Professional Documents

Culture Documents

Training Manual

Uploaded by

Fiaz HussainOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Training Manual

Uploaded by

Fiaz HussainCopyright:

Available Formats

See

discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/270902389

Training manual on land and water management

technologies

Technical Report January 2014

DOI: 10.13140/2.1.3076.3846

CITATIONS

READS

34

1 author:

Muhammad Ramzan Anser

Ayub Agricultural Research Institute

5 PUBLICATIONS 1 CITATION

SEE PROFILE

Available from: Muhammad Ramzan Anser

Retrieved on: 11 September 2016

TRAINING MANUAL ON LAND &

WATER MANAGEMENT

TECHNOLOGIES

Muhammad Ramzan Anser, Bashir Hussain, Shahid Munir,

Syed Zia ul Hassan, M. Rafique Sajjad and Malik Ajmal Khan

Soil and Water Conservation Research Institute, Chakwal

13 km, Talagang Road, Chakwal, Punjab, Pakistan

Science for farmers & by the farmers

CONTENTS

Foreword

1.

Farm runoff harvesting structures/check dams for erosion

control and water harvesting on terraces

2.

Micro-catchment rainwater harvesting techniques for

profitable use of sloping/gullied lands to grow high value

crops

3.

High efficiency irrigation systems (drip and bubbler) to

ensure

water

saving

and

enhance

crop

12

water

productivity.

4.

Moisture conservation and crop yield improvement

through gypsum and green manuring

18

Science for farmers & by the farmers

Foreword

Land degradation is a serious constraint to increasing agricultural productivity in

rainfed areas of Punjab, Pakistan. Water erosion, the major cause of land degradation,

has already affected 1.9 m ha area in Punjab; major part of which lies in Pothwar tract.

The region mainly depends on rainfall for crop production, which is erratic resulting in

low crop yields. The runoff harvesting potential has been estimated to be around 3

MAF, part of which has been harvested in the form of small dams, mini dams and

ponds; but not being utilized efficiently. The eroded areas need sustainable

rehabilitation to ensure food security in the region. The long-term international

collaboration of SAWCRI with ICARDA (International Center for Agricultural

Research in the Dry Areas, Syria) has resulted in development of some environmental

friendly and cost-effective resource conservation technologies. The long-term research

data indicates that adoption of such technologies by farming communities can help to

achieve food security in the region and improve livelihood of rural communities on

sustainable basis.

Ensuring adequate food and water to all and achieving sustainable rural

development and livelihoods for current and future generations all hinge upon the

responsible management of natural resources. Resource conservation technologies are

tools empower farmers to increase crop water productivity and thus attain higher

incomes. I hope this manual which contains detailed methodologies and salient

features of conservation technologies would be useful for use by professionals of line

departments, NGOs and other field units in private and public sector and would

facilitate dissemination of the technologies to the end users.

Malik Ajmal Khan

January 19, 2014

Director,

SAWCRI, Chakwal

Science for farmers & by the farmers

1. FARM RUNOFF STRUCTURES/CHECK DAMS FOR EROSION CONTROL &

WATER HARVESTING ON TERRACES:

In Pothwar, the fields are usually not flat but various field terraces are situated at different elevation

levels (Fig 1). The major land use of such terraces is usually field crop production. Usually farmers

make earthen contour embankments to retain rainwater and conserve soil as the region receives

70% of annual rainfall during short monsoon season (July-Sep) as torrential showers which produce

substantial runoff.

Fig.1 Terraced cultivated lands in Pothwar

However, farmers reported that the runoff while moving from higher to lower fields causes

breaching of field embankments/bunds (Fig 2).

Fig.2 Breached terrace bund/embankment

1

Science for farmers & by the farmers

The moving water not only takes with it top fertile soil but also essential nutrients and organic

carbon thereby reduces productive capacity of soils. The sediments are often deposited in

water reservoirs at downstream and greatly reduce their capacity and life. If the breached

bund is not repaired before next rainy season, it leads to formation of gullies and rendering

area out of plough, a great national loss. Crop yield on such eroded lands are poor and

livelihood of resource-poor farmers is affected adversely.

Conventional rehabilitation measures:

I.

