Professional Documents

Culture Documents

Vav Systems

Uploaded by

coolth2Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vav Systems

Uploaded by

coolth2Copyright:

Available Formats

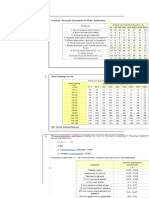

VAV SYSTEMS

TRANE CHILLED WATER VAV SYSTEMS

For constant volume systems, supply fan must be sized by summing the peak

design airflow requirements

For vav systems, supply fan may be sized based on the worst case block

airflow; 6

Using multiple air handling units(under 24 000 lps) is preferable than having

one large unit; 11

Cooling coils at 2.5m/s

Limit flexible duct length to 2m; 71

If reducer is needed, locate at least 3 duct diameters upstream to the VAV

unit; 74

Add balancing dampers to runout ducts downstream of VAV unit; 74s

If variable volume supply fan motor is larger than 7.3 KW, ashrae 90.1

requires the motor to be equipped with a VSD; 132

Do not locate duct static pressure sensor at the discharge of the supply fan

unless fan pressure optimization control is used

Vav systems that use DDC on VAV terminal units, fan pressure optimization is

required; 132

Single zone vav excellent for large, densely occupied zones that have

variable cooling loads such as gyms, lecture halls, arenas, auditoriums and

places of worship;157

Single zone vav control for any AHU that contains chilled water cooling coil

and supply fan that has a motor greater than 5 hp

Space pressure control common approach is install VAV for return;

modulates to provide positive or negative pressure in the space; 187

FAN TYPES

Forward curved fans used to deliver large volumes of air against low static

pressures

Backward curved fans for systems that require greater than 750 pa static

pressure

ZONING

Zone space or group of spaces within a building with heating and cooling

requirements that are sufficiently similar so that desired conditions can be

maintained throughout using a single sensor

More often an art than science and requires judgement by design engineer

Zoning can be:

o Single room separated by physical boundaries

o Group of several rooms one VAV would be used to serve the entire group of

rooms and one sensor would be installed in only one of the rooms

Open area may be provided with several zones to provide better temp.

control

AHU

Draw thru fan arrangement results in shorter AHU since less distance is needed

between upstream cooling coil and the fan; 37

Box filters and bag filters MERV 13 16

MERV 13 filter to clean both return and outdoor air for LEED; 44

At least MERV 6 installed upstream of all wet surfaces including cooling coils as per

ASHRAE standard 62.1 ; 44

Final heap filters may be required for hospitals, clinics, etc. 45

Avoid blow thru config for final filters ; 45

If using UV-C lamps in AHU, include interlock switches and warning signs at each

entry location, substitute or shield any susceptible materials, replace as per

manufacturer; 49

at least 3 diameters of straight duct after ahu supply

when elbow or junction is needed near AHU, consider a discharge plenum

downstream of a housed fan

place main duct runs, and VAV units above hallways and other unoccupied areas; 73

Linear Slot Diffusers

maximum separation distance end to end is 3 diffuser length; to wall is 2 diffuser

lengths

maintain parallel distribution; 76

for return air linear slots, place them perpendicular to supply diffusers

Return Plenums

pressure drop thru return grilles should be 5 7.5 pa

ZONE SENSOR LOCATION

Do not place zone sensor near diffuser discharge to avoid influence; 100

Make sure only one VAV unit serves particular zone sensor

Do not place on walls with large amount of heat loss

Methods to asses zone population; 117

o Time of day occupancy schedules cafeterias and some classrooms ; 187

o Occupancy sensors- private offices, open plan office spaces

o Carbon dioxide sensors - recommended for zones that are densely occupied

such as gyms, conference rooms, auditoriums; 186

o

OUTDOOR AIR VENTILATION

When supply air temp is lower than Tzone is delivered thru zone thru ceiling

mounted diffusers the system is 100 % effective at getting outdoor air to actual

breating zone; 103

A more common practice is to locate the static pressure sensor approximately 2/3 of

distance between supply fan outlet and inlet to the critical VAV terminal unit; 173

2 common methods to control outdoor air temp; 172

o Varying position of OA damper in proportion to the change in supply airflow ,

which is determined by the signal being sent to the VSD on the supply fan

o Using an airflow measuring device to directly measure and control the outdoor

airflow; 172

For vav systems that use DDC, if design system outdoor airflow is greater than 1.4

m3/s or if AHU is equipped with a modulating outdoor air damper, Demand controlled

ventilation is required for any zone larger than 50 m2 that has a design occupancy of

