Professional Documents

Culture Documents

Datasheet For Ball Valve

Uploaded by

Damu JankerboyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Datasheet For Ball Valve

Uploaded by

Damu JankerboyCopyright:

Available Formats

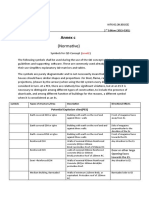

BALL VALVE DATA SHEETS

A

REV

Issued for Review and Comments

DATE

DESCRIPTION

BY

CHK'D

TOTAL OR PARTIAL REPRODUCTION AND / OR UTILISATION OF THIS DOCUMENTATION ARE FORBIDDEN

WITHOUT PRIOR WRITTEN AUTHORIZATION OF THE OWNER

Document No:

XXX-VALVE-DTS-XXXX

VE DATA SHEETS

UTILISATION OF THIS DOCUMENTATION ARE FORBIDDEN

N AUTHORIZATION OF THE OWNER

APPR

CLIENT

CLIENT :

REVISION : A

SHEET No. : 1 OF 1

GENERAL

SERVICE: HydroCarbon and Vapour

REV

VENDOR COMPLIANCE

Valve Tag No.

Size Range

Valve Type

Standard

Rating

Valve operation

End Connection

Face to Face dimension

VB8-42(FB)

1/2" - 1 1/2"

Ball Valve

BS 5351 (As per ASME B, 16.34 as a minimum)

CL 800

Lever Operated

(Note 2)

ASME B 16.10 / MFG STD

2

3

4

5

6

7

8

9

10

Body

Type of mounting

Port

Bolted or screwed body

Floating Ball

Full Bore

12

13

14

15

16

Body

Ball

Stem

Seat

Seal

Gland Packing

ASTM A 216 WCB (Note-4)

ASTM A 182 F 316

ASTM A 182 F 316

Filled Teflon

Filled Teflon-Niton

RPTFE/Graphite (Note-5)

18

19

20

21

22

23

Bolting

PTFE Coated

24

Design Pressure (kg/cm2 g)

Design Temperature (Deg C)

Corrosion Allowance

As per Piping Material Specification

As per Piping Material Specification

3 mm

25

26

27

28

29

30

31

Body

Seat

Test pressure with Air

Test std

Fire safe design

*

*

*

API 598

API 607

33

34

35

36

37

Test Pressure

Test Pressure shall be in Accordance with ASME B 16.34 and Valve Inspection and

testing procedure shall be in Accordance with API 598.

38

Fire Safe (API 6FA, API 607 or BS 6755

Part-2)

Yes

39

Anti Static Device

Yes

40

Auto Body Cavity Pressure Relief

Yes

41

Blow Out Proof Stem

Yes

42

Painting

To be confirmed during Purchase order

43

Special Requirements

Not Applicable

44

Certification Requirements

EN 10204-3.1B

45

TESTS

DESIGN CONDITIONS

MATERIALS

CONSTRUCTION

11

17

32

GENERAL NOTES

SUPPLEMENTARY REQUIREMENTS

Radiography Examination

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

1. Valves shall be supplied with position indicator

2. SW to ASME B16.11 (3000# for 1/2", 3/4" to 1 1/2")

3. No cutting / overwritting by vendor on this specification is allowed

4, Vendor to advice for cost effective Manufacturing Technique

5. MFG STD, Material to be suitable for fluid service and qualified in API-607

62

DATE

REV

DESCRIPTION

PREPARED

CHECKED

APPD

CLIENT

CLIENT :

REVISION : A

SHEET No. : 1 OF 1

GENERAL

SERVICE: HydroCarbon and Vapour

REV

VENDOR COMPLIANCE

Valve Tag No.

VB8-42

Size Range

1/2" - 1 1/2"

Valve Type

Ball Valve

Standard

BS 5351 (As per ASME B, 16.34 as a minimum)

Rating

CL 800

Valve operation

Lever Operated

End Connection

(Note 2)

Face to Face dimension

ASME B 16.10 / MFG STD

8

9

10

TESTS

DESIGN CONDITIONS

MATERIALS

CONSTRUCTION

11

Body

Bolted or screwed body

12

Type of mounting

Floating Ball

13

Port

Reduced Bore

14

15

16

17

Body

ASTM A 216 WCB (Note-4)

18

Ball

ASTM A 182 F 316

19

Stem

ASTM A 182 F 316

20

Seat

Filled Teflon

21

Seal

Filled Teflon-Niton

22

Gland Packing

RPTFE/Graphite (Note-5)

23

Bolting

PTFE Coated

24

Design Pressure (kg/cm 2 g)

As per Piping Material Specification

25

Design Temperature (Deg C)

As per Piping Material Specification

26

Corrosion Allowance

3 mm

27

28

29

30

31

32

Body

33

Seat

34

Test pressure with Air

35

Test std

API 598

36

Fire safe design

API 607

37

Test Pressure

Test Pressure shall be in Accordance with ASME B 16.34 and Valve Inspection and testing

procedure shall be in Accordance with API 598.

38

Fire Safe (API 6FA, API 607 or BS 6755 Part-2)

Yes

39

Anti Static Device

Yes

40

Auto Body Cavity Pressure Relief

Yes

41

Blow Out Proof Stem

Yes

42

Painting

To be confirmed during Purchase order

43

Special Requirements

Not Applicable

44

Certification Requirements

EN 10204-3.1B

45

SUPPLEMENTARY

REQUIREMENTS

Radiography Examination

46

47

2. SW to ASME B16.11 (3000# for 1/2", 3/4" to 1 1/2")

48

3. No cutting / overwritting by vendor on this specification is allowed

49

4. Vendor to advice for cost effective Manufacturing Technique

50

5. MFG STD, Material to be suitable for fluid service and qualified in API-607

51

GENERAL NOTES

1. Valves shall be supplied with position indicator

52

53

54

55

56

57

58

59

60

61

62

DATE

REV

DESCRIPTION

PREPARED

CHECKED

APPROVED

CLIENT

CLIENT :

REVISION : A

SHEET No. : 1 OF 1

GENERAL

SERVICE: HydroCarbon and Vapour

REV

VENDOR COMPLIANCE

Valve Tag No.

