Professional Documents

Culture Documents

Installation Guide Installation Manual

Uploaded by

american_guy10Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Guide Installation Manual

Uploaded by

american_guy10Copyright:

Available Formats

INSTALLATION MANUAL

WAAREE ENERGIES LIMITED

Head Office:

602, Western Edge-I,

Off. Western Express Highway,

Borivali (E), Mumbai 400066,

Maharashtra, India

Tel: +91-22-66444400

waaree@waaree.com

Factory Address:

Plot No. 231 236,

Surat Special Economic Zone,

Diamond Park, Sachin,

Surat- 394230, Gujarat

Tel: +91-261-2398661

WEL/ IM/ 05/ 18.10.2014

CONTENTS

INTRODUCTION .................................................................................................................................................... 3

DISCLAIMER OF LIABILITY ..................................................................................................................................... 3

GENERAL INFORMATION...................................................................................................................................... 3

GUIDELINES & PRECAUTIONS FOR UNPACKING, HANDLING & STORAGE OF PV MODULE ................................. 5

CLIMATIC CONDITIONS......................................................................................................................................... 6

NOTES ON INSTALLATION .................................................................................................................................... 6

SPECIFICATIONS.................................................................................................................................................... 7

SOLAR PV MODULE MOUNTING GUIDELINES ...................................................................................................... 7

GROUNDING....................................................................................................................................................... 10

ELECTRIC WIRING ............................................................................................................................................... 11

CABLE PROTECTION............................................................................................................................................ 12

DIODES................................................................................................................................................................ 12

MAINTENANCE SAFETY ...................................................................................................................................... 13

GENERAL SAFETY ................................................................................................................................................ 13

GUIDELINES & PRECAUTIONS FOR CLEANING OF PV MODULE ......................................................................... 14

Page 2 of 15

www.waaree.com

Sun Power Forever

WEL/ IM/ 05/ 18.10.2014

INTRODUCTION

This manual contains information regarding installation, operation, maintenance and safe handling of

WAAREE Photo Voltaic (PV) Modules. Before installation or using the PV Modules, it is important to read this

manual and understand the instructions carefully.

DISCLAIMER OF LIABILITY

Since the use of this Installation, Operation and Maintenance Manual and the conditions of installation,

operation, use and maintenance of the Module are beyond WAAREEs control; WAAREE does not assume

responsibility and expressly disclaims liability for loss, damage, injury or expense arising out of or in any way

connected with such installation, operation, use or maintenance of the Modules.

WAAREE assumes no responsibility for any infringement of patents or other rights of third parties that may

result from use of the Module. No license is granted by implication or otherwise under any patent or patent

rights.

The information in this Manual is based on our knowledge and experience and is believed to be reliable; but

such information including product specifications (without limitations) and suggestions do not

constitute a warranty, expressed or implied. WAAREE reserves the right to make changes to the product,

specifications or this manual without prior notice.

GENERAL INFORMATION

The installation of solar PV Modules requires great degree of skills, it should only be performed by a qualified

and licensed professional, including, without limitation, licensed contractors and licensed electricians. The

installer assumes the risk of all injury that might occur during installation, including without limitation, the

risk of electric shock.

For your safety and the safety of others, please read the entire Installation,

Operation and Maintenance Manual carefully prior to installing, wiring, operating

and performing maintenance of PV modules. Also, carefully read the Module Data

Sheet provided with this product. Determine local permits, installation and

inspection requirements before installing module(s). If not otherwise specified, it is

recommended that the requirements of the National Electric Code (NEC) be

followed.

Page 3 of 15

www.waaree.com

Sun Power Forever

WEL/ IM/ 05/ 18.10.2014

The photovoltaic Module produces electricity when exposed to the sunlight, even at low light levels or when

other sources illuminate the front face. The voltage of a single Module is less than 50 V DC. However, the

voltage increases as Modules are connected in series and the available current increases as the Modules are

connected in parallel. Thus, for a Module connected within a system, contact with electrically active parts of

the Module such as terminals can result in lethal shock, sparks and burns. The only way to eliminate this

hazard is to prevent exposure of the Module(s) to light.

To avoid the hazard of electric shock and injury when installing,

wiring, operating and maintaining the PV modules, below guidelines

shall be strictly followed.

Cover the entire front surface of the PV Module with a dense, opaque material such as cardboard box,

during installation and handling of the Modules.

