Professional Documents

Culture Documents

Armstrong Lever Drain Trap Specifications

Uploaded by

civil270986Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Armstrong Lever Drain Trap Specifications

Uploaded by

civil270986Copyright:

Available Formats

873_Drainers.

qxd

4/4/06

10:12 AM

Page LD-37

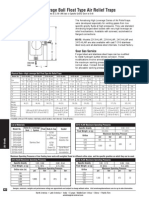

Free Floating Lever Drain Traps

For Loads to 50,000 lb/hr (22,679 kg/hr)...Pressures to 1,000 psig (69 bar)

Table LD-14. Maximum Operating Pressures for Handling Different Specific Gravity Liquids With Orifices Available in Guided Free Floating Lever Drain Traps. (See pages LD-29 and LD-30.)

Sp. Grav.

1.00

.95

.90

.85

.80

.75

.70

.65

Orifice

Maximum Operating Pressure psig (bar)

in

psig

bar

psig

bar

psig

bar

psig

bar

psig

bar

psig

bar

psig

bar

psig

bar

1/8

121

8.3

109

7.6

98

6.8

87

6.0

75

5.2

64

4.4

52

3.6

41

2.8

7/64

143

9.9

130

9.0

116

8.0

103

7.1

89

6.1

75

5.2

62

4.3

48

3.3

1-LD

#38

182

12.5

164

11

147

10.2

130

9.0

113

7.8

95

6.6

78

5.4

61

4.2

5/64

300

20.7

289

19.9

259

17.8

228

15.7

198

13.7

168

11.6

137

9.5

107

7.4

1/8

176

12.1

161

11.1

146

10.1

130

9.0

115

7.9

100

6.9

85

5.8

69

4.8

7/64

209

14

191

13

173

12

155

10.7

137

9.4

119

8.2

100

6.9

82

5.7

11-LD

#38

264

18

242

17

219

15

196

14

173

12

150

10.4

127

8.8

104

7.2

5/64

400

28

400

28

384

27

344

24

304

21

264

18

224

15

183

13

5/16

22

1.5

20

1.4

18

1.3

17

1.1

15

1.0

13

0.9

11

0.8

10

0.7

1/4

36

2.5

33

2.3

30

2.1

27

1.9

24

1.7

22

1.5

19

1.3

16

1.1

2-LD to 250 psi

3/16

79

5.5

73

5.0

67

4.6

60

4.2

54

3.7

47

3.3

41

2.8

35

2.4

(17 bar)

5/32

137

9.4

126

8.7

115

7.9

104

7.2

93

6.4

82

5.6

71

4.9

60

4.1

1/8

234

16.1

215

14.8

196

13.5

178

12.2

159

10.9

140

9.6

121

8.4

102

7.1

22-LD to 533 psi

7/64

299

20.6

275

19

251

17.3

227

15.7

203

14

179

12

155

10.7

131

9.0

(475 bar)

#38

372

25.7

342

23.6

313

21.6

283

19.5

253

17.4

223

15

193

13

163

11.2

5/64

533

37

475

33

461

32

417

29

372

26

328

23

284

20

240

17

5/16

29

2.0

26

1.8

23

1.6

21

1.4

18

1.2

15

1.0

12

0.9

10

0.7

1/4

47

3.3

43

3.0

38

2.6

34

2.3

29

2.0

25

1.7

20

1.4

16

1.1

3/16

104

7.2

94

6.5

85

5.8

75

5.2

65

4.5

55

3.8

45

3.1

35

2.4

5/32

180

12

163

11

146

10

129

8.9

112

7.7

95

6.5

78

5.4

61

4.2

32-LD

1/8

307

21

278

19

249

17

220

15

191

13

162

11

133

9

104

7.2

7/64

393

27

356

25

319

22

282

19

245

17

207

14

170

12

133

9

#38

489

34

443

31

397

27

351

24

304

21

258

18

212

15

166

11

5/64

600

41

600

41

585

40

517

36

449

31

381

26

313

22

244

17

0.6

0.5

0.4

1/2

16

1.1

14

1.0

13

0.9

12

0.8

10

0.7

9

7

6

3-LD to 250 psi

1.3

1.1

0.9

3/8

33

2.3

31

2.1

28

1.9

25

1.7

22

1.5

19

16

13

(17 bar)

(Cast Iron)

2.1

1.7

1.4

5/16

54

3.7

49

3.4

44

3.0

39

2.7

35

2.4

30

25

20

2.7

2.3

1.9

9/32

71

4.9

65

4.5

59

4.0

52

3.6

46

3.2

40

34

27

13-LD to 570 psi

4.1

3.5

2.8

1/4

107

7.4

97

6.7

88

6.1

79

5.4

69

4.8

60

50

41

(39 bar)