Size Range

VB1-60

2" - 4"

2

3

Valve Type

Standard

Ball Valve

BS 5351 (As per ASME B, 16.34 as a minimum)

4

5

Rating

Valve operation

CL 150

Lever Operated

6

7

End Connection

Face to Face dimension

(Note 2)

ASME B 16.10 / MFG STD

8

9

10

TESTS

DESIGN CONDITIONS

MATERIALS

CONSTRUCTION

11

Body

Type of mounting

Port

12

13

14

Reduced Bore

15

16

17

Body

Ball

Stem

ASTM A 216 WCB (Note-4)

ASTM A 182 F 316

ASTM A 182 F 316

Seat

Filled Teflon

20

21

Seal

Gland Packing

Filled Teflon-Niton

RPTFE/Graphite (Note-5)

22

23

Bolting

PTFE Coated

24

Design Pressure (kg/cm2 g)

As per Piping Material Specification

25

Design Temperature (Deg C)

Corrosion Allowance

As per Piping Material Specification

3 mm

26

27

18

19

28

29

30

31

32

Body

Seat

*

*

33

34

Test pressure with Air

Test std

*

API 598

35

36

Fire safe design

API 607

37

Test Pressure

Test Pressure shall be in Accordance with ASME B 16.34 and Valve Inspection and

testing procedure shall be in Accordance with API 598.

38

Fire Safe (API 6FA, API 607 or BS 6755

Part-2)

Yes

39

Anti Static Device

Yes

40

Auto Body Cavity Pressure Relief

Yes

41

Blow Out Proof Stem

Yes

42

Painting

To be confirmed during Purchase order

43

Special Requirements

Not Applicable

44

Certification Requirements

EN 10204-3.1B

45

Radiography Examination

SUPPLEMENTARY

REQUIREMENTS

Bolted Body

Floating Ball 150# 2" TO 4" VB (FB)

GENERAL NOTES

46

1. Valves shall be supplied with position indicator

2. RF Flanged end, As per ASME B 16.5

47

48

3. No cutting / overwritting by vendor on this specification is allowed

4. Vendor to advice for cost effective Manufacturing Technique

49

50

5. MFG STD, Material to be suitable for fluid service and qualified in API-607

51

52

53

54

55

56

57

58

59

60

61

62

DATE

REV

DESCRIPTION

PREPARED

CHECKED

APPROVED

CLIENT

CLIENT :

REVISION : A

SHEET No. : 1 OF 1

GENERAL

SERVICE: HydroCarbon and Vapour

REV

VENDOR COMPLIANCE

Valve Tag No.

VB1-60(FB)

Size Range

2" - 4"

Valve Type

Ball Valve

Standard

BS 5351 (As per ASME B, 16.34 as a minimum)

Rating

CL 150

Valve operation

Lever Operated

End Connection

(Note 2)

Face to Face dimension

ASME B 16.10 / MFG STD

8

9

10

TESTS

DESIGN CONDITIONS

MATERIALS

CONSTRUCTION

11

Body

Bolted Body

12

Type of mounting

Floating Ball

13

Port

Full Bore

14

15

16

17

Body

ASTM A 216 WCB (Note-4)

18

Ball

ASTM A 182 F 316

19

Stem

ASTM A 182 F 316

20

Seat

Filled Teflon

21

Seal

Filled Teflon-Niton

22

Gland Packing

RPTFE/Graphite (Note-5)

23

Bolting

PTFE Coated

24

Design Pressure (kg/cm 2 g)

As per Piping Material Specification

25

Design Temperature (Deg C)

As per Piping Material Specification

26

Corrosion Allowance

3 mm

27

28

29

30

31

32

Body

33

Seat

34

Test pressure with Air

35

Test std

API 598

36

Fire safe design

API 607

37

Test Pressure

Test Pressure shall be in Accordance with ASME B 16.34 and Valve Inspection and testing

procedure shall be in Accordance with API 598.

38

Fire Safe (API 6FA, API 607 or BS 6755 Part-2)

Yes

39

Anti Static Device

Yes

40

Auto Body Cavity Pressure Relief

Yes

41

Blow Out Proof Stem

Yes

42

Painting

To be confirmed during Purchase order

43

Special Requirements

Not Applicable

44

Certification Requirements

EN 10204-3.1B

45

SUPPLEMENTARY

REQUIREMENTS

Radiography Examination

46

47

2. RF Flanged end, As per ASME B 16.5

48

3. No cutting / overwritting by vendor on this specification is allowed

49

4. Vendor to advice for cost effective Manufacturing Technique

50

5. MFG STD, Material to be suitable for fluid service and qualified in API-607

51

GENERAL NOTES

1. Valves shall be supplied with position indicator

52

53

54

55

56

57

58

59

60

61

62

DATE

REV

DESCRIPTION

PREPARED

CHECKED

APPROVED

CLIENT

CLIENT :

REVISION : A

SHEET No. : 1 OF 1

GENERAL

SERVICE: HydroCarbon and Vapour

REV

VENDOR COMPLIANCE

Valve Tag No.