Using tractor to repair breached bund:

The breached bund is repaired using tractor front blade. This involves cost (minimum

one tractor hour). It has been observed that the repaired bund point remains prone to

breaching during successive rainy seasons. In this way, farmers have to bear repair

cost continuously after each rainy season. On the average, seasonal cost varies from

1-3 tractor hours (Rs. 1300-3900).

II.

Installing masonry structures:

The department of Soil Conservation helps farmers by installing masonry structures

for soil conservation, however, these have been found costly and beyond the reach of

poor farmers.

After long-term research at farmers fields in Pothwar, multidisciplinary teams of

SAWCRI has standardized and evaluated loose stone structures as alternate solutions

adopting principal approach of Catch water where it drops and only allow surplus water

to dispose off safely. Design parameters and other detail is given below:

A. Design parameters:

a. Determination of discharge (Q): The discharge is calculated using Rational Formula

Q=CIA

[Eq.# 1]

Where

Q = Discharge (cfs)

[cfs = cubic foot per second]

C = Coefficient of runoff. [0.3=Light soil & slight slope; 0.4= Medium soil & medium slope;

0.5=Heavy soil and steep slope].

I = Intensity of rain fall (inches per hour)

A= Area in acres.

2

Science for farmers & by the farmers

SAWCRI assumed Coefficient of runoff (C) as 0.4 and Rainfall intensity (I) as 4

inches per hour in designing loose stone structures in Pothwar as these figures were

considered representative for the area.

By putting these value in Rational Formula (Eq.# 1) we get:

Q = 0.4 x 4 x A

Q = 1.6A

(Eq. # 2)

With the help of Eq. # 2, one can easily determine discharge by knowing catchment

area of a structure.

For Example: If catchment area of a structure is 10 acres, Then, Q will be = 1.6 10 = 16 cfs.

b. Calculating breadth ( )of a structure

The breadth of structure can be determined using Weir Formula

Q=3.33BH1.5

or

B=Q/3.33H1.5

(Eq. # 3)

Where

B = Breadth/width of a structure (ft)

Q = Discharge (cfs). [ already calculated using Eq. # 2]

H = Height of side walls of a structure (ft)

Box 1.1: How to decide height of side walls (H) of a structure:

Height of side walls of a structure should be equal to height of field bund/embankment where

structure is to be installed. H normally ranges from 1.02.5 ft.

For different values of H, the H1.5 will be as under:

If H=1.0,

the value of H1.5 will be = (1.0)1.5 = 1.00

If H=1.5,

the value of H1.5 will be = (1.5)1.5 = 1.84

If H=2.0,

the value of H1.5 will be = (2.0)1.5 = 2.83

If H=2.5

the value of H1.5 will be = (2.5)1.5 = 3.95

We can also assume the breadth of a structure in Eq. #3 and determine height of side walls but field

experience shows that this practice is un-economical. To avoid calculations, field supervisors normally keep

breadth of a structure equal to the breadth of broken embankment, more quantity of dry stone is used, which

After deciding the height of side walls of a structure (Box 1.1), we can easily determine the

increases cost of a structure. This practice should be avoided.

Science for farmers & by the farmers

Example to calculate breadth of a structure using Eq. No.3:

If

Q = 16 cfs

[calculated using Eq. # 2, keeping area=10 acres]

H = 1.5 ft

[Equal to field embankment/bund]

Then,

Breadth of structure will be:

B=Q/3.33H1.5

B= 16/{3.33 (1.5)1.5}

B= 16/(3.33 1.84)

B= 2.6 feet

[from Box 1.1]

It means, the breadth of structure will be 2.6 ft

One can avoid above calculations and use graph (Fig 3), to determine breadth/width

of structure by knowing discharge (from Eq. # 2, (Q = 1.6 A), and assuming height of

walls of structure equal to height of his field bund.

Fig 3. Diagram to determine width of structure and height of wall

Examples to Elaborate Graph Usage:

Example 1:

Suppose using simplified formula (Q = 1.6A), you have determined Q = 20 cfs

Height (h) of walls will be 1.5 ft

The width of structure will be 4 ft;

Example 2:

Suppose you have determined Q = 60 cfs

The width of structure = 8.0 ft

Height (h) of walls will be 2.0 ft

Example 3:

Suppose you have determined: Q = 100 cfs Height (h) of walls will be 2.5 f

The width of structure will be 9 ft

t

4

Science for farmers & by the farmers

Fig 4 Cross-section of a loose stone structure

BOX 1.2: How to decide the type of structure: (Whether stone protection or cascade)

Stone protection is normally installed when natural slope exists and field to field drop either

does not exist or is lower. We need only to protect slope and allow safe disposal of surplus

runoff.