5.9

5.0

4.0

7/32

153

10.5

139

9.6

126

8.7

112

7.7

99

6.8

85

72

59

(Stainless)

6.1

8.9

7.5

3/16

230

16

209

14

189

13

169

12

149

10.3

129

108

88

33-LD to 900 psi

14

12

9.5

5/32

359

25

327

23

296

20

264

18

233

16

201

169

138

(62 bar)

28

24

19

1/8

726

50

662

46

598

41

534

37

470

32

406

342

278

(Steel)

36

30

25

7/64

900

62

847

58

765

53

683

47

601

41

519

437

356

21

1.4

19

1.3

18

1.2

16

1.1

15

1.0

13

0.9

12

0.8

10

0.7

1-1/16

32

2.2

30

2.1

28

1.9

26

1.8

23

1.6

21

1.4

19

1.3

16

1.1

7/8

47

3.2

44

3.0

40

2.8

37

2.5

34

2.3

30

2.1

27

1.9

24

1.6

3/4

72

4.9

67

4.6

61

4.2

56

3.9

51

3.5

46

3.2

41

2.8

36

2.5

5/8

95

6.5

88

6.1

81

5.6

75

5.2

68

4.7

61

4.2

55

3.8

48

3.3

9/16

138

9.5

128

8.8

118

8.1

108

7.5

99

6.8

89

6.1

79

5.4

69

4.8

1/2

196

13

182

13

168

12

154

11

140

10

126

8.7

112

7.7

98

6.8

7/16

6-LD

Cast Iron

250

17

250

17

250

17

243

17

221

15

199

14

177

12

155

11

3/8

250

17

250

17

250

17

250

17

250

17

250

17

236

16

207

14

11/32

250

17

250

17

250

17

250

17

250

17

250

17

250

17

250

17

5/16

250

17

250

17

250

17

250

17

250

17

250

17

250

17

250

17

9/32

250

17

250

17

250

17

250

17

250

17

250

17

250

17

250

17

1/4

250

17

250

17

250

17

250

17

250

17

250

17

250

17

250

17

7/32

250

17

250

17

250

17

250

17

250

17

250

17

250

17

250

17

3/16

1.1

1.01

0.91

0.81

0.71

0.6

0.5

0.4

1-1/16

16

15

13

12

10

9

7

6

1.1

0.95

0.79

0.63

1.7

1.6

1.4

1.3

16

14

11

9

7/8

25

23

21

18

2.5

2.3

2.1

1.8

1.6

1.4

1.1

0.91

3/4

36

33

30

27

23

20

17

13

3.9

3.5

3.1

2.8

2.4

2.1

1.7

1.4

5/8

56

51

46

41

35

30

25

20

5.1

4.6

4.2

3.7

3.2

2.8

2.3

1.8

9/16

74

67

60

54

47

40

34

27

7.4

6.7

6.0

5.4

4.7

4.0

3.4

2.7

1/2

107

97

88

78

68

58

49

39

10.5

9.6

8.6

7.6

6.7

5.7

4.8

3.8

7/16

152

138

125

111

97

83

69

55

36-LD

Forged Steel

17

15

14

12

9.0

7.5

6.0

3/8

240

218

197

175

153 10.5

131

109

87

22

20

18

16

14

12

10

8.0

11/32

320

291

262

233

203

174

145

116

28

26

23

21

18

15

13

5/16

411

374

336

299

262

224

187

149 10.3

17

13

37

34

30

27

24

20

244

195

9/32

539

490

441

392

343

293

54

49

44

39

35

30

25

20

1/4

788

716

644

573

501

429

357

286

63

56

49

42

35

28

7/32

1,000 69

1,000 69

910

808

707

606

505

403

68

57

46

3/16

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

992

826

660

Specific Gravity

1.00

.95

.90

.85

.80

.75

.70

.65

NOTE: If specific gravity falls between those shown in the chart, use the next lower gravity. For example, if specific gravity is 0.73, use 0.70 gravity data.