VB3-65(FB)

Size Range

2" - 4"

Valve Type

Ball Valve

Standard

BS 5351 (As per ASME B, 16.34 as a minimum)

Rating

CL 300

Valve operation

Lever Operated

End Connection

(Note 2)

Face to Face dimension

ASME B 16.10 / MFG STD

8

9

10

TESTS

DESIGN CONDITIONS

MATERIALS

CONSTRUCTION

11

Body

Bolted Body

12

Type of mounting

Floating Ball

13

Port

Full Bore

14

15

16

17

Body

ASTM A 216 WCB (Note-4)

18

Ball

ASTM A 182 F 316

19

Stem

ASTM A 182 F 316

20

Seat

Filled Teflon

21

Seal

Filled Teflon-Niton

22

Gland Packing

RPTFE/Graphite (Note-5)

23

Bolting

PTFE Coated

24

Design Pressure (kg/cm 2 g)

As per Piping Material Specification

25

Design Temperature (Deg C)

As per Piping Material Specification

26

Corrosion Allowance

3 mm

27

28

29

30

31

32

Body

33

Seat

34

Test pressure with Air

35

Test std

API 598

36

Fire safe design

API 607

37

Test Pressure

Test Pressure shall be in Accordance with ASME B 16.34 and Valve Inspection and testing

procedure shall be in Accordance with API 598.

38

Fire Safe (API 6FA, API 607 or BS 6755 Part-2)

Yes

39

Anti Static Device

Yes

40

Auto Body Cavity Pressure Relief

Yes

41

Blow Out Proof Stem

Yes

42

Painting

To be confirmed during Purchase order

43

Special Requirements

Not Applicable

44

Certification Requirements

EN 10204-3.1B

45

SUPPLEMENTARY

REQUIREMENTS

Radiography Examination

46

47

2. RF Flanged end, As per ASME B 16.5

48

3. No cutting / overwritting by vendor on this specification is allowed

49

4. Vendor to advice for cost effective Manufacturing Technique

50

5. MFG STD, Material to be suitable for fluid service and qualified in API-607

51

GENERAL NOTES

1. Valves shall be supplied with position indicator

52

53

54

55

56

57

58

59

60

61

62

DATE

REV

DESCRIPTION

PREPARED

CHECKED

APPROVED

CLIENT

CLIENT :

REVISION : A

SHEET No. : 1 OF 1

GENERAL

SERVICE: HydroCarbon and Vapour

REV

VENDOR COMPLIANCE

Valve Tag No.

VB8-42(FB)

Size Range

1/ 2" - 1 1/2"

Valve Type

Ball Valve

Standard

BS 5351 (As per ASME B, 16.34 as a minimum)

Rating

CL 800

Valve operation

Lever Operated

End Connection

(Note 2)

Face to Face dimension

ASME B 16.10 / MFG STD

8

9

10

TESTS

DESIGN CONDITIONS

MATERIALS

CONSTRUCTION

11

Body

Bolted Body

12

Type of mounting

Floating Ball

13

Port

Full Bore

14

15

16

17

Body

ASTM A 216 WCB (Note-4)

18

Ball

ASTM A 182 F 316

19

Stem

ASTM A 182 F 316

20

Seat

Filled Teflon

21

Seal

Filled Teflon-Niton

22

Gland Packing

RPTFE/Graphite (Note-5)

23

Bolting

PTFE Coated

24

Design Pressure (kg/cm 2 g)

As per Piping Material Specification

25

Design Temperature (Deg C)

As per Piping Material Specification

26

Corrosion Allowance

3 mm

27

28

29

30

31

32

Body

33

Seat

34

Test pressure with Air

35

Test std

API 598

36

Fire safe design

API 607

37

Test Pressure

Test Pressure shall be in Accordance with ASME B 16.34 and Valve Inspection and testing

procedure shall be in Accordance with API 598.

38

Fire Safe (API 6FA, API 607 or BS 6755 Part-2)

Yes

39

Anti Static Device

Yes

40

Auto Body Cavity Pressure Relief

Yes

41

Blow Out Proof Stem

Yes

42

Painting

To be confirmed during Purchase order

43

Special Requirements

Not Applicable

44

Certification Requirements

EN 10204-3.1B

45

SUPPLEMENTARY

REQUIREMENTS

Radiography Examination

46

47

2. SW to ASME B16.11 (6000# for 1/2", 3/4" to 1 1/2")

48

3. No cutting / overwritting by vendor on this specification is allowed

49

4. Vendor to advice for cost effective Manufacturing Technique

50

5. MFG STD, Material to be suitable for fluid service and qualified in API-607

51

GENERAL NOTES

1. Valves shall be supplied with position indicator

52

53

54

55

56

57

58

59

60

61

62

DATE

REV

DESCRIPTION

PREPARED

CHECKED

APPROVED

CLIENT

CLIENT :

REVISION : A

SHEET No. : 1 OF 1

GENERAL

SERVICE: HydroCarbon and Vapour

REV

VENDOR COMPLIANCE

Valve Tag No.

