Professional Documents

Culture Documents

Viii/Ii/Ii": United States Patent (191 (11) Patent Number: 4,708,208

Uploaded by

mohammadreza91Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Viii/Ii/Ii": United States Patent (191 (11) Patent Number: 4,708,208

Uploaded by

mohammadreza91Copyright:

Available Formats

United States Patent [191

[11] Patent Number:

Halbardier

[45]

[54]

4,566,535

METHOD AND APPARATUS FOR SE'I'IING,

PACKER

Date of Patent:

4,708,208

Nov. 24, 1987

1/ 1986 Sanford ...... .I ..................... .. 166/ 152

[75] Inventor: Floyd A. Halbardier, Pasadena, Tex.

[73] Assignee: Baker Oil Tools, Inc., Orange, Calif.

Primary Examiner-Stephen J. Novosad

Assistant Examiner-Terry L. Melius

Attorney, Agent, or Firm-Norve11_& Associates

[57]

ABSTRACT

[21] Appl. No.: 877,421

Methods and apparatus are provided for retrieving an

[22] Filed:

Jun. 23, 1986

ln?atable packer of a type WhlCh may be passed through

[51] Int. (31.4 .................... .. EZIB 33/127; E21B 33/13

Us. Cl. .................................. .

a small dlameter tubing, seal against a relatively large

diameter casing by passing ?uid to the packer through

a remedial tubing and then be retrieved to the surface

166/132; 277/34-3

through the small diameter tubing. If the downhole

[58] Field of Search ............. .. 166/ 123, 181, 182, 187,

166/373374 387; 277/3 34 34's 34'6

equipment assembly becomes hung up during retrieval

?uid may be passed through the remedial tubing to

[56]

release an upper portion of the packer actuator assem

bly from a lower portion of the packer actuator assem

References Cited

U.S. PATENT DOCUMENTS

3,044,553 7/1962

3,762,470 10/1973 Eggleston .

3,912,014 10/1975 Wetzel ........ ..

4,003,581 1/1977 Hutchison .

Bradley

4,082,298 4/1978

4,163,562 8/1979

Sanford

. .. . .

bly. The released upper portion and remedial tubing

. . . ..

277/34

166/182

166/240

166/ 187

may then be retrieved to the surface, and a conventional

?shing tool utilized to subsequently retrieve the lower

portion and the packer.

.. 277/343

18 Claims, 6 Drawing Figures

Sanford ............................ .. 277/34.3

120 \

1.

VI/ "

1VI /A

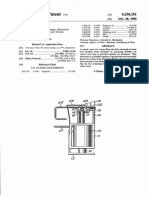

U. S. Patent Nov. 24, 1987

Sheet 1 of 3

4,708,208

%

O

2\

v

a\

/ /\/ \/./ /-/ /

Ali.

#//Wa/r\/ \/ W%/ / 7/

/w\

Z/ mA

\\\\:\\

4

\

8\

/@

/

/

.M5%

MWWW6wWm6

"WM

40%

\%QMQmmm@wmw?mn%wwM

fwm

63mgmmmww3%wx

E

\,,w

FIG. ll

FIG. 1A

U. S. Patent Nov. 24, 1987

FIG. 2

Sheet 3 of3

FIG. 3

4,708,208

4,708,208

Set screws have been utilized to connect the coiled

METHOD AND APPARATUS FOR SETI'ING,

UNSETIING, AND RETRIEVING A PACKER

FROM A SUBTERRANEAN WELL

tubing to the packer actuation assembly, and such set

screws tend to loosen during downhole operations,

allowing the tubing to pull away from the packer actua

tion assembly. Also, coiled tubing has broken off down

hole above the packer actuation assembly/coiled tubing

connection. In either event, retrieval of the packer actu- '

BACKGROUND OF THE INVENTION

1. Field of the Invention

The present invention relates to methods and appara

ation assembly, the packer, and interconnected down

hole equipment is then a major problem, often requiring

sophisticated ?shing tool retrieval techniques.

tus for setting and unsetting an in?atable packer in .a

subterranean oil or gas well by using coiled tubing or

remedial tubing for pumping ?uids to the packer. More

particularly, the invention relates to improved methods

SUMMARY OF THE INVENTION

Improved methods and apparatus are provided for

casing through a relatively small diameter production

setting and unsetting an in?atable packer of the type

15 which is passed through a small diameter tubing, effec

tubing.

2. Description of the Prior Art

tively seals against a relatively large diameter casing,

and apparatus for retrieving a packer sized to set in a

Those skilled in the art relating to remedial opera

and is then retrieved to the surface through the small

tions associated with drilling, production, and comple

diameter tubing. The packer is set by passing ?uid

through the remedial tubing to the packer actuation

tion of subterranean oil and gas wells have long utilized

threaded or coupled remedial tubing inserted through

production tubing for pumping ?uids from the surface

assembly. When pressure increases, a poppet valve

opens, exposing a piston member to ?uid pressure.

When ?uid pressure reaches a predetermined level, the

to one or more in?atable packers. More recently, con

tinuous coiled remedial tubing has frequently replaced

piston securing pin shears, permitting ?uid to pass to the

packer and in?ate the pa'cker. When ?uid pressure

reaches a predetermined maximum preferred value and

the packer is set, a plug pin shears, dumping ?uid to the

threaded or coupled tubing to pass ?uid to a packer,

since coiled tubing may be more rapidly inserted into

the well, and may be easily passed through production

tubing and related downhole equipment because its

diameter is consistently the same size.

