Professional Documents

Culture Documents

Piezoelectric Constants - Elastic Compliance - APCI PDF

Uploaded by

Ahmad DanielOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Piezoelectric Constants - Elastic Compliance - APCI PDF

Uploaded by

Ahmad DanielCopyright:

Available Formats

12/20/2016

PiezoelectricConstants|ElasticCompliance|APCI

GET CONNECTED:

SEARCH search...

CONTACT US

Home

Knowledge Center

PIEZO THEORY

Piezoelectric Constants

P I EZ OELECTR I C CO NS TAN TS

HOME

Because a piezoelectric ceramic is anisotropic, physical constants relate to both the

PRODUCTS & SERVICES

the applied force. Consequently, each constant generally has two subscripts that indicate

APC MATERIALS

ABOUT US

KNOWLEDGE CENTER

PIEZO THEORY

Piezoelectricity

Piezo Sensor Applications

direction of the applied mechanical or electric force and the directions perpendicular to

the directions of the two related quantities, such as stress (force on the ceramic element

/ surface area of the element) and strain (change in length of element / original length of

element) for elasticity. The direction of positive polarization usually is made to coincide

with the Zaxis of a rectangular system of X, Y, and Z axes (Figure 1.6). Direction X, Y, or Z

is represented by the subscript 1, 2, or 3, respectively, and shear about one of these axes

is represented by the subscript 4, 5, or 6, respectively. Definitions of the most frequently

used constants, and equations for determining and interrelating these constants, are

summarized here. The piezoelectric charge constant, d, the piezoelectric voltage

constant, g, and the permittivity, e, are temperature dependent factors.

Piezo Accelerometers

Piezoelectric Generators

Figure 1.6 The direction of positive polarization usually is made to coincide with the Zaxis.

Piezo Actuators

Piezoelectric Charge Constant

What is PZT?

The piezoelectric charge constant, d, is the polarization generated per unit of mechanical stress (T) applied to a piezoelectric

Piezoelectric Constants

material or, alternatively, is the mechanical strain (S) experienced by a piezoelectric material per unit of electric field applied. The

Soft vs. Hard Ceramics

Behavior of a Piezoelectric

Element

Determining Resonance

Frequency

Applications

New Materials

Modes of Vibration for

first subscript to d indicates the direction of polarization generated in the material when the electric field, E, is zero or,

alternatively, is the direction of the applied field strength. The second subscript is the direction of the applied stress or the induced

strain, respectively. Because the strain induced in a piezoelectric material by an applied electric field is the product of the value for

the electric field and the value for d, d is an important indicator of a material's suitability for straindependent (actuator)

applications.

d33

direction 3

Piezoelectric Elements

or

What's a Transducer?

APC PIEZO CALC

induced polarization in direction 3 (parallel to direction in which ceramic element is polarized) per unit stress applied in

induced strain in direction 3 per unit electric field applied in direction 3

d31

induced polarization in direction 3 (parallel to direction in which ceramic element is polarized) per unit stress applied in

BLOG

direction 1 (perpendicular to direction in which ceramic element is polarized)

FAQ

or

WHITEPAPERS & TECHNICAL

UPDATES

induced strain in direction 1 per unit electric field applied in direction 3

d15

induced polarization in direction 1 (perpendicular to direction in which ceramic element is polarized) per unit shear

EMAIL ARCHIVE

stress applied about direction 2 (direction 2 perpendicular to direction in which ceramic element is polarized)

INDUSTRY RESOURCES

or

induced shear strain about direction 2 per unit electric field applied in direction 1

MARKETS

CONTACT US

Piezoelectric Voltage Constant

The piezoelectric voltage constant, g, is the electric field generated by a piezoelectric material per unit of mechanical stress applied

or, alternatively, is the mechanical strain experienced by a piezoelectric material per unit of electric displacement applied. The first

subscript to g indicates the direction of the electric field generated in the material, or the direction of the applied electric

displacement. The second subscript is the direction of the applied stress or the induced strain, respectively. Because the strength of

the induced electric field produced by a piezoelectric material in response to an applied physical stress is the product of the value

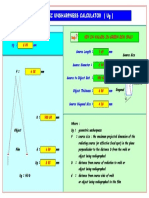

APC PIEZO

CALCULATOR

Calculate the most common

physical & electrical properties

of our piezo products with ease!

for the applied stress and the value for g, g is important for assessing a material's suitability for sensing (sensor) applications.

g33

induced electric field in direction 3 (parallel to direction in which ceramic element is polarized) per unit stress applied

in direction 3

or

induced strain in direction 3 per unit electric displacement applied in direction 3

g31

induced electric field in direction 3 (parallel to direction in which ceramic element is polarized) per unit stress applied

in direction 1 (perpendicular to direction in which ceramic element is polarized)

or

induced strain in direction 1 per unit electric displacement applied in direction 3

g15

induced electric field in direction 1 (perpendicular to direction in which ceramic element is polarized) per unit shear

stress applied about direction 2 (direction 2 perpendicular to direction in which ceramic element is polarized)

or

induced shear strain about direction 2 per unit electric displacement applied in direction 1

Permittivity

The permittivity, or dielectric constant, , for a piezoelectric ceramic material is the dielectric displacement per unit electric field.