VB6-70

Size Range

1/2" - 3"

Valve Type

Ball Valve

Standard

BS 5351 (As per ASME B, 16.34 as a minimum)

Rating

CL 600

Valve operation

Lever Operated

End Connection

(Note 2)

Face to Face dimension

ASME B 16.10 / MFG STD

8

9

10

TESTS

DESIGN CONDITIONS

MATERIALS

CONSTRUCTION

11

Body

Bolted Body

12

Type of mounting

Floating Ball

13

Port

Reduced Bore

14

15

16

17

Body

ASTM A 216 WCB (Note-4)

18

Ball

ASTM A 182 F 316

19

Stem

ASTM A 182 F 316

20

Seat

Filled Teflon

21

Seal

Filled Teflon-Niton

22

Gland Packing

RPTFE/Graphite (Note-5)

23

Bolting

PTFE Coated

24

Design Pressure (kg/cm 2 g)

As per Piping Material Specification

25

Design Temperature (Deg C)

As per Piping Material Specification

26

Corrosion Allowance

3 mm

27

28

29

30

31

32

Body

33

Seat

34

Test pressure with Air

35

Test std

API 598

36

Fire safe design

API 607

37

Test Pressure

Test Pressure shall be in Accordance with ASME B 16.34 and Valve Inspection and testing

procedure shall be in Accordance with API 598.

38

Fire Safe (API 6FA, API 607 or BS 6755 Part-2)

Yes

39

Anti Static Device

Yes

40

Auto Body Cavity Pressure Relief

Yes

41

Blow Out Proof Stem

Yes

42

Painting

To be confirmed during Purchase order

43

Special Requirements

Not Applicable

44

Certification Requirements

EN 10204-3.1B

45

SUPPLEMENTARY

REQUIREMENTS

Radiography Examination

46

47

2. RF Flanged end, As per ASME B 16.5

48

3. No cutting / overwritting by vendor on this specification is allowed

49

4. Vendor to advice for cost effective Manufacturing Technique

50

5. MFG STD, Material to be suitable for fluid service and qualified in API-607

51

GENERAL NOTES

1. Valves shall be supplied with position indicator

52

53

54

55

56

57

58

59

60

61

62

DATE

REV

DESCRIPTION

PREPARED

CHECKED

APPROVED

CLIENT

CLIENT :

REVISION : A

SHEET No. : 1 OF 1

GENERAL

SERVICE: HydroCarbon and Vapour

REV

VENDOR COMPLIANCE

Valve Tag No.

Size Range

Valve Type

Standard

Rating

Valve operation

End Connection

Face to Face dimension

VB8-42

1/2" - 3"

Ball Valve

BS 5351 (As per ASME B, 16.34 as a minimum)

CL 800

Lever Operated

(Note 2)

ASME B 16.10 / MFG STD

2

3

4

5

6

7

8

9

10

Body

Type of mounting

Port

Bolted Body

Floating Ball

Reduced Bore

12

13

14

15

16

Body

Ball

Stem

Seat

Seal

Gland Packing

ASTM A 216 WCB (Note-4)

ASTM A 182 F 316

ASTM A 182 F 316

Filled Teflon

Filled Teflon-Niton

RPTFE/Graphite (Note-5)

18

19

20

21

22

23

Bolting

PTFE Coated

24

Design Pressure (kg/cm2 g)

Design Temperature (Deg C)

Corrosion Allowance

As per Piping Material Specification

As per Piping Material Specification

3 mm

25

26

27

28

29

30

31

Body

Seat

Test pressure with Air

Test std

Fire safe design

*

*

*

API 598

API 607

33

34

35

36

37

Test Pressure

Test Pressure shall be in Accordance with ASME B 16.34 and Valve Inspection and

testing procedure shall be in Accordance with API 598.

38

Fire Safe (API 6FA, API 607 or BS 6755

Part-2)

Yes

39

Anti Static Device

Yes

40

Auto Body Cavity Pressure Relief

Yes

41

Blow Out Proof Stem

Yes

42

Painting

To be confirmed during Purchase order

43

Special Requirements

Not Applicable

44

Certification Requirements

EN 10204-3.1B

45

TESTS

DESIGN CONDITIONS

MATERIALS

CONSTRUCTION

11

17

32

GENERAL NOTES

SUPPLEMENTARY REQUIREMENTS

Radiography Examination

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

1. Valves shall be supplied with position indicator

2. SW to ASME B16.11 (3000# for 1/2", 3/4" to 1 1/2")

3. No cutting / overwritting by vendor on this specification is allowed

4. Vendor to advice for cost effective Manufacturing Technique

5. MFG STD, Material to be suitable for fluid service and qualified in API-607

62

DATE

REV

DESCRIPTION

PREPARED

CHECKED

APPROVED

CLIENT

CLIENT :

REVISION : A

SHEET No. : 1 OF 1

GENERAL

SERVICE: HydroCarbon and Vapour

REV

VENDOR COMPLIANCE

Valve Tag No.

VB8-42(FB)

Size Range

1/2" - 3"

Valve Type

Ball Valve

Standard

BS 5351 (As per ASME B, 16.34 as a minimum)

Rating

CL 800

Valve operation

Lever Operated

End Connection

(Note 2)

Face to Face dimension

ASME B 16.10 / MFG STD

8

9

10

TESTS

DESIGN CONDITIONS

MATERIALS

CONSTRUCTION

11

Body

Bolted Body

12

Type of mounting

Floating Ball

13

Port

Full Bore

14

15

16

17

Body

ASTM A 216 WCB (Note-4)

18

Ball

ASTM A 182 F 316

19

Stem

ASTM A 182 F 316

20

Seat

Filled Teflon

21

Seal

Filled Teflon-Niton

22

Gland Packing

RPTFE/Graphite (Note-5)

23

Bolting

PTFE Coated

24

Design Pressure (kg/cm 2 g)

As per Piping Material Specification

25

Design Temperature (Deg C)

As per Piping Material Specification

26

Corrosion Allowance

3 mm

27

28

29

30

31

32

Body

33

Seat

34

Test pressure with Air

35

Test std

API 598

36

Fire safe design

API 607

37

Test Pressure

Test Pressure shall be in Accordance with ASME B 16.34 and Valve Inspection and testing

procedure shall be in Accordance with API 598.