Typical remedial coiled tubing apparatus is described

in the 1973 Composite Catalog of Oil Field Equipment

and Services, at page 662 (Gulf Publishing 00., Houston,

Texas), and manufactured by Bowen Tools, Inc. of

Houston, Texas. Apparatus relating to this coiled tubing

technique is more particularly described in U.S. Pat.

35

Nos. 3,182,877 and 3,614,019.

The need frequently arises in remedial or stimulation

well and closing the poppet valve to retain the packer in

sealed engagement with the casing. After the remedial

or stimulation operation is complete, pressure above

and below the packer is applied by opening a port be

tween the interior of the apparatus and the annulus

above the packer. The packer is unset by pulling up

ward on the remedial tubing until a third pin shears,

allowing the collet to move axially relative to the hous

ing, dumping ?uid from the packer.

During retrieval, the tool may become hung up to the

operations to pass an in?atable packer through small

extent that the maximum recommended axial force on

diameter restrictions,-e.g. 3% inch production tubing, set

the remedial tubing cannot free the obstruction. Rather

the packer in relatively large diameter casing, e.g., 7

inch casing, unset the packer, and then retrieve the 40 than break the remedial tubing or the tubing/packer

actuator assembly connection, another ball may be

packer to the surface through the small diameter tubing.

dropped through the remedial tubing to seal with a seat

on the upper portion of the packer actuation assembly,

such small diameter tubing, effectively seal with a , and ?uid again pumped through the remedial tubing to

larger diameter casing, and then be retrievable to the 45 shear a fourth pin, enabling the upper sub assembly to

be released from the remainder of the packer actuation

surface through the small diameter tubing.

assembly. The upper subassembly and remedial tubing

A signi?cant problem in the art concerns retrieval of

may then be retrieved together to the surface, and a

the packer and the packer actuation apparatus, side

conventional ?shing tool lowered for grasping an ex

pocket mandrels and similar tooling interconnected to

Recent advances, such as those disclosed in U.S. Pat.

No. 4,349,204, enable in?atable packers to pass through

the packer. During retrieval, if the packer or tooling get

hung up on a restriction and conventional threaded

remedial tubing is utilized to supply ?uid to the packer,

the remedial tubing may be rotated to free the mis

match and enable the equipment to be removed through

the production tubing. This technique is not utilized

with coiled tubing, however, since the coiled tubing

50

posed ?shing neck portion of the lower subassembly at

the actuator assembly. The ?shing tool and wireline

may then be used to retrieve the remaining portion of

the packer actuator assembly, the packer, and intercon

nected equipment.

BRIEF DESCRIPTION OF THE DRAWINGS

FIGS. 1, 1A, 1B and 1C are vertical sectional views,

cannot be effectively rotated. One technique for allevi

ating this problem is to attach a partial cone-shaped end

to the lower end of the coiled tubing to permit the

collectively partially in cross-section, showing the

motion on the tubing, as disclosed in U.S. Pat. No.

sleeve moved axially with respect to the housing to

packer actuation assembly, a packer, and a plug accord

tubing to slide off the obstruction. Another technique 60 ing to the present invention.

alters the position of the end of the tubing with cams for

FIG. 2 is a vertical view, partially in crosssection, of

producing a rotary motion in response to longitudinal

a portion of the apparatus shown in FIG. 1 with the

3,912,014.

de?ate the packer.

Another problem associated with the prior art con 65 FIG. 3 is a vertical view, partially in crosssection,

cerns the interconnection of the coiled tubing with the

showing the upper subassembly of the packer actuator

downhole packer actuation assembly. In?atable packers

may be unset by pulling upwardly on the coiled tubing.

assembly in position to be disconnected from the re

mainder of the actuator assembly.

4,708,208

DETAILED DESCRIPTION OF PREFERRED

EMBODIMENTS

FIGS. 1, 1A, 1B and 1C depict a packer actuator

59 and the pin sub 70. Lower sub 74 is threaded at 78 to

piston sub 80, which in turn is threaded at 82 to upper

assembly according to the present invention connected

packer sub 84. Poppet valve 76 is housed between the

lower sub 74 and the sleeve 62, and is normally held in

the sealed position by a coil spring 88. Slidable piston 90

to an end of coiled remedial tubing 10. Either coiled

tubing 10 or conventional threaded remedial tubing

may be utilized to lower the packer to its desired posi

has an upper piston surface 92 and a lower piston sur

face 94, and is normally axially secured relative to pis'

ton sub 80 by shear pin 96.

tion in a well by passing through production tubing 8.

Packer 16 is thus positioned between upper packer

The packer is actuated to seal against the interior sur

sub 84 and lower packer sub 98 in a conventional man

ner. Sub 100 is threaded at 102 with lower packer sub

98, and includes a removable plug 104. The lower end

of sleeve 62 is threaded at 106 with plug sub 108, which

face of easing 6, is subsequently deactivated or unset,

and then may be retrieved to the surface through the

production tubing 8. Setting and unsetting of the packer

is controlled by passing ?uid under pressure from the

surface to the packer actuator assembly through the

coiled tubing 10.

The packer actuator assembly includes a removable

upper subassembly 12 and-a main body subassembly 14

described subsequently. The actuator assembly controls

contains conventional exterior pipe threads 110 for

engagement with additional conventional oil?eld equip

ment. Plug 112 is normally secured to plug sub 108 by a

plurality of shear pins 114, and contains seat 116 for

sealing engagement with ball 118.

It should thus be understood that the entire assembly

passage of ?uid to and from packer 16 to set and unset 20 shown in FIG. 1 may be lowered in a subterranean well

the packer against the interior wall of casing 6. The

lower plug assembly 18 is disposed beneath packer 16,

and is utilized during the setting and unsetting opera

through production tubing 8 by a coiled tubing 10. With

the packer 16 positioned at a selected position within

the casing 6, the packer setting operation may be com

menced.

tion.

