Professional Documents

Culture Documents

1374138689risk Assessment

Uploaded by

rusyadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1374138689risk Assessment

Uploaded by

rusyadCopyright:

Available Formats

Feed

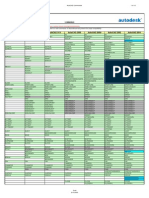

Risk analysis of the chain of biodiesel processing

8. Risk based approach

for glycerine

1. General risk: Biodiesel Processing

HAZARD

CAT.

CHANCE

SERIOUSNESS

RISK

CLASS.

Quality of water

C/B/

P

Low

High

JUSTIFICATION

Water is used in the

production of biodiesel.

LEGISLATION,

INDUSTRY STANDARDS

According to

Regulation

183/2005/EC water

used during the

manufacture of feed

shall be of suitable

quality.

CONTROL MEASURE

REMARKS

Apply suitable water of

drinking quality.

Dedicate water circuits

Cleaning agents

Low

Medium

Cleaning come into

contact with the product.

Cleaning agents used in the

production system should be

flushed. Cleaning agents used

must be evaluated and

appropriate measures taken

to bring risk to acceptable

levels.

Flying in birds

Low

Medium

Toxins from pest

control materials

Very low

High

Lubricants

Low

High

Use of lubricant should be

evaluated before use and

appropriate measures be

taken to bring risk to

acceptable levels

Insects and

rodents

Medium

Low

Building proofing, cleaning

programs and pest control

system as part of the pre

requisite programme

Not a common risk

as most

productions

facilities are

continuous process

Closed building can

prohibit this hazard

Poison bait from open

boxes could cause cross

contamination

Sector reference document on the manufacturing of safe feed materials from biodiesel processing

A pest control programme

must be applied. Appropriate

measures should be taken to

minimise risk

14

Purchasing

specifications. Risk

is low as oils are

checked before use

Feed

Risk analysis of the chain of biodiesel processing

8. Risk based approach

for glycerine

2. Reception of feedstock vegetable oil

CAT.

CHANCE

SERIOUSNESS

RISK

CLASS.

Contamination by

the previous

cargo during the

transport by truck

or barge or ocean

going vessel

Low

High

Foreign materials

Low

Low

Contamination

with undesirable

substances

- Dioxins

- Nickel

- PCB, dlPCB

HAZARD

LEGISLATION,

INDUSTRY

STANDARDS

CONTROL MEASURE

REMARKS

Transport of vegetable

oils usually takes place

in dedicated transport

vehicles

Risk must be evaluated and

appropriate measures must

be taken to bring this risk to

acceptable levels. Dedicated

transport, control of the

three previous cargos.

Visual checks

Foreign materials may

be present.

Dedicated buildings and

circuits filters, staff hygiene,

glass procedure, good

maintenance practices

High

In general, most

contaminants do not

concentrate in the

glycerine

Monitoring plan

Very Low

High

EU Regulation of

225/2012 on Dioxins

Monitoring plan

Low

High

EU Regulation

68/2013 Catalogue of

Feed Materials

Monitoring plan

Very Low

High

EU Regulation

32/2002 on

undesirable

substances on feed

materials

Monitoring plan

Low

JUSTIFICATION

Sector reference document on the manufacturing of safe feed materials from biodiesel processing

15

Contamination with

undesirable substance

normal cases CHANCE

is LOW if

manufacturer

purchases a raw

material of lower

quality the risk

elevates to medium

Nickel in most cases

not used in biodiesel

production

Feed

Risk analysis of the chain of biodiesel processing

- PAH

Low

High

Pesticide residues

above the minimal

risk levels (MRL),

i.e. residues of

herbicides,

insecticides,

fungicides or

rodenticides

above the MRL.

Low

Medium

Regular monitoring of

pesticide residues on

crude oil shows that

residue levels remain

within legal limits.

Regulation 396/2005

sets limits for

residues of

pesticides. This

regulation allows

using a transfer

factor for authorised

pesticides into

processed products,

providing food safety

is assured.

Monitoring plan

Most pesticides are not

water soluble and will

not move to the

glycerine water phase

Pesticides

residues as listed

in EU Directive

2002/32 for

undesirable

substances in

feeding stuff

Very low

High

Some of the banned

pesticides may be

present in the

environment. The chance

of finding them in crude

soybean oil, however, is

very low. The use of

endosulfan is allowed on

soybeans. Monitoring

data show that its

residue in crude oil

remains within the legal

limit.