.60

.55

.50

Liquid Drainers

Model No.

psig

29

35

44

77

54

64

81

143

8

13

28

49

83

107

133

196

7

12

25

44

75

96

120

176

5

10

16

21

32

45

68

106

214

274

9

14

20

31

41

59

85

133

178

228

250

250

250

250

4

7

10

15

20

29

41

65

87

112

146

214

302

494

bar

2.0

2.4

3.0

5.3

3.7

4.4

5.6

9.9

0.5

0.9

2.0

3.4

5.8

7.4

9.2

14

0.5

0.8

1.8

3.0

5.2

6.6

8

12

0.3

0.7

1.1

1.4

2.2

3.1

4.7

7.3

15

19

0.6

1.0

1.4

2.1

2.8

4.1

5.8

9.0

12

16

17

17

17

17

0.3

0.47

0.68

1.05

1.4

2.0

2.9

4.5

6.0

7.7

10.1

15

21

34

.60

psig

18

21

26

47

39

46

59

103

6

10

22

38

65

83

103

152

4

7

16

27

46

59

73

108

3

7

11

15

22

32

48

74

150

192

7

12

17

26

34

50

71

111

148

191

250

250

250

250

3

5

7

10

13

19

27

43

58

74

97

142

201

328

bar

1.2

1.4

1.8

3.2

2.7

3.2

4.0

7.1

0.4

0.7

1.5

2.6

4.5

5.7

7.1

10.5

0.3

0.5

1.1

1.9

3.2

4.1

5.1

7

0.2

0.5

0.8

1.0

1.5

2.2

3.3

5.1

10.3

13

0.5

0.8

1.2

1.8

2.4

3.4

4.9

7.7

10

13

17

17

17

17

0.2

0.31

0.45

0.69

0.92

1.3

1.9

3.0

4.0

5.1

6.7

9.8

14

23

.55

psig bar

6

0.4

7

0.5

9

0.6

16

1.1

24

1.6

28

1.9

36

2.5

63

4.3

4

0.3

7

0.5

16

1.1

27

1.8

46

3.2

59

4.0

73

5.0

108

7.4

2

0.1

3

0.2

6

0.4

10

0.7

17

1.2

22

1.5

27

1.9

40

2.8

0.1

2

0.3

4

0.4

6

0.6

8

0.9

13

1.2

18

1.9

27

2.9

43

5.9

86

110 7.6

6

0.4

9

0.6

14

0.9

21

1.4

28

1.9

40

2.8

57

3.9

90

6.2

119

8.2

153

11

201

14

250

17

250

17

250

17

0.1

1

0.16

2

0.22

3

0.34

5

0.46

7

10 0.66

14 0.94

1.5

21

2.0

29

2.5

37

3.3

48

4.9

70

6.9

99

163 11.2

.50

High Temperature Service

Maximum allowable working pressures

of floats decrease at temperatures

above 100F (37.8C). Allow for approximately:

10% decrease at 200F (93.3C)

15% decrease at 300F (148.9C)

20% decrease at 400F (204.4C)

The float is not always the limiting factor, however.

Consult with Armstrong Application Engineering if you

have a high-temperature application that also requires

maximum operating pressures.

520

LD-37

Armstrong Steam and Condensate Group, 816 Maple St., Three Rivers, MI 49093 USA Phone: (269) 273-1415 Fax: (269) 278-6555

www.armstrong-intl.com

Next

873_Drainers.qxd

4/4/06

10:12 AM

Page LD-38

Free Floating Guided Lever Drain Traps

For Loads to 49,000 lb/hr (22,226 kg/hr)...Pressures to 300 psig (21 bar)

Armstrongs cast iron, free-floating guided lever drain traps

use the same bodies, caps, lever mechanisms, valves and

seats of Armstrong inverted bucket steam traps that have

been proven in years of service. Elliptical floats and high

leverage make it possible to open large orifices to provide

adequate capacity for drain trap size and weight.

The hemispherical valve, seat and leverage of the 1-LD,

2-LD, 3-LD and 6-LD cast iron traps are identical in design,

materials and workmanship to those for saturated steam

service up to 300 psig (21 bar) with the exception of the

addition of a guidepost to assure a positive, leaktight valve

closing under all conditions.

List of Materials

For a fully detailed certified drawing, refer to:

1-LD

CD #1070

2-LD, 3-LD, 6-LD CD #1034

Table LD-15.

Model

No.

Valve &

Seat

1-LD

2-LD

3-LD

6-LD

Leverage

System

Float

Stainless Steel

Body & Cap

Gasket

Cast Iron

ASTM A48

Class 30

Compressed

Asbestos-free

For information on special materials, consult the Armstrong Application

Engineering Department.

Vent

Figure LD-33.

No. 2-LD, 3-LD and 6-LD cast iron guided

lever drain traps. No. 1-LD has standard top

inlet and optional side connection.

Physical Data

Table LD-16. Armstrong Guided Lever Liquid Drain Traps

Cast Iron

Model No.