Do not expose Back sheet directly to sunlight.

Work only under dry conditions, with dry Modules and Insulated tools.

Be sure to completely ground all Modules.

Since sparks may occur, do not install the Module where flammable gases or vapors are present.

Module installation and operation should be performed by qualified personnel only. Children and

unauthorized persons should not be allowed near the installation of PV Modules.

Use Module for its intended function only.

Be sure that all other system components are compatible, and they do not subject the Module to

mechanical or electrical hazards.

Do not touch terminals while Module is exposed to light or during installation. As a precaution use

properly insulated tools only.

Do not damage or scratch the back sheet of the Module.

Do not use the junction box to hold or transport the Module.

Do not drop Module or allow objects to fall on the Module.

Do not stand or step on the Module.

Do not disassemble, modify or adapt the Module or remove any part or labeling installed/ pasted by the

manufacturer.

When carrying a Module, two or more people should carry it by its frame wearing non-slip gloves (to

avoid injury by a slipped Module, or by the edge of frame, and so on).

Only PV Modules with the same cell type and size should be connected in series.

Avoid uneven shade on the PV Module surface. Shaded cells may become hot (hot spot phenomenon)

which may result in permanent damage to the Module.

Do not drill holes in the frame or glass of the Module, it may compromise the frame strength and cause

corrosion of the frame and also voids the warranty.

Do not treat back sheet and front surface of the Module with paint and adhesives.

Do not artificially concentrate light on the Module.

Do not wear metallic jewelry while installing or trouble shooting the Module.

Page 4 of 15

www.waaree.com

Sun Power Forever

WEL/ IM/ 05/ 18.10.2014

Do not change the wiring of bypass diodes.

CAUTION: In any case DO NOT STAND OR STEP on the modules, Do not drop or place

objects on the module(s) (such as tools), do not thump / give extra pressure on the

surface of the module(s) as localized high loads can induce severe micro-cracks at the

cell level, which in turn may compromise module reliability. Failure to comply with

above caution will void WAAREEs warranty.

GUIDELINES & PRECAUTIONS FOR UNPACKING, HANDLING & STORAGE OF

PV MODULE

The handling of Modules requires great diligence. Therefore, caution is required while unpacking,

transporting and temporarily storing these Modules.

Unpack Module pallet with extreme care. Be careful while unpacking, transporting and storing the

Modules. Avoid Module mishandling during unloading.

Do not stack more than the maximum amount of allowable pallets on top of each other.

At the installation site, take care to keep Modules and particularly their electrical contacts clean.

Do not carry the Module on Head.

When carrying a bigger Module, two or more people should carry it by its frame and wear non-slip

gloves (to avoid injury by a slipping Module, cuts by the edge of a frame etc.). Do not leave the Module

unsupported or unsecured prior to installation.

Store Modules in a dry and ventilated room.

Do not place Modules on an uneven surface, for example, wind can cause a Module which is leaning

against a fence to fall and break.

Avoid applications of excessive bending or twisting of the Module, it may cause severe micro-cracks at

the cell level, which in turn may compromise Module reliability.

A Module with broken glass or torn backsheet cannot be repaired and must not be used since contact

with any Module surface or the frame can produce electrical shock.

Page 5 of 15

www.waaree.com

Sun Power Forever

WEL/ IM/ 05/ 18.10.2014

Broken or damaged Modules must be handled carefully and disposed off properly. Broken glass can be

sharp and may cause injury if not handled with appropriate protective equipment.

Do not stand, step, walk and/or jump on the Module. Do not drop or place objects on the Modules (such

as tools.)

Do not mark the Modules with sharp instrument. Particularly attention should be taken to avoid Module

backsheet to come in contact with sharp objects, as scratches may directly affect product safety and

reliability.

CLIMATIC CONDITIONS

The relative humidity shall be below 85 %.

WAAREE Modules are rated for Mechanical load 5400 Pa on the front and 2400 Pa on the rear.

Operating Temperature of Modules shall be within -40C to 85C with ambient temperature -20C to

50C

Note: - Rated electrical characteristics are within 10% of the values measured at Standard Test Conditions

(STC) of 1000W/m2 irradiance, 25C cell temperature and AM 1.5.

