Professional Documents

Culture Documents

Design and Analysis of Fog Removal System For Helmet

Uploaded by

esatjournalsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Analysis of Fog Removal System For Helmet

Uploaded by

esatjournalsCopyright:

Available Formats

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

DESIGN AND ANALYSIS OF FOG REMOVAL SYSTEM FOR HELMET

Vivek Verma1, Ashwani Sharma2, Ashwini Kumar Shrivastava3, Himal Hazra4

1

2

Assistant Professor, Mechanical and Automation Engineering, Amity University, U.P, India

Assistant Professor, Mechanical and Automation Engineering, Amity University, U.P, India

3

Student, Mechanical and Automation Engineering, Amity University, U.P, India

4

Student, Mechanical and Automation Engineering, Amity University, U.P, India

Abstract

This paper deals with the design and analysis of fog removal system for motorcycle helmet. The system consists mainly of a

resistive wire for thermal convection between the heating element and the helmet visor. When electrical voltage is applied to the

heating element, it will create a temperature difference across the helmet visor. The model is designed and thermal analysis has

been carried out using Ansys. The analysis shows efficient mist removal from the visor in few minutes.

Keywords: - Fog Removal System, Helmet, Thermal Convection, Thermal Analysis

--------------------------------------------------------------------***---------------------------------------------------------------------1. INTRODUCTION

The continuous development of automobile industry has

revolutionized new invention, not only for the safety, but

also for comfort of the rider. In winter most of the northern

India suffers from foggy morning with less to none

visibility. The concern over the safety of vehicle drivers in

foggy weather has pushed for invention of new equipment

that can save lives. This project is based on the working of a

fog removal system, which uses a heating element system,

and bike battery for its energy source the design is simple

and hence cost effective.

2. BACKGROUND

During winter we often face fog. Fog is a natural

phenomenon in which cloud water or ice crystal stays in a

suspended stagnant motion heavily influenced by nearby

water body or by low atmospheric temperature, fog reduces

visibility to up to less than 1 km. Formation of fog starts

from when water vapor condenses into tiny water droplet, as

to how water is added, by convergence into upward motion

precipitation from above, daytime heating evaporation,

transpiration from plants, trees, cool air moving over

warmer water. Fog occurs at a relative humidity near 100%,

this occurs by either addition of water vapor or falling in

ambient temperature.

Fog is a natural phenomena but it also cause major problem

for riders and vehicle drivers, Cloud, fog, mist droplets are

very small, their mean diameter is actually around 10- 15

micron , but the question lies why rider or driver have

problem in seeing while water is transparent in nature?

Answer will be as water droplets are small and large in

number, light ray scatters around them neither reflecting nor

refracting, and hence it only gives a sense of vision nothing

clear at all. Now due this the water droplets which is

stagnant in nature sticks to the visor of the rider now

fogging on the visor occurs due to drastic temperature

difference in inside the visor and the ambient temperature,

when the rider breathes he exhales hot air through nose or

mouth the visor being cold as it has been exposed due to

cold weather comes in contact with hot air, the air condenses

on the visor due to which it fogs up the visor and hence

render difficulties to the rider.

Hence to remove this difficulty various ideas are being

implemented for car rider they have various techniques to

remove fogging difficulties comes to the motor cycle riders,

now this is where our project throws light fog removal

system for helmet. There are various methods to remove fog

from helmet visor like heated element, sonar or UV ray

detection or an externally fitted ventilation system with

forced exhaust system. In this project we have opted for

heated visor system with a nickel plated steel wire heating

the visor externally to remove the fog formation and to

render clear visibility. The project will run its course in

various design and analysis procedure like analysis for heat

producing body, thermal analysis (steady state, transient

state) analysis, CFD analysis, airflow analysis to check

whether the heating element proves viable in cold

conditions.