Directive 2002/32/EC

sets limits for a

number of pesticides

residues in feeding

stuff.

Monitoring plan

Most pesticides are not

water soluble and will

not move to the

glycerine water phase

Low

Medium

Microbiological

contamination

Monitoring plan

Sector reference document on the manufacturing of safe feed materials from biodiesel processing

Monitoring plan

16

Feed

Risk analysis of the chain of biodiesel processing

8. Risk based approach

for glycerine

3. Storage of the incoming material

LEGISLATION,

INDUSTRY

STANDARDS

CAT.

CHANC

E

SERIOUSNES

S

RISK

CLASS.

Contamination by

cleaning agents

Low

Medium

This risk classification applies to

terminals that store both

chemicals and vegetable oils.

They may abstain from using

cleaning agents that are

suitable for use in the food

industry. For tank terminals in

the EU that apply HACCP and

that keep the storage of

vegetable oils and chemicals

separated, the chance of using

the wrong cleaning agents is

very low.

Cleaning agents used must

be evaluated and

appropriate measures taken

to bring risk to acceptable

levels.

Thermal heating

fluids from failing

equipment

Low

High

Toxic thermal heating fluids

may still be used. However, due

to the relatively low heating

temperatures applied during

storage, the chance of leakage

of thermal heating fluids into

the product is low.

Documentation on nett

losses and analyse

accordingly, if necessary.

Cross

contamination

Low

Medium

Sources of risk include

equipment malfunction and

operator accident. Extremely

low frequency of occurrence.

Preventative measures to

reduce impact include

automated safety mechanisms,

spill containment, site security,

restricted site access.

Storage procedure in place

HAZARD

JUSTIFICATION

Sector reference document on the manufacturing of safe feed materials from biodiesel processing

CONTROL MEASURE

17

REMARKS

The use of water and

steam heating is

recommended.

Thermal heating fluids

are not commonly used

Feed

Risk analysis of the chain of biodiesel processing

8. Risk based approach

for glycerine

HAZARD

Processing aids

(alkali solution,

acids)

4. Stage 1 of 3 Trans esterification (Reaction stage)

CAT.

CHANCE

SERIOUSNESS

RISK

CLASS

Low

Medium

JUSTIFICATION

LEGISLATION,

INDUSTRY

STANDARDS

Processing aids come into

contact with the product.

CONTROL MEASURE

REMARKS

Processing aids that directly

come into contact with the

oil must be evaluated and

appropriate measures taken

to bring risk to acceptable

levels.

Online process monitoring,

correct labelling of the

chemical containers

Contamination

caused during

addition of

Catalyst

(Methanol)

Low

Medium

Undesirable substances in

the Methanol

Apply methanol of suitable

quality

Described in the contract

specification

Online process monitoring,

correct labelling of the

chemical containers

Sector reference document on the manufacturing of safe feed materials from biodiesel processing

18

In very small scale

operations, the

handling of dangerous

chemicals may pose a

greater risk to the

operator if these

chemicals are manually

transferred and

employed in a batch

process versus an

automated system.

Feed

Risk analysis of the chain of biodiesel processing

8. Risk based approach

for glycerine

5. Stage 2 of 3 Trans esterification (Separation stage)

CAT.

CHANCE

SERIOUSNESS

RISK

CLASS.

Methyl ester

remaining in

glycerine

Low

High

Methanol in

glycerine

Medium

High

HAZARD

JUSTIFICATION

Separation of biodiesel

from coproducts - stage 1

LEGISLATION, INDUSTRY

STANDARDS AND/OR

CONTRACT TERMS

Legalisation 68/2003

mentions: May contain

up to 4% of Matter

Organic Non Glycerol

(MONG comprising of

Fatty ACID Methyl

Esters, Fatty Acid Ethyl

Esters, Free Fatty Acids

and Glycerides

Legislation 68/2013

mentions: May contain up to

0,5 % methanol

Sector reference document on the manufacturing of safe feed materials from biodiesel processing

19

CONTROL MEASURE

Monitoring plan and

process follow up

CCP: analysis methanol or

control by process

parameters

REMARKS

Feed

Risk analysis of the chain of biodiesel processing

8. Risk based approach

for glycerine

HAZARD

Processing aids

(alkali solution,

acids)

Pesticide residues

above the MRL,

i.e. residues of

herbicides,

insecticides,

fungicides or

rodenticides

above the MRL.

Delivery of Fatty

Matter

6. Stage 3 of 3 - Acidulation and FFA separation

CAT.

CHANCE

SERIOUSNESS

RISK

CLASS.