Upper sub assembly 12 includes a top sub 20 intercon 25 To set the packer, ball 118 may be dropped from the

surface through coiled tubing 10 and central passage

nected to tubing 10 by a plurality of threaded set screws

way 120 of the packer setting assembly and engage the

22. Top sub 20 includes a ?shing neck portion 24 for

plug 112 and seal against seat 116. Pressurized ?uid may

receiving a conventional ?shing tool under circum

then be pumped from the surface through the coiled

; stances described subsequently. The top sub is threaded

tubing 10 to central passageway 120 and through in?a

at 26 for engagement with an upper pilot sub 28 carry

tion port 122 in sleeve 62. Pressurized ?uid in passage

ing a plurality of collet ?ngers 30. Outer sleeve 32 is

way 124 between sleeve 62 and lower sub 74 thus acts

threaded at 33 for engagement with the upper pilot sub

against poppet valve 76, causing poppet valve 76 to

28, and houses piston 34 having an upper surface 36 and

compress spring 88 until ?uid passes by the poppet

a lower surface 38. A lower pilot sub 40 is threaded at

42 for engagement with sleeve 32. When lowering the 35 valve and into passageway 126. A further increase in

?uid pressure acting on upper surface 92 of piston 90

assembly shown in FIG. 1, 1A, 1B and 1C in the well,

causes pin 96 to shear at a preselected pressure, e. g., 900

subassembly 12 is interconnected to main body subas

p.s.i.g. Piston 90 thus moves downward until surface 94

sembly 14 since collet ?ngers 30 are prevented from

engages stop surface 128 on upper packer sub 84 (see

~ moving radially outwardly because of piston 34 which

5; is secured in position by a shear screw 60. The ends of 40 FIG. 2). It may be seen that downward movement of

piston 90 allows ?uid to bypass piston seals 130, allow

" collet ?ngers 30 thus engage surface 44 of upper sub 46

ing ?uid to pass from passageway 126 to passageways

to prevent axial movement of subassembly 12 relative to

subassembly 14.

provided by a plurality of elongate upper grooves 132 in

upper sub 46 by shear pin 60.

recommended pressure of the packer is obtained, e.g.,

sleeve 62, and enabling ?uid to pass to the in?atable

Upper sub 46 is threaded at 48 to collar 50, which in

turn is threaded at 52 to elongate sleeve 54 of subassem 45 members in the packer 16 and in?ate the packer.

Once the packer has been in?ated to effectively seal

bly 14. Upper sub 46 includes a ?shing neck portion 56

against the inner wall of the casing 6, the pressure in

and a ball seat 58 whose function is described subse

central passageway 120 will increase until the maxium

quently. Slidable piston 34 is normally ?xed relative to

The lower end of sleeve 54 is threaded at 57 for en

gagement with intermediate sub 59, which in turn is

threaded at 61 for engagement with sleeve 62. Ball seat

170 covers radial ports 178 in intermediate sub 59. Re

tainer 174 is sandwiched between sub 59 and sleeve 62,

1700 p.s.i.g. At this point, pins 114 will shear, allowing

plug 112 and ball 118 to be discharged from plug sub

108, thereby rapidly lowering the pressure in the central

passageway 120. This pressure decrease, in combination

with spring 88, will cause poppet valve 76 to return to

and shear pins 172 interconnect the retainer and the ball 55 its sealed position, with edge seal 134 returning to sealed

engagement with lower sub 74, and seal 136 providing

seat. Seals 180 provide sealed engagement between ball

sealing engagement between poppet valve 76 and sleeve

seat 170 and sub 59. As explained hereafter, ball 176

62. Thus once plug 112 is blown out of the bottom of

seats on surface 180, and ?uid pressure above the ball

plug sub 108, ?uid at the desired pressure of, e.g., 1700

shears pins 172, thereby allowing ?uid to pass through

port 178 in sub 59 and out port 140. The majority of 60 p.s.i.g., is retained within the packer 16 to enable the

packer to effectively seal against the casing 6.

sleeve 54 is protected within housing 64 having an end

When it is desired to unset the packer after comple

portion 66 in sliding engagement with the outer surface

tion of the remedial or stimulation operation, intermedi

of sleeve 54.

ate ball 176 may be dropped from the surface through

Housing 64 is threaded at 68 for engagement with pin

sub 70, which in turn is threaded at 72 for engagement 65 the tubing string, and seat against surface 180. Thereaf

ter, ?uid pressure is applied through the tubing string

with lower sub 74. Upward movement of intermediate

against the ball until the selected ?uid pressure, e.g.

sub 59 relative to housing 64 is normally prevented by

1700 p.s.i.g., is suf?cient to shear pins 172. Once

shear pin 75, which interconnects the intermediate sub

4,708,208

sheared, the ball and seat are pushed downward

through the bore of the tool, and ?uid communication is

established between the interior 120 of the subassembly

14 and the annulus between the subassembly 14 and the

casing 6.

collet ?ngers 30 are free to move radially outwardly

relative to upper sub 46 (see FIG. 3), so that upper pilot

sub 28 may become disconnected from upper sub 46.