3. SELECTION AND ANALYSIS OF THE

HEATING MATERIAL

First we thought of using Nichrome (Ni, Fe, Cr alloy) as it is

what they use basically in all heating elements, we obtained

one from an old thermo heater but we did not expect the

heat to be too high that it started melting the polycarbonate

visor on a 12 volt D.C. source. As Nichromeholds a

resistivity of 100 x 10^-8 ohm and a very less conductivity

of 0.10 x 107 / ohm-meter. The electrical resistance depends

on the length area as well as on the material of the wire now

the question was how to choose an element that will provide

a higher resistance but at the same time does no harm to the

visor.The formula which describes the resistance of a wire is

Resistance= resistivity x length/area

R=(l/a)

_______________________________________________________________________________________

Volume: 05 Issue: 05 | May-2016, Available @ http://ijret.esatjournals.org

369

IJRET: International Journal of Research in Engineering and Technology

= resistivity of the material given,

l = length of the material given,

a = area of the material given,

5. JOULES LAW OF HEATING

After various considerations we stumbled upon the idea of

wire we were using wire hence thought of guitar a few

guitar uses nickel plated steel which fall right into our

goldilocks region as steel provides strength and less thermal

expansion and also relatively high temperature without

burning out the visor but when steel plated with nickel gives

it more strength, corrosion resistivity and increases

conductance of electricity.

In metallurgy, stainless steel is defined as a steel alloy with

a minimum composition of 11% chromium content by mass

[3]. Stainless steel does not stains neither corrodes nor rusts

as easily as ordinary steel but not only its stain-proof. It is

also called corrosion resistant steel when the alloy type and

grade are not mentioned,[3] especially in the aviation

industry, there are different types of grades and surface

finishes of stainless steel to suit the environment to which

the material will be subjected in its machine life.

4.

ANALYSIS

AND

SPECIFICATIONS

Polycarbonate properties are higher than its predecessor and

it does provide a high impact strength and excellent strength

retention at high temperatures. It also possesses high tensile,

shear, and flexural strength. It has high modulus of

elasticity and low deformation under load which helps it to

retain a tough structure. It has low coefficient of thermal

expansion and hence doesnt expand much on elevated

temperature. Further it also possesses good electrical

insulation properties and is very easy to fabricate & machine

stuff. Acrylic helps in increasing the visibility by 3% up to

92%.Acrylic is a type of a polymer called poly (methyl

methacrylate) (PMMA), is also known by its commercial

names such as Lucite, Perspex and Plexiglas. It is used as a

sturdy substitute for glass for products such as aquariums,

motorcycle helmet visors, aircraft windows, viewing

windows of submersibles, and lenses of exterior lights of

automobiles. It is widely used to make signs, including

lettering and logos. In medicine, it is used in bone cement

and to replace eye lenses. Acrylic paint consists of PMMA

particles suspended in water.

Refractive Index

1.584-1.586

Water Absorption

0.1%

Tensile Strength

5575 MPa

Elongation

80150%

Hardness Rockwell

M70

Izod Impact

600850 J/m

Poissons Ratio

0.37

The heat is formed due to current flowing in the wire, the

amount of electric current flowing in the wire is directly

proportional to square of the amount of the current flowing

in the circuit I.e. H is directly proportional to the square of

current flowing. Heat is generated due to the flow of current

which is proportional to current flowing in the wire:

H is directly proportional to product of current(i) square

resistance and time.

H = heat generated in joules.

i = current flowing in the wire.

R = resistance of the wire.

j = constant known as mechanical equivalent of heat.

With the help of ohms law we get

OF

POLYCARBONATE ACRYLIC VISOR

Table 1 Various Properties of Polycarbonate Acrylic

Density

1.20-1.22 g/cm^3

eISSN: 2319-1163 | pISSN: 2321-7308

with joules law of heating we can find the amount of heat

energy provided by the wire in unit time when the process is

going taking place.

Table 2. Relationship between Area of the visor and the

Heat Generated.

Area of the Visor

Volume of the

Heat

(m square)

Water(m cube)

Generated

1.80x 10^-7

406.8 Joules

0.0180

1.35 x 10^-7

305.1 Joules

0.0135

0.90 x 10^-7

203.4 Joules

0.0090

0.50

x

10^-7

113.0 Joules

0.0050

0.22 x 10^-7

68.8 Joules

0.0022

Table 3. Relationship between Area of the visor and the

time required to Heat of the mist.

Area of the Visor (m

Time Required to Heat of

square)

the Mist (minutes)

9.95

0.018

7.74

0.0135

4.96

0.009

3.25

0.005

1.68

0.002

Table 4. The relationship between Areas vs. Final

Temperature of the Visor.