Low

High

JUSTIFICATION

Processing aids come into

contact with the product.

Risk of overdoses

Low

Low

Medium

High

Regular monitoring of

pesticide residues shows

that residue levels

remain within legal limits.

Pesticides do not

concentrate in the

glycerine

LEGISLATION,

INDUSTRY

STANDARDS

Regulation 68/2013

set limits for

maximum contents

of chemical

impurities resulting

from manufacturing

process or from

processing aids

CONTROL MEASURE

REMARKS

Processing aids that directly

come into contact with the oil

must be must be evaluated

and appropriate measures

taken to bring risk to

acceptable levels.

Online process monitoring

(consumption rates)

Regulation 396/2005

sets limits for

residues of

pesticides.

Sector reference document on the manufacturing of safe feed materials from biodiesel processing

If fatty matter is delivered as

a by product, label fatty

matter as nonfeed/nonfood

in order to assure this is not

used in feed sector

20

Fatty acids with

methyl esters (also

called fatty matter)

collected after

methanol recovery at

a biodiesel

production, are

prohibited for feed

purposes, since

liphophile additives,

used in biodiesel

production,

concentrate in fatty

acids.

Feed

Risk analysis of the chain of biodiesel processing

8. Risk based approach

for glycerine

7. Storage

LEGISLATION,

INDUSTRY

STANDARDS

AND/OR

CONTRACT TERMS

CAT.

CHANCE

SERIOUSNESS

RISK

CLASS.

Contamination

due to lack of

segregation

Low

High

Contamination by

cleaning agents

Low

Medium

This risk classification applies to

terminals that store both

chemicals and vegetable oils.

They may abstain from using

cleaning agents that are

suitable for use in the food

industry. For tank terminals in

the EU that apply HACCP and

that keep the storage of

vegetable oils and chemicals

separated, the chance of using

the wrong cleaning agents is

very low.

Cleaning agents used must

be evaluated and

appropriate measures

taken to bring risk to

acceptable levels

Thermal heating

fluids from failing

equipment

Low

High

Toxic thermal heating fluids

may still be used. However, due

to the relatively low heating

temperatures applied during

storage, the chance of leakage

of thermal heating fluids into

the product is low.

If thermal heating fluids

have been used, the

storage company must

provide for documentation

on nett losses and analyse

accordingly, if necessary.

Cross

contamination

Medium

Medium

HAZARD

JUSTIFICATION

CONTROL MEASURE

REMARKS

Storage procedures in

place to reduce the risk of

cross contamination

Dedicated tanks

Sector reference document on the manufacturing of safe feed materials from biodiesel processing

Dedicated circuits and

storage tanks. Storage

procedure in place

21

The use of water and

steam heating is

recommended.

Thermal heating fluids

are not commonly used

Feed

Risk analysis of the chain of biodiesel processing

8. Risk based approach

for glycerine

8. Transport of glycerine

LEGISLATION,

INDUSTRY

STANDARDS

AND/OR CONTRACT

TERMS

CAT.

CHANCE

SERIOUSNESS

RISK

CLASS.

Contamination by

previous cargo

P/C/B

Low

Medium

- Tank cars, rail

tanks and barges

Low

High

Contamination by

cleaning agents

Low

High

Tank cars

Low

Little

Foreign bodies

Low

High

A quality plan should require

the loading of tank cars with

glycerine under a roof.

Pest

Medium

Medium

PRP program for pest control

HAZARD

JUSTIFICATION

CONTROL MEASURE

REMARKS

Control of the three previous

cargoes

Transport of glycerine

based on customer

requirements

EC Regulation No.

183/2005 setting

rules in the

transport of feed

materials

Check previous cargoes via

IDTF database

Transport suitable for feed

materials as described in the

European Code for the

industrial manufacturing for

safe feed materials

Stainless steel tanks are

used which are heated

with cooling water from

the motor through a

system of double walls

(and not coils).