38

Fire Safe (API 6FA, API 607 or BS 6755 Part-2)

Yes

39

Anti Static Device

Yes

40

Auto Body Cavity Pressure Relief

Yes

41

Blow Out Proof Stem

Yes

42

Painting

To be confirmed during Purchase order

43

Special Requirements

Not Applicable

44

Certification Requirements

EN 10204-3.1B

45

SUPPLEMENTARY

REQUIREMENTS

Radiography Examination

46

47

2. SW to ASME B16.11 (3000# for 1/2", 3/4" to 1 1/2")

48

3. No cutting / overwritting by vendor on this specification is allowed

49

4. Vendor to advice for cost effective Manufacturing Technique

50

5. MFG STD, Material to be suitable for fluid service and qualified in API-607

51

GENERAL NOTES

1. Valves shall be supplied with position indicator

52

53

54

55

56

57

58

59

60

61

62

DATE

REV

DESCRIPTION

PREPARED

CHECKED

APPROVED

CLIENT

CLIENT :

REVISION : A

SHEET No. : 1 OF 1

GENERAL

SERVICE: HydroCarbon and Vapour

REV

VENDOR COMPLIANCE

Valve Tag No.

VB6-76 (FB)

Size Range

4" - 6"

Valve Type

Ball Valve

Standard

BS 5351 (As per ASME B, 16.34 as a minimum)

Rating

CL 600

Valve operation

Lever Operated

End Connection

(Note 2)

Face to Face dimension

ASME B 16.10 / MFG STD

8

9

10

TESTS

DESIGN CONDITIONS

MATERIALS

CONSTRUCTION

11

Body

Bolted Body, Renewable seats

12

Type of mounting

Trunion Mounted

13

Port

Full Bore

14

15

16

17

Body

ASTM A 216 WCB (Note-4)

18

Ball

ASTM A 182 F 316

19

Stem

ASTM A 182 F 316

20

Seat

Nylon / Viton

21

Seal

Filled Teflon-Niton

22

Gland Packing

RPTFE/Graphite (Note-5)

23

Bolting

PTFE Coated

24

Design Pressure (kg/cm 2 g)

As per Piping Material Specification

25

Design Temperature (Deg C)

As per Piping Material Specification

26

Corrosion Allowance

3 mm

27

28

29

30

31

32

Body

33

Seat

34

Test pressure with Air

35

Test std

API 598

36

Fire safe design

API 607

37

Test Pressure

Test Pressure shall be in Accordance with ASME B 16.34 and Valve Inspection and testing

procedure shall be in Accordance with API 598.

38

Fire Safe (API 6FA, API 607 or BS 6755 Part-2)

Yes

39

Anti Static Device

Yes

40

Auto Body Cavity Pressure Relief

Yes

41

Blow Out Proof Stem

Yes

42

Painting

To be confirmed during Purchase order

43

Special Requirements

Not Applicable

44

Certification Requirements

EN 10204-3.1B

45

SUPPLEMENTARY

REQUIREMENTS

Radiography Examination

46

47

2. RF Flanged end, As per ASME B 16.5

48

3. No cutting / overwritting by vendor on this specification is allowed

49

4. Vendor to advice for cost effective Manufacturing Technique

50

5. MFG STD, Material to be suitable for fluid service and qualified in API-607

51

GENERAL NOTES

1. Valves shall be supplied with position indicator

52

53

54

55

56

57

58

59

60

61

62

DATE

REV

DESCRIPTION

PREPARED

CHECKED

APPROVED

CLIENT

CLIENT :

REVISION : A

SHEET No. : 1 OF 1

GENERAL

SERVICE: HydroCarbon and Vapour

REV

VENDOR COMPLIANCE

Valve Tag No.

VB25-126

Size Range

1/2" - 1 1/2"

Valve Type

Ball Valve

Standard

BS 5351 (As per ASME B, 16.34 as a minimum)

Rating

CL 2500

Valve operation

Lever Operated

End Connection

(Note 2)

Face to Face dimension

ASME B 16.10 / MFG STD

8

9

10

TESTS

DESIGN CONDITIONS

MATERIALS

CONSTRUCTION

11

Body

Bolted Body, Renewable seats

12

Type of mounting

Floating mounted

13

Port

Full Bore

14

15

16

17

Body

22% Cr, ASTM A 815, UNS S31803 (Note-4)

18

Ball

22% Cr,ASTM A 815, UNS S31803

19

Stem

22% Cr, ASTM A 815, UNS S31803

20

Seat

Filled Teflon

21

Seal

Filled Teflon

22

Gland Packing

RPTFE/Graphite (Note-5)

23

Bolting

ASTM A 182(F51)/ ASTM A 193 DSS 2507

24

Design Pressure (kg/cm 2 g)

As per Piping Material Specification

25

Design Temperature (Deg C)

As per Piping Material Specification

26

Corrosion Allowance

3 mm

27

28

29

30

31

32

Body

33

Seat

34

Test pressure with Air

35

Test std

API 598

36

Fire safe design

API 607

37

Test Pressure

Test Pressure shall be in Accordance with ASME B 16.34 and Valve Inspection and testing

procedure shall be in Accordance with API 598.