Area of the visor

Heat Energy

Final

needs to be heated (Joules)

Temperature in

(m square)

degree Celsius

406.8

38.34

0.0180

305.1

35.11

0.0135

203.4

33.94

0.009

113.4

32.94

0.005

67.80

31.32

0.002

_______________________________________________________________________________________

Volume: 05 Issue: 05 | May-2016, Available @ http://ijret.esatjournals.org

370

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

Figure 1: The graph represent the relationship between Time Required to Heat of the Mist (minutes) and Area of the Visor (m

square).

Figure 2: The graph represents the relationship between Areas vs. Final Temperature.

6. DESIGN OF HELMET AND VISOR

The feature based parametric modeling technique helps a

designer to enable his designs into the original design

content into constructing its desired model. The word

parametric means the geometric definition of designs such

as measurements that can be alter with respect to time.

Processing and creating the main features of the design with

the help of the computer software achieve parametric

modeling. The design constant and variables are described

in sketches and features can be used to quickly modify the

designs.

_______________________________________________________________________________________

Volume: 05 Issue: 05 | May-2016, Available @ http://ijret.esatjournals.org

371

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

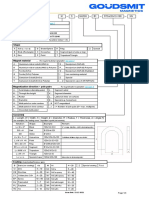

Figure3:The above image show case the all sections of the visor the three wires with diameter of 1 mm is bounded on the visor in

equal interval of 40 mm on a total width of 159 mm.

effects have gone. Use steady-state thermal analysis to find

out temperatures, thermal gradients, heat flow rates, and

heat fluxes in an object that are caused by thermal load in

the model. These loads include:

Convections

RADIATION

Heat flow rates

Heat fluxes (heat flow per unit area)

Heat generation rates (heat flow per unit volume)

Constant temperature boundaries

Figure 4: The final finished product after design modeling

in Creo 2.0

7. THERMAL ANALYSIS OF THE HELMET

AND VISOR

A thermal analysis calculates the temperature distribution

and thermal quantities in or of a system the usual thermal

quantities are specified the temperature distributions, the

amount of heat formed or dissipated, Thermal gradients and

Thermal fluxes.

Thermal simulations are important in designing of many

engineering applications, including internal combustion

engines, turbine, heat exchangers, piping systems and

electronic components. In cases, engineers follow a thermal

analysis to calculate with stress analysis to calculate thermal

analysis.

Steady-state thermal analysis also can be the last step of a

transient thermal analysis; performed after all transient

Solution for Visor Thermal Analysis in:

Temperature

Total Heat Flux

Directional Heat Flux

Besides steady state analysis it also performs transient

thermal analysis follows basically the same steps as a

steady-state thermal analysis. The maincomparison is that

most applied loads in a transient analysis are functions of

time. To specify time-dependentloads, we can either use the

Function Tool to define an equation or function describing

the curve or then applythe function as a boundary condition,

or we can divide the load-versus-time curve into load. After

analysis the file is saved in .wbpj file format.

RESULT&DISCUSSION

The following three images shows the results of thermal

analysis in

Temperature

Total Heat Flux

Directional Heat Flux

_______________________________________________________________________________________

Volume: 05 Issue: 05 | May-2016, Available @ http://ijret.esatjournals.org

372

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

in heat the temperature heat flux and directive heat flux are

all shown in results, proves that the model will hold steady

in a cold weather with high fog density , after analysis is

completed thermal imaging of the model delivers a heat of

28 degree Celsius for 60 sec in surrounding ambient

temperature of 5 degree Celsius smoothly. The helmet is

worn and it shows great improvements in practical

situations however power source is the main issue but for

performance it can be increased.

CONCLUSION

Figure 5 : Temperature variation of visor

The report projects the analysis of the fog removal system to

its utmost content analysis being done on the Ansys shows

us temperature and heat flux variations joules law and

convection with conservation of energy, Creo provides us

with perfect modeling of Helmet and visor while joules law

helps us to calculate the heat energy from the current

flowing in the visor. Care has been taken in all mathematical

calculation. Also riders safety and comfort is also taken

care of so as not only it provides safety but also feeling of

comfort efforts have been made on reducing cost and

increasing effectiveness of the system.