Once the piston has moved downward, the coiled tub

ing 10 with subassembly 12 may be pulled to the sur

The above-described operation equalizes the pressure

in the casing 6 above the packer 16 to approximately the

pressure below the packer 16, since ?uid in the casing

face, exposing ?shing neck portion 56 of upper sub 46

for engagement with a conventional ?shing tool. Using

a conventional ?shing tool and a wireline (not shown),

below the packer is free to travel up the central passage

the ?shing tool may grasp the special ?shing neck por

way of the tool and through ports 178 and 140 once pins 0 tion 56 of upper sub 46, and a substantial upward and/or

172 shear. If pressure is not substantially equalized

rotational force exerted on upper sub 56 through the

above and below the packer before the packer is depres

surized, the higher pressure in the casing 6 below the

wireline to free the hang up and enable the remaining

apparatus, including the packer, to pass through the

packer 16 may create a sufficient upward force on the

packer to buckle or break the coiled tubing 10. In such

a case, not only is the tubing 10 damaged, but the packer

16 thereafter may not be de?ated in its intended manner.

Once pressure equalization has occurred, an upward

force may be applied to coiled tubing 10, thereby exert

production tubing 8.

The present invention thus enables the subassembly

12 to be easily detached from the subassembly 14 con

nected to the packer, so that subassembly 12 may be

removed with the coiled tubing rather than subject

tubing 10 to a higher than recommended axial force. If,

ing an upward force on intermediate sub 59 relative to 20 for some reason, tubing 10 should ever become inadver

pin sub 70. Once a selected upward force, e. g., 3400

tently disconnected from subassembly 12, the remainder

pounds, has been applied to tubing 10, pins 75 will

of the tubing 10 may be removed from the wellbore, and

a conventional ?shing tool lowered by wireline (not

shear, enabling sleeve 54 to move upwardly relative to

housing 64 (see FIG. 2). As sleeve 62 moves upward

with sleeve 54 relative to lower sub 74, upper grooves

132 pass by poppet valve 76 and seals 138, allowing

shown) for engagement with ?shing neck portion 24.

Those skilled in the art will recognize that a plurality

of static seals, such as O-rings 158, are provided at the

?uid to discharge from the packer through port 140 in

housing 64. Simultaneously, a plurality of elongate

locations indicated in the ?gures, and maintain sealing

lower grooves 142 in sleeve 62 provide a ?ow discharge

path from packer 16 past seals 144. Fluid may thus be 30

- simultaneously discharged from the packer at locations

both above and below the packer, causing the packer to

de?ate. Upward jarring movement of sleeve 62 relative

to lower sub 74 is cushioned when shock absorbing

sleeve 146 is compressed between the end of intermedi

ate sub 59 and the stop surface 148 on housing 64.

engagement between the respective components illus

trated. The relatively large diameter passageway 120

enables tooling to be passed down through the assembly

shown in FIGS. 1, 1A, 1B and 1C subsequent to the

expulsion of plug 112, in order that additional opera

tions may be performed beneath the set packer.

As used herein, the term remedial tubing refers to

conduit used to pass ?uids to a packer to set the packer

in a subterranean well, and includes both coiled tubing

During the packer retrieval operation, it is possible

previously described and threaded or coupled tubing

for the packer or equipment connected therewith to

become hung up or caught, so that the removal

sections.

Although the invention has been described in terms

operation cannot proceed. This hang up condition

40 of the speci?ed embodiments which are set forth in

' - may be due to to a lower component in the assembly

detail, it should be understood that this is by illustration

only and that the invention is not necessarily limited

thereto, since alternative embodiments and operating

techniques will become apparent to those skilled in the

the recommended force for the coiled tubing, since the 45 art in view of the disclosure. Accordingly, modi?ca

below pilot sub, such as the packer, catching on a com

ponent in the well. In either event, it is undesirable to

exert an upward force on the coiled tubing 10 beyond

tubing may break at a location above the top sub 20,

tions are contemplated which can be made without

creating a major problem for the subsequent removal of

the packer actuator assembly and the packer. Accord

ing to the present invention, methods and apparatus are

provided for enabling subassembly 12 to be discon

departing from the spirit of the described invention.

What is claimed and desired .to be secured by Letters

Patent is:

1. A method for setting, unsetting, and retrieving an

in?atable packer utilizing a downhole packer actuator

assembly having an upper connector portion and a

lower actuator portion, a remedial tubing string and a

50

nected from subassembly 14 when such a hang up con

dition occurs.

If the assembly shown in FIG. 1 cannot be freed with

the maximum recommended axial force on tubing 10,

another ball 151 (see FIG. 3) may be dropped from the

surface through the coiled tubing 10 and seat on ball

seat 58 of upper sub 46. Thereafter, ?uid may be in

jected through the coiled tubing, causing ?uid to pass

through gap 152 between upper sub 46 and top sub 20.

Fluid passes by the collet ?ngers 30, and a pressure 60

increase in passageway 153 acts on top surface 36 of

piston 34 until a selected ?uid pressure, e.g., 1075 p.s.i.,

is obtained, causing pin 60 to shear and forcing piston 34

downwardly against stop surface 154 (see FIG. 3).

Since ?uid pressure beneath seat 58 is lower than the 65

pressure above ball 151, the downward movement of

piston 34 expels ?uid beneath the piston through pas

sageway 156. Once the piston 34 has moved downward,

wireline in a subterranean well including a large diame

ter bore and a relatively small diameter tubing string,

comprising:

structurally connecting the upper connector portion

of the packer actuator assembly and the lower

portion of the packer actuator assembly, the upper

connector portion of the packer actuator assembly

and the remedial tubing string, and the lower actu

ator portion of the packer actuator assembly and

the in?atable packer,

thereby suspending the packer actuator assembly and

the in?atable packer from the remedial tubing

string;

lowering the in?atable packer while suspended from

the remedial tubing string downhole through the

4,708,208

small diameter tubing string and to a selected loca

tion within the subterranean well;

nean well including a large diameter bore and a rela

passing pressurized ?uid through the remedial tubing

tively small diameter tubing string, comprising:

string, the lower actuator portion, and to the in?at

able packer to set the packer within the large diam 5

eter bore;