38

Fire Safe (API 6FA, API 607 or BS 6755 Part-2)

Yes

39

Anti Static Device

Yes

40

Auto Body Cavity Pressure Relief

Yes

41

Blow Out Proof Stem

Yes

42

Painting

To be confirmed during Purchase order

43

Special Requirements

Not Applicable

44

Certification Requirements

EN 10204-3.1B

45

SUPPLEMENTARY

REQUIREMENTS

Radiography Examination

46

47

2. SW to ASME B16.11 (3000# for 1/2", 3/4" to 1 1/2")

48

3. No cutting / overwritting by vendor on this specification is allowed

49

4. Vendor to advice for cost effective Manufacturing Technique

50

5. MFG STD, Material to be suitable for fluid service and qualified in API-607

51

GENERAL NOTES

1. Valves shall be supplied with position indicator

52

53

54

55

56

57

58

59

60

61

62

DATE

REV

DESCRIPTION

PREPARED

CHECKED

APPROVED

CLIENT

CLIENT :

REVISION : A

SHEET No. : 1 OF 1

GENERAL

SERVICE: HydroCarbon and Vapour

REV

VENDOR COMPLIANCE

Valve Tag No.

Size Range

Valve Type

Standard

Rating

Valve operation

End Connection

Face to Face dimension

VB25-134

1/2" - 1 1/2"

Ball Valve

BS 5351 (As per ASME B, 16.34 as a minimum)

CL 2500

Lever Operated

(Note 2)

ASME B 16.10 / MFG STD

2

3

4

5

6

7

8

9

10

Body

Type of mounting

Port

Bolted Body, Renewable seats

Floating mounted

Full Bore

12

13

14

15

16

Body

Ball

Stem

22% Cr, ASTM A 815, UNS S31803 (Note-4)

22% Cr,ASTM A 815, UNS S31803

22% Cr, ASTM A 815, UNS S31803

Seat

Seal

Gland Packing

Filled Teflon

Filled Teflon

RPTFE/Graphite (Note-5)

18

19

20

21

22

23

Bolting

ASTM A 182(F51)/ ASTM A 193 DSS 2507

24

Design Pressure (kg/cm2 g)

Design Temperature (Deg C)

Corrosion Allowance

As per Piping Material Specification

As per Piping Material Specification

3 mm

25

26

27

28

29

30

31

Body

Seat

Test pressure with Air

Test std

Fire safe design

*

*

*

API 598

API 607

33

34

35

36

37

Test Pressure

Test Pressure shall be in Accordance with ASME B 16.34 and Valve Inspection and

testing procedure shall be in Accordance with API 598.

38

Fire Safe (API 6FA, API 607 or BS 6755

Part-2)

Yes

39

Anti Static Device

Yes

40

Auto Body Cavity Pressure Relief

Yes

41

Blow Out Proof Stem

Yes

42

Painting

To be confirmed during Purchase order

43

Special Requirements

Not Applicable

44

Certification Requirements

EN 10204-3.1B

45

TESTS

DESIGN CONDITIONS

MATERIALS

CONSTRUCTION

11

17

32

GENERAL NOTES

SUPPLEMENTARY REQUIREMENTS

Radiography Examination

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

1. Valves shall be supplied with position indicator

2. RTJ Flanged end, As per ASME B 16.5

3. No cutting / overwritting by vendor on this specification is allowed

4. Vendor to advice for cost effective Manufacturing Technique

5. MFG STD, Material to be suitable for fluid service and qualified in API-607

62

DATE

REV

DESCRIPTION

PREPARED

CHECKED

APPROVED

CLIENT

You might also like

- Bb.g-Vsp-Pve-Ed-20-Me-Das-001 - 0Document24 pagesBb.g-Vsp-Pve-Ed-20-Me-Das-001 - 0Luong AnhNo ratings yet

- WPI-KE-1104-SP141-QM5433 (Datasheet)Document4 pagesWPI-KE-1104-SP141-QM5433 (Datasheet)Jèfrì PìnémNo ratings yet

- 600 # ANSI Piping DataDocument16 pages600 # ANSI Piping DataMekar MeinaNo ratings yet

- XV Data SheetDocument1 pageXV Data SheetMathivanan Anbazhagan100% (1)

- Ball Valve Data Sheet: Item Requirement NotesDocument1 pageBall Valve Data Sheet: Item Requirement NotesVivi OktaviantiNo ratings yet

- Piping Material SpecificationDocument36 pagesPiping Material Specificationravirawat15100% (2)

- Customer Name Date Bid Due Date: Sweco Fab Inc. Customer RFQ FormDocument2 pagesCustomer Name Date Bid Due Date: Sweco Fab Inc. Customer RFQ FormGustavo GarciaNo ratings yet

- MIS-M-DS-04053 50m3 Slop Tank Data Sheet-BDocument2 pagesMIS-M-DS-04053 50m3 Slop Tank Data Sheet-Bhappale2002No ratings yet

- VDS (Valve Data Sheet)Document1 pageVDS (Valve Data Sheet)Shandi Hasnul Farizal0% (1)

- Output Summary: SI UnitsDocument42 pagesOutput Summary: SI UnitsAkhil JoseNo ratings yet

- MTO ValveDocument2 pagesMTO ValveAgus MarpaungNo ratings yet

- Pressure RELIEF VALVE DATA SHEETDocument4 pagesPressure RELIEF VALVE DATA SHEETAlvin Smith100% (1)

- 7-12-0017 Rev 5Document2 pages7-12-0017 Rev 5cynideNo ratings yet

- Manual Valves Datasheet. Rev 1Document7 pagesManual Valves Datasheet. Rev 1eke23No ratings yet

- Pid Btorf - Rev 0 HighlightDocument20 pagesPid Btorf - Rev 0 HighlightBayuPawitraBrodjonegoroNo ratings yet

- U00034-PL-MTO-0001 - MTO For Export PipelinesDocument7 pagesU00034-PL-MTO-0001 - MTO For Export PipelinesThiên KhánhNo ratings yet