REFRENCE

[1]. Holdeman, J.T. "A Hermite finite element method for

incompressible fluid flow", Int. J. Numer. Meth.

(2010),

[2]. Ladyzhenskaya, O.A., The Mathematical Theory of

viscous Incompressible Flow (2nd ed.) (1969)

[3]. Flake C. Campbell, A Elements of Metallurgy and

Alloys, (1st ed.) 2008

[4]. Emadi, D; L. V. Whiting; S. Nafisi; R. Ghomashchi

Journal of Thermal Analysis and Calorimetry (2005).

Figure 6 : Heatflux variation on the visor

BIOGRAPHIES

Mr. Vivek Verma, Assistant Professor,

Mechanical and Automation Engineering.

Amity

University,

Lucknow

and

vverma@lko.amity.edu

Mr. Ashwani Sharma, Assistant Professor,

Mechanical and Automation Engineering.

Amity

University,

Lucknow

and

ashwani28585@gmail.com

Ashwini Kumar Shrivastava, UG Student of

Mechanical and Automation Engineering,

Amity

University,

Lucknow,

and

ash96shrivastava@gmail.com

Figure 7: Heat Fluxof Helmet and visor after 60 sec.

From ANSYS thermal analysis the result showed the

heating element heats the visor throughout the visor with a

steady and clear heat distribution without any fluctuations

Himal Hazra, UG Student of Mechanical

and

Automation

Engineering,

Amity

University,

Lucknow

and

mercuwings@gmail.com

_______________________________________________________________________________________

Volume: 05 Issue: 05 | May-2016, Available @ http://ijret.esatjournals.org

373

You might also like

- PTE 3 Week Study ScheduleDocument3 pagesPTE 3 Week Study ScheduleesatjournalsNo ratings yet

- An Improved Geo-Encryption Algorithm in Location Based Services PDFDocument4 pagesAn Improved Geo-Encryption Algorithm in Location Based Services PDFesatjournalsNo ratings yet

- An Efficient Information Retrieval Ontology System Based Indexing For Context PDFDocument7 pagesAn Efficient Information Retrieval Ontology System Based Indexing For Context PDFesatjournalsNo ratings yet

- Analysis and Optimization of Sand Casting Defects With The Help of Artificial Neural Network PDFDocument6 pagesAnalysis and Optimization of Sand Casting Defects With The Help of Artificial Neural Network PDFesatjournalsNo ratings yet

- A Study and Survey On Various Progressive Duplicate Detection MechanismsDocument3 pagesA Study and Survey On Various Progressive Duplicate Detection MechanismsesatjournalsNo ratings yet

- Analytical Assessment On Progressive Collapse Potential of New Reinforced Concrete Framed Structure PDFDocument5 pagesAnalytical Assessment On Progressive Collapse Potential of New Reinforced Concrete Framed Structure PDFesatjournalsNo ratings yet

- Analysis of Outrigger System For Tall Vertical Irregularites Structures Subjected To Lateral Loads PDFDocument5 pagesAnalysis of Outrigger System For Tall Vertical Irregularites Structures Subjected To Lateral Loads PDFesatjournalsNo ratings yet

- Analysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFDocument7 pagesAnalysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFesatjournalsNo ratings yet

- Analysis and Characterization of Dendrite Structures From Microstructure Images of Material PDFDocument5 pagesAnalysis and Characterization of Dendrite Structures From Microstructure Images of Material PDFesatjournalsNo ratings yet

- Analysis and Optimization of Electrodes For Improving The Performance of Ring Laser Gyro PDFDocument4 pagesAnalysis and Optimization of Electrodes For Improving The Performance of Ring Laser Gyro PDFesatjournalsNo ratings yet

- An Octa-Core Processor With Shared Memory and Message-Passing PDFDocument10 pagesAn Octa-Core Processor With Shared Memory and Message-Passing PDFesatjournalsNo ratings yet

- Analysis of Cylindrical Shell Structure With Varying Parameters PDFDocument6 pagesAnalysis of Cylindrical Shell Structure With Varying Parameters PDFesatjournalsNo ratings yet

