Professional Documents

Culture Documents

IWP - MagazineFeb - Mar - 2016 - File - Forwebupload - 1

Uploaded by

kpch0 ratings0% found this document useful (0 votes)

30 views3 pagesAn article written on wind turbine components transportation in India

Original Title

IWP_MagazineFeb_ Mar_2016_ File _forWebupload_1 (3)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAn article written on wind turbine components transportation in India

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

30 views3 pagesIWP - MagazineFeb - Mar - 2016 - File - Forwebupload - 1

Uploaded by

kpchAn article written on wind turbine components transportation in India

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

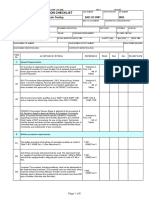

Volume: 1

Issue: 8

February - March 2016

` 10/-

Bimonthly, Chennai

Staying Ahead of Challenges in

Wind Turbine Blades Transportation

K.P. Chandrasekar

Deputy Vice President Logistics, ReGen Powertech Private Limited

Manufacturers of wind turbines and their components are

challenged to work out with customised transportation solutions

to transport the gigantic Multi-Megawatt Turbine structures

efficiently and continually, across India.

Transportation of less than 40 meter length of blade is

becoming the thing of past in India and currently transportation

of blade length between 50 meter and 60 meter are on hot

and in future onshore turbine blade length may reach up to 90

meter, translating into large, heavy and expensive super cargo

loads. These super loads transportation must be done by using

combination of Telescopic Trailer with Rotor Blade Adapter.

Beginning of 2000 when Sub 1 MW wind turbine installations

took deep root in India, the wind turbine components

transportation in India was not that much challenged as in the

present days. Then the blades were mounted on 70 feet flat

bed mechanical trailer coupled with Tata or Ashok Leyland less

powered prime mover to transport these blades across India.

These rigid axles mechanical trailers were more than sufficient to

cart blades even to up hills like Tirupati to install wind turbines.

Over the last two decades period, the individual blade size and

length has been increased phenomenally from 15 meters to

60 meters. Similarly, the mechanical flat bed trailer loading

platform length has also increased to enable the transportation

of lengthier blade in India. In year 2002 beginning, 70 feet

February - March 2016

Indian Wind Power

flatbed mechanical trailers were used to transport sub 30 Meter

blades, by the time, year 2014 came, the flat bed mechanical

trailers length has been extended to 115 feet to meet the

requirements of transportation of 40 meter plus blades and

these mechanical trailers served all these years well in India are

fast approaching to the period of phasing out from the regular

usage due to the limitations of these mechanical trailers utility.

Indian market is always been highly price sensitive market for

any products. All along with the help of local mechanical trailers

manufacturers support, rotor blades been transported across

India using locally made rigid axles trailers with least freight cost.

Now, world over, every wind turbine manufacturers are using

Telescopic Trailers in transporting the higher length of blades. In

India, the Telescopic Trailers usage has been started few years

back. Initially, the Telescopic Trailers required were imported

from Goldhofer, Cometto, Nicolas etc. The costs of imported

Telescopic Trailers are quite prohibitive in Indian standards and

pushed the trailer hiring charges upward. Hence, these types of

Telescopic Trailers were used by few and for selective lengthier

blades transportation in India.

Currently, Indian wind turbine market is moving on higher

megawatt turbines and this industry is operating on completely

outsourced logistics. The outsourced logistics service providers

are sensing the shift of Telescopic Trailers requirements

27

for transportation of lengthier blades and have started to

importing Telescopic Trailers from cheaper destinations like

China and locally designed and manufactured under "Make

in India" program. The locally manufactured Telescopic Trailers

are matching their counterparts in Europe in offering quality

Telescopic Trailers and in fact capable of carrying two lengthier

blades on one Telescopic Trailer. The locally made Telescopic

Trailers at present juncture are capable of carrying two sub 52

meter rotor blades on one Telescopic Trailer, across India.

Wind Turbine Components transportation is a specialised field,

wherein across India very limited numbers of transporters are

involved and they have been upgrading their trailers and prime

movers, based on the natural forces of demand and supply.