9. A method for setting, unsetting, and retrieving an

inflatable packer of the type positionable in a subterra

'

suspending a packer actuator assembly and the in?at

able packer from a ?exible coiled tubing string;

lowering the in?atable packer while suspended from

the coiled tubing string downhole through the

unsetting the in?atable packer;

passing pressurized ?uid through the remedial tubing

small diameter tubing string and to a selected loca

string and to the packer actuator assembly for re

tion within the subterranean well;

leasing the upper connector portion of the packer

actuator assembly from the lower actuator portion

of the packer actuator assembly;

retrieving the upper connector portion of the packer

actuator assembly from the subterranean well

passing pressurized ?uid through the coiled tubing

string and to the in?atable packer to set the packer

within the large diameter bore;

sealingly closing a passageway through the packer

actuator assembly at a position above the set

through the small diameter tubing string by raising

the remedial tubing string from the well while the

lower portion of the packer actuator assembly and

in?atable packer remain within the well;

structurally interconnecting the wireline and the

lower portion of the packer actuator assembly 20

while positioned within the well;

retrieving the lower portion of the packer actuator

assembly and the in?atable packer from the subter

ranean well through the small diameter tubing

25

string by raising the wireline.

'

2. The method as de?ned in claim 1, wherein the

packer;

increasing fluid pressure in the passageway to a level

suf?cient to open a port between the passageway

and the annulus at a position above the set packer,

thereby substantially equalizing pressure above and

below the set packer in the annulus between the

packer actuator assembly and the large diameter

bore so as to substantially eliminate an upward

force on the coiled tubing string during a subse

quent packer unsetting operation;

exerting an upward force on the coiled tubing string

packer is unset by exerting an upward force on the

suf?cient to enable axial movement of components

remedial tubing string.

within the packer actuator assembly to release

pressurized ?uid from the packer and unset the

3. The method as defined in claim 2, wherein the

upward force exerted on the tubing string to unset the 30

packer;

retrieving the packer actuator assembly and the

packer from the subterranean well through the

small diameter tubing string.

packer is greater than a preselected force suf?cient to

enable axial movement of components within the

packer actuator assembly to release pressurized ?uid

from the packer.

10. The method as de?ned in claim 9, wherein the

4. The method as de?ned in claim 1, further compris 35 step of substantially equalizing pressure further com

prises:

mg:

releasing pressurized ?uid from the lower packer

actuator portion while retaining pressurized ?uid

providing a valve seating means within the packer

actuator assembly;

within the packer suf?cient to maintain the packer

passing a valve means from the surface into sealed

engagement with the valve seating means to seal

set.

ingly close the passageway.

5. The method as de?ned in claim 1, wherein the step

of passing pressurized ?uid to the packer actuator as

sembly to release the upper connector portion of the

packer actuator assembly from the lower actuator por

tion of the packer actuator assembly comprises:

11. The method as de?ned in claim 9, further com

prising:

structurally connecting a ?rst portion of the packer

45.

actuator assembly and a second portion of a packer

actuator assembly, the ?rst portion of the packer

actuator assembly and the coiled tubing string, and

the second portion of the packer actuator assembly

and the in?atable packer; and

dropping a ball through the remedial tubing to seal

with a surface on the upper connector portion of

the packer actuator assembly.

6. The method as de?ned in claim 5, further compris

passing pressurized ?uid through the coiled tubing

mg:

string and to the packer actuator assembly for re

leasing the ?rst portion of the packer actuator as

sembly from the second portion of the packer actu

ator assembly.

12. The method as defmed'in claim 11, wherein the

restricting release of the upper connector portion of

the packer actuator assembly from the lower actua

tor portion of the packer actuator assembly until

pressurized ?uid within the remedial tubing string

55

reaches a preected value.

step of retrieving the packer actuator assembly and

7. The method as defined in claim 1, further compris

packer comprises:

mg:

retrieving the ?rst portion of the packer actuator

assembly from the subterranean well through the

small diameter tubing string by raising the coiled

tubing string from the well while the second por

tion of the packer actuator assembly and packer

remain within the well;

substantially equalizing pressure above and below the

set packer in the annulus between the packer actua

tor assembly and the large diameter bore.

8. The method as de?ned in claim 7, wherein the step

of substantially equalizing pressure comprises:

sealingly closing a passageway through the packer

structurally interconnecting a wireline and the sec

actuator assembly at a position above the set

packer; and

increasing ?uid pressure in the passageway to a level

suf?cient to open a port between the passageway

and the annulus at a position above the set packer.

65

ond portion of the packer actuator assembly while

positioned within the well;

retrieving the second portion of the packer actuator

assembly and the packer from the subterranean

4,708,208

10

well through the small diameter tubing string by

raising the wireline.

tion, and said piston comprises a sleeve surrounding said

collet latching heads in said latched position.

13. Apparatus for retrieving from a subterranean well

an in?atable packer of the type positionable within a

15. The apparatus of claim 14 wherein said down

wardly facing annular abutment surface is de?ned by a

?shing neck formed on the top end of said lower portion

large diameter well bore by passing through a smaller

diameter conduit while suspended from a remedial tub

of the apparatus.