Cascade ( or ladder type) structure in generally installed when field to field drop

(fall) is higher and natural slope does not exits:

Other important considerations:

If facilities for topographic survey are not available, one can determine drainage point of

the area (where structure is to be installed) by observation and discussion with farmer.

The crest of structure is kept 6-9 inches raised from soil surface to encourage in situ

rainwater conservation.

While determining discharge for a downstream field, 3040% discharge from upstream

field should be added into it for effective performance.

5

Science for farmers & by the farmers

After completing installation of structure, the roots (along with soil) of grasses growing in

vicinity of structure should be planted or spread in the gaps between stones to encourage

grass growth. Natural grass acts as cementing agent.

Avoid installation of structure at the onset of monsoon season; dry stones require time to

settle. The Post-monsoon season is best time for installation of structures.

Advantages of loose stone structures:

1. Conserve land and retain rainwater in field for crop use.

2. Safely dispose off surplus rainwater to downstream fields (Runoff regulation).

3. Cheap, easy to construct and maintain. No cement or concrete is used. Naturally

growing grass acts as cementing agent. No repair cost. Structures are not fixed-type

rather flexible: automatic stone settlement on rodent burrows.

4. Crop yield improvement up to 20%.

5. Pay back period is 2-3 years.

Fig 5. Installation of a farm runoff structure in the field Fig 6. A loose stone structure in the field

Fig 7. Farm runoff harvesting loose stone structures installed to manage a

gully in a watershed. Note that structures are installed in zig zag pattern to

increase water flow path, reduce runoff velocity and encourage higher in situ

rainwater harvesting.

6

Science for farmers & by the farmers

2. MICRO-CATCHMENT RAINWATER HARVESTING:

In Pothwar, fruit plants such as olive, grapes, citrus etc. are being grown mostly in

round basins with supplemental irrigation employing different irrigations systems. The huge

cost of irrigation water and its application has been reported to reduce profitability of growing

such high value crops and considered a major constraint in their adoption by farmers with

limited water availability.

Micro-catchment rainwater harvesting techniques can help growers in this scenario. These

techniques harvest rainwater and make available to grow high value crops. Irrigation cost is

cut down to a great extent by adopting these techniques.

What is a micro-catchment?

Micro-catchment is a specially contoured area with slopes and berms designed to increase

runoff from rain, concentrate it in a planting area where it infiltrates and stored in the root

zone. The stored water remains available to plants for longer period and is protected from

evaporation.

What is water harvesting?

It is the process or technique of collecting and storing rainwater for future productive use.

Types:

Depending upon soil type, topography and slope of the land, different types of microcatchments are used: These may be

Rectangular or square shaped: This technique is used to harvest rainwater near

plant root zone on flat lands.

Fig 8: Rectangular microcatchments

Science for farmers & by the farmers

V-shaped or Negarim: This technique is used for rain water harvesting on sloping

lands with slope ranging from 0 to 5%.

Fig 9: V-Shaped micro-catchments

Semi-circle or half-moon terrace: This technique is used to harvest rainwater on

sloping lands with slope ranging between 5-10%.

Catch the water where it drops

Fig 10: Semi-circle microcatchments showing rainwater harvest

8

Science for farmers & by the farmers

Designing of micro-catchments:

Micro-catchment works best on gentle slopes (ideally <5%). The catchment area (C) to

cultivated area (CA) area ratio should be 3:1. This ratio generally varies from 1:1 to 3:1.

Following formula may be used to calculate C/CA ratio:

( )

.

Runoff coefficient (Kc): it is the ratio between rainfall and runoff:

Kc =

All the rain is not converted into runoff, therefore, Runoff (mm) = kc Rainfall (mm).

Kc depends on catchment characteristics such as soil type, slope, vegetative cover/nature,

rainfall intensity, rainfall duration etc.

Runoff coefficient varies from 0.11.0, however, generally values from 0.1 0.5 are

adopted (as not ideal conditions, some leaching etc).

The canopy of a plant is normally assumed as the cultivated area.