Sector reference document on the manufacturing of safe feed materials from biodiesel processing

22

Check on pest activity

You might also like

- HACCP Planrefinedpalm, Plamkerneloil 2010Document16 pagesHACCP Planrefinedpalm, Plamkerneloil 2010JyShe_laNo ratings yet

- Risk Assessment Palm OilDocument22 pagesRisk Assessment Palm Oilanniq141100% (1)

- HACCP Plan-Refined Palm-Palm Kernel OilDocument5 pagesHACCP Plan-Refined Palm-Palm Kernel OilSYju Elias100% (3)

- Flowchart-Production Chain of CNO (FEDIOL)Document17 pagesFlowchart-Production Chain of CNO (FEDIOL)Lim Chee SiangNo ratings yet

- Compressed Air BcasfoodgradecodeDocument11 pagesCompressed Air BcasfoodgradecodeSujit NairNo ratings yet

- Aijn Hygiene CodeDocument53 pagesAijn Hygiene CodeAnilZapateNo ratings yet

- Pesticides Manufacturing PDFDocument4 pagesPesticides Manufacturing PDFwakasensei99No ratings yet

- Foodchem PresentationDocument21 pagesFoodchem PresentationFarhanaNo ratings yet

- HACCPDocument64 pagesHACCPvalsvalsaraj50% (2)

- Food Safety Management: A Practical Guide for the Food IndustryFrom EverandFood Safety Management: A Practical Guide for the Food IndustryHuub L. M. LelieveldRating: 5 out of 5 stars5/5 (12)

- Pestisides Formulation PDFDocument4 pagesPestisides Formulation PDFwakasensei990% (1)

- ff5 - Haccp Frying (2004)Document22 pagesff5 - Haccp Frying (2004)Banuraspati100% (1)

- Safety Data Sheet: Product Name: MOBILITH SHC 220Document9 pagesSafety Data Sheet: Product Name: MOBILITH SHC 220patelchiragisNo ratings yet

- RC Maleic AnhydrideDocument5 pagesRC Maleic AnhydrideTuan Phan NguyenNo ratings yet

- AccessC PeptideCalibratorDocument5 pagesAccessC PeptideCalibratorDiego CostantiniNo ratings yet

- En BeDocument17 pagesEn Beمحمد مقلدNo ratings yet

- CAC Fruit and VegitableDocument31 pagesCAC Fruit and VegitableSunil GirdharNo ratings yet

- Cleaning and disinfection of food factories: a practical guideFrom EverandCleaning and disinfection of food factories: a practical guideNo ratings yet

- Processing Contaminants in Edible Oils: MCPD and Glycidyl EstersFrom EverandProcessing Contaminants in Edible Oils: MCPD and Glycidyl EstersNo ratings yet

- Microbiological Standard Values and Stability of FlavoringsDocument5 pagesMicrobiological Standard Values and Stability of Flavoringslisi_aresNo ratings yet

- Safety Data Sheet: Product Name: MOBILGREASE 33Document10 pagesSafety Data Sheet: Product Name: MOBILGREASE 33Anibal RiosNo ratings yet

- Hygiene and Sanitary Conditions in A Meat Processing Plant PDFDocument30 pagesHygiene and Sanitary Conditions in A Meat Processing Plant PDFsureshNo ratings yet

- HEB EspecificacionesDocument7 pagesHEB EspecificacionesAna María SnzNo ratings yet

- AIJN Hygiene CodeDocument53 pagesAIJN Hygiene CodeLayflo100% (1)

- XXXVI/3. Absorber Pads Based On Cellulosic Fibres For Food PackagingDocument4 pagesXXXVI/3. Absorber Pads Based On Cellulosic Fibres For Food Packaging刘佳奇No ratings yet

- Example HACCP StudyDocument9 pagesExample HACCP Studycassilda_carvalho@hotmail.comNo ratings yet

- Pesticides Use and ManagementDocument16 pagesPesticides Use and ManagementBudi SiswantoNo ratings yet

- Vegoil PPAHDocument3 pagesVegoil PPAHChinedu NwufoNo ratings yet

- QCVN02 32 1 - 09082019BNN (E)Document7 pagesQCVN02 32 1 - 09082019BNN (E)Thanh Tâm TrầnNo ratings yet

- SDB 2684 Ie enDocument13 pagesSDB 2684 Ie en2121 2323No ratings yet

- Faculty Science and Techonlogy: Matriculation No: Identity Card No.: Telephone No.: E-Mail: Learning CentreDocument21 pagesFaculty Science and Techonlogy: Matriculation No: Identity Card No.: Telephone No.: E-Mail: Learning CentreNatasha YusofNo ratings yet

- Axion Liq LimónDocument7 pagesAxion Liq Limónyenni viviana67% (3)

- Rymax Themis ISO VG 220 CLP en GB LUB006912 SDS 201607 PDFDocument8 pagesRymax Themis ISO VG 220 CLP en GB LUB006912 SDS 201607 PDFAnuj ShahNo ratings yet

- BIOGAS PresentationDocument33 pagesBIOGAS PresentationAndreas Abraham91% (11)