16. Apparatus as de?ned in claim 13, wherein the

radially shiftable latching means comprises:

ing string and set by passing pressurized ?uid to the

packer through the remedial tubing string, comprising:

?rst connection means for structurally connecting an

upper tubular portion of the apparatus with the l0

remedial tubing string;

second connection means for structurally connecting

a lower tubular portion of the apparatus with the

a ?rst plurality of collet ?ngers secured to one of the

upper portion and the lower portion of the appara

tus; and a collet latching surface formed on the

other of the upper portion and the lower portion of

the apparatus.

packer;

17. The apparatus as de?ned in claim 13, wherein the

releasable interconnection means for interconnecting 15 sealing means is a ball member adapted for sealing en

the upper tubular portion of the apparatus with the

gagement with a sealing surface on the lower portion of

lower tubular portion the apparatus when in a

the apparatus.

latched position and for enabling axial movement

of the upper portion of the apparatus relative to the

lower portion of the apparatus when in the un 20

latched position; said releasable interconnection

means comprising radially shiftable means de?ning

latching means; a ?uid pressure chamber adjacent

said latching means; an axially shiftable piston

shearably secured in said ?uid pressure chamber 25

and abutting said latching means to secure same in

18. A method for retrieving an in?atable packer in

serted in a subterranean well by a remedial tubing string

and susceptible to becoming stuck in the wall during

retrieval of the remedial tubing string comprising the

steps of:

'

. securing the in?atable packer to a sleeve having a

?shing neck on the top thereof;

securing a collet to the bottom end of the remedial

tubing string with the collet heads engagable with

said ?shsing neck;

said latched position; radial port means axially

above and below said piston respectively commu

nicating with the bores of said upper and lower

tubular portions to normally prevent any pressure

forming an annular ?uid pressure chamber around

said collet heads;

shearably securing an annular piston to said sleeve

with one portion of said annular piston sealably

mounted in said annular piston chamber and an

differential across said piston; and means for seal

ing the bore of one of said upper and lower tubular

portions intermediate said radial port means,

whereby ?uid pressure applied through the reme

dial tubing string applies a ?uid pressure differen 35

tial to said piston to shift said piston axially to re

lease said upper portion of the apparatus from said

other portion securing said collet heads in engage

ment with said ?shing neck;

and supplying ?uid pressure through said remedial

tubing string to said annular piston to move said

annular piston out of engagement with the collet

lower portion of the apparatus.

14. The apparatus of claim 13 wherein said radially

heads to release the remedial tubing string there

from and expose the ?shing neck portion of said

shiftable latching means comprises a collet on said

sleeve, thereby permitting wireline retrieval of said

upper tubular portion, said collet having peripherally

spaced latching heads engaging a downwardly facing,

annular, abutment surface on_ said lower tubular por

in?atable packer by engagement of a wireline ?sh

ing tool with said ?shing neck

*

45

50

55

60

65

You might also like

- Derma Notes 22pages. DR - Vishwa Medical CoachingDocument23 pagesDerma Notes 22pages. DR - Vishwa Medical CoachingΝίκος ΣυρίγοςNo ratings yet

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- Uses of PackersDocument13 pagesUses of Packersmohamed_sahnoun_enisNo ratings yet

- United States "Patents PDFDocument17 pagesUnited States "Patents PDFTien Nguyen VanNo ratings yet

- Inspección, Pruebas, Y Mantenimiento de Gabinetes de Ataque Rápido E HidrantesDocument3 pagesInspección, Pruebas, Y Mantenimiento de Gabinetes de Ataque Rápido E HidrantesVICTOR RALPH FLORES GUILLENNo ratings yet

- ?é4%.276 /4.7 Easter: RT - A2 (Alw'celeteDocument8 pages?é4%.276 /4.7 Easter: RT - A2 (Alw'celeteСлэйтер Строительная компанияNo ratings yet

- Tese Beatbox - Florida PDFDocument110 pagesTese Beatbox - Florida PDFSaraSilvaNo ratings yet

- Leadership and Management in Different Arts FieldsDocument10 pagesLeadership and Management in Different Arts Fieldsjay jayNo ratings yet

- Genil v. Rivera DigestDocument3 pagesGenil v. Rivera DigestCharmila SiplonNo ratings yet

- Definisi Komponen Wellhead Dan XtreeDocument7 pagesDefinisi Komponen Wellhead Dan XtreeLuthfan Desmono Silalahi100% (1)

- Registration ListDocument5 pagesRegistration ListGnanesh Shetty BharathipuraNo ratings yet

- Pig Launcher and ReceiverDocument5 pagesPig Launcher and ReceiverEbby Onyekwe88% (8)

- Pig Launcher and ReceiverDocument7 pagesPig Launcher and ReceiverGerman Felipe Torres100% (4)

- US 518 Centrifuge ManualDocument109 pagesUS 518 Centrifuge ManualMarius50% (2)

- 518 STD USA Centrifuge Manual Part 90-90-061-RevADocument109 pages518 STD USA Centrifuge Manual Part 90-90-061-RevAkanwarNo ratings yet

- Us 5988287Document14 pagesUs 5988287mohammadreza91No ratings yet

- Us 4676137Document6 pagesUs 4676137fghdfjerNo ratings yet

- Filed Sept. 30, 1963: C. C. BrownDocument8 pagesFiled Sept. 30, 1963: C. C. BrownyasamanNo ratings yet

- References Cited Robiatiorlial Movergents. Pat Least One ElaitigallybexaatrlidDocument7 pagesReferences Cited Robiatiorlial Movergents. Pat Least One Elaitigallybexaatrlidmohammadreza91No ratings yet

- United States Patent (19) : Wood (45) Date of Patent: Jan. 8, 1985Document5 pagesUnited States Patent (19) : Wood (45) Date of Patent: Jan. 8, 1985mohammadreza91No ratings yet

- May 13, 1969 M. R. Jones: So, 1966 L Of4 Filed DecDocument16 pagesMay 13, 1969 M. R. Jones: So, 1966 L Of4 Filed DecluiscremaschiNo ratings yet