The efficiency factor (K) takes into account the inefficiency of uneven distribution of

water within field as well as losses due to evaporation and deep percolation. Where the

cultivated/catchment area is leveled and smooth, the efficiency is higher. The efficiency

factor normally varies from 0.5 to 0.7.

Example to calculate C/CA:

Crop water requirement

= 525 mm

Design rainfall

= 350 mm

Runoff coefficient

= 0.4

Efficiency factor

= 0.6

Putting the values in above equation, we get

. .

=2

Therefore, catchment area should be double than cultivated area.

9

Science for farmers & by the farmers

Calculation of total catchment area:

After knowing C/CA ratio, next step is to calculate total catchment area. We need to know

canopy diameter or radius for this calculation.

Example:

a) Calculation of canopy or cultivated area:

C/CA

=2

Dia of canopy or cultivated area = 8ft [Radius =diameter/2 or 8/2 = 4ft]

Canopy or cultivated area of a = r2

circle

= 3.14 42

= 50 ft2

b) Calculation of total catchment area

Total Catchment area

= Canopy or cultivated area C/CA

= 50 2

= 100 ft2

Measurement of Micro catchment area and percent slope:

Use following formulae to calculate areas of different geometrical shapes:

1. Rectangular shape:

(Length x width )

L

W

2. Square shape:

(Length)2

b

3. Triangular shape

=1/2 ab

a

(a= length of perpendicular; b= base length) and then multiply with 2 to get area of V

shaped triangle.

Circular

Square

Rectangular

10

Square (with basin at center)

Science for farmers & by the farmers

Procedure to be followed in the field

Material: measuring tape, scale/ruler, note book, pencil, calculator, leveler

Step 1: Use measuring tap to measure the length and width of micro-catchment i.e.

square/rectangular/V-shaped.

Step 2: Measure the radius (r) or diameter (d) of canopy area.

Step 3: Measure slope by using following formula:

% Slope

x 100

Where:

H1: Lowest elevation point (base of plant)

H2: Highest elevation point (bottom of bund)

First take measurements of rectangular shaped catchment:

Length of catchment (L) in ft or m

Width of catchment (W) in ft or m

Suppose:

L = 20 ft; W = 20ft; r = 5 ft

Then: Total area of the catchment = L x W = 20 x 20 = 400 ft2

And canopy or cultivated area (CA) = r2 = 3.14 x 52 = 79 ft2

Therefore, catchment area (C) = Total area canopy or cultivated area (CA)

= 400 79 = 321 ft2

Therefore, C/CA = 321/79 = 4

That means catchment area is 4 times than the cultivated area

Slope:

Suppose

Elevation difference

= 4 inches

Distance between plant and bund

Putting these values in above equation, we get:

% Slope=

% Slope= 3.33

= 10 ft (or 120 inches)

x 100

[It means the developed micro-catchment with 3.33% slope].

11

Science for farmers & by the farmers

3. HIGH EFFICIENCY IRRIGATION SYSTESMS:

Government of the Punjab have spent billions of rupees on development of numerous water

resources such as dug wells, surface ponds, mini dams and small dams in Pothwar to ensure

food security and uplift of agriculture in these areas. The stored rainwater is very precious

commodity as compared to irrigated areas and must be used for growing high value crops to

justify its investment instead of using it for wheat and other arable crops.

The long-term field experimentation in rainfed areas has identified Drip and Bubbler

techniques as high efficiency irrigation systems (more water saving) with better adoption

potential for these areas. Water saving through these techniques can help bring more area

under irrigation. The challenge is to demonstrate these techniques to interested growers and

facilitate them in adoption.

In drip irrigation system water is supplied to plant, drop by drop, through emitters

attached with drip pipe. The system is mainly used for newly planted fruit plants &

vegetables.

Fig 11: Drip line installed for supplemental irrigation to Guava plants.

In Bubbler irrigation system (Fig 12), bubbler showers water in plant basin in the form of

an umbrella. Bubbler irrigation is mostly used for mature fruit plants and for plant species

whose water requirement is higher.

12

Science for farmers & by the farmers

Fig 12: Bubbler system installed for supplemental irrigation to olive plants.

Benefits:

No land leveling is required for water application through drip and bubbler.

Saves 60-70% of irrigation water. This can help bring more area under irrigated

agriculture.