T is the permittivity at constant stress, S is the permittivity at constant strain. The first subscript to > indicates the direction of

the dielectric displacement; the second is the direction of the electric field.

https://www.americanpiezo.com/knowledgecenter/piezotheory/piezoelectricconstants.html

1/4

12/20/2016

PiezoelectricConstants|ElasticCompliance|APCI

The relative dielectric constant, K, is the ratio of , the amount of charge that an element constructed from the ceramic material can

store, relative to the absolute dielectric constant, 0 , the charge that can be stored by the same electrodes when separated by a

vacuum, at equal voltage (0 = 8.85 x 1012 farad / meter).

T11

permittivity for dielectric displacement and electric field in direction 1 (perpendicular to direction in which ceramic

S33

permittivity for dielectric displacement and electric field in direction 3 (parallel to direction in which ceramic element is

element is polarized), under constant stress

polarized), under constant strain

Elastic Compliance

Elastic compliance, s, is the strain produced in a piezoelectric material per unit of stress applied and, for the 11 and 33 directions, is

the reciprocal of the modulus of elasticity (Young's modulus, Y). sD is the compliance under a constant electric displacement; sE is

the compliance under a constant electric field. The first subscript indicates the direction of strain, the second is the direction of

stress.

sE11

elastic compliance for stress in direction 1 (perpendicular to direction in which ceramic element is polarized) and

sD33

elastic compliance for stress in direction 3 (parallel to direction in which ceramic element is polarized) and accompanying

accompanying strain in direction 1, under constant electric field (short circuit)

strain in direction 3, under constant electric displacement (open circuit)

Young's Modulus

Young's modulus, Y, is an indicator of the stiffness (elasticity) of a ceramic material. Y is determined from the value for the stress

applied to the material divided by the value for the resulting strain in the same direction.

Electromechanical Coupling Factor

The electromechanical coupling factor, k, is an indicator of the effectiveness with which a piezoelectric material converts electrical

energy into mechanical energy, or converts mechanical energy into electrical energy. The first subscript to k denotes the direction

along which the electrodes are applied; the second denotes the direction along which the mechanical energy is applied, or

developed.

k values quoted in ceramic suppliers' specifications typically are theoretical maximum values. At low input frequencies, a typical

piezoelectric ceramic can convert 30 75% of the energy delivered to it in one form into the other form, depending on the

formulation of the ceramic and the directions of the forces involved.

A high k usually is desirable for efficient energy conversion, but k does not account for dielectric losses or mechanical losses, nor for

recovery of unconverted energy. The accurate measure of efficiency is the ratio of converted, useable energy delivered by the

piezoelectric element to the total energy taken up by the element. By this measure, piezoelectric ceramic elements in well

designed systems can exhibit efficiencies that exceed 90%.

The dimensions of a ceramic element can dictate unique expressions of k. For a thin disc of piezoelectric ceramic the planar coupling

factor, kp , expresses radial coupling the coupling between an electric field parallel to the direction in which the ceramic element

is polarized (direction 3) and mechanical effects that produce radial vibrations, relative to the direction of polarization (direction 1

and direction 2). For a disc or plate of material whose surface dimensions are large relative to its thickness, the thickness coupling

factor, kt , a unique expression of k33 , expresses the coupling between an electric field in direction 3 and mechanical vibrations in

the same direction. The resonance frequency for the thickness dimension of an element of this shape is much higher than the

resonance frequency for the transverse dimensions. At the same time, strongly attenuated transverse vibrations at this higher

resonance frequency, a result of the transverse contraction / expansion that accompanies the expansion / contraction in thickness,

make kt lower than k33 , the corresponding factor for longitudinal vibrations of a thin rod of the same material, for which a much

lower longitudinal resonance frequency more closely matches the transverse resonance frequency.

k 33

factor for electric field in direction 3 (parallel to direction in which ceramic element is polarized) and longitudinal

vibrations in direction 3

(ceramic rod, length >10x diameter)

kt

factor for electric field in direction 3 and vibrations in direction 3

(thin disc, surface dimensions large relative to thickness; kt < k33)

k 31

factor for electric field in direction 3 (parallel to direction in which ceramic element is polarized) and longitudinal

vibrations in direction 1 (perpendicular to direction in which ceramic element is polarized)

(ceramic rod)

kp

factor for electric field in direction 3 (parallel to direction in which ceramic element is polarized) and radial vibrations in

direction 1 and direction 2 (both perpendicular to direction in which ceramic element is polarized)

(thin disc)

Dielectric Dissipation Factor

The , tan , for a ceramic material is the tangent of the dielectric loss angle. tan is determined by the ratio of effective

conductance to effective susceptance in a parallel circuit, measured by using an impedance bridge. Values for tan typically are

determined at 1 kHz.