- United States Patent (19) 11 4,274,432: 75 Inventors: Karl N. Tunstall, Farmers Branch E636 / ... 137/315Document5 pagesUnited States Patent (19) 11 4,274,432: 75 Inventors: Karl N. Tunstall, Farmers Branch E636 / ... 137/315Taufik Budi WibowoNo ratings yet

- Filed March 20, 1943Document8 pagesFiled March 20, 1943Andrés RamírezNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2012/0227970 A1Document14 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2012/0227970 A1zbhdzpNo ratings yet

- Us 5271461Document18 pagesUs 5271461ask101No ratings yet

- United States Patent (19) : 11) Patent Number: 5,181,477 45 Date of Patent: Jan. 26, 1993Document10 pagesUnited States Patent (19) : 11) Patent Number: 5,181,477 45 Date of Patent: Jan. 26, 199312348No ratings yet

- Filed Sept. 8, l942Document4 pagesFiled Sept. 8, l942HaithemNo ratings yet

- 8%, ZGZFMWMD @144': June 4, 1968 R. E. Roy 3,386,336Document9 pages8%, ZGZFMWMD @144': June 4, 1968 R. E. Roy 3,386,336tyrer567899No ratings yet

- United States Patent (19) : Övertröa 2, 7080 Heimdal KjetilDocument5 pagesUnited States Patent (19) : Övertröa 2, 7080 Heimdal Kjetilhernidasari hasibuanNo ratings yet

- ReadingDocument6 pagesReadingTrinh Quang ThanhNo ratings yet

- United States Patent (19) : George Et Al. 11 Patent Number: 4,969,525 45) Date of Patent: Nov. 13, 1990Document9 pagesUnited States Patent (19) : George Et Al. 11 Patent Number: 4,969,525 45) Date of Patent: Nov. 13, 1990Cuenta InformacionNo ratings yet

- Us2996100 PDFDocument8 pagesUs2996100 PDFerzrzretgertfertgeNo ratings yet

- Rod Pump ThesisDocument6 pagesRod Pump Thesisbsqfc4d5100% (2)

- O/65ézá / /zzáez: Ozzezz67Document4 pagesO/65ézá / /zzáez: Ozzezz67TECUMCE GOMEZ PEREZNo ratings yet

- United States Patent (19) (111 4,230,151: Jonsson (45) Oct. 28, 1980Document8 pagesUnited States Patent (19) (111 4,230,151: Jonsson (45) Oct. 28, 1980Stanislas AchardNo ratings yet

- United States Patent: BittnerDocument8 pagesUnited States Patent: BittneronlyaqmalNo ratings yet

- Centrifugal CompressorDocument7 pagesCentrifugal Compressorrohan112358No ratings yet

- Hawkins 1 US4534485Document5 pagesHawkins 1 US4534485gobinath VPNo ratings yet

- United States Patent (191: (73) AssigneeDocument6 pagesUnited States Patent (191: (73) AssigneeRodrigoPomaNo ratings yet

- Berthier Us1366863Document9 pagesBerthier Us1366863cll1968No ratings yet

- SL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296Document7 pagesSL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296lucasmosnaNo ratings yet

- Us4522106 PDFDocument13 pagesUs4522106 PDFJin Song100% (1)

- Us 6557638Document21 pagesUs 6557638daniel_iosif_glNo ratings yet

- United States Patent (19) : Putnam, Jr. Et Al. (11) 4,171,605Document13 pagesUnited States Patent (19) : Putnam, Jr. Et Al. (11) 4,171,605kartikkeyyanNo ratings yet

- Us4171605 PDFDocument13 pagesUs4171605 PDFkartikkeyyanNo ratings yet

- A Borehole Packer Instruction ManualDocument28 pagesA Borehole Packer Instruction Manualluis albertNo ratings yet

- Hawkins US5011035Document5 pagesHawkins US5011035gobinath VPNo ratings yet

- J. H. Wilson: Inventor.Document6 pagesJ. H. Wilson: Inventor.lfilippiniNo ratings yet

- US527955Document5 pagesUS527955moonstarNo ratings yet

- ZZ? ??/?? ???P?c222/Z: Filed April 20, 1945Document5 pagesZZ? ??/?? ???P?c222/Z: Filed April 20, 1945Edikan AkpanNo ratings yet

- United States PatentDocument7 pagesUnited States PatentBrilliant DavidsonNo ratings yet

- Us 6131519Document4 pagesUs 6131519dgfhjsdg hfsdhyjNo ratings yet

- 915 9000 990 112 /// 325 Aaa 3002 295 022 225 464 710 965 150 DWWDocument15 pages915 9000 990 112 /// 325 Aaa 3002 295 022 225 464 710 965 150 DWWMetin MehelNo ratings yet

- United States Patent (19) : GrainDocument5 pagesUnited States Patent (19) : Grainاحمد عبدالكريمNo ratings yet

- United States Patent: SchwartzmanDocument4 pagesUnited States Patent: SchwartzmanJames LindonNo ratings yet

- Tow Target Release Mechanism (1927)Document5 pagesTow Target Release Mechanism (1927)CAP History LibraryNo ratings yet

- United States Patent: Attorney-Pastoriza and KellyDocument4 pagesUnited States Patent: Attorney-Pastoriza and KellyEnrico FermiNo ratings yet

- Us 3460614Document7 pagesUs 3460614scibduser001No ratings yet

- United States Patent (19) (11) 4,298,078Document9 pagesUnited States Patent (19) (11) 4,298,078lfilippiniNo ratings yet