Pipe Connections

2-LD

1-LD

3-LD

6-LD

mm

in

mm

in

mm

in

mm

1/2*

15*

1/2, 3/4

15, 20

1/2, 3/4, 1

15, 20, 25

1-1/2, 2

40, 50

259

3-3/4

95

5-1/4

133

6-3/8

162

10-3/16

5-1/2

140

203

10-5/8

270

17

432

D

K (CL Outlet to CL Inlet)

2-7/8

73

4-3/8

111

6-3/32

155

8-3/8

213

13/16

21

1-7/8

48

2-7/16

62

2-7/8

73

4-5/8

117

Approx. Wt. lb (kg)

Max. Allow. Pressure

(Vessel Design)

4 (2)

13 (6)

300 psig @ 200F

(21 bar @ 93C)

22 (10)

Liquid Drainers

in

80 (36)

250 psig @ 450F (17 bar @ 232C)

NOTE: Vessel design pressure may exceed float collapse pressure in some cases.

Pipe size of vent connection is same as that of inlet and outlet connections.

*1/4" (6 mm) outlet.

For pressures not exceeding 250 psig (17 bar), a maximum temperature of 450F (232C) is allowed.

All dimensions and weights are approximate. Use certified print for exact dimensions. Design and materials are subject to change without notice.

Armstrong Steam and Condensate Group, 816 Maple St., Three Rivers, MI 49093 USA Phone: (269) 273-1415 Fax: (269) 278-6555

www.armstrong-intl.com

521

Next LD-38

873_Drainers.qxd

4/4/06

10:12 AM

Page LD-39

Free Floating Guided Lever Drain Traps

For Loads to 9,500 lb/hr (4,309 kg/hr)...Pressures to 570 psig (39 bar)

Armstrongs stainless steel, free-floating guided lever drain

traps use the same bodies, caps, lever mechanisms, valves

and seats of Armstrong inverted bucket steam traps that

have been proven in years of service. Elliptical floats and

high leverage make it possible to open large orifices to

provide adequate capacity for drain trap size and weight.

The hemispherical valve, seat and leverage of the 11-LD,

22-LD and 13-LD stainless steel traps are identical in design,

materials and workmanship to those for saturated steam

service up to 570 psig (39 bar) with the exception of the

addition of a guidepost to assure a positive, leaktight valve

closing under all conditions.

List of Materials

For a fully detailed certified drawing, refer to list below:

11-LD

CD #1066

13-LD and 22-LD CD #1086

Table LD-17.

Model

No.

Valve &

Seat

11-LD

22-LD

13-LD

Leverage

System

Float

Stainless Steel

Body & Cap

Gasket

Sealed

Stainless Steel,

304L

For information on special materials, consult the Armstrong Application

Engineering Department.

K

A

Figure LD-34.

No. 11-LD, 22-LD and 13-LD stainless steel guided lever

liquid drain trap with sealed, tamperproof construction.

Physical Data

Table LD-18. Armstrong Guided Lever Liquid Drain Traps

Stainless Steel

Model No.

13-LD

in

mm

in

mm

in

3/4*

20*

3/4

20

25

2-3/4

70

3-15/16

100

4-1/2

114

7-1/4

184

8-13/16

224

11-3/8

289

76

6-1/8

156

9/16

14

7/8

22

1-3/16

30

2-5/8

67

3-9/32

Pipe Connections

Liquid Drainers

22-LD

11-LD**

Approx. Wt. lbs (kg)

Max. Allowable Pressure

(Vessel Design)

mm

83

1-3/4 (0.79)

3-1/4 (1.5)

7-1/2 (3.4)

500 psig @ 100F (35 bar @ 38C)

440 psig @ 500F (30 bar @ 260C)

600 psig @ 100F (41 bar @ 38C)

475 psig @ 500F (33 bar @ 260C)

570 psig @ 100F (39 bar @ 38C)

490 psig @ 500F (34 bar @ 260C)

Note: Vessel design pressure may exceed float collapse pressure in some cases.

Pipe size of vent connection is same as that of inlet and outlet connections.

*1/2" (15 mm) outlet. **No side connection.

522

LD-39

All dimensions and weights are approximate. Use certified print for exact dimensions. Design and materials are subject to change without notice.

Armstrong Steam and Condensate Group, 816 Maple St., Three Rivers, MI 49093 USA Phone: (269) 273-1415 Fax: (269) 278-6555

www.armstrong-intl.com

Next

873_Drainers.qxd

4/4/06

10:12 AM

Page LD-40

180 Series Free Floating Lever Drain Traps

All Stainless Steel for Horizontal Installation

For pressures to 400 psig (28 bar) . . . Capacities to 2,000 lb/hr (907 kg/hr)

Armstrongs stainless steel, free-floating guided lever

drain traps use the same bodies, caps, lever mechanisms,

valves and seats as Armstrong inverted bucket steam traps

that have been proven in years of service. Elliptical floats

and high leverage make it possible to open large orifices

to provide adequate capacity for drain trap size and weight.