Minimize fertilizer losses due to localized application and reduced leaching.

Lowers labor cost. Conventional irrigation system for fruit plants involves irrigation

through labour using plastic pipe, which is very costly.

Measurement of discharge:

Emitters/Drippers which are used in drip irrigation system have discharge of water 4-8 liters per

hour (lph) while bubblers have 4-10 liters per minute (lpm). The discharge can be increased or

decreased through drip emitter or bubbler. The discharge can be measured by placing a beaker or

bucket under an emitter/bubbler for one minute. It will give us the discharge per minute.

Multiply it by 60, to have discharge per hour. If more number of emitters is installed on drip line,

then multiply discharge by number of emitters to have total discharge for one plant.

13

Science for farmers & by the farmers

How to calculate the material required to install drip in a given area:

a) How to calculate number of plants?

No. of plants =

Suppose area of field

Spacing between rows

Spacing between plants

Then

= 198 ft 220 ft = 43560 Sq.ft

= 20ft

= 20 ft

Number of plants

Determine length and

width of field, where

drip irrigation is to be

installed, using

measuring tape

= 109 plants

b) How to determine length of main line (2-3 inch dia)?

The length of main line will be equal to the distance between field and water source.

c) How to determine total length of drip line (13mm, 16mm) required for given

area:

First calculate the number of drip lines. If your main line is installed along length of

the field, then the calculation will be as under

Number of drip lines =

Number of drip lines =

= 11

The number of drip lines can also be determined in the same manner if main line is

installed along the width of the field

We know that length of one drip line is = 198 ft [width of field]

Number of drip lines

= 11

So the total length of drip line will be = 198 x 11 = 2178ft

d) How to determine number of drippers?

We know that total number of plants

= 109 (calculated above}

Total number of dripper required

= 109 x 2 = 218

14

Each plant requires two

drippers

Science for farmers & by the farmers

Parts of drip and bubbler irrigation system

Water source, overhead tank. Electric motor and diesel engine with pump.

Main line

Sub mainline

Fittings

Drip line 13mm,16mm

Drippers/emitters

Bubbler

GTO and GTO washel

Bubbler filter

Control valve for zoning

Fig 13: Main parts of drip and bubbler irrigation systems

Installation Procedure:

I.

II.

III.

IV.

Laydown the main line and connect with water source.

Connect drip lines with main line using clamp or GTO with washel with control valve

(1/2-3/4).

Two drippers should be fitted on drip line at each plant location in such a manner that one

dripper is fitted to the right and other to the left at of planta distance of 1ft.

Plug the end of each drip line.

The procedure for installation of bubbler system is similar as described for drip systesm

except that bubbler system requires installation of sub-mainline between two plant rows

as shown in Fig 16.

15

Science for farmers & by the farmers

OPEN MAIN LINE

MAKE HOLE FOR GTO

FIT DRIP PIPE

FIT SANATERY FITTINGS

MAIN LINE ND SUB MAIN LINE

FIT GTO WASHEL

MAKE HOLE WITH NEEDLE

DRILL IN PIPE

FIT GTO

FIT DRIPPER

Fig 14: Step-wise procedure for installation of drip and bubbler irrigation systems

Field layout of drip and bubbler irrigation systems

Fig 15: Field layout for drip irrigation system

16

Science for farmers & by the farmers

Fig 16: Field layout for bubbler irrigation system

System Cost:

Cost of the drip or bubbler irrigation system depends upon the plant to plant and row to row

distance and pumping source. On the average, cost of these systems varies from Rs 50,000

150,000 per acre. The payback period is around 2 years. The systems at farmers fields are

performing perfectly since last two years without filters. No chocking has been reported.

Other detail:

A. How to determine head loss:

The head loss may be calculated

using Hazzen William formula given below:

Where:

Hf is the frictional head loss (m)

K = 1.21 x 1010

Q is the pipeline discharge (lps)

C is the friction coefficient for pipe sections

D is the inside diameter (mm)

L is the pipeline length (m)

Le is the equivalent length of pipe and accessories

17

B. How to select a pump:

Select suitable pump using following

equation:

HP = Q x H/ (76 x Pump efficiency)

Where:

Q = Discharge/Flow rate (lph)

H = Total head required (m)

Science for farmers & by the farmers

4. MOISTURE CONSERVATION AND CROP YIELD IMPROVEMENT THROUGH

GYPSUM & GREEN MANURING

In rainfed areas, crop yields are low due to moisture stress. The successful crop

production depends on conservation of moisture. SAWCRI evaluated the role of gypsum and

green manuring for moisture conservation & crop yield improvement on normal/non-saline

rainfed areas and found 19 to 46% increase in crop yield. The salient features of these

technologies are narrated below:

a) Gypsum application methodology:

i.