- A Comparative Investigation On Physical and Mechanical Properties of MMC Reinforced With Waste Materials PDFDocument7 pagesA Comparative Investigation On Physical and Mechanical Properties of MMC Reinforced With Waste Materials PDFesatjournalsNo ratings yet

- A Review On Fake Biometric Detection System For Various ApplicationsDocument4 pagesA Review On Fake Biometric Detection System For Various ApplicationsesatjournalsNo ratings yet

- A Review Paper On Smart Health Care System Using Internet of ThingsDocument5 pagesA Review Paper On Smart Health Care System Using Internet of ThingsesatjournalsNo ratings yet

- A Servey On Wireless Mesh Networking ModuleDocument5 pagesA Servey On Wireless Mesh Networking ModuleesatjournalsNo ratings yet

- A New Type of Single-Mode Lma Photonic Crystal Fiber Based On Index-Matching Coupling PDFDocument8 pagesA New Type of Single-Mode Lma Photonic Crystal Fiber Based On Index-Matching Coupling PDFesatjournalsNo ratings yet

- A Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemDocument8 pagesA Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemesatjournalsNo ratings yet

- A Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemDocument8 pagesA Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemesatjournalsNo ratings yet

- I JR Et 20160503007dfceDocument5 pagesI JR Et 20160503007dfcegtarun22guptaNo ratings yet

- A Survey On Identification of Ranking Fraud For Mobile ApplicationsDocument6 pagesA Survey On Identification of Ranking Fraud For Mobile ApplicationsesatjournalsNo ratings yet

- A Servey On Wireless Mesh Networking ModuleDocument5 pagesA Servey On Wireless Mesh Networking ModuleesatjournalsNo ratings yet

- A Critical Review On Experimental Studies of Strength and Durability Properties of Fibre Reinforced Concrete Composite PDFDocument7 pagesA Critical Review On Experimental Studies of Strength and Durability Properties of Fibre Reinforced Concrete Composite PDFesatjournalsNo ratings yet

- A Review On Fake Biometric Detection System For Various ApplicationsDocument4 pagesA Review On Fake Biometric Detection System For Various ApplicationsesatjournalsNo ratings yet

- I JR Et 20160503007dfceDocument5 pagesI JR Et 20160503007dfcegtarun22guptaNo ratings yet

- Ad Hoc Based Vehcular Networking and ComputationDocument3 pagesAd Hoc Based Vehcular Networking and ComputationesatjournalsNo ratings yet

- A Review Paper On Smart Health Care System Using Internet of ThingsDocument5 pagesA Review Paper On Smart Health Care System Using Internet of ThingsesatjournalsNo ratings yet

- A Three-Level Disposal Site Selection Criteria System For Toxic and Hazardous Wastes in The PhilippinesDocument9 pagesA Three-Level Disposal Site Selection Criteria System For Toxic and Hazardous Wastes in The PhilippinesesatjournalsNo ratings yet

- A Women Secure Mobile App For Emergency Usage (Go Safe App)Document3 pagesA Women Secure Mobile App For Emergency Usage (Go Safe App)esatjournalsNo ratings yet

- A Survey On Identification of Ranking Fraud For Mobile ApplicationsDocument6 pagesA Survey On Identification of Ranking Fraud For Mobile ApplicationsesatjournalsNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ICHAZ Microstructure Impacts HSLA Steel ToughnessDocument10 pagesICHAZ Microstructure Impacts HSLA Steel ToughnessFilipe RenanNo ratings yet

- Magnets Design Guide: Table 2.1 Magnet Material ComparisonsDocument44 pagesMagnets Design Guide: Table 2.1 Magnet Material ComparisonsVandear GoalcantaraNo ratings yet

- Fibre Carbon - Tensile Test (Unidirection)Document5 pagesFibre Carbon - Tensile Test (Unidirection)AlsonChinNo ratings yet

- Forces of Attraction Unit 1 CAPE Chem (PDF)Document70 pagesForces of Attraction Unit 1 CAPE Chem (PDF)Shadecia Dinnall100% (1)

- Properties Saturated AmmoniaDocument3 pagesProperties Saturated AmmoniafidelcardenasayalaNo ratings yet

- NETZSCH GlassProcessing CGS eDocument2 pagesNETZSCH GlassProcessing CGS ejojibaNo ratings yet