The hemispherical valve, seat and leverage of the 180-LD

and 181-LD stainless steel traps are identical in design,

materials and workmanship to those for saturated steam

service up to 570 psig (39 bar), except that the 180 Series

traps have a guidepost to ensure a positive, leak-tight valve

closing under all conditions. The 180 Series is designed

for situations where mounting a drainer close to the floor

is critical. A back vent connection is required.

For a fully detailed certified drawing, refer to list below:

180-LD CD #1276

181-LD CD #1276

List of Materials

Table LD-19.

Valve &

Seat

Model No.

Leverage

System

Float

Body & Cap

P

P

180-LD

181-LD

Sealed Stainless

Steel 304L

Stainless Steel

D

D

Physical Data

Table LD-20. Armstrong 180 Series Free Floating Lever Drain Traps

in

mm

in

1/2

15

3/4

20

2-11/16

68

2-11/16

68

135

6-9/16

167

A (Diameter)

B (Height)

mm

C (Face to Face)

4-5/16

110

4-5/16

110

D (Bottom to CL Inlet)

5-1/8

113

5-9/16

141

Weight, lb (kg)

1-3/4 (0.8)

Figure LD-35.

Model 180-LD

2-3/8 (1.1)

Chart LD-13. Model 180-LD Capacity

Chart LD-14. Model 181-LD Capacity

Pressure, bar

0.1

10

0.1

Pressure, bar

2

3

5

1

120

60

3

350

500

300

100

200

70

150

Capacity, lb/hr

150

Capacity, kg/h

200

300

#38

250

5/64

400

700

300

1/8

10

125

1,000

225

#38

500

250

1/8

500

5/64

200

400

150

300

250

100

200

70

150

50

10

100

100

1

Pressure, psi

Liquid Drainers

60

700

Capacity, lb/hr

500

1,000

100

Figure LD-36.

Model 181-LD

Capacity, kg/h

Pipe Connections

50

2

10

100

Pressure, psi

All dimensions and weights are approximate. Use certified print for exact dimensions. Design and materials are subject to change without notice.

Armstrong Steam and Condensate Group, 816 Maple St., Three Rivers, MI 49093 USA Phone: (269) 273-1415 Fax: (269) 278-6555

www.armstrong-intl.com

523

Next LD-40

873_Drainers.qxd

4/4/06

10:12 AM

Page LD-41

Liquid Drainers

Notes

524

LD-41

Armstrong Steam and Condensate Group, 816 Maple St., Three Rivers, MI 49093 USA Phone: (269) 273-1415 Fax: (269) 278-6555

www.armstrong-intl.com

Next

873_Drainers.qxd

4/4/06

10:12 AM

Page LD-42

Free Floating Guided Lever Drain Traps

For Loads to 42,000 lb/hr (19,050 kg/hr)...Pressures to 1,000 psig (69 bar)

Armstrongs forged steel, free floating guided lever drain traps

use the same bodies, caps, lever mechanisms, valves and

seats of Armstrong inverted bucket steam traps that have

been proven in years of service. Elliptical floats and high

leverage make it possible to open large orifices to provide

adequate capacity for drain trap size and weight.

The hemispherical valve, seat and leverage of the 32-LD,

33-LD and 36-LD forged steel traps are identical in design,

materials and workmanship to those for saturated steam

service up to 1,000 psig (69 bar) with the exception of the

addition of a guidepost to assure a positive, leaktight valve

closing under all conditions.

List of Materials

For a fully detailed certified drawing, refer to CD #1035.

Table LD-21.

Model

No.

Valve &

Seat

32-LD

33-LD

36-LD

Leverage

System

Float

Stainless Steel

Body & Cap

Gasket

Forged Steel

ASTM A105

Compressed

Asbestos-free

For information on special materials, consult the Armstrong Application

Engineering Department.

VENT

K

A

Figure LD-37.

No. 32-LD, 33-LD and 36-LD forged steel guided lever drain

trap. Socketweld or flanged connections are also available.

Physical Data

Table LD-22. Armstrong Guided Lever Liquid Drain Traps

Forged Steel

Model No.

33-LD

36-LD

in

mm

in

mm

in

mm

1/2, 3/4, 1

15, 20, 25

1/2, 3/4, 1

15, 20, 25

1-1/2, 2

40, 50

302

6-3/4

171

203

11-7/8

10-3/16

259

11-9/16

294

17-1/8

435

5-9/16

141

6-1/16

154

229

1-1/4

32

1-7/16

37

2-1/8

54

3-3/8

86

3-9/16

90

6-1/16

154

Approx. Wt. lbs (kg)

Max. Allowable Pressure

(Vessel Design)

31 (14)

49 (22)

Liquid Drainers

Pipe Connections

32-LD

163 (74)

1,000 psig @ 100F (69 bar @ 38C)

600 psig @ 750F (41 bar @ 400C)

600 psig @ 100F (41 bar @ 38C)

500 psig @ 750F (35 bar @ 400C)

Note: Vessel design pressure may exceed float collapse pressure in some cases.