40 pax/100 m2

o Exception systems with supply and/or outdoor airflow less than 0.6 m3/s

o Systems with exhaust air energy recovery

NOISE

If barrier walls are used for air cooled chillers , they should be at least 0.6 m taller

than chiller

Use lined flexible ductwork to connect VAV terminal units to supply air diffusers

COLD AIR VAV SYSTEMS

Cold air vav systems typically deliver supply air at temperature of 7 11 C

ENERGY RECOVERY

Recommended for systems with higher amounts of outdoor air or for tightly

constructed buildings with minimal amount of local exhaust

For dry climates, it is often unnecessary to mechanically dehumidify outdoor air such

as coil loops and fixed plate heat exchangers; 163

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- BasicStainedGlassMakingLookInsidetheBook PDFDocument10 pagesBasicStainedGlassMakingLookInsidetheBook PDFComan Eduard100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- BMS Sequence of OperationsDocument18 pagesBMS Sequence of OperationsRa Ar100% (2)

- Chapter 9 Fire Fighter Tools and EquipmentDocument3 pagesChapter 9 Fire Fighter Tools and EquipmentMuhammad Alshikh100% (1)

- Installation, Operation and Maintenance Manual: Model BCSW-FRPDocument12 pagesInstallation, Operation and Maintenance Manual: Model BCSW-FRPcoolth2No ratings yet

- Fire Pro SpecsDocument11 pagesFire Pro Specscoolth2No ratings yet

- 00 HVAC DatDocument52 pages00 HVAC DatSyed ShahbazNo ratings yet

- Philippines Green Building CodeDocument79 pagesPhilippines Green Building CodeRaphael Mana-ay100% (3)

- Api Asphalt TankDocument18 pagesApi Asphalt Tankgen_lethal100% (1)

- Chilled Water Systems Ashrae Systems 2012Document4 pagesChilled Water Systems Ashrae Systems 2012coolth2No ratings yet

- RC Tie Beam DesignDocument8 pagesRC Tie Beam DesignArfel BartianaNo ratings yet

- Case Study - Club HouseDocument26 pagesCase Study - Club HouseRithika Raju Challapuram50% (4)

- I05 HyperV TShootDocument65 pagesI05 HyperV TShootvjmehta78No ratings yet

- Sap PP Project ImplementatinstepsDocument5 pagesSap PP Project ImplementatinstepsKomali Kancharla100% (1)

- Inspection GuidelinesDocument67 pagesInspection GuidelinesMohammed Amjad Ali67% (3)

- 4by4 HouseDocument8 pages4by4 HousePratik Patel100% (1)

- Configuration Nokia by Manual - enDocument12 pagesConfiguration Nokia by Manual - enSarimSomalyNo ratings yet

- Concrete Design Excel SheetDocument16 pagesConcrete Design Excel SheetCleth Hiren Santos25% (4)

- Motion Control Engineer - Lexmark Research - Development CorporationDocument2 pagesMotion Control Engineer - Lexmark Research - Development Corporationcoolth2No ratings yet

- Project Name:: Falcon URIDocument2 pagesProject Name:: Falcon URIcoolth2No ratings yet

- NL Master Specification Guide For Public Funded Buildings: Re-Issued 2017/05/31Document7 pagesNL Master Specification Guide For Public Funded Buildings: Re-Issued 2017/05/31coolth2No ratings yet

- Concrete Design Excel SheetDocument4 pagesConcrete Design Excel Sheetcoolth2No ratings yet

- Kitchen VentDocument5 pagesKitchen Ventcoolth2No ratings yet

- ReportDocument1 pageReportcoolth2No ratings yet

- And So It Goes: Life According To Kurt VonnegutDocument2 pagesAnd So It Goes: Life According To Kurt Vonnegutcoolth2No ratings yet

- Ventilation Brochure ECPEN11-203 Ventilation Catalogue UK Tcm511-252287Document39 pagesVentilation Brochure ECPEN11-203 Ventilation Catalogue UK Tcm511-252287coolth2No ratings yet

- Bs Electrical Engineering CurriculumDocument2 pagesBs Electrical Engineering Curriculumcoolth2No ratings yet

- Air Handling Unit Noise Generation - Original AttenuatorDocument4 pagesAir Handling Unit Noise Generation - Original Attenuatorcoolth2No ratings yet