- United States Patent: (10) Patent N0.: Hoifman Et Al. (45) Date 0f PatentDocument10 pagesUnited States Patent: (10) Patent N0.: Hoifman Et Al. (45) Date 0f Patentmohammadreza91No ratings yet

- ?zyzyzzz: Wzzzzzzzzzzzzzzzºzrae?Document3 pages?zyzyzzz: Wzzzzzzzzzzzzzzzºzrae?KundanNo ratings yet

- J. A. Stevens,: Zzzz/WeezsDocument4 pagesJ. A. Stevens,: Zzzz/WeezsbbNo ratings yet

- US6390148 Valvula de LlenadoDocument8 pagesUS6390148 Valvula de LlenadoFreddy SalinasNo ratings yet

- Filed Oct. 22, 1951: P. C. HuttonDocument5 pagesFiled Oct. 22, 1951: P. C. HuttonGalo YambayNo ratings yet

- United States Patent (191: Sullivan Et A1Document21 pagesUnited States Patent (191: Sullivan Et A1fghdfjerNo ratings yet

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Document13 pages(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuNo ratings yet

- United States Patent: (10) Patent N0.: Hoifman Et Al. (45) Date 0f PatentDocument10 pagesUnited States Patent: (10) Patent N0.: Hoifman Et Al. (45) Date 0f Patentmohammadreza91No ratings yet

- Us5361479 PDFDocument5 pagesUs5361479 PDFmohammadreza91No ratings yet

- Ullltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992Document7 pagesUllltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992mohammadreza91No ratings yet

- United States Patent (191 (11) Patent Number: 5 363 542: Sorem Et A1. (45) Date of Patent: Nov. 15, 1994Document6 pagesUnited States Patent (191 (11) Patent Number: 5 363 542: Sorem Et A1. (45) Date of Patent: Nov. 15, 1994mohammadreza91No ratings yet

- 11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555Document5 pages11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555mohammadreza91No ratings yet

- Introduction CompilerDocument47 pagesIntroduction CompilerHarshit SinghNo ratings yet

- Mueller Hinton Agar (M-H Agar) : CompositionDocument2 pagesMueller Hinton Agar (M-H Agar) : CompositionRizkaaulyaaNo ratings yet

- Been There, Done That, Wrote The Blog: The Choices and Challenges of Supporting Adolescents and Young Adults With CancerDocument8 pagesBeen There, Done That, Wrote The Blog: The Choices and Challenges of Supporting Adolescents and Young Adults With CancerNanis DimmitrisNo ratings yet

- MFE Module 1 .Document15 pagesMFE Module 1 .Adarsh KNo ratings yet

- G2 Rust Grades USA PDFDocument2 pagesG2 Rust Grades USA PDFSt3fandragos4306No ratings yet

- SG110CX: Multi-MPPT String Inverter For SystemDocument2 pagesSG110CX: Multi-MPPT String Inverter For SystemKatherine SmithNo ratings yet

- Hare and Hyena: Mutugi KamundiDocument18 pagesHare and Hyena: Mutugi KamundiAndresileNo ratings yet

- Smartfind E5 g5 User ManualDocument49 pagesSmartfind E5 g5 User ManualdrewlioNo ratings yet

- Quotation of Suny PDFDocument5 pagesQuotation of Suny PDFHaider KingNo ratings yet

- Educationusa 2022globalguide Final Reduced SizeDocument84 pagesEducationusa 2022globalguide Final Reduced SizeAnna ModebadzeNo ratings yet

- Module 5 What Is Matter PDFDocument28 pagesModule 5 What Is Matter PDFFLORA MAY VILLANUEVANo ratings yet

- Is 2 - 2000 Rules For Rounded Off For Numericals PDFDocument18 pagesIs 2 - 2000 Rules For Rounded Off For Numericals PDFbala subramanyamNo ratings yet

- RARE Manual For Training Local Nature GuidesDocument91 pagesRARE Manual For Training Local Nature GuidesenoshaugustineNo ratings yet

- ISA InTech Journal - April 2021Document50 pagesISA InTech Journal - April 2021Ike EdmondNo ratings yet

- Ultracold Atoms SlidesDocument49 pagesUltracold Atoms SlideslaubbaumNo ratings yet

- Magic Bullet Theory - PPTDocument5 pagesMagic Bullet Theory - PPTThe Bengal ChariotNo ratings yet

- Five Reasons Hazards Are Downplayed or Not ReportedDocument19 pagesFive Reasons Hazards Are Downplayed or Not ReportedMichael Kovach100% (1)

- 40 Sink and FloatDocument38 pages40 Sink and Floatleandro hualverdeNo ratings yet

- PD3 - Strategic Supply Chain Management: Exam Exemplar QuestionsDocument20 pagesPD3 - Strategic Supply Chain Management: Exam Exemplar QuestionsHazel Jael HernandezNo ratings yet

- Yetta Company ProfileDocument6 pagesYetta Company ProfileAfizi GhazaliNo ratings yet

- AMICO Bar Grating CatalogDocument57 pagesAMICO Bar Grating CatalogAdnanNo ratings yet

- Manuel SYL233 700 EDocument2 pagesManuel SYL233 700 ESiddiqui SarfarazNo ratings yet

- Pathogenic Escherichia Coli Associated With DiarrheaDocument7 pagesPathogenic Escherichia Coli Associated With DiarrheaSiti Fatimah RadNo ratings yet

- Teaching Trigonometry Using Empirical Modelling: 2.1 Visual Over Verbal LearningDocument5 pagesTeaching Trigonometry Using Empirical Modelling: 2.1 Visual Over Verbal LearningJeffrey Cariaga Reclamado IINo ratings yet