Under normal conditions, a photovoltaic Module may experience conditions that produce more current

and voltage than reported at standard component test conditions. Accordingly, the values of Isc and Voc

marked on UL listed Modules should be multiplied by a factor of 1.25 when determining voltage ratings,

conductor capacities, fuse sizes, and size of controls connected to the Module output.

NOTES ON INSTALLATION

Please read this guide completely before installation or use of the Modules.

Modules shall be mounted with the orientation and tilt angle required for consistent performance

(seasonally, yearly). The location selected shall have direct access to sunlight from 9:00A.M. to 3.00P.M.

on the shortest day of the year. Calculate the tilt angle by using the site latitude, with Modules facing

south in the northern latitudes and north in the southern latitudes. This will result in consistent energy

output throughout the year.

A minimum slope of 5 in/ft. for installation over a roof is required to maintain the fire class rating.

Refer to your local authority for guidelines and requirements for building or structural fire safety. For

roof application, the Modules should be mounted over a fire resistant covering rated for the application.

Modules should be firmly fixed in place in a manner suitable to withstand all expected loads, including

wind and snow loads. Module mounting holes are provided for easy installation and proper mechanical

loading.

The Modules shall be mounted so that the junction box remains in the uppermost position to minimize

the ingress of moisture/water.

Appropriate material should be used for mounting hardware to prevent the Module frame, mounting

structure etc. from corrosion.

Install Modules where they are not shaded by obstacles like buildings and trees. Especially pay attention

to avoid partial shading of Modules by obstacles during the daytime.

Page 6 of 15

www.waaree.com

Sun Power Forever

WEL/ IM/ 05/ 18.10.2014

Clearance between the Module frame and the mounting surface is required to allow cooling air to

circulate around the back of the Module. This also allows any condensation or moisture to dissipate. The

Module should never be sealed to the mounting surface with sealant that prevents air from circulating

under the Module. For roof mounted systems, provide adequate rear ventilation (100mm: 4inch gap

minimum) for cooling of Modules.

Please contact WAAREES authorized representative for any questions regarding mounting profiles for

Modules.

SPECIFICATIONS

Please refer latest Module datasheet for Specifications.

SOLAR PV MODULE MOUNTING GUIDELINES

General Mounting Guidelines:

The Module should be facing true south in northern hemisphere and true north in southern hemisphere

for maximum power production.

We recommend leaving a space of at least 10 mm between two Modules considering linear thermal

expansion of the Module frames.

Since sparks may occur, do not install the Module where flammable gases or vapors are present.

During installation all local and national electrical and building codes and regulations shall be strictly

observed.

Avoid using a mounting method that will block the drainage holes in the Module frame.

Do not install SPV Modules in a location where they will be immersed in or continually exposed to water.

Site-specific loads such as wind and snow need to be taken into consideration to ensure that the

pressure of such a load does not exceed the specified maximum load.

Always abide by the instructions and safety precautions included with the Module. The mounting

structure and all hardware like bolts, nuts and washers should be of stainless steel so as to eliminate the

possibility of rust.

When installing a free standing ground mounted system, be sure to select the appropriate height of the

support Module mounting structure. It is also important to select the appropriate height of the

mounting system to prevent the lowest edge of the Module from being covered by snow for a long time

in areas that experience heavy snowfall.

Page 7 of 15

www.waaree.com

Sun Power Forever

WEL/ IM/ 05/ 18.10.2014

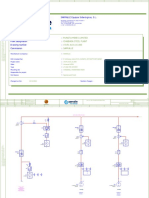

A Sample drawing is shown for installation of Module

(a) Mounting guidelines for Bolting of Modules:Modules must be mounted on mounting holes located at rear side with the M6 stainless steel nut, bolt and

washer. It is recommended to use stainless steel fixing only. Module mounting must use the pre-drilled

mounting holes in the frame. Always select the length of mounting screw after considering a clearance of 510 mm between the Module back face & screw face to avoid any breakage of Module while tightening.

Note: - Do not drill additional mounting holes on the frame & glass surface of the Module.

Doing so will void the warranty.

1.

2.

3.

4.

5.