Pipe size of vent connection is same as that of inlet and outlet connections.

Available in Type 316 stainless steel. Consult factory.

525

Armstrong Steam and Condensate Group, 816 Maple St., Three Rivers, MI 49093 USA Phone: (269) 273-1415 Fax: (269) 278-6555

www.armstrong-intl.com

Next LD-42

You might also like

- Rig DesginDocument25 pagesRig Desginriobm100% (1)

- Rig DesginDocument25 pagesRig DesginImam PranadipaNo ratings yet

- Network CompTIADocument38 pagesNetwork CompTIApedrazini18100% (1)

- PThread API ReferenceDocument348 pagesPThread API ReferenceBenoy BoseNo ratings yet

- Hammer UnionsDocument16 pagesHammer Unionsram_river808100% (2)

- BladderDocument7 pagesBladderJohnSengsuNo ratings yet

- Oilfield Hoses Fittings AccembliesDocument29 pagesOilfield Hoses Fittings Accembliesthapa786mNo ratings yet

- UBC ASTM July 2017 To July 2018 UseDocument1,349 pagesUBC ASTM July 2017 To July 2018 UseAadelNo ratings yet

- Method Statement ScaffoldingDocument18 pagesMethod Statement ScaffoldingAsep Hidayat100% (1)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- BSE Recycling Works, LLC: Machine Specification Sheet International Baler Model Ld-54-SdDocument4 pagesBSE Recycling Works, LLC: Machine Specification Sheet International Baler Model Ld-54-SdAbhinav JhaNo ratings yet

- Bank Soal Matematika SBMPTN dan STANDocument6 pagesBank Soal Matematika SBMPTN dan STANIntan DwiNo ratings yet

- Electro ValvulasDocument89 pagesElectro ValvulasJuan Domingo OrlandiniNo ratings yet

- Hammer Unions and Swivel Joints GuideDocument16 pagesHammer Unions and Swivel Joints GuideFabricio100% (1)

- 1.8 Casing Design1.9 Burst, Collapse, TensionDocument19 pages1.8 Casing Design1.9 Burst, Collapse, TensionCristian Camilo Cruz Romero100% (1)

- Manual de Parte Grove RT 9130EDocument1,157 pagesManual de Parte Grove RT 9130EAlejandro Torrealba100% (8)

- Hammer Union CatalogueDocument7 pagesHammer Union CatalogueSantosh Kumar AlpeteNo ratings yet

- One Company Unlimited SolutionsDocument20 pagesOne Company Unlimited SolutionsjobinjsNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- 1 Casing DesignDocument73 pages1 Casing DesignHasril Fauzul AziNo ratings yet

- PSI PumpsDocument12 pagesPSI PumpsagiacomuzoNo ratings yet

- Container SpecificationsDocument46 pagesContainer SpecificationsPARALELO10100% (1)

- Katalog Gunung Garuda NewDocument36 pagesKatalog Gunung Garuda Newabduh81No ratings yet

- Bomba Rexroth PDFDocument36 pagesBomba Rexroth PDFplasticos_jfm6580100% (11)

- Stainless Steel Guided Lever Liquid Drain Traps Up to 9,500 lb/hrDocument1 pageStainless Steel Guided Lever Liquid Drain Traps Up to 9,500 lb/hrJorge FigulsNo ratings yet

- Yidro PoutsesqwerfqwefvqwerfgvqrvqerfvgqrfDocument2 pagesYidro PoutsesqwerfqwefvqwerfgvqrvqerfvgqrfTravelergr KallogiroyNo ratings yet

- Antlies Hudro Pumps ServiceqwerfvqervqerDocument2 pagesAntlies Hudro Pumps ServiceqwerfvqervqerTravelergr KallogiroyNo ratings yet

- Roper Serie 3600 PDFDocument2 pagesRoper Serie 3600 PDFantonioNo ratings yet

- Cylinder and Container GuideDocument12 pagesCylinder and Container GuideClaudio SantellanesNo ratings yet

- LP-GAS SHUTOFF VALVES - UL Product IqDocument3 pagesLP-GAS SHUTOFF VALVES - UL Product IqsarmientollocllajNo ratings yet

- CMSH Brochure ReducedDocument6 pagesCMSH Brochure ReducedTim SquareNo ratings yet

- Flowserve Lined Flush BottomDocument32 pagesFlowserve Lined Flush BottomDevdatt WaghuleNo ratings yet