- Acoustic CalculationDocument14 pagesAcoustic Calculationcoolth2No ratings yet

- ConversionDocument1 pageConversionCosmin CinciNo ratings yet

- Sims4 CheatsDocument2 pagesSims4 Cheatscoolth2No ratings yet

- Expansion Vessel Sizing GuideDocument1 pageExpansion Vessel Sizing Guidecoolth2No ratings yet

- Product Data 23XRV en PDFDocument32 pagesProduct Data 23XRV en PDFMarianela MasyRubiNo ratings yet

- Ref Pipe Sizing Ver 02 21 11Document12 pagesRef Pipe Sizing Ver 02 21 11coolth2No ratings yet

- Reading Guitar Tablature II - Guitar Lessons at Ultimate-GuitarDocument6 pagesReading Guitar Tablature II - Guitar Lessons at Ultimate-Guitarcoolth2No ratings yet

- Ordinary Song TabDocument2 pagesOrdinary Song Tabcoolth2No ratings yet

- 40LM050 FCU CarrierDocument2 pages40LM050 FCU CarrierprokjongNo ratings yet

- 40LM 120-200 Model CarrierDocument12 pages40LM 120-200 Model CarrierEngr.Mmosaad100% (1)

- OAPU SizingDocument2 pagesOAPU Sizingcoolth2No ratings yet

- VR FDocument1 pageVR Fcoolth2No ratings yet

- Vav SystemsDocument4 pagesVav Systemscoolth2No ratings yet

- 1903 Connection Point Designation and IdentifiersDocument13 pages1903 Connection Point Designation and Identifiersbuturca sorinNo ratings yet

- MPN Program and Benefit Usage GuideDocument8 pagesMPN Program and Benefit Usage GuideAnonymous zC5j7T100% (1)

- Assignment 1Document5 pagesAssignment 1Syếđ AbữBâkarNo ratings yet

- PAPERCRETE-Towards A New Beginning: CategoryDocument25 pagesPAPERCRETE-Towards A New Beginning: CategoryKristian Marlowe OleNo ratings yet

- Compaction Quality Control of Earth Fills Using Dynamic Cone PenetrometerDocument10 pagesCompaction Quality Control of Earth Fills Using Dynamic Cone PenetrometerDannyChaconNo ratings yet

- Thanigai Tips Blogspot ComDocument3 pagesThanigai Tips Blogspot ComMohd JaheerNo ratings yet

- Distributed Content Configuration and TroubleshootingDocument63 pagesDistributed Content Configuration and TroubleshootingLakeAlexNo ratings yet

- Navis GuideDocument12 pagesNavis GuideFandy MaulanaNo ratings yet

- Resilient and Sustainable InfrastructureDocument47 pagesResilient and Sustainable InfrastructureLuis FernandoNo ratings yet

- 4 - SPC-FD-Part 4 of 5-Division 26Document1 page4 - SPC-FD-Part 4 of 5-Division 26Fathy RamadanNo ratings yet

- Rcs 501 2018 19Document2 pagesRcs 501 2018 19pthepronabNo ratings yet

- Armoured Csta CablesDocument5 pagesArmoured Csta CablesMd Irshad AlamNo ratings yet

- Parasoft Soatest 9.x TutorialDocument9 pagesParasoft Soatest 9.x Tutorialblunt2vitreNo ratings yet

- VLAN Routing: Huawei Technologies Co., LTDDocument14 pagesVLAN Routing: Huawei Technologies Co., LTDmangla\No ratings yet

- Programming The Msp430 Via The Jtag InterfaceDocument69 pagesProgramming The Msp430 Via The Jtag InterfaceBenjamin E NewmanNo ratings yet

- Morphing Wing MechanismDocument16 pagesMorphing Wing MechanismG KEERTHANA KRISHNANNo ratings yet

- Overview of Microcontrollers, Embedded Control and The Motorola HC12 FamilyDocument15 pagesOverview of Microcontrollers, Embedded Control and The Motorola HC12 FamilyJuanNo ratings yet

- AS STAKED 19KA0081 Revised As Per Contract Price For Sheet PilesDocument59 pagesAS STAKED 19KA0081 Revised As Per Contract Price For Sheet PilesPrincess Angel AporilloNo ratings yet

- Chapter 1 Introduction To Data Communications: Networking in The Internet AgeDocument48 pagesChapter 1 Introduction To Data Communications: Networking in The Internet AgeJohn Joshua MontañezNo ratings yet