Frequency Constant

When an unrestrained piezoelectric ceramic element is exposed to a high frequency alternating electric field, an impedance

minimum, the planar or radial resonance frequency, coincides with the series resonance frequency, fs. The relationship between the

https://www.americanpiezo.com/knowledgecenter/piezotheory/piezoelectricconstants.html

2/4

12/20/2016

PiezoelectricConstants|ElasticCompliance|APCI

radial mode resonance frequency constant, NP , and the diameter of the ceramic element, D , is expressed by:

NP = fs D

At higher resonance, another impedance minimum, the axial resonance frequency, is encountered. The thickness mode frequency

constant, NT , is related to the thickness of the ceramic element, h, by:

NT = fs h

A third frequency constant, the longitudinal mode frequency constant, is related to the length of the element:

NL = fs l

MostUsed Constants and Equations

Aging Rate

Aging rate = (Par2 Par1) / ((Par1) (log t2 log t1))

Bandwidth

B kfp or B kfs

Dielectric Constant (Relative)

permittivity of ceramic material / permittivity of free space*

KT = T / < 0

*8.85 x 1012 farad / meter

Dielectric Dissipation Factor (Dielectric Loss Factor)

conductance / susceptance for parallel circuit equivalent to ceramic element;

tangent of loss angle (tan d)

measure directly, typically at 1 kHz

Elastic Compliance

strain developed / stress applied;

inverse of Young's modulus (elasticity)

s = 1 / 2

sD33 = 1 / YD33

sE33 = 1 / YE33

sD11 = 1 / YD11

sE11 = 1 / YE11

Electromechanical Coupling Factor

mechanical energy converted / electric energy input

or

electric energy converted / mechanical energy input

Static / low frequencies

ceramic plate

k312 = d312 / (sE11 T33 )

ceramic disc

kp 2 = 2d312 / ((sE11 + sE12) T33 )

ceramic rod

k332 = d332 / (sE33 T33 )

Higher frequencies

ceramic plate

ceramic disc

kp [(2.51 (fn fm) / fn) ((fn fm) / fn)2]

ceramic rod

k332 = ( / 2) (fn / fm) tan [( / 2) ((fn fm) / fn)]

any shape

keff2 = (fn2 fm2 ) / fn2

Frequency Constant

resonance frequency o linear dimension governing resonance

NL (longitudinal mode) = fs l

NP (radial mode) = fs D

NT (thickness mode) = fs h

Mechanical Quality Factor

reactance / resistance for series circuit equivalent to ceramic element

Qm = fn2 / (2fm C0 Z m (fn2 fm2))

Piezoelectric Charge Constant

electric field generated by unit area of ceramic / stress applied

or

strain in ceramic element / unit electric field applied

d = k(sE T )

d31 = k31(sE11 T33 )

d33 = k33(sE33 T33 )

d15 = k15E55 T11 )

Piezoelectric Voltage Constant

https://www.americanpiezo.com/knowledgecenter/piezotheory/piezoelectricconstants.html

3/4

12/20/2016

PiezoelectricConstants|ElasticCompliance|APCI

electric field generated / stress applied

or

strain in ceramic element / electric displacement applied

g = d / T

g31 = d31 / T33

g33 = d33 / T33

g15 = d15 / T11

Young's Modulus

stress applied / strain developed

Y = (F / A) / (l / l) = T / S

Relationship among d, T, and g

g = d / T or d = g T

Symbols

A

surface area of ceramic element (m2 )

bandwidth (frequency)

piezoelectric charge constant (C / N)

diameter of ceramic disc or rod (m)

permittivity of free space (8.85 x 1012 farad / m)

permittivity of ceramic material (farad / m) (at constant stress

force

fm

minimum impedance frequency (resonance frequency) (Hz)

fn

maximum impedance frequency (antiresonance frequency) (Hz)

fp

parallel resonance frequency (Hz)

fs

series resonance frequency (Hz)

piezoelectric voltage constant (Vm / N)

height (thickness) of ceramic element (m)

electromechanical coupling factor

keff

effective coupling factor

KT

relative dielectric constant (at constant stress)

initial length of ceramic element (m)

frequency constant (Hz*m)

Par1

value for parameter Par at t1 (days)

Par2

value for parameter Par at t2 (days)