Aluminium Frame

M6 Stainless bolts

Flat Stainless washer

Spring Stainless washer

HEX Stainless Nut

(b) Mounting guidelines for Clamping of Modules:Each Module must be securely fixed to the mounting structure at a minimum of four points. The Module

clamps shall not come into contact with the front glass and must not deform the frame. Be sure to avoid

shadowing effects from the Module clamps. The Module frame is not to be modified under any

circumstances. When choosing this type of clamp-mounting method, please be sure to use at least four

clamps on each Module, two clamps should be attached on each long sides and 2 clamps on each short side

of the Module. Depending on the local wind and snow loads, if excessive pressure load is expected,

additional clamps or support would be required to ensure that the Module can bear the load. The applied

Page 8 of 15

www.waaree.com

Sun Power Forever

WEL/ IM/ 05/ 18.10.2014

torque shall be big enough to fix it steadily. For safety, it is better to follow the clamp manufacturers

recommendations.

Clamp types:-

Mid clamps: - They hold each neighbouring panel on the purlin.

End clamps: They hold the panel at fringes at their position.

INSTALLATION DIAGRAM:Fringe module installation

Middle module installation

Page 9 of 15

www.waaree.com

Sun Power Forever

WEL/ IM/ 05/ 18.10.2014

2400 Pa

5400 Pa

Note: - The clamp position must be in range L/8 e L/4, a 6cm

GROUNDING

All Module frames and mounting racks must be properly grounded in accordance with respective national

electrical code. The earth grounding connection shall be done by a qualified electrician. The longer sides of

the Module frames are equipped with predrilled Earthing holes in their centre. These holes shall be used only

for grounding purposes and not for mounting purpose. The grounding wire must be properly fastened to the

Module frame to assure good electrical contact. Use the recommended type or an equivalent connector for

this wire.

Module frames should be connected to an earth ground for safety and protection from lightning. A good

connection between the grounding hardware is essential for an effective ground. The anodization on a

Module frame provides a coating to minimize the corrosion due to weather and it acts as a barrier that

reduces the effectiveness of the grounding connection. For an adequate ground, the grounding hardware

should pierce the anodization layer. WAAREE Modules are provided with earthing hole and same must be

used for the purpose.

Page 10 of 15

www.waaree.com

Sun Power Forever

WEL/ IM/ 05/ 18.10.2014

Proper grounding is achieved by bonding the Module frame(s) and all metallic structural members together

continuously using a suitable grounding conductor. The grounding conductor or strap may be copper, copper

alloy, or any other material acceptable for use as an electrical conductor. The devices have to be installed in

accordance with the grounding device manufacturers specified instructions. The grounding must be cross

verified for its proper continuity.

Note: - Please avoid negative bias of the cells with respect to the grounded frames.

ELECTRIC WIRING

All wiring should be done in accordance with applicable electrical codes.

All wiring should be done by a qualified, licensed professional. Wiring should be protected to help

ensure personal safety and to prevent its damage.

Modules can be wired in series to increase voltage. Connect wires from positive terminal of one Module

to the negative terminal of the next Module. All Modules connected in series should be of the same

model number and/or type.

Connect Modules in parallel to increase current. Connect wires from the positive terminal of the one

Module to the positive terminal of the next Module. Do not connect Modules in parallel without using a

connection box.

WAAREE Modules contain factory installed bypass diodes. If the Modules are incorrectly connected to

each other, the bypass diodes, cables, or junction box may be damaged.

The term array is used to describe the assembly of several Modules on a support structure with

associated wiring. Use wire that is sunlight resistant and is insulated to withstand the maximum possible

system open circuit voltage. Check your local codes for requirements.

Use system wiring with suitable cross-sectional areas and connectors that are approved for use at the

maximum short-circuit current of the Module.

The maximum open circuit voltage of the system must not be greater than the specified maximum

system voltage for the Module. The Module open-circuit voltage (Voc) increases with decrease in

temperature and therefore allowable maximum system voltage must take into account the lowest

temperature that is attainable in the area where the Module is intended to be used.

When reverse currents can exceed the value of the maximum protective fuse, a properly rated and

certified over current device (fuse or circuit breaker) must be connected in series with each Module or

string of Modules.

Match the polarities of cables and terminals when making the connections; failure to do so may result in

damage to the Module.

Connecting Modules in reverse polarity to a high current source, such as a battery, will destroy the

bypass diodes and render the Module inoperative. Bypass diodes are not user replaceable.

The junction box, cable and connectors shall not be altered in any case. Modules with a suspected

electrical problem should be returned to WAAREE for inspection and possible repair or replacement as

per the warranty policy shall be provided by WAAREE.