- Architectural Products Group: C-APG08Document16 pagesArchitectural Products Group: C-APG08lesgiuNo ratings yet

- 30-DC Series Automatic Differential Condensate Controllers: DescriptionDocument2 pages30-DC Series Automatic Differential Condensate Controllers: DescriptionJozsef MagyariNo ratings yet

- ASMEDocument7 pagesASMEASI.KHMED100% (1)

- Sway Braces: Restoring Force For Sch.40 Pipe (Empty)Document2 pagesSway Braces: Restoring Force For Sch.40 Pipe (Empty)azraq68No ratings yet

- E4Document14 pagesE4juanca_eduNo ratings yet

- App B Piping Specifications PDFDocument4 pagesApp B Piping Specifications PDFirawan_epNo ratings yet

- Mark 695 Series - Piloted Tank Blanketing Regulator (2 Inch)Document4 pagesMark 695 Series - Piloted Tank Blanketing Regulator (2 Inch)prihartono_diasNo ratings yet

- Manual de TrampasDocument2 pagesManual de TrampasHector MagallonNo ratings yet

- Important DataDocument8 pagesImportant DataAbdelrahman AliNo ratings yet

- Control Valve Vent CalculationDocument3 pagesControl Valve Vent Calculationrudi 01No ratings yet

- Square DDocument4 pagesSquare DIvana IlickovicNo ratings yet

- Liquid Nitrogen Container Instruction ManualsDocument25 pagesLiquid Nitrogen Container Instruction Manualsm_najmanNo ratings yet

- CP LeftletDocument4 pagesCP LeftletSiang LingNo ratings yet

- Air Vents & Liquid Drainers SECTION Guided Lever Drain TrapsDocument1 pageAir Vents & Liquid Drainers SECTION Guided Lever Drain Trapscloudno911No ratings yet

- CIRCOR D-Series Technical BrochureDocument12 pagesCIRCOR D-Series Technical BrochureJAYNo ratings yet

- Mr. Bentum CASINDocument19 pagesMr. Bentum CASINSarkodie KwameNo ratings yet

- The Inverted Bucket Steam Trap: Energy Efficient Because It's So ReliableDocument4 pagesThe Inverted Bucket Steam Trap: Energy Efficient Because It's So ReliablesgrsthNo ratings yet

- L & M Series Ultra-Capacity Float & Thermostatic Steam Trap: Description How To OrderDocument2 pagesL & M Series Ultra-Capacity Float & Thermostatic Steam Trap: Description How To OrderJozsef MagyariNo ratings yet

- 2010 BurndyDocument99 pages2010 BurndycarloscaduNo ratings yet

- Container Specifications Hapag LloydDocument12 pagesContainer Specifications Hapag LloydBeautyma Company siteNo ratings yet

- Armstrong International SA - Com 80-DC Series Automatic Differential Condensate ControllersDocument2 pagesArmstrong International SA - Com 80-DC Series Automatic Differential Condensate ControllersWalid SaifNo ratings yet

- Rotametro ABBDocument10 pagesRotametro ABBjoticamario123No ratings yet

- TVS 80-DC Series Automatic Differential Condensate ControllersDocument2 pagesTVS 80-DC Series Automatic Differential Condensate ControllersJozsef MagyariNo ratings yet

- 2200 Series PDFDocument3 pages2200 Series PDFhendrabudimanNo ratings yet

- Fisher D4 Product BulletinDocument12 pagesFisher D4 Product BulletindocrafiNo ratings yet

- Accumulators and Reservoirs - Tactair Fluid ControlsDocument2 pagesAccumulators and Reservoirs - Tactair Fluid Controlshanie.zomorodiNo ratings yet

- A1200 Red Thread II PipingDocument0 pagesA1200 Red Thread II PipingjimmycabreraNo ratings yet

- HYD. PumpDocument40 pagesHYD. Pumprohitbhat2345No ratings yet

- Gestra Steam Trap - Thermostatic Steam Trap BK 29: Class Rating: ANSI 900 Available SizesDocument2 pagesGestra Steam Trap - Thermostatic Steam Trap BK 29: Class Rating: ANSI 900 Available SizesdcarunchioNo ratings yet

- USA Range - Piston Accumulators DatasheetDocument2 pagesUSA Range - Piston Accumulators DatasheetrinshonsanNo ratings yet

- 8311 Pressure Regulators Technical BulletinDocument16 pages8311 Pressure Regulators Technical BulletinEduardo RodriguesNo ratings yet

- Ss01014 SmithDocument6 pagesSs01014 SmithAchmad TabaNo ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168From EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168No ratings yet