Qm

mechanical quality factor

density of ceramic (kg / m3 )

elastic compliance (m2 / N)

strain

t1

time 1 after polarization (days)

t2

time 2 after polarization (days)

tan

dielectric dissipation factor

stress

To

temperature

TC

Curie point (C)

>

velocity of sound in the ceramic material (m / s)

width of ceramic element (m)

Young's modulus (N / m2 )

Zm

minimum impedance at fm (ohm)

For much more information about piezoelectric ceramics and their uses, order our book

Piezoelectric Ceramics: Principles and Applications

HOME

PRODUCTS & SERVICES

ABOUT US

KNOWLEDGE CENTER

CONTACT US

CAREERS

SITEMAP

Privacy Policy | Copyright 2016, All Rights Reserved. APC International, Ltd.

https://www.americanpiezo.com/knowledgecenter/piezotheory/piezoelectricconstants.html

P: 1.570.726.6961 | E: sales@americanpiezo.com

WEBDESIGN by WEBPAGEFX

4/4

You might also like

- LP Formulation MITDocument27 pagesLP Formulation MITAhmad DanielNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFAhmad Daniel100% (1)

- MT 10 Om 02 LDocument20 pagesMT 10 Om 02 LAhmad DanielNo ratings yet

- UgCalculator V1.1Document1 pageUgCalculator V1.1Ahmad DanielNo ratings yet

- CEng Pink BookDocument46 pagesCEng Pink BookAhmad DanielNo ratings yet

- NRC - 10 CFR Part 20-Standards For Protection Against RadiationDocument81 pagesNRC - 10 CFR Part 20-Standards For Protection Against RadiationAhmad DanielNo ratings yet

- Target Band 7 Trial Listening Edition4Document3 pagesTarget Band 7 Trial Listening Edition4Ahmad DanielNo ratings yet

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- API Exams CalculationsDocument20 pagesAPI Exams CalculationssyedsayeediNo ratings yet

- BLOB AnalysisDocument9 pagesBLOB AnalysisAhmad DanielNo ratings yet

- Playing Arpeggios Over Changes Ex in DmajDocument4 pagesPlaying Arpeggios Over Changes Ex in DmajMiguel PereiraNo ratings yet

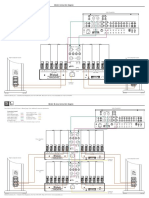

- MC452 Connection DiagramDocument2 pagesMC452 Connection DiagramAhmad DanielNo ratings yet

- NRC Regulations for Industrial RadiographyDocument24 pagesNRC Regulations for Industrial RadiographyAhmad DanielNo ratings yet

- Periodic Table IsotopesDocument1 pagePeriodic Table IsotopeslamantreveurNo ratings yet

- NRC - 10 CFR Part 71-Packaging and Transportation of Radioactive MaterialDocument70 pagesNRC - 10 CFR Part 71-Packaging and Transportation of Radioactive MaterialAhmad DanielNo ratings yet

- Alessandro Amp ArticleDocument1 pageAlessandro Amp ArticleAhmad DanielNo ratings yet

- X-Desk X-Panded Recall SheetDocument1 pageX-Desk X-Panded Recall SheetAhmad DanielNo ratings yet

- MT 10 Om 02 LDocument20 pagesMT 10 Om 02 LAhmad DanielNo ratings yet

- WA Sabrina Hi Fi News 08-15Document3 pagesWA Sabrina Hi Fi News 08-15Ahmad DanielNo ratings yet

- Bigsby Parts 2010Document85 pagesBigsby Parts 2010Ahmad DanielNo ratings yet

- Blues Scale W/tapping: 3-Notes Per Strings Mayones School #5Document1 pageBlues Scale W/tapping: 3-Notes Per Strings Mayones School #5Ahmad DanielNo ratings yet

- XLogic X-Desk Install GuideDocument48 pagesXLogic X-Desk Install GuideAhmad DanielNo ratings yet

- HFN Pro-JectClassic LowresDocument3 pagesHFN Pro-JectClassic LowresAhmad DanielNo ratings yet

- Funk Guitar Rhythms Pt1 PDFDocument2 pagesFunk Guitar Rhythms Pt1 PDFAlvaro RodriguesNo ratings yet

- API 570 FormulasDocument2 pagesAPI 570 FormulasArif Mokhtar89% (9)

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielNo ratings yet

- Hamka Dibawah Lindungan KabahDocument1 pageHamka Dibawah Lindungan KabahAhmad DanielNo ratings yet

- Audeze LCD-X PathosDocument3 pagesAudeze LCD-X PathosAhmad DanielNo ratings yet

- HFN Pro-JectClassic LowresDocument3 pagesHFN Pro-JectClassic LowresAhmad DanielNo ratings yet

- WA Sabrina Hi Fi News 08-15Document3 pagesWA Sabrina Hi Fi News 08-15Ahmad DanielNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)