Page 11 of 15

www.waaree.com

Sun Power Forever

WEL/ IM/ 05/ 18.10.2014

CABLE PROTECTION

The values of short-circuit current and open-circuit voltage marked on this Module should be multiplied

by a factor of 1.25 when determining component voltage ratings, conductor current carrying capacity,

fuse sizes and size of controls connected to the PV output.

Secure the cables to the mounting system using UVresistant cable ties.

Protect exposed cables from damage with appropriate precautions (e.g. locate them within plastic

conduit).

Avoid exposure to the direct sunlight.

Ensure that the cables will be away from areas where water can form puddles.

When disconnecting wires under load, an electric arc may result. Such arcs may start fires and may

otherwise create problems. To disconnect the PV system while under load, turn off the inverter first and

then switch on the DC-circuit breaker.

DIODES

BYPASS DIODES

When the Modules are shaded partially, it may cause reverse voltage across cells or Modules, because the

current from other cells in the same series is forced to flow through the shaded area. This may cause

undesirable heating to occur. When a bypass diode is wired in parallel with the series string, the forced

current will flow through the diode and bypass the shaded Module, thereby minimizing Module heating and

array current losses. The use of a diode to bypass the shaded area can minimize both heating and array

current reduction.

Note: - All WAAREE Modules are equipped with factory installed bypass diodes. The factory installed diodes

provide proper circuit protection for the systems within the specified system voltage, so that you do not need

any other additional bypass diodes. If your system specifications require you to add or change diodes, please

contact authorized WAAREE representative for recommendations for the proper diode type.

BLOCKING DIODES

Blocking diodes are typically placed between the battery and the PV Module output to prevent battery

discharge at night. WAAREE Modules do not contain a blocking diode when shipped from the factory. It is

recommended that a charge controller be used to prevent the batteries from being overcharged and

discharged at night.

Note: - The non-use of blocking diode or any reverse current protection in battery operated system will void

all applicable warranties.

Page 12 of 15

www.waaree.com

Sun Power Forever

WEL/ IM/ 05/ 18.10.2014

MAINTENANCE SAFETY

Safety instructions must be followed during maintenance of PV Modules. Any Maintenance work must be

performed by a certified installer/servicer to ensure system integrity and safety.

Do not pull the PV cables. Do not place/drop objects onto the PV Modules.

Do not damage, pull, bend or place heavy material on Junction box, cables & connectors.

Upon completion of any service or repairs, ask the installer/servicer to perform routine checks to

determine that the PV Modules are in safe and proper operating condition.

Do not stand or step on the Module.

Do not disassemble, modify or adapt the Module or remove any part or labeling installed/ pasted by the

manufacturer.

Do not drill holes in the frame; do not treat back sheet and front surface of the Module with paint and

adhesives.

Do not artificially concentrate light on the Module.

GENERAL SAFETY

Follow all permission, installation and inspection requirements.

Before installing Modules, contact the appropriate authorities to determine permissions,

installation, and inspection requirements which shall be followed.

Electrically ground Modules for all systems of any voltage.

If not otherwise specified, it is recommended that requirements of the latest National Electrical Code or

other national or international electrical standards be used.

Be sure that the construction or structure (roof, facade, etc.) where the Modules are being installed has

enough strength. For Modules mounted on roofs, special construction or structures may be required to

help provide proper installation. Both roof construction and Module installation design affects the fire

resistance of a building. Improper installation may contribute to fire hazards. Additional devices such as

ground fault detector, fuses, and disconnects may be required.

Do not use Modules of different specifications in the same system.

Only PV Modules with the same cell size should be connected in series.

Follow all safety precautions of other system components used.

Wiring and grounding method of the frame of arrays shall comply with national, regional and local

codes, laws and standards.

PV Modules shall be installed and maintained by qualified personnel, only installation/service personnel

should have access to the PV Module installation site.

Keep children away from PV Modules.

Prior to installation, do not store Modules outdoors or in a damp environment.

When PV Modules are installed on roofs or any other structures above ground, appropriate safety

practices should be followed and appropriate safety equipment should be used in order to avoid

possible safety hazards. Note that the installation of PV Modules on some roof types may require the

addition of fireproofing, as required by local building/fire codes.

Follow all safety precautions of other components used in the system.