Indian Government is setting up an ambitious Wind Turbine

installations targets and IWTMA predicts 3.5 GW capacity

additions for FY 2015-16. Estimated transportation of 5000 plus

lengthier blade in a year requires minimum of 300 specialised

Telescopic Trailers and an investment of Rs.400 Crores for

blades transportation alone.

The Wind Energy Developers, Turbine and Components

manufacturers and other stakeholders are recognising the

herculean task of transporting oversized and lengthier rotor

blades across India in all seasons throughout the year is

encouraging the transport service providers to use best in

class transportation equipment to transport blades across India

to achieve Indian Government vision of having 60 GW wind

energy operational on March 2022.

The benefit Wind Turbine Industry is getting by transporting

two rotor blades on one Telescopic Trailer is enormous. The

cost of hiring articulated telescopic trailer is less per blade

transportation, the requirements of skilled manpower consist

of Drivers Crew is modest, the consumption of environment

polluting diesel is going to be reduced drastically, the turning

radius required at wind farm sites are minimal, the transit

days required to deliver the blades are less when compared

to Mechanical Trailers. Overall, the Telescopic Trailer has many

advanced and latest features with steering axles.

Globally, Rotor Blade Adapter has been in use to transport

blade vertically for short hauling near wind farm sites, where

horizontal hurdles are more. The usage of Rotor Blade Adapter

is so far not taking root in India.

Last few decades in India, the infrastructure developments

are happening in rapid pace, this development leads to

requirements of heavy and oversized equipment transportation

across India. The local players like Tata, Ashok Leyland etc.

are totally preoccupied in supplying General Cargo carrying

vehicles missed an opportunity to provide Indian truck market

higher powered prime movers or pullers. This vacuum were

filled by foreign players like Scania, Volvo, Benz, Man, AMW

etc. by setting up manufacturing units in India and offered

Indian market world class prime movers to transport lengthier

Wind Turbine Blades. Now, even, local players like Tata, Ashok

Leyland, Eicher and Mahindra are also offering high powered

prime movers suiting to Indian Truck Market.

28

The present Indian Government is placing enormous thrust on

producing everything in India through Make in India program

and has shown enormous care on environmental issues and

setting an ambitious target for renewable energy capacity

addition on year on year and supporting the progress through

the Ministry of New and Renewable Energy (MNRE).

Transporters are on their part offering latest trailer tractors

coupled with Articulate Steerable Axles Telescopic Trailers to

transport lengthier blades. Unfortunately, transporters are facing

plenty of delay and costs increase at every RTOs, as these latest

Extendable Telescopic Trailers, though mandatory due to nature

of cargo, but the present Indian Motor Vehicles Acts are yet to

be amended to permit these special vehicles to ply on Indian

roads, officially.

To transport a rotor blade from Bangalore in Karnataka to Indore

in Madhya Pradesh, a distance of 1400 KM has to pass through

21 RTOs (Nelamangala, Tumkur, Sira, Hiriyur, Chitradurga,

Davangere, Hospet, Koppal, Bagalkot, Bijapur, Zalki, Solapur

(Maharashtra entry), Solapur Town, Tembhurni, Ahmed Nagar,

Sirampur, Yeola, Malegaon, Dhule, Maharastra outer border,

Madhya Pradesh in border) before reaching the destination.

Hence, there is a need that all the stakeholders should join

hands and present to Ministry of Road Transport and Highways

the need for recognising this special transportation and amend

the Motor Vehicles Acts accordingly to permit these telescopic

trailers to ply on Indian roads legally, carrying rotor blades, so

as to enable the Wind Industry to expedite the addition of Wind

Energy Installations as targeted year on year.

Indian Wind Power

February - March 2016

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- (X) Selection Guide - PowerFlex Low Voltage Drives - PFLEX-SG002K-En-P - February 2017Document178 pages(X) Selection Guide - PowerFlex Low Voltage Drives - PFLEX-SG002K-En-P - February 2017Nicolás A. SelvaggioNo ratings yet

- ELER v3 Technical ManualDocument141 pagesELER v3 Technical ManualAlla Eddine G CNo ratings yet

- (Customer) 04 DX75-5B Control Valve (BCV-65) (To Print)Document8 pages(Customer) 04 DX75-5B Control Valve (BCV-65) (To Print)AimHighNo ratings yet

