-study. The VE job plan is a systematic

plan to make sure that the VE analyzing team understands

customer requirements and develops a cost-effective solution.

Park [4] has said: No matter how many steps there are, the

process is always the same, analysis, creativity, evaluation and

development. A key point in organizing the VE effort is the

use of the job plan or value study. The information phase is a

fact-finding phase. The purpose is to accumulate all the factual

information available in regard to the proposed area of study.

The function analysis phase is the heart of the Value Methodology. Mudge [5] has formulated that function analysis is

based on two major parts: define a function and evaluate the

function relationships. The VE team evaluates the ideas generated in the creativity phase using one of a number of tech-

IJSER 2012

http://www.ijser.org

International Journal of Scientific & Engineering Research Volume 3, Issue 5, May-2012

ISSN 2229-5518

niques, many of which depend upon some form of weighted

vote. This stage forms a crude filter for reducing the ideas

generated to a manageable number for further study [6]. The

purpose of the post-study is to assure the implementation of

the approved value study change recommendations. Implementation tasks are made by the VE team, the organizations

own personnel or together [7].

ferent manufacturers in the same category.

Value of this product can be increased by maintaining its functions and reducing its cost by changing its design, changing the

material and process.

b) OBTAIN PRODUCT INFORMATION

Product specifications

4 FIVE PHASES OF VE PROCESS

Production

process

a. Information Phase - During this phase, the VE team

gathers as much information as possible about the program

requirements, project design, background, constraints, and

estimated/projected costs. The team performs functional

analysis of systems and subsystems to identify high cost areas.

The project designer provides additional design data and participates in the initial VE team conference.

b. Speculative/Creative Phase - The team uses a group interaction process to identify alternative ideas for accomplishing the function of a system or subsystem.

c. Evaluation/Analytical Phase - The ideas generated during the speculative/creative phase are screened and evaluated

by the team. The ideas showing the greatest potential for cost

savings and project improvement are selected for further

study.

d. Development/Recommendation Phase - The team researches the selected ideas and prepares descriptions,

sketches, and life cycle cost estimates to support the VE proposal (VEP) recommendations.

e. Report Phase - The team presents the VEPs to the company during an oral presentation at the conclusion of the

workshop. Shortly after the completion of the VE workshop, a

preliminary VE report encompassing the entire VE effort is

prepared by the VE team leader and submitted to the company. [8], [9]

Material

used

Aluminum Alloy

C.N.C. drilling and

Milling.

Weight

540 gm

C.N.C

turning

1.5 min

C.N.C.

milling

9.5 min.

Cycle

time

20.5

min.(machining)

Finishing

operations

15 min.(drilling,

taping, filing)

Black

anodizing

6 min.

Total cost

Rs 450

5 CASE STUDY

In this paper we have discussed a part of the company Labotron

India Pvt. Ltd. located in Ambala which produces medical instruments. The part considered is Slit Housing on which the value engineering job plan is applied. This company is one of the top

quality manufacturers of the medical instruments and is a wellknown name in the medical industry. Many of the products developed here are conforming to the international standards. It is

an ISO certified company for the manufacturing of medical

products.

The process of Implementation of Value Engineering is discussed

as follows:-

c) FUNCTIONAL ANALYSIS OF PRESENT F UNCTIONS

TABLE 1: FUNCTIONAL ANALYSIS

Component

Basic

Function

Verb

Slit Housing

Provide

Provide

Basic

Function

Noun

Housing

Support

Secondary Function

Verb

Support

Fix

a) PLAN FOR PRODUCT SELECTION

Product selected is Slit Housing which is used as a component in

assembly of microscope in the field of eye inspection at moisture

free environment. The present specifications of this part and its

material used are costlier than the average industry cost. This

product is chosen because of the increased competition from dif-

d) DEVELOP ALTERNATE DESIGN OR METHODS

During brainstorming these ideas were listed:-

IJSER 2012

http://www.ijser.org

Secondary

Function

Noun

Cam Shaft

Slit knobs

International Journal of Scientific & Engineering Research Volume 3, Issue 5, May-2012

ISSN 2229-5518

Creative Worksheet

Ideas:

i.

ii.

iii.

iv.

v.

vi.

vii.