Deep ploughing of field with Moldboard plough (Raja hal)

ii.

Broadcasting gypsum powder on soil surface @ 1 tonne per acre (20 bags). To

ensure uniform broadcasting 10 bags should be applied length wise and 10 bags

width wise.

iii.

Shallow cultivation using cultivator to mix gypsum into the soil and avoid blowing

with winds (Fig 17).

Fig: 17 A farmer mixing gypsum into the soil after broadcasting

The research data showed that gypsum should be applied at least two months before

sowing of winter and summer crops to allow it to improve soil structure and conserve

moisture in the soil profile for use by succeeding crop. On an average, the residual effect of

gypsum lasts for three years; therefore, gypsum should not be applied every year.

18

Science for farmers & by the farmers

Important considerations:

Gypsum is not applied as fertilizer; rather, fertilizer should be applied as per

recommendations of the agriculture department for each crop in the field where gypsum

was applied.

Gypsum is only recommended for normal soils and should not be applied in salt-affected

soils for moisture conservation.

b) GREEN MANURING

Any green/fresh plant material incorporated into the soil to improve its fertility &

consequently productivity is called as green manure. In long-term experiments, SAWCRI

evaluated the performance of various legume crops as green manure and found cowpea and

guar as suitable for rainfed areas. The experimental data indicated that guar was best cover

crop as well as green manure crop for low rainfall areas (<400 mm annual rainfall); and

cowpeas for medium and high rainfall areas.

Methodology:

After harvest of winter crop, sowing of guar/cowpeas should be completed up to

mid-June through broadcasting seed @ 20-24 kg per acre. In case of delay in monsoon

rains, dry sowing can be practiced and has been found effective.

Crop should be incorporated into the soil with moldboard plough (Fig 18) or rotavator by

mid-August to allow sufficient time (~2 months) for decomposition. Delay in

incorporation beyond mid-August leaves less moisture in the soil profile for succeeding

winter-season crop.

Fig:18 Incorporation of Cowpea crop with Moldboard plough

19

Science for farmers & by the farmers

Before sowing of winter crop, the green manure field should be given two shallow

cultivations with cultivator at early morning or evening to facilitate decomposition and

control weeds.

Sowing of winter crop should be done as per recommendations of the department.

Benefits:

Green manure crop completely covers soil surface (Fig 19) during summer season,

therefore, reduces the risk of water erosion during this period.

Fig: 19 Cowpea crop completely covering soil surface

Green manure crops fix N in the soil and therefore, improve soil fertility.

Green manuring improves infiltration rate in the soil and therefore, enhances in situ

rainwater harvesting.

The improvement in physical properties of soils helps conserve more soil moisture

which remains available to winter crop for relatively longer period of time and

results in good crop establishment. .

Green manuring helps to increases yield of succeeding crops up to 22%. The impact

of green manuring is mostly visible during 2nd year after incorporation.

20

Science for farmers & by the farmers

Ensuring adequate food and water to all and achieving sustainable rural development

and livelihoods for current and future generations all hinge upon the responsible

management of natural resources

PLEASE JOIN HANDS WITH SAWCRI

In empowering farming communities to rehabilitate watersheds &

improve livelihood in an eco-friendly manner through demonstration

and dissemination of resource conservation technologies

For queries and feedback, please feel free to contact:

Malik Ajmal Khan

Director,

Soil and Water Conservation

Research Institute, Chakwal

Phone: 0543 594488

Fax:

0543 594504

sawcri@gmail.com

www.facebook.com/sawcri

www.sawcri.org

Soil and Water Conservation Research Institute, Chakwal

13 km, Talagang Road, Chakwal, Punjab, Pakistan

21

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Practical-5 Right Angle TriangleDocument13 pagesPractical-5 Right Angle TriangleFiaz HussainNo ratings yet

- Practical-2 Pond AreaDocument11 pagesPractical-2 Pond AreaFiaz HussainNo ratings yet