Page 13 of 15

www.waaree.com

Sun Power Forever

WEL/ IM/ 05/ 18.10.2014

In order to avoid risk of injury or electrical shock, do not allow anyone (unqualified or having limited

knowledge of PV Modules) to handle damaged PV Modules. Place defective PV Modules in cartons so

that no light falls on PV cell.

Avoid uneven shade on the PV Module surface. Shaded cells may become hot (hot spot phenomenon)

which may result in permanent damage to the Module.

Never expose PV Modules to sunlight concentrated with mirrors, lenses or other means.

The maximum open circuit voltage of an array must not be greater than the specified maximum system

voltage. Voltage is directly proportional to the number of PV Modules in series and is affected by

weather conditions.

GUIDELINES & PRECAUTIONS FOR CLEANING OF PV MODULE

It is common for dust and dirt particles to accumulate on the surface of the Module. This can reduce the

optimal output performance of the solar Modules. Normally, the accumulated dust can be washed with

water, but in some instances some maintenance is recommended to clean the surface of the glass with

water and a soft cloth or sponge to remove layer of dirt. A mild non-abrasive detergent may be applied

to remove persistent dirt.

PV Module Cleaning should be done only by properly trained personnel who understand the risks of

applying water to electrical components.

It is advisable to perform periodic inspection of the Modules for damage to glass, backsheet, frame,

junction box or external electrical / loose connections and corrosion by the authorized professional.

No aggressive and abrasive cleansers or chemicals should ever be used on the coated front glass. No

alkali-based chemicals should be used, including ammonia based solutions.

Always wear rubber gloves for electrical insulation while maintaining, washing or cleaning

Modules. Appropriate electrically insulating Personal Protective Equipment (PPE) must be worn during

any cleaning or inspection operations.

Acceptable Module cleaning methods are to spray the Modules with low-pressure water closely

matched in temperature to the Module or to use a dry brushing technique. Do not apply water that is

more than 20C warmer or colder than Module surface temperature as during the generation time the

temperature of Module is higher and washing may cause thermal stress in Module.

Always make sure that Cleaning should not be done during Generation time, the recommended time to

clean Modules is from dusk to dawn when production is not affected and risk of electrical shock hazard

is minimized.

For cleaning of Modules Fresh water (TDS < 1500 mg/l) may be used. If needed, a mild, non-abrasive,

non-caustic detergent with a final fresh water and detergent solution mix between 6.5 < pH < 8.5 at 25C

may be used.

When using water, RO water provides the best results. In absence of RO water, tap water with low

mineral content (total hardness <75 mg/l) or deionized water may be used. Calcium should not exceed:

75 mg/ml. Do not use solutions containing hydrochloric acid, D-Limonene, ammonia or sodium

hydroxide.

Clean the Module either with a soft sponge or a soft rubber wiper. Do not use abrasive cleaners or degreasers on the Module. Do not scrub the Module with abrasive brushes. Such brush fibers may scratch

the glass, reducing the power output of the panel.

Page 14 of 15

www.waaree.com

Sun Power Forever

WEL/ IM/ 05/ 18.10.2014

In case if soft water (with low mineral content) is not available, Module can be dry cleaned with the help

of a soft cloth or with soft sponge to remove dirt, dust. One can also use wet cloth, sponge to clean dirt

which is not easily removed by dry cleaning.

Do not clean or spray water at the Junction Box or any area on the backside of the Module.

Frequency of Cleaning will vary depending upon any special conditions in the area where the Modules

are installed. Modules installed in high windy or dusty areas should be inspected more frequently.

If excessive soiling is present, a non-conductive soft brush, sponge, or other mild agitating method may

be used before using water. Ensure brushes or agitating tools are not abrasive to glass.

Module damage that arises as a result of improper cleaning will not be warranted by WAAREE Energies

Ltd.

Do not clean the glass surface with chemicals. Do not let water stay on the glass surfaces of PV Modules

for a long time. This creates a risk of permanent damage to the glass, such as white efflorescence,

otherwise known as glass disease, which may cause reduced power output.

To avoid dirt accumulation or white efflorescence due to water accumulation, do not install PV Modules

horizontally (flat).

