Professional Documents

Culture Documents

Making DuPont Jumper Wires

Uploaded by

tsipornCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Making DuPont Jumper Wires

Uploaded by

tsipornCopyright:

Available Formats

1

Making DuPont Jumper Wires

DuPont jumper wires can easily be made if you use the correct crimpers. Although you can solder

the wire connection, and use needle nose pliers to secure the strain relief, soldering makes the

connection rigid and prone to breakage. Your crimping tool must match the connector type!

A single operation crimper has two teeth, one wider than the other. You insert the wire with

connector from the wider side of tooth side.

The first step in the process is to cut one of the pins off of the connector strip. Make sure you cut

the carrier rail as seen in the image. Do not remove this carrier strip from the connector.

Depending on the connector just cut, strip off about 1/8 or 3/32 of an inch of insulation from a

22-24 AWG stranded wire.

The proper way to hold the jumper wire and connector is seen in the image.

Note the placement of the wire on the connector.

This image shows a connector in a crimping tool without the wire. Note the carrier strip

(bottom of the tool) is tight against the tool's surface.

The business side of the connector must extend all the way out past the tools upper surface!

If it is not, you will pinch the connector and it will not function.

You are now ready to complete the crimp by fully compressing the tools handles.

We see the finished crimped connector with the carrier strip removed. Note, in this image, there is

a slight flaring or un-crimped portion that can be reworked by crimping the connector a second

time.

It is often necessary to slightly compress the strain relief portion of the connector so it will easily

fit into a connector housing.

We see the finished crimped connector inserted into a single pin housing.

This shows a higher quality connector. It has a plating of gold to prevent oxidization.

Once again, you clip off a pin. Note in this case you can use the small raised portion on the carrier

as a registration point to make your cut.

Comparing two female pins that are available. Distance A to B is the same on both pins. This is

the important measurement as the housing requires it. The pin on the left is better as the strain

relief will have more insulation to grasp and the wings that capture the stripped wire are longer.

As before, we hold the stripped wire in place on the pin prior to inserting it into your tool.

Again you must position the carrier strip flush against the crimp tool.

Notice the extra extension on the business end for this longer pin.

10

Finished crimped pin.

Always test your crimp buy tugging on the wire while holding the connector pin.

11

Comparison between the crimped longer and shorter pins.

A male pin prior to crimping.

12

Finished crimped male pin.

Combined male and female pin. Notice the tip of the male pin should be visible when fully

inserted.

13

If the female pin was crushed while crimping, the two pins will not mate properly.

The female connectors have a compression tongue.

If the mating male pin is on the loose side, compress the tongue inwards to tighten the pin spring.

14

If you plan to make these jumper wires regularly, you might want to invest in a wire wrapping wire

stripper. This tool does not nick or cut any of the strands during the stripping process.

An insulated wire is positioned at the point where you want the stripping to start. Then you pull

the wire through the stripper. You can easily remove 1/8 to 2 inches of insulation without

damaging or losing the strands.

15

After pulling the wire through the stripper, you may be left with a small piece of insulation still

attached. Cut this off with flush cutters.

Side view of the stripping tool, ST-100

http://www.stanleysupplyservices.com/ok-industries-st100-22-24-wire-awg-cut-strip-tool/p/118-050

16

- You may want to cut several female and male connector pins from their carrier strips ahead of

time so they will be ready to use. Having a collection of different sized DuPont housings is

handy so you can immediately make up your assemblies.

- Two row housings are also available.

- You can also epoxy or crazy glue two single row housings to make a two row version.

- If you want to polarize your housings make one of the pins male with the rest female.

- Note: in image C, there is a small triangle on the housing to identify pin one.

Some examples showing insulation and wire gauge differences.

17

Some finished cable wiring harnesses.

- Top, 1 to 2 male to male.

- Middle, 7 to 3, 3, 1 male to male.