- Ciscenje Hadnjaka HyundaiDocument4 pagesCiscenje Hadnjaka HyundaiAjdin Herc AhmetovicNo ratings yet

- WavelengthPeriodFrequency QuestionsDocument2 pagesWavelengthPeriodFrequency QuestionssalmasomaNo ratings yet

- Development Length of Standard Hook in Tension (Only)Document1 pageDevelopment Length of Standard Hook in Tension (Only)Piseth HengNo ratings yet

- Products Guide Book: - Crawler CranesDocument16 pagesProducts Guide Book: - Crawler CranesSarifa Rangunwala Sen100% (1)

- This Manual Includes: Repair Procedures Fault Codes Electrical and Hydraulic SchematicsDocument298 pagesThis Manual Includes: Repair Procedures Fault Codes Electrical and Hydraulic SchematicsJugaro OscarNo ratings yet

- Electronic Patient Record Use During Ward Rounds: A Qualitative Study of Interaction Between Medical StaffDocument8 pagesElectronic Patient Record Use During Ward Rounds: A Qualitative Study of Interaction Between Medical StaffpsikubNo ratings yet

- PJM535 StudentCourseSyllabusDocument7 pagesPJM535 StudentCourseSyllabusRonald McflurryNo ratings yet

- 410e Repair ExampleDocument6 pages410e Repair ExampleYurii Chinov71% (7)

- SRM-RMPM Registration Report For EvDocument3 pagesSRM-RMPM Registration Report For EvAAKASH J (RA2111043020035)No ratings yet

- CadburyDocument4 pagesCadburyWong Kai WeiNo ratings yet

- ANSI E1.50-1 2017 Entertainment Technology - Requirements For The Structural Support of Temporary LED, Video & Display SystemsDocument19 pagesANSI E1.50-1 2017 Entertainment Technology - Requirements For The Structural Support of Temporary LED, Video & Display SystemsGabriel neagaNo ratings yet

- An Introduction To SAP Business One CloudDocument14 pagesAn Introduction To SAP Business One CloudBharathkumar PalaniveluNo ratings yet

- ARAMCO UT Inspection Checklist - SAIC-UT-2001Document6 pagesARAMCO UT Inspection Checklist - SAIC-UT-2001Anonymous hBBam1n100% (1)

- Supersot Sot23 NPN Silicon Power (Switching) Transistors: Fmmt617 Fmmt618 Fmmt619 Fmmt624 Fmmt625Document4 pagesSupersot Sot23 NPN Silicon Power (Switching) Transistors: Fmmt617 Fmmt618 Fmmt619 Fmmt624 Fmmt625BBFulNo ratings yet

- Wartsila O E W 50DF PG Product GuideDocument180 pagesWartsila O E W 50DF PG Product GuideFábio Almeida100% (1)

- Resistance in The Fluid System PDFDocument21 pagesResistance in The Fluid System PDFDyo MandeNo ratings yet

- Design and Detailing of RCC BeamsDocument4 pagesDesign and Detailing of RCC BeamsPhilip JohnNo ratings yet

- BitBox CarList 2018 08 23Document42 pagesBitBox CarList 2018 08 23manutecNo ratings yet

- Katalog Firme MGDocument74 pagesKatalog Firme MGJovanNisNo ratings yet

- Atmospheric Foam Storage TanksDocument3 pagesAtmospheric Foam Storage TanksmbloexNo ratings yet

- Tollgate-Based Project Management TemplateDocument9 pagesTollgate-Based Project Management TemplateKulanthaivelu RamasamyNo ratings yet

- Sullair AWFDocument4 pagesSullair AWFOscar BedregalNo ratings yet

- Success and Failure Factors of BPRDocument29 pagesSuccess and Failure Factors of BPRMohammad Hamid MahmoodNo ratings yet

- Burj KhalifaDocument29 pagesBurj KhalifaAnonymous hprsT3WlPNo ratings yet

- EMI and ACDocument14 pagesEMI and ACbharathNo ratings yet

- QCL Certification Pvt. LTDDocument3 pagesQCL Certification Pvt. LTDRamaKantDixitNo ratings yet

- Vapour AbsorptionDocument10 pagesVapour Absorptiongayakwad12_ramNo ratings yet