- Pipe Class Data Sheet - Rev.1Document4 pagesPipe Class Data Sheet - Rev.1bonnicoNo ratings yet

- Datasheet Pressure Indicating Controller PDFDocument5 pagesDatasheet Pressure Indicating Controller PDFHimawan Sigit NugrohoNo ratings yet

- Peq001-03-Dcom-0000-Pl-T601-3001-2 - General Drawing Tlt-La-3170Document1 pagePeq001-03-Dcom-0000-Pl-T601-3001-2 - General Drawing Tlt-La-3170Carlin BabuchasNo ratings yet

- TDW - D2000 Quick Opening ClosureDocument7 pagesTDW - D2000 Quick Opening ClosureBayu PutraNo ratings yet

- Common Materilas For CS PipingDocument2 pagesCommon Materilas For CS PipingValiullah SarpanchNo ratings yet

- Api 674 Pump Data SheetDocument5 pagesApi 674 Pump Data Sheetroronoa_zorro11No ratings yet

- BFW Cooler Datasheet Rev-2Document3 pagesBFW Cooler Datasheet Rev-2Anonymous iCFJ73OMpDNo ratings yet

- Vessel Calculation 200Document37 pagesVessel Calculation 200Phát NguyễnNo ratings yet

- BELP-SPBEL-MS-EDS-F005-Rev 0 Data Sheet Instrument Air Receiver (LMU-V-14012) (Replace)Document5 pagesBELP-SPBEL-MS-EDS-F005-Rev 0 Data Sheet Instrument Air Receiver (LMU-V-14012) (Replace)Tegar Arief PratamaNo ratings yet

- Data Sheet For Barred Tee 010719Document1 pageData Sheet For Barred Tee 010719Heru Agung SetyantoNo ratings yet

- Bolt Torque Calculations for ASME B16.5 FlangesDocument17 pagesBolt Torque Calculations for ASME B16.5 FlangespirataenriqueNo ratings yet

- 16-02 - Fuel-Gas Filter SeparatorsDocument8 pages16-02 - Fuel-Gas Filter SeparatorsFolayemiNo ratings yet

- Design of Flanges - Welded-On Integral Type 2010Document59 pagesDesign of Flanges - Welded-On Integral Type 2010bakellyNo ratings yet

- Choke Valve DatasheetDocument1 pageChoke Valve DatasheetMuhammad Rizqi SiregarNo ratings yet

- B313 Mitre Ver 1.1Document5 pagesB313 Mitre Ver 1.1nizardsouissiNo ratings yet

- Thermowell Velocity Calculations: Company: Tag No: Project No: Date: Reference: RevDocument2 pagesThermowell Velocity Calculations: Company: Tag No: Project No: Date: Reference: RevFatoni Gea AirlanggaNo ratings yet

- Data Sheet Ball ValveDocument1 pageData Sheet Ball ValveIkhsan Hj SiratNo ratings yet

- BuoyancyDocument1 pageBuoyancyLcm TnlNo ratings yet

- TDS For Basket StrainerDocument2 pagesTDS For Basket StrainerRAGHVENDRA PRATAP SINGHNo ratings yet

- Pig Calc PDFDocument286 pagesPig Calc PDFJaroslaw KoniecznyNo ratings yet

- Tie-In List p1Document1 pageTie-In List p1Andreas Schlager100% (1)

- NKGSB PRS CL 008 A4 D Foam Solution Demand CalculationDocument8 pagesNKGSB PRS CL 008 A4 D Foam Solution Demand Calculationahmad santoso100% (2)

- SGP Stress Analysis ReportDocument14 pagesSGP Stress Analysis ReportDenstar Ricardo Silalahi100% (2)

- 13205-PPE-DS-V-003-1 - DataSheet - CVDocument7 pages13205-PPE-DS-V-003-1 - DataSheet - CVAnggun RushNo ratings yet

- ENG-JOB-010-TMS-DSH-03.001 MDS For Pig Launcher (Tanjung Batu)Document4 pagesENG-JOB-010-TMS-DSH-03.001 MDS For Pig Launcher (Tanjung Batu)m khaeronNo ratings yet

- Air Eliminator Datasheet PDFDocument2 pagesAir Eliminator Datasheet PDFbecpavanNo ratings yet

- Mechanical Data Sheet for Fuel Gas ScrubberDocument2 pagesMechanical Data Sheet for Fuel Gas ScrubberwahyuNo ratings yet

- Actuated Ball Valve 357 D - BDKDocument4 pagesActuated Ball Valve 357 D - BDKfarhanakhtar ansariNo ratings yet

- A11Document1 pageA11liviu_dovaNo ratings yet

- Air Blowe DatasheetDocument1 pageAir Blowe DatasheetMoein PNo ratings yet

- Metering Pumps SpecDocument2 pagesMetering Pumps Spececsuperal100% (1)

- Crue Oil 7500bbl API 650 DatasheetDocument16 pagesCrue Oil 7500bbl API 650 DatasheetrobertantoreniNo ratings yet

- Fire Protection in Refineries: Api Recommended Practice 2001 Draft Ninth EditionDocument5 pagesFire Protection in Refineries: Api Recommended Practice 2001 Draft Ninth EditionEmilioTSNo ratings yet

- PSV Force Rev0bDocument1 pagePSV Force Rev0bdumbledoreaaaaNo ratings yet

- Vent Silencer Specification SheetDocument2 pagesVent Silencer Specification SheetAqeel Bisma100% (1)

- Final Weld Strength CalnsDocument5 pagesFinal Weld Strength CalnsamachmouchiNo ratings yet