TABLE 4: COST EVALUATION

Change material

Change design

Use ABS plastic

Make it lighter

Change the dimensions

Change the process

Make product through casting

Item

Material

cost (Rs.)

Machining

cost (Rs)

Anodizing

cost (Rs.)

Slit Housing

Casted Slit

Housing

Part Eliminated

Difference/part

86.8

64.48

54

24

15

10

Total

cost

(Rs.)

155.8

98.48

22.32

30

57.32

f)

RESULT

e) EVALUATION PHASE

The total savings after the implementation of value engineering are given below:-

For judging the ideas, the following designs were considered:

A.

B.

C.

D.

E.

Ease of Operation

Durability

Maintainability

Safety

Reliability

The following criteria was used for evaualting the ideas

Weight age analysis

Major difference

Medium difference

Minor differences

Points

3

2

1

6 CONCLUSION

TABLE 2: PAIRED COMPARISON

Weig

ht

B2

B

C2

B2

C

D3

B3

C2

D

E3

E3

E2

E2

E

0

7

4

3

10

Total

Adj.

Weig

ht

1

8

5

4

11

29

Total Existing Cost Rs 155.8/Total Proposed Cost Rs 98.48/Saving per product Rs 57.32/Percentage saving per product 36.79%

Annual Demand of the product 10,000

Total Annual Saving Rs 5,73,200/Value Improvement - 58.20%

%

Wei

ght

03.44

27.58

17.24

13.79

37.93

Value analysis is a technique with immense possibilities, and

systematically employed, it can achieve great Economies and

increased efficiency. Although good results have been obtained in

several individual cases in some industries, only a large scale and

systematic application of this technique in all industries can result

in substantial economies on a national scale.

In the Case Study discussed above we see that how Value Engineering is used for the cost reduction and hence improving the value of the product. A thorough analysis has been done

for choosing the most viable option from the various feasible

choices available.

This is not the end of the value improvement of the

product. In Future we can make the changes in the design so that

the Value of the product can even be enhanced. Various other

Industrial Engineering tools like the QFD, TRIZ can be integrated

with Value Engineering which can further enhance the value of

the product.

Alternatives:

Serial No

1

2

3

Idea

Use ABS plastic

Make through

casting

Existing

Symbol

a

b

c

REFERENCES

[1]

[2]

[3]

Cooper, R. & Slagmulder, R.:Target Costing and Value Engineering.Productivity Press, Portland Oregon (1997)

Access to success: Value Engineering, Mani Mala, Advancements & Futuristic Trends In Mechanical & Industrial Engineering, November, 2010

DellIsola, A.: Value Engineering.Practical Applications..for Design,

Construction, Maintenance & Operations. R.S.Means Company Inc.

Kingston MA (1997)

IJSER 2012

http://www.ijser.org

International Journal of Scientific & Engineering Research Volume 3, Issue 5, May-2012

ISSN 2229-5518

[4]

Park, R.: Chrysler Corporation, Cost, Function, Value Analysis, Value

Control Manual.St. Lucie Press, New York (1978)

[5] Mudge, A. E.: Value Engineering.McGraw-Hill, New York (1971)

[6] Kelly, J. and Male, S.: Value Management in Design and Construction. E

& FN Spon, U.S (1993)

[7] F. Bomarius and H. Iida (Eds.): PROFES 2004, LNCS 3009, pp. 471484,

2004. Springer-Verlag Berlin Heidelberg 2004

[8] F. Jariri & S.H. Zegordi Quality Function Deployment, Value Engineering

and Target Costing, an Integrated Framework in Design Cost Management: A Mathematical Programming Approach, Scientia Iranica, Vol. 15,

No. 3, pp 405-411 Sharif University of Technology, June 2008

[9] Policies and Procedures,United States Department of Agriculture Research, Education, and Economics, July 9, 1998

[10] Gage, W. L., (1967), Value Analysis, McGraw Hill, London

[11] Norton, B. R. and McElligott, W. C., (1995), Value management in construction: a practical guide, MacMillan

[12] Gibson, J. F., (1968), Value Analysis: The Rewarding Infection, Pergamon Press Limited, Oxford

Table 3: Ranking for Alternatives Proposed

ATTRIBUTE

% WEIGHT

03.44

27.58

ALTERNATIVES

A

2*03.44

1*27.58

B

3*03.44

3*27.58

C

1*03.44

2*27.58

Note: From the above table it is seen that the

has the maximum value score.