- Bottom, you can polarize your connectors: 1 male with 2 female to 1 female with 2 male.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Pervertible Practices: Playing Anthropology in BDSM - Claire DalmynDocument5 pagesPervertible Practices: Playing Anthropology in BDSM - Claire Dalmynyorku_anthro_confNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 2012 Honeywell Users Group EMEA Asset Management SolutionsDocument29 pages2012 Honeywell Users Group EMEA Asset Management SolutionstsipornNo ratings yet

- Q&A from Honeywell Webinar on PID Controller Performance MonitoringDocument4 pagesQ&A from Honeywell Webinar on PID Controller Performance MonitoringtsipornNo ratings yet

- Sample PPP Lesson PlanDocument5 pagesSample PPP Lesson Planapi-550555211No ratings yet

- Pechem 101Document38 pagesPechem 101tsipornNo ratings yet

- 21 Candlestick Patterns Every Trader Should KnowDocument83 pages21 Candlestick Patterns Every Trader Should KnowAlex Dela RosaNo ratings yet

- Negotiating For SuccessDocument11 pagesNegotiating For SuccessRoqaia AlwanNo ratings yet

- English: Quarter 1 - Module 1Document16 pagesEnglish: Quarter 1 - Module 1Ryze100% (1)

- Villadolid, Thea Marie J - 1st CENTURY SKILLS CATEGORIESDocument4 pagesVilladolid, Thea Marie J - 1st CENTURY SKILLS CATEGORIESThea Marie Villadolid100% (1)

- Delays in Control SystemsDocument4 pagesDelays in Control SystemstsipornNo ratings yet

- Server cabinet diagram with iDRAC and LAN portsDocument1 pageServer cabinet diagram with iDRAC and LAN portstsipornNo ratings yet

- Engel FinPerformance Modelling of Manufacturing EquipmentalDocument5 pagesEngel FinPerformance Modelling of Manufacturing EquipmentaltsipornNo ratings yet

- Advanced Control of A Water Supply System: A Case StudyDocument8 pagesAdvanced Control of A Water Supply System: A Case StudyRavi Shankar KolluruNo ratings yet

- 20+ Years Providing CBM Solutions WorldwideDocument1 page20+ Years Providing CBM Solutions WorldwidetsipornNo ratings yet

- Mat LabDocument129 pagesMat Labzorro21072107No ratings yet

- MATLAB IntroDocument104 pagesMATLAB IntroCarlos Salas LatosNo ratings yet

- Hon Am14 Winters Asset ManagementDocument33 pagesHon Am14 Winters Asset ManagementtsipornNo ratings yet

- FFT ExampleDocument184 pagesFFT ExampletsipornNo ratings yet

- The Case For Condition-Based Maintenance: Executive SummaryDocument3 pagesThe Case For Condition-Based Maintenance: Executive SummarytsipornNo ratings yet

- Finding The Needle in The Haystack: Visualizing Control Performance ProblemsDocument11 pagesFinding The Needle in The Haystack: Visualizing Control Performance ProblemstsipornNo ratings yet

- Production Optimization Through Advanced Condition Monitoring of Upstream Oil and Gas AssetsDocument7 pagesProduction Optimization Through Advanced Condition Monitoring of Upstream Oil and Gas AssetstsipornNo ratings yet

- Ug OmniPage17UserGuideDocument121 pagesUg OmniPage17UserGuideHerman Orellana MelladoNo ratings yet

- Equipment Condition Monitor Boosts Production and Reduces Operating Costs For Oil & Gas CompanyDocument2 pagesEquipment Condition Monitor Boosts Production and Reduces Operating Costs For Oil & Gas CompanytsipornNo ratings yet

- Mindmap PrintingDocument1 pageMindmap PrintingtsipornNo ratings yet

- HoneywellEquipmentConditionMonitor BR489 PDFDocument4 pagesHoneywellEquipmentConditionMonitor BR489 PDFtsipornNo ratings yet

- 653 HON AdvSol CPM Pandpvariationreductionpart1 25aug11 WPDocument9 pages653 HON AdvSol CPM Pandpvariationreductionpart1 25aug11 WPtsipornNo ratings yet

- Honeywell Equipment Condition Monitor Performance Monitoring Offshore Gas Compressor Tin659Document5 pagesHoneywell Equipment Condition Monitor Performance Monitoring Offshore Gas Compressor Tin659tsipornNo ratings yet

- Matri Kono PCT PN OptimizerDocument1 pageMatri Kono PCT PN OptimizertsipornNo ratings yet

- Control of Boiler Operation Using PLC - SCADADocument6 pagesControl of Boiler Operation Using PLC - SCADAvikyarifNo ratings yet