- Logic DiagramDocument1 pageLogic Diagramcivil270986No ratings yet

- Armstrong Lever Drain Trap - Specifications PDFDocument6 pagesArmstrong Lever Drain Trap - Specifications PDFcivil270986No ratings yet

- Liquid DrainersDocument28 pagesLiquid Drainerscivil270986No ratings yet

- 38 Feam Ejb EngDocument4 pages38 Feam Ejb EngSaufi YatimNo ratings yet

- Cap 1000 - Recover - Recover 1000 PDFDocument1 pageCap 1000 - Recover - Recover 1000 PDFcivil270986No ratings yet

- Release Notes Sap 2000 V 1801Document12 pagesRelease Notes Sap 2000 V 1801Mohamed Mostafa IbrahimNo ratings yet

- ReadMe PDFDocument5 pagesReadMe PDFcivil270986No ratings yet

- Angle HRDocument6 pagesAngle HREduward Klinton NainggolanNo ratings yet

- ERWPipeDocument11 pagesERWPipeezzularabNo ratings yet

- Round&DeformedbarDocument2 pagesRound&Deformedbarem13unNo ratings yet

- ReadMe PDFDocument5 pagesReadMe PDFcivil270986No ratings yet

- Treadmill 95T-DOMLX-DOMHX-INTHX-01 - Service - Manual - M051 - 00K65-A003Document94 pagesTreadmill 95T-DOMLX-DOMHX-INTHX-01 - Service - Manual - M051 - 00K65-A003powerliftermiloNo ratings yet

- Windows Updates and Patch ManagementDocument10 pagesWindows Updates and Patch ManagementViorel StefanescuNo ratings yet

- Storeonce EMDocument138 pagesStoreonce EMVelly GeorgeNo ratings yet

- App Ids For Ics ScadaDocument6 pagesApp Ids For Ics Scadaantonio hhNo ratings yet

- Wildlife Management R139Document4 pagesWildlife Management R139Ovidiu LambruNo ratings yet

- 80L CylinderDocument2 pages80L CylinderHaty ATie67% (3)

- XLG3 OverviewDocument44 pagesXLG3 OverviewVALDEMIRNo ratings yet

- Marketing Turnaround - How Eicher Motors Revived The Royal Enfield BrandDocument4 pagesMarketing Turnaround - How Eicher Motors Revived The Royal Enfield BrandAbhishek SinghNo ratings yet

- Stanley College of Engineering and Technology For Women, Hyderabad Department of Information and Technology Course Plan Class: B.E. Sem: 3Document4 pagesStanley College of Engineering and Technology For Women, Hyderabad Department of Information and Technology Course Plan Class: B.E. Sem: 3J RaviNo ratings yet

- Correction Td2 2Document6 pagesCorrection Td2 2Islem OthNo ratings yet

- Lab 8.4.2Document8 pagesLab 8.4.2Luis David López TelloNo ratings yet

- Is 12469 1988Document9 pagesIs 12469 1988phaindikaNo ratings yet

- Iso 9000-2000 Clause's and CoveragesDocument12 pagesIso 9000-2000 Clause's and CoveragesPrabhu VelidindiNo ratings yet

- Skrill Payments Interface ManualDocument27 pagesSkrill Payments Interface ManualzsddeNo ratings yet

- Smart Energy Metering Using Lpwan Iot Technology: January 2018Document6 pagesSmart Energy Metering Using Lpwan Iot Technology: January 2018bulanarumNo ratings yet

- Connection Issues Xiaomi Push Service LogsDocument143 pagesConnection Issues Xiaomi Push Service LogsARIEF PRIAMBODONo ratings yet

- Unit2l3s - Multimeters - 30-04-01Document15 pagesUnit2l3s - Multimeters - 30-04-01Mohamed HarbNo ratings yet

- HeliCoil Primer Free II ApplicationsDocument2 pagesHeliCoil Primer Free II ApplicationsAce Industrial SuppliesNo ratings yet

- LTE-A Low Throughput Analysis for CA SitesDocument6 pagesLTE-A Low Throughput Analysis for CA SitesAkhmad Hafid IrawanNo ratings yet

- VHDL Program for Subprogram OverloadingDocument2 pagesVHDL Program for Subprogram OverloadingVidhya DsNo ratings yet

- LBB 1938 20 Plena Power Amplifier Data Sheet EnUSDocument4 pagesLBB 1938 20 Plena Power Amplifier Data Sheet EnUSvtcuongNo ratings yet

- 7 - Spec of Train18Document60 pages7 - Spec of Train18Guiller84No ratings yet

- GMK 5210Document18 pagesGMK 5210cornel_lupuNo ratings yet

- Quality Control and Continuous ImprovementDocument14 pagesQuality Control and Continuous ImprovementGarmentLearnerNo ratings yet