17.24

13.79

37.93

1*17.24

1*13.79

2*17.24

2*13.79

1*17.24

2*13.79

alternative a

NOTE: I AM UNABLE OT PUT THIS TABLE IN THE ABOVE

FORMAT. KINDLY DO THE REQUIRED FORMATTING FOR

ME. I WOULD BE VERY THANKFUL OF YOU. THIS TABLE

HAS TO BE LOCATED JUST BEFORE TABLE 4.

IJSER 2012

http://www.ijser.org

1*37.93

3*37.93

2*37.93

PERFORMANCE

SCORE

COST

VALUE

SCORE

97.22

259.62

176.18

30.6

98.48

155.8

3.17

2.63

1.13

You might also like

- Implementation of Value Engineering - A Case Study: Amit Sharma, Dr. R.M.BelokarDocument7 pagesImplementation of Value Engineering - A Case Study: Amit Sharma, Dr. R.M.BelokarThameem Ul AnsariNo ratings yet

- WCECS2012 pp1330-1333Document4 pagesWCECS2012 pp1330-1333Dhanabal Palanisamy PNo ratings yet

- Ve ManualDocument74 pagesVe Manualirinuca12No ratings yet

- 15890Document9 pages15890singh1984_09No ratings yet

- Optimization of Blank Holding Force in Deep DrawingDocument21 pagesOptimization of Blank Holding Force in Deep Drawingsingh1984_09No ratings yet

- Senior Engineer ResumeDocument7 pagesSenior Engineer Resumesingh1984_09No ratings yet

- Indian Defence ReviewDocument3 pagesIndian Defence Reviewsingh1984_09No ratings yet

- (Megafileupload) VivekDocument211 pages(Megafileupload) Viveksingh1984_09No ratings yet

- AFSPADocument5 pagesAFSPAsingh1984_09No ratings yet

- Pitch Circles of Mating Gears Are Tangent To One AnotherDocument5 pagesPitch Circles of Mating Gears Are Tangent To One AnotherAnkush KhuranaNo ratings yet

- Stack-Up AnalysisDocument14 pagesStack-Up Analysissingh1984_09No ratings yet

- India - 222S New Cold Start War ...Document12 pagesIndia - 222S New Cold Start War ...singh1984_09No ratings yet

- Excel TutorialDocument6 pagesExcel TutorialVarabookNo ratings yet

- OeeDocument6 pagesOeesingh1984_09No ratings yet

- Pro E Model CheckDocument270 pagesPro E Model CheckJawahar RajNo ratings yet

- December Diary - With The Battle AxesDocument12 pagesDecember Diary - With The Battle Axessingh1984_09No ratings yet

- The Vishnu Purana Book 4 of 6 - 9781605066608Document215 pagesThe Vishnu Purana Book 4 of 6 - 9781605066608singh1984_09No ratings yet

- Third Vs First AngleDocument2 pagesThird Vs First AngleKiran KashyapNo ratings yet

- HCL Insights June2010Document2 pagesHCL Insights June2010singh1984_09No ratings yet

- ProENGINEER Tutorial Creating a Revolved Bottle StopperDocument5 pagesProENGINEER Tutorial Creating a Revolved Bottle Stoppersingh1984_09No ratings yet

- 4 Yugas, 14 Manus, Brahma's Lifespan Grafix - Interfaith ForumsDocument12 pages4 Yugas, 14 Manus, Brahma's Lifespan Grafix - Interfaith Forumssingh1984_09No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Ies CollegeDocument5 pagesIes Collegeravi maheshwari100% (1)

- TQ UcspDocument11 pagesTQ UcspDeron C. De CastroNo ratings yet

- CBCS Syllabus Ecology FinalDocument49 pagesCBCS Syllabus Ecology FinalRahul DekaNo ratings yet