WAAREE ENERGIES LIMITED

602, Western Edge-I, Off. Western Express Highway

Borivali (E), Mumbai 400066, Maharashtra, India

Tel: +91-22-66444400

waaree@waaree.com

Page 15 of 15

www.waaree.com

Sun Power Forever

You might also like

- Online OgilvieDocument7 pagesOnline Ogilvietito1628No ratings yet

- How To: Use The GLP Feature On The Groline HI981420 Hydroponics MonitorDocument1 pageHow To: Use The GLP Feature On The Groline HI981420 Hydroponics Monitoramerican_guy10No ratings yet

- CR PDFDocument48 pagesCR PDFamerican_guy10No ratings yet

- EWM Rules 2016 English 23.03.2016Document42 pagesEWM Rules 2016 English 23.03.2016Mukesh PadwalNo ratings yet

- Calculating A PH Slope Percentage Hanna Instruments PDFDocument2 pagesCalculating A PH Slope Percentage Hanna Instruments PDFamerican_guy10No ratings yet

- En 12756Document10 pagesEn 12756scribdetc88100% (1)

- Lecture Electro-Chemical ProcessesDocument6 pagesLecture Electro-Chemical Processesamerican_guy10No ratings yet

- Lecture Electro-Chemical Processes PDFDocument61 pagesLecture Electro-Chemical Processes PDFamerican_guy10No ratings yet

- MicroDelightRecipe BookDocument10 pagesMicroDelightRecipe Bookamerican_guy10No ratings yet

- AN-392 Application Note: Circuit Design and Applications of The ADM663A/ADM666A Micropower Linear Voltage RegulatorsDocument8 pagesAN-392 Application Note: Circuit Design and Applications of The ADM663A/ADM666A Micropower Linear Voltage Regulatorsamerican_guy10No ratings yet

- Lecture Electro-Chemical ProcessesDocument6 pagesLecture Electro-Chemical Processesamerican_guy10No ratings yet

- Rubber PolicemanDocument2 pagesRubber Policemanamerican_guy10No ratings yet

- Case Studies On Implementing Low-Cost Modification To Improve Potw Nutrient Reduction-Combined 508 - AugustDocument147 pagesCase Studies On Implementing Low-Cost Modification To Improve Potw Nutrient Reduction-Combined 508 - Augustamerican_guy10No ratings yet

- Foster Cold Room ManualDocument45 pagesFoster Cold Room Manualamerican_guy10100% (1)

- Rubber PolicemanDocument2 pagesRubber Policemanamerican_guy10No ratings yet

- Lecture 7Document55 pagesLecture 7Pavan KalyanNo ratings yet

- 4Document4 pages4american_guy10No ratings yet

- En2703 2C-4Document7 pagesEn2703 2C-4american_guy10No ratings yet

- BLG UNDP 77.2 Rev1 pg1-35Document18 pagesBLG UNDP 77.2 Rev1 pg1-35american_guy10No ratings yet

- Scrubber PDFDocument20 pagesScrubber PDFamerican_guy10No ratings yet

- AnaerobicDigestion PDFDocument7 pagesAnaerobicDigestion PDFamerican_guy10No ratings yet

- 10 Steps To Cleaning A Spill in A Biosafety CabinetDocument8 pages10 Steps To Cleaning A Spill in A Biosafety Cabinetamerican_guy10No ratings yet

- FAQ On EstatesDocument20 pagesFAQ On Estatesseeyem2000No ratings yet

- BioTreatmentTypes PDFDocument5 pagesBioTreatmentTypes PDFamerican_guy10No ratings yet

- Total SolidsDocument6 pagesTotal SolidsGabriel Vitola DíazNo ratings yet

- Specification For Epoxy Flooring in UHV LabDocument4 pagesSpecification For Epoxy Flooring in UHV Labamerican_guy10No ratings yet

- 1 Fruergaard Advanced Aseptic Processing ISPEDocument57 pages1 Fruergaard Advanced Aseptic Processing ISPEamerican_guy10100% (1)

- b2 13 Media FillsDocument23 pagesb2 13 Media FillsBrian WilliamsNo ratings yet

- Analisis de Riesgo 2010MA-Online - QuintoDocument9 pagesAnalisis de Riesgo 2010MA-Online - QuintoSteven Correa MNo ratings yet

- 582 1749 1 PBDocument5 pages582 1749 1 PBamerican_guy10No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Fusion Module 1000 ADocument102 pagesFusion Module 1000 ASaile TenorioNo ratings yet

- An Overview of ESD Protection DevicesDocument5 pagesAn Overview of ESD Protection DevicespguadagniniNo ratings yet

- Medical Equipment and SuppliesDocument2 pagesMedical Equipment and SuppliesJanna FabiaNo ratings yet