- Product Key MX - Magnet PermanentDocument4 pagesProduct Key MX - Magnet PermanentFooNo ratings yet

- Catalogo Brossard ParafusosDocument0 pagesCatalogo Brossard ParafusosMarco ViniciusNo ratings yet

- Scribd Download - Com Pipeline Pigging Visit HTTP Piping Info Blogspot ComDocument2 pagesScribd Download - Com Pipeline Pigging Visit HTTP Piping Info Blogspot Comeng20072007No ratings yet

- Technical Studies & Research Center Mechanical Technology Branch Mechatronics Graduate Program Machine Element, Course Fall 2008-09Document30 pagesTechnical Studies & Research Center Mechanical Technology Branch Mechatronics Graduate Program Machine Element, Course Fall 2008-09PRASAD326100% (11)

- Application Note-G-PAEK - PEK (Polyether Ketone) An Ideal Polymer For Nuclear Power SectorDocument6 pagesApplication Note-G-PAEK - PEK (Polyether Ketone) An Ideal Polymer For Nuclear Power SectorjlsinghNo ratings yet

- Mae 1153 Characteristics For DurabilityDocument9 pagesMae 1153 Characteristics For DurabilityMohammad AL HaririNo ratings yet

- Material Data Sheet for S355J2 Structural Steel GradeDocument3 pagesMaterial Data Sheet for S355J2 Structural Steel Gradedinesh kumarNo ratings yet

- Software Verification Test of SAFE ProgramDocument5 pagesSoftware Verification Test of SAFE ProgramHaytham ZaghloulNo ratings yet

- Materials Today: ProceedingsDocument6 pagesMaterials Today: ProceedingsزهرةالياسمينNo ratings yet

- DS-DuraForm Flex Plastic USDocument2 pagesDS-DuraForm Flex Plastic USBahadır UysalNo ratings yet

- AS5430 A1semi PDFDocument9 pagesAS5430 A1semi PDFMarco MachadoNo ratings yet

- Shear in Reinforced Concrete BeamsDocument3 pagesShear in Reinforced Concrete Beamsksshashidhar100% (1)

- 2 - Hydrostatic - Pressure - Update OCT20 PDFDocument62 pages2 - Hydrostatic - Pressure - Update OCT20 PDFfaiz291No ratings yet

- Glaeser 2nd Chapter OneDocument28 pagesGlaeser 2nd Chapter OneSheri DeanNo ratings yet

- Final Programme of Frontiers of NanoEngineeringDocument11 pagesFinal Programme of Frontiers of NanoEngineeringCinthya ToroNo ratings yet

- Analysis of Heat and Mass Transfer in Cooling Tower FillDocument8 pagesAnalysis of Heat and Mass Transfer in Cooling Tower FillabdulazizrohmanhakimNo ratings yet

- PPE AssignmentDocument16 pagesPPE AssignmentlibbissujessyNo ratings yet

- Review of Nanofluids For Heat Transfer Applications (Edit)Document10 pagesReview of Nanofluids For Heat Transfer Applications (Edit)mohamed mustafaNo ratings yet

- Electrcal 300l AttendanceDocument4 pagesElectrcal 300l AttendancebennykurfNo ratings yet

- Load Factor Load: Project:-Location: - Design Code: Designed by DateDocument1 pageLoad Factor Load: Project:-Location: - Design Code: Designed by DateSantosh BapuNo ratings yet

- Four-Die Radial Forging Device - An Attached Improvement For Conventional Forging PressesDocument9 pagesFour-Die Radial Forging Device - An Attached Improvement For Conventional Forging PressesMin HanNo ratings yet

- Heat Transfer and Pressure Drop in Heat ExchangerDocument13 pagesHeat Transfer and Pressure Drop in Heat ExchangernocheslargasNo ratings yet

- 1 s2.0 S0043135416301270 MainDocument31 pages1 s2.0 S0043135416301270 MainhernanfloresNo ratings yet

- Mechanical Behavior of Aluminum-Lithium Alloys at Cryogenic TemperaturesDocument7 pagesMechanical Behavior of Aluminum-Lithium Alloys at Cryogenic TemperaturesHani AshriNo ratings yet