- Build A Culture For Learning Based On Collaboration, Teamwork, and Shared VisionDocument3 pagesBuild A Culture For Learning Based On Collaboration, Teamwork, and Shared VisionMaria Eleonor C. Bañares92% (12)

- The PHD in Construction ManagementDocument11 pagesThe PHD in Construction ManagementPalanisamy RajaNo ratings yet

- Impact of Students Industrial Work Experience Scheme (Siwes) On Devellity SkillsDocument11 pagesImpact of Students Industrial Work Experience Scheme (Siwes) On Devellity SkillsEizijesu Virtue Obahaiye100% (1)

- Thesis PaperDocument68 pagesThesis PaperKerbi De LeonNo ratings yet

- PSR Theory Essay FinalDocument9 pagesPSR Theory Essay Finalapi-238869728No ratings yet

- IT107 HandOut 009Document4 pagesIT107 HandOut 009jin_adrianNo ratings yet

- Ostwald CV Jan2023Document7 pagesOstwald CV Jan2023api-612465446No ratings yet

- Article Iii Bill of Rights: Section 4Document4 pagesArticle Iii Bill of Rights: Section 4Khrislyne Jamae BanataoNo ratings yet

- Task 3 Assessment CommentaryDocument9 pagesTask 3 Assessment Commentaryapi-317861393No ratings yet

- Spiderwoman Theatre challenges colonial stereotypesDocument12 pagesSpiderwoman Theatre challenges colonial stereotypesdenisebandeiraNo ratings yet

- Development Guidelines For Technology Business IncubatorsDocument134 pagesDevelopment Guidelines For Technology Business IncubatorsSteveEpsteinNo ratings yet

- Vikash KUMARDocument2 pagesVikash KUMARsantoshkurkal7438No ratings yet

- LearnEnglish EfE Unit 7 Support PackDocument4 pagesLearnEnglish EfE Unit 7 Support PackAnaAleksicNo ratings yet

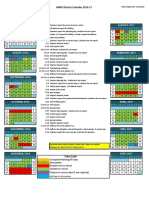

- 2016-17 District CalendarDocument1 page2016-17 District Calendarapi-311229971No ratings yet

- Macugay, Julia Stephanie - Purposive Communication PortfolioDocument20 pagesMacugay, Julia Stephanie - Purposive Communication PortfolioJulia MacugayNo ratings yet

- Module 1: Metacognition: Presented By: Rocelyn Mae B. Herrera UE02 - Facilitating Learning Prof. Russel V. SantosDocument14 pagesModule 1: Metacognition: Presented By: Rocelyn Mae B. Herrera UE02 - Facilitating Learning Prof. Russel V. SantosUe ucuNo ratings yet

- ENG-G4-LP-Uldok The War Hero PDFDocument24 pagesENG-G4-LP-Uldok The War Hero PDFRonnie Francisco Tejano100% (4)

- Online Portfolio - Warren 2014 - MHSDocument11 pagesOnline Portfolio - Warren 2014 - MHSdavemightbeNo ratings yet

- Application Summary Group InformationDocument12 pagesApplication Summary Group InformationKiana MirNo ratings yet

- Employment / Job ApplicationDocument4 pagesEmployment / Job Applicationapi-532187335No ratings yet

- Devildog PaperDocument2 pagesDevildog PaperEthanBrandtNo ratings yet

- MemoDocument4 pagesMemoCindy RellaNo ratings yet

- Navy Engineer ProgramDocument10 pagesNavy Engineer ProgramflawlessjessNo ratings yet

- American Psychological Association Rapid GuidelinesDocument20 pagesAmerican Psychological Association Rapid GuidelinesPACEROMENo ratings yet

- Developing Your Yoga Teaching ScriptDocument31 pagesDeveloping Your Yoga Teaching ScriptLee Pin Wei100% (16)

- An Action Research I. Research ProblemDocument3 pagesAn Action Research I. Research Problemsalve renomeronNo ratings yet

- Assignment 2 (Group)Document5 pagesAssignment 2 (Group)Selva Bavani SelwaduraiNo ratings yet