- L&T Double Block and Bleed Plug ValvesDocument12 pagesL&T Double Block and Bleed Plug Valvesvijay10484No ratings yet

- Calculate Shell and Stem ThicknessDocument16 pagesCalculate Shell and Stem Thicknesspatiltushar79No ratings yet

- Dgar Famegvir: Laftetitersigineas India Umit1EdDocument2 pagesDgar Famegvir: Laftetitersigineas India Umit1EdcynideNo ratings yet

- BK16-M-DS-003 - A - Data Sheet For Manual ValvesDocument3 pagesBK16-M-DS-003 - A - Data Sheet For Manual ValvesHiếu NguyênNo ratings yet

- Calculation 950122Document36 pagesCalculation 950122fafcoNo ratings yet

- Technical Comparison Format - Process Gas Reciprocating CompressorDocument11 pagesTechnical Comparison Format - Process Gas Reciprocating CompressorAlvin Smith100% (1)

- VAAS C47 Series Cryo Ball Valve CatalogueDocument8 pagesVAAS C47 Series Cryo Ball Valve CatalogueDanielle JohnsonNo ratings yet

- Ansi - 2012 - Ball ValveDocument12 pagesAnsi - 2012 - Ball ValveFAR_A_DAYNo ratings yet

- Types of Concrete Blocks in Construction (14 Types)Document10 pagesTypes of Concrete Blocks in Construction (14 Types)hhNo ratings yet

- Access Scaffolding CalculationDocument8 pagesAccess Scaffolding CalculationSarah HaiderNo ratings yet

- Trestles Design 1Document10 pagesTrestles Design 1Anonymous sfkedkymNo ratings yet

- Experiment # 6 Bernoulli's Theorem Demonstration Apparatus: LABORATORY MANUAL For ENGR2860U-Fluid MechanicsDocument11 pagesExperiment # 6 Bernoulli's Theorem Demonstration Apparatus: LABORATORY MANUAL For ENGR2860U-Fluid MechanicsAbdullah AlshihriNo ratings yet

- Ampt - Advanced Materials Processing TechniquesDocument26 pagesAmpt - Advanced Materials Processing TechniquesIshaan ThakerNo ratings yet

- Reinforcing Detailing of RCCDocument40 pagesReinforcing Detailing of RCCThamaraiselvan Ramadoss100% (1)

- L4 BeamsDocument10 pagesL4 BeamsFairiey Izwan Azazi100% (1)

- Whats New in ASME B31 3Document15 pagesWhats New in ASME B31 3Anonymous qhVGVpNo ratings yet

- Alternative Method To Calculate Bolt Stress For Evaluate TemperatureDocument3 pagesAlternative Method To Calculate Bolt Stress For Evaluate TemperaturePranpath NarupantawartNo ratings yet

- Sheet PilingDocument12 pagesSheet PilingTanvi Rane100% (1)

- Multi9 Acti9 Substitution TableDocument530 pagesMulti9 Acti9 Substitution TableKar Keong LewNo ratings yet

- Cassette Inverter (2020) Technical Specification SheetDocument1 pageCassette Inverter (2020) Technical Specification SheetOwais AhmedNo ratings yet

- IATG 02.20 symbolsDocument3 pagesIATG 02.20 symbolsturamyuwiteka samuelNo ratings yet

- Acoustic Emission Testing Method: Questions AnswersDocument22 pagesAcoustic Emission Testing Method: Questions AnswersSadhasivam Velu100% (2)

- Design Basis Memorandum - Mechanical Equipment and SystemsDocument26 pagesDesign Basis Memorandum - Mechanical Equipment and SystemsLuojisi Cil50% (2)

- Decking (Composite & 2 Layers Reinf)Document41 pagesDecking (Composite & 2 Layers Reinf)Than Than SoeNo ratings yet

- ElectricityDocument31 pagesElectricityJagdip ShethNo ratings yet

- Tripole University: Glass-Ceramic "MME660"Document3 pagesTripole University: Glass-Ceramic "MME660"amnajamNo ratings yet

- Unit G Punchlist ItemsDocument8 pagesUnit G Punchlist ItemsjhecyNo ratings yet

- 42NH Ductable in Room Fan Coil With Multi Speed Motor: Performance Summary For Soba Za IgruDocument2 pages42NH Ductable in Room Fan Coil With Multi Speed Motor: Performance Summary For Soba Za Igruvelikimag87No ratings yet

- Design of Syphon AqueductDocument118 pagesDesign of Syphon AqueductGuru MurthyNo ratings yet

- Mechanical Supervisor ResumeDocument4 pagesMechanical Supervisor ResumeAnwar Rahman100% (4)

- Cracks in RC PDFDocument23 pagesCracks in RC PDFAndreOnifeAlwynWhiteNo ratings yet

- Air Duct CalculatorDocument6 pagesAir Duct CalculatorrakeshamechNo ratings yet

- DSR 12-13Document279 pagesDSR 12-13Chandrashekhar ChopdekarNo ratings yet

- Piping Material Specification 2010014 00 l0 Gs 001Document215 pagesPiping Material Specification 2010014 00 l0 Gs 001Wilson Xavier Orbea Bracho100% (1)

- Water Treatment DegasifierDocument6 pagesWater Treatment DegasifierEDUARDONo ratings yet

- VCCT For Abaqus PDFDocument14 pagesVCCT For Abaqus PDFFelipe Dornellas SilvaNo ratings yet

- INFX8000C Ceailing HightDocument2 pagesINFX8000C Ceailing HightKhan KakaNo ratings yet

- Jobsheet MasonDocument6 pagesJobsheet MasonLudivino Toto Ledesma CondalorNo ratings yet