- Rain Water ManagementDocument35 pagesRain Water ManagementFiaz HussainNo ratings yet

- Practical 1 PacingDocument13 pagesPractical 1 PacingFiaz Hussain0% (1)

- Practical-3 Distance by Wheel, Speedometer, OdometerDocument2 pagesPractical-3 Distance by Wheel, Speedometer, OdometerFiaz HussainNo ratings yet

- Practical 4 RangingDocument11 pagesPractical 4 RangingFiaz HussainNo ratings yet

- Practical 1 PacingDocument13 pagesPractical 1 PacingFiaz Hussain0% (1)

- Lahoregroundwatermanagemnetpaper WWD 2011 FinalDocument13 pagesLahoregroundwatermanagemnetpaper WWD 2011 FinalFiaz HussainNo ratings yet

- US EvaporationDocument4 pagesUS EvaporationFiaz HussainNo ratings yet

- MultiDocument6 pagesMultiFiaz HussainNo ratings yet

- A Case Study at Pingtung PlainDocument46 pagesA Case Study at Pingtung PlainFiaz HussainNo ratings yet

- Book Name: Ramadan Ki Baharain: Live Chat (Islam/support/)Document1 pageBook Name: Ramadan Ki Baharain: Live Chat (Islam/support/)Fiaz HussainNo ratings yet

- A Case Study at Pingtung Plain PDFDocument901 pagesA Case Study at Pingtung Plain PDFFiaz HussainNo ratings yet

- Hydro Excel 116Document46 pagesHydro Excel 116Rohit JainNo ratings yet

- Food Security Issues and Challenges: A Case Study of PotoharDocument24 pagesFood Security Issues and Challenges: A Case Study of PotoharFiaz HussainNo ratings yet

- Bolt LoadingDocument7 pagesBolt LoadingFiaz HussainNo ratings yet

- Fire Flow Calculator Worksheet 2011Document7 pagesFire Flow Calculator Worksheet 2011walitedisonNo ratings yet

- TractorDocument1 pageTractorFiaz HussainNo ratings yet

- PQD Wasa PDFDocument18 pagesPQD Wasa PDFFiaz HussainNo ratings yet

- Fire Flow Calculator Worksheet 2011Document7 pagesFire Flow Calculator Worksheet 2011walitedisonNo ratings yet

- RIPPA Sustainable Land and Water Management in Arid AreasDocument24 pagesRIPPA Sustainable Land and Water Management in Arid AreasFiaz HussainNo ratings yet

- Analytical Reasoning - Short Notes - Part 1 of 5Document7 pagesAnalytical Reasoning - Short Notes - Part 1 of 5Muhammad Zubair ShahzadaNo ratings yet

- Pakistan Vision 2025 PDFDocument120 pagesPakistan Vision 2025 PDFTayyab HussainNo ratings yet

- Fiaz ResumeDocument5 pagesFiaz ResumeFiaz HussainNo ratings yet

- Alternate Wetting and Drying Irrigation (AWD) : A Technology For Water Saving in Rice ProductionDocument11 pagesAlternate Wetting and Drying Irrigation (AWD) : A Technology For Water Saving in Rice ProductionFiaz HussainNo ratings yet

- 54f29a5.irrigation System of PakDocument28 pages54f29a5.irrigation System of PakFiaz HussainNo ratings yet

- 3 Sediment Transport in RiversDocument32 pages3 Sediment Transport in RiversFiaz HussainNo ratings yet

- FIAZDocument3 pagesFIAZFiaz HussainNo ratings yet

- Gradually Varied Flow in Open ChannelDocument30 pagesGradually Varied Flow in Open ChannelFiaz HussainNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- East West Pipe Rack For Piping Project J-80: Sendan International Company LTDDocument25 pagesEast West Pipe Rack For Piping Project J-80: Sendan International Company LTDFarrukh Javed100% (1)

- Instrumentation - Aeroplanes: 22.01. Flight InstrumentsDocument27 pagesInstrumentation - Aeroplanes: 22.01. Flight InstrumentsveenadivyakishNo ratings yet

- HF Transceiver PDFDocument13 pagesHF Transceiver PDFlg900df5063No ratings yet

- Gasoline Direct InjectionDocument21 pagesGasoline Direct InjectionhoangNo ratings yet