- Parker FoodDocument28 pagesParker FoodMahiKapoorNo ratings yet

- Safety Data Sheet: Metraclin - Simsd01Document5 pagesSafety Data Sheet: Metraclin - Simsd01deppit pedNo ratings yet

- Haccp Potatoes PDFDocument22 pagesHaccp Potatoes PDFRoberto Carlos Marin Perez50% (2)

- Section2 CODDocument14 pagesSection2 CODfabian_granoblesNo ratings yet

- Lactuca LT 3000: Safety Data SheetDocument12 pagesLactuca LT 3000: Safety Data SheetsheldonNo ratings yet

- Safety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingDocument10 pagesSafety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingGEINER ANDRES OSSA GALVISNo ratings yet

- Development of Haccp Protocols For The Production of Soy MilkDocument18 pagesDevelopment of Haccp Protocols For The Production of Soy MilkTyooNoersatyoNo ratings yet

- Cxs 152e CodexDocument3 pagesCxs 152e CodexGisela Prima PaskhalienNo ratings yet

- Mimas Grovrent - SDS - ENDocument18 pagesMimas Grovrent - SDS - ENlopezionNo ratings yet

- Agrochemicals Accepted by The BBPADocument13 pagesAgrochemicals Accepted by The BBPAanon_623653380No ratings yet

- Control of Chemicals in Gots GoodsDocument4 pagesControl of Chemicals in Gots GoodsTHYAGUNo ratings yet

- MSDS 609680Document8 pagesMSDS 609680Manish GoyalNo ratings yet

- Lurgi BiodieselDocument8 pagesLurgi BiodieselManish KumarNo ratings yet

- SDS - High Temp Premium 2Document9 pagesSDS - High Temp Premium 2Georgina SuleNo ratings yet

- Msds For TretinionDocument10 pagesMsds For TretinionYen Ling NgNo ratings yet

- HACCP GUIDELINE - Canning Corned BeefDocument22 pagesHACCP GUIDELINE - Canning Corned BeefChen Li100% (4)

- Dallethrin Spec Eval March 04Document23 pagesDallethrin Spec Eval March 04yeotekarprasadNo ratings yet

- Conqor 303 ADocument6 pagesConqor 303 AjelaapeNo ratings yet

- Sds Gwax Eur EnglishDocument11 pagesSds Gwax Eur Englishperret.yap.weilunNo ratings yet

- HACCP of Fried FoodsDocument7 pagesHACCP of Fried FoodsChrisa KargiotouNo ratings yet

- (CRC Industries LTD) Ados Food Grade Silicone Sealant Translucent H3590 24-11-2015Document6 pages(CRC Industries LTD) Ados Food Grade Silicone Sealant Translucent H3590 24-11-2015Syarif HidayatullahNo ratings yet

- Engen Transformer Oil PDFDocument5 pagesEngen Transformer Oil PDFUrsula JohnsonNo ratings yet

- MSDS 480680 - 2Document11 pagesMSDS 480680 - 2Carlos SantosNo ratings yet

- Mobilfluid 350 MSDS 012808Document8 pagesMobilfluid 350 MSDS 012808lupilla RoNo ratings yet

- Chlorine Spectroquant 100602 Method 2000Document20 pagesChlorine Spectroquant 100602 Method 2000rafaeldelperu1982No ratings yet

- SRB-Hydraulic 46ES Oil MSDSDocument4 pagesSRB-Hydraulic 46ES Oil MSDSBen WigginsNo ratings yet

- Gleason's Flat Earth Map PDFDocument1 pageGleason's Flat Earth Map PDFrusyad100% (6)

- Superol Kpo Tds 2012Document1 pageSuperol Kpo Tds 2012rusyadNo ratings yet

- Boiling PointDocument3 pagesBoiling PointrusyadNo ratings yet

- Na OHDocument2 pagesNa OHrusyadNo ratings yet

- Carbon AktivDocument4 pagesCarbon AktivrusyadNo ratings yet

- Glycerine Ecogreen SpecDocument1 pageGlycerine Ecogreen SpecrusyadNo ratings yet

- Vacuum TheoryDocument79 pagesVacuum TheoryrusyadNo ratings yet

- 7) Hydro TestDocument3 pages7) Hydro TestPramod AthiyarathuNo ratings yet

- APN 9.02.01 Biodiesel Glycerol RefiningDocument2 pagesAPN 9.02.01 Biodiesel Glycerol RefiningrusyadNo ratings yet