- DX14 Tue PM S1 Paper3Document8 pagesDX14 Tue PM S1 Paper3tsipornNo ratings yet

- 656 HON AdvSol CPM Pandapvariationreuctionpart2 25aug11 WPDocument8 pages656 HON AdvSol CPM Pandapvariationreuctionpart2 25aug11 WPtsipornNo ratings yet

- Mindmap PrintingDocument1 pageMindmap PrintingtsipornNo ratings yet

- Mindmap PrintingDocument1 pageMindmap PrintingtsipornNo ratings yet

- Disability Election ManifestoDocument2 pagesDisability Election ManifestoDisability Rights AllianceNo ratings yet

- Present Tense Simple (Exercises) : Do They Phone Their Friends?Document6 pagesPresent Tense Simple (Exercises) : Do They Phone Their Friends?Daniela DandeaNo ratings yet

- Network Profiling Using FlowDocument75 pagesNetwork Profiling Using FlowSoftware Engineering Institute PublicationsNo ratings yet

- Centre's Letter To States On DigiLockerDocument21 pagesCentre's Letter To States On DigiLockerNDTVNo ratings yet

- Term2 WS7 Revision2 PDFDocument5 pagesTerm2 WS7 Revision2 PDFrekhaNo ratings yet

- Com 10003 Assignment 3Document8 pagesCom 10003 Assignment 3AmandaNo ratings yet

- School of Architecture, Building and Design Foundation in Natural Build EnvironmentDocument33 pagesSchool of Architecture, Building and Design Foundation in Natural Build Environmentapi-291031287No ratings yet

- Specification Table - Stocks and ETF CFDsDocument53 pagesSpecification Table - Stocks and ETF CFDsHouse GardenNo ratings yet

- HRU Stowage and Float-free ArrangementDocument268 pagesHRU Stowage and Float-free ArrangementAgung HidayatullahNo ratings yet

- Future42 1675898461Document48 pagesFuture42 1675898461Rodrigo Garcia G.No ratings yet

- Interpersonal Communication LPDocument3 pagesInterpersonal Communication LPprincesslove.taduraNo ratings yet

- Derivatives 17 Session1to4Document209 pagesDerivatives 17 Session1to4anon_297958811No ratings yet

- 12A1HDocument11 pages12A1HAlvaro SolisNo ratings yet

- Polisomnografí A Dinamica No Dise.: Club de Revistas Julián David Cáceres O. OtorrinolaringologíaDocument25 pagesPolisomnografí A Dinamica No Dise.: Club de Revistas Julián David Cáceres O. OtorrinolaringologíaDavid CáceresNo ratings yet

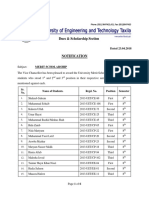

- Dues & Scholarship Section: NotificationDocument6 pagesDues & Scholarship Section: NotificationMUNEEB WAHEEDNo ratings yet

- Principles of DisplaysDocument2 pagesPrinciples of DisplaysShamanthakNo ratings yet

- Intro to Financial Management Chapter 1 SummaryDocument11 pagesIntro to Financial Management Chapter 1 SummaryweeeeeshNo ratings yet

- Container sizes: 20', 40' dimensions and specificationsDocument3 pagesContainer sizes: 20', 40' dimensions and specificationsStylefasNo ratings yet

- Hidaat Alem The Medical Rights and Reform Act of 2009 University of Maryland University CollegeDocument12 pagesHidaat Alem The Medical Rights and Reform Act of 2009 University of Maryland University Collegepy007No ratings yet

- Information BulletinDocument1 pageInformation BulletinMahmudur RahmanNo ratings yet

- Barnett Elizabeth 2011Document128 pagesBarnett Elizabeth 2011Liz BarnettNo ratings yet

- CV Finance GraduateDocument3 pagesCV Finance GraduateKhalid SalimNo ratings yet

- Zsoka PDFDocument13 pagesZsoka PDFMasliana SahadNo ratings yet

- BMW E9x Code ListDocument2 pagesBMW E9x Code ListTomasz FlisNo ratings yet

- Vipinesh M K: Career ObjectiveDocument4 pagesVipinesh M K: Career ObjectiveJoseph AugustineNo ratings yet