- Equipment Damage Curves TransformersDocument8 pagesEquipment Damage Curves TransformersrobertoseniorNo ratings yet

- S8 PDFDocument184 pagesS8 PDFsrdsosonpurNo ratings yet

- Course Objective and Outcome FormDocument2 pagesCourse Objective and Outcome FormSajedur Rahman MishukNo ratings yet

- ATMega8 UcDocument40 pagesATMega8 UcnrjchopraNo ratings yet

- History of UASDocument44 pagesHistory of UASAswin BalasubramaniamNo ratings yet

- A-Dec 571 and 6300 Dental Light PDFDocument24 pagesA-Dec 571 and 6300 Dental Light PDFSergio RodriguezNo ratings yet

- Soil Test Report KolhapurDocument35 pagesSoil Test Report Kolhapuryedida viswanadhNo ratings yet

- Design and Build Contract TemplateDocument9 pagesDesign and Build Contract TemplateAlexanderNo ratings yet

- Product Data: Convertible Air Handlers 1-1/2 - 5 TonDocument28 pagesProduct Data: Convertible Air Handlers 1-1/2 - 5 TonJonathan CapraNo ratings yet

- FIDIC Red Book Construction Contract 1st Edition 1 9Document9 pagesFIDIC Red Book Construction Contract 1st Edition 1 9raviNo ratings yet

- VentureDeckingInstallationInstructions LRDocument13 pagesVentureDeckingInstallationInstructions LRGhislainTremblayNo ratings yet

- Chapter 12 Solutions To ExercisesDocument41 pagesChapter 12 Solutions To ExercisesMuhammad Awais56% (9)

- Premier University Department of Computer Science and Engineering (DCSE) Class Schedule (Updated) Session: Fall 2020Document6 pagesPremier University Department of Computer Science and Engineering (DCSE) Class Schedule (Updated) Session: Fall 2020X streamNo ratings yet

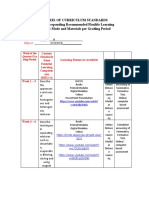

- Matrix of Curriculum Standards With Corresponding Recommended Flexible Learning Delivery Mode and Materials Per Grading PeriodDocument2 pagesMatrix of Curriculum Standards With Corresponding Recommended Flexible Learning Delivery Mode and Materials Per Grading PeriodNora HerreraNo ratings yet

- Dr. Assad Abu-Jasser, ECE-iugaza: Electrical Machines (EELE 4350)Document37 pagesDr. Assad Abu-Jasser, ECE-iugaza: Electrical Machines (EELE 4350)MohammedSaadaniHassani67% (6)

- SSA 716 StudentGuide 20150211Document551 pagesSSA 716 StudentGuide 20150211Ashok Kumaresan100% (1)

- 3.5 Dump Valve PDFDocument5 pages3.5 Dump Valve PDFBaciu NicolaeNo ratings yet

- Motordata Manual en PDFDocument12 pagesMotordata Manual en PDFVut TheaNo ratings yet

- Science 10 BowDocument10 pagesScience 10 BowGERRY CHEL LAURENTENo ratings yet

- Warranty Card PDFDocument1 pageWarranty Card PDFEy AhNo ratings yet

- Design of Queensland Road Infrastructure For High Risk EnvironmentsDocument7 pagesDesign of Queensland Road Infrastructure For High Risk EnvironmentsAnonymous fS6Znc9No ratings yet

- Fundamentals of The Automotive Cabin Climate Control SystemDocument6 pagesFundamentals of The Automotive Cabin Climate Control SystemSeddik MaarfiNo ratings yet

- Presentation On Usb 3.0Document21 pagesPresentation On Usb 3.0Anuj KumarNo ratings yet

- Manual Daiwa Tanacom 500 PDFDocument37 pagesManual Daiwa Tanacom 500 PDFHenrique BelliniNo ratings yet

- Leeson Speedmaster ManualDocument80 pagesLeeson Speedmaster ManualOrbán Árpád100% (1)

- AnalysisofUnder reamedPilesSubjectedtoDifferentTypesofLoadinClayeySoil 1 8 PDFDocument9 pagesAnalysisofUnder reamedPilesSubjectedtoDifferentTypesofLoadinClayeySoil 1 8 PDFAkhilesh Kumar SinghNo ratings yet