- Award Report TemplateDocument3 pagesAward Report Templatechriscivil12No ratings yet

- Ispmach 4000V/B/C/Z Family: FeaturesDocument100 pagesIspmach 4000V/B/C/Z Family: Featuresjose morenoNo ratings yet

- Autocad R12 Autocad R13 Autocad R14 Autocad 2000 Autocad 2000I Autocad 2002 Autocad 2004Document12 pagesAutocad R12 Autocad R13 Autocad R14 Autocad 2000 Autocad 2000I Autocad 2002 Autocad 2004veteranul13No ratings yet

- Draft Tech Proposal NTB UtmDocument20 pagesDraft Tech Proposal NTB Utmdudi hidayatNo ratings yet

- HRSG Design and Operation On Unit Reliability and Remaining LifeDocument74 pagesHRSG Design and Operation On Unit Reliability and Remaining LifeNisal PereraNo ratings yet

- HT Service-ManualDocument31 pagesHT Service-ManualMonete FlorinNo ratings yet

- ANSI-IEEE, NEMA and UL Requirements For SwitchgearDocument4 pagesANSI-IEEE, NEMA and UL Requirements For Switchgearefmartin21No ratings yet

- The Effectiveness of Acceptance and Commitment-BasDocument18 pagesThe Effectiveness of Acceptance and Commitment-BasRaphaele ColferaiNo ratings yet

- Brazing Solutions For Car Body Production+ (EN)Document2 pagesBrazing Solutions For Car Body Production+ (EN)komklaveNo ratings yet

- CMM 25-11-466529430584234180428Document288 pagesCMM 25-11-466529430584234180428Radmanovic Uros MrmyNo ratings yet

- Urea ProjectDocument17 pagesUrea ProjectAbdo Shaaban100% (2)

- Crichton, Michael - NextDocument351 pagesCrichton, Michael - NextrtarakNo ratings yet

- RoundingDocument65 pagesRoundingSourav Kumar100% (1)

- White Paper - SuperUserDocument16 pagesWhite Paper - SuperUsermdsauberNo ratings yet

- 1st Quarter EIM 4Document6 pages1st Quarter EIM 4Victor RosalesNo ratings yet

- Rules For Building and Classing Marine Vessels 2022 - Part 5C, Specific Vessel Types (Chapters 1-6)Document1,087 pagesRules For Building and Classing Marine Vessels 2022 - Part 5C, Specific Vessel Types (Chapters 1-6)Muhammad Rifqi ZulfahmiNo ratings yet

- Chapter Eighteen: Creating Competitive AdvantageDocument34 pagesChapter Eighteen: Creating Competitive AdvantageSana MehmoodNo ratings yet

- Isuzu REDTech 4J Lit SheetDocument2 pagesIsuzu REDTech 4J Lit SheetVăn Tuấn NguyễnNo ratings yet

- Ann (02) 23 08 2018Document73 pagesAnn (02) 23 08 2018Paul RajNo ratings yet

- The Basics of Business Management Vol I PDFDocument284 pagesThe Basics of Business Management Vol I PDFKnjaz Milos100% (1)

- Letter Calling For State Department of Oil and Gas To Investigate Gas LeakDocument4 pagesLetter Calling For State Department of Oil and Gas To Investigate Gas LeakLos Angeles Daily NewsNo ratings yet

- NTE931 Integrated Circuit 3-Terminal Positive Voltage Regulator 5V, 3ADocument2 pagesNTE931 Integrated Circuit 3-Terminal Positive Voltage Regulator 5V, 3AWilfredo MolinaNo ratings yet

- BC-2800 - Service Manual V1.1 PDFDocument109 pagesBC-2800 - Service Manual V1.1 PDFMarcelo Ferreira CorgosinhoNo ratings yet

- Heidenhain MotorsDocument44 pagesHeidenhain MotorsmarhiNo ratings yet

- Urethyn HG 0 - Pi - (Gb-En)Document2 pagesUrethyn HG 0 - Pi - (Gb-En)CriVe OffeNo ratings yet

- IA-NT-PWR-2.4-Reference GuideDocument110 pagesIA-NT-PWR-2.4-Reference GuideSamuel LeiteNo ratings yet

- Litografia Soft LithographyDocument33 pagesLitografia Soft Lithographyrfm147No ratings yet

- CV FaisalDocument3 pagesCV FaisalAnonymous UNekZM6No ratings yet

- Dispersant Manual WebDocument108 pagesDispersant Manual Webcamilinrodriguezzzz100% (1)