- Design and Analysis of Threaded Fasteners and JointsDocument41 pagesDesign and Analysis of Threaded Fasteners and JointsRa Balamurugan67% (3)

- Practical Electronics 1969 10Document92 pagesPractical Electronics 1969 10Carlos Soares100% (2)

- Fans Static Head Calculation SheetDocument1 pageFans Static Head Calculation SheetraifaisalNo ratings yet

- Cutler-Hammer: Learning Module 26: DevicenetDocument41 pagesCutler-Hammer: Learning Module 26: Devicenetksenthil77No ratings yet

- Parker SSD 650 Easy Start GuideDocument17 pagesParker SSD 650 Easy Start Guideeng_karamazabNo ratings yet

- 240 Preventive Check Sheet of Tube Bending Machine ReDocument4 pages240 Preventive Check Sheet of Tube Bending Machine ReAjayNo ratings yet

- 3.4.1.7 Lab - Research A Hardware UpgradeDocument2 pages3.4.1.7 Lab - Research A Hardware UpgradeLinnaNo ratings yet

- An Amazing Journey Into The Depth of My Hard DriveDocument37 pagesAn Amazing Journey Into The Depth of My Hard DriveDenis KalabinNo ratings yet

- P3-No.10.9 TBEA Power Transformer BrochureDocument28 pagesP3-No.10.9 TBEA Power Transformer Brochurehamza shahzadNo ratings yet

- TM100 ManualDocument2 pagesTM100 Manualefrain rivasNo ratings yet

- CRT, LCD, LED, TV Technologies Like Liquid Crystal DisplayDocument28 pagesCRT, LCD, LED, TV Technologies Like Liquid Crystal DisplayKundan VanamaNo ratings yet

- GP Electronic Wiring DiagramDocument2 pagesGP Electronic Wiring DiagramRamon Thales DomeniconiNo ratings yet

- 6.target Finding BuggyDocument5 pages6.target Finding BuggySumith KumarNo ratings yet

- G9190 Motor Grader Parts CatalogDocument393 pagesG9190 Motor Grader Parts Catalogမင္း သီဟ100% (4)

- Electromagnetic Brakes ClutchesDocument8 pagesElectromagnetic Brakes Clutchesfsilassie8012100% (1)

- Model 1207: Microprocessor Motor Speed ControllersDocument2 pagesModel 1207: Microprocessor Motor Speed ControllersBortomaq100% (1)

- Sewing Tools and EquipmentDocument8 pagesSewing Tools and EquipmentChareLyn CaronggayNo ratings yet

- Design and Analysis of Electrical SystemDocument8 pagesDesign and Analysis of Electrical Systemphyohtet201525No ratings yet

- Description Features: 3-Channel High-Performance TCXO/LVCMOS Clock Buffer Family 5PB12xx DatasheetDocument16 pagesDescription Features: 3-Channel High-Performance TCXO/LVCMOS Clock Buffer Family 5PB12xx Datasheetreza_azadNo ratings yet

- 19191.6101.01.000 LF MCC Single Line DiagramDocument5 pages19191.6101.01.000 LF MCC Single Line DiagramSOUMENNo ratings yet

- TM1 RM1Document16 pagesTM1 RM1Nikulas HawlaNo ratings yet

- Computer Networking Lab Manual TitleDocument4 pagesComputer Networking Lab Manual Titlemusfirah hamidNo ratings yet

- REF - NO.PSE/P 2603-2 List: HBL Power Systems LTDDocument22 pagesREF - NO.PSE/P 2603-2 List: HBL Power Systems LTDmukesh_kht1No ratings yet

- Vhf/Uhf: Dual-Band Twinlead J-Pole AntennaDocument2 pagesVhf/Uhf: Dual-Band Twinlead J-Pole AntennaPABLO MAURONo ratings yet

- Test Report Rev.02 Doosan BobcatDocument1 pageTest Report Rev.02 Doosan BobcatHamoda HananNo ratings yet

- Service Manual: USB/MP3/CD/Micro Systems MC-5210SUDocument32 pagesService Manual: USB/MP3/CD/Micro Systems MC-5210SUhumberto100% (1)

- Allen-Bradley Parts: Installation InstructionsDocument76 pagesAllen-Bradley Parts: Installation InstructionsSting EyesNo ratings yet