Professional Documents

Culture Documents

Uwm Plastic Parts Mat Selec

Uploaded by

azadsingh1Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uwm Plastic Parts Mat Selec

Uploaded by

azadsingh1Copyright:

Available Formats

Designing Plastic Parts

for the Injection Molding

Process

General Information

Course enrollment is limited. Please reserve your place now!

Business, Engineering & Technology

161 West Wisconsin Ave., Ste. 6000

Milwaukee, WI 53203-2602

Learn from a Practitioner

in Plastics Technology

If you need special accommodations, please advise us when registering. Requests will be kept confidential.

Signature ______________________________________________

Office use only: Order # __________________Initials __________________ Date ________________

Exp.Date ______________________________________________

Card Holders Name ______________________________________

Check enclosed (Make payable to UWMilwaukee. Check must

accompany registration form.)

_________

_________

American Express

MasterCard

VISA

Bill my organization. (see information above)

Cr.Cd.Acct.# _________ _________

* Gift Certificate #: ____________________________________________

amount (if applicable*) $____________ = Total $ ____________________

Subtotal $: ______________________ Less Gift Certificate or discount

Discount Explanation:__________________________________________

PO# __________________________________________________

JA-51-08-W

Method of Payment

Address ____________________________________________________

Organization Name ____________________________________________

Attention ______________________________________________

Bill to information (if different than above)

City / State / Zip ______________________________________________

MESSAGE CODE:

Please enter the keycode located to the

left of the name on the mailing panel. KEYCODE:

Fax ________________________________________________________

Evening Phone ______________________________________________

Day Phone __________________________________________________

City / State / Zip ______________________________________________

Business Title ________________________________________________

Address ____________________________________________________

Email ______________________________________________________

Organization Name ____________________________________________

lists to organizations outside of UWM.)

Yes! I would like to receive program information by email. (We do not sell our

Milwaukee, WI

Milwaukee, WI

Prog. #4830-8316

Prog. #4830-8315

June 4-6, 2008

December 17-19, 2008

Milwaukee, WI

Milwaukee, WI

No. Please do not send program information by email.

Your confirmation and any correspondence will be sent to the address below.

Please call Jon Koeller at (414) 227-3226 for more information.

Please Print:

Customized on-site training is the increasing trend

in enhancing the productivity of your workforce.

A well-trained workforce is a sustainable competitive

advantage in the market place.

Name ______________________________________________________

Onsite and Customized Training

CALL US ABOUT

ON-SITE TRAINING!

414-227-3226

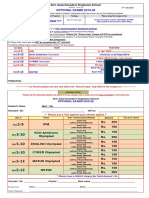

Enrollment Form

Six Sigma Black Belt Training

Starts Sep. 16, 2008

Fee: $990

Tolerance Stack-Up Analysis

Oct. 15-17, 2008

Plastic Material Selection

PHONE:

8a-5p (Central) M-F

414-227-3200 Direct

800-222-3623 Toll Free

Geometric Dimensioning & Tolerancing

Sep. 10-12, 2008

June 4-6, 2008

December 17-19, 2008

Fee: $790

Other Programs of Interest:

Plastic Material Selection

Prog. #4830-8310

Prog. #4830-8309

School of Continuing Education

UWM School of Continuing Education

161 West Wisconsin Avenue, Milwaukee, WI 53203, 414-227-3100 - 7th Floor

June 2-3, 2008

December 15-16, 2008

LOCATION:

June 2-3, 2008

December 15-16, 2008

Designing Plastic Parts

for the Injection Molding Process

No Wisconsin tax dollars were used

in the printing of this publication.

I cannot attend, but please keep me on your mailing list.

You may make your own lodging

arrangements at the facility of your choice.

Hotel/motel information will be mailed with

your enrollment confirmation. When contacting

the hotel, mention that you will be attending

the University of WisconsinMilwaukee

seminar to obtain the best available rate.

In the event of course cancellation, the

University of WisconsinMilwaukee will

reschedule the course, refund course fees or

apply the fee payment to any other School of

Continuing Education engineering course

offered in the next twelve months. Liability of

course cancellation is specifically limited to the

amount of the pre-paid course fee and excludes

any incidental or consequential damages.

PLEASE PHOTOCOPY FOR MULTIPLE PERSON REGISTRATIONS.

If you attend nine or more days of

continuing education offered by the University

of WisconsinMilwaukee, all in a specific

program area and within a three-year time

frame, you will be eligible for a special

Certificate award. This award is to be given in

recognition of your accomplishment in that

particular specialized area.

UWM reserves the right to amend the

program should circumstances warrant such

action.

IN PERSON: (advanced registration only)

161 W. Wisconsin Ave., Ste. 6000

Milwaukee, WI

Plankinton Bldg. adjacent to

Grand Avenue Mall

8a-5p (Central) M-F

The fee includes program materials,

continental breakfasts and breaks. Lodging and

other meals are not included. A Certificate of

Participation is presented to each registrant.

Proceedings are not published.

For more information contact Murali

Vedula, Program Director, at 414-227-3121 or

mvedula@uwm.edu, or Debra ONeil, Program

Assistant, at 414-227-3100, 888-947-9947, or

oneil@uwm.edu.

FAX:

414-227-3146 Direct

800-399-4896 Toll Free

ONLINE:

www.sce-registration.uwm.edu

Mail to: Noncredit Registration Office

University of WisconsinMilwaukee

Drawer No. 491

Milwaukee, WI 53293

Internet: www.sce-eng.uwm.edu

MAIL:

Noncredit Registration

UWMilwaukee

Drawer No. 491

Milwaukee, WI 53293-0491

Fax: 800-399-4896 (Toll Free)

414-227-3146 (Local)

For cancellations please notify our

department at 414-227-3100 at least seven (7)

days before the course starts, and we will

refund your fee. Cancellations received less than

seven days before the course may be subject

to a late cancellation fee. You may enroll a

substitute at any time before the course starts,

or you may apply the enrollment fee to a future

course.

Check Course(s)

Attending

There are four easy ways to register:

Phone: 800-222-3623 (Toll Free)

414-227-3200 (Local)

Avoid Costly Mistakes Through Proper

Understanding of the Concepts

To be added to our email database

send an email to mvedula@uwm.edu

All Classes Held in Milwaukee, WI

School of

Continuing Education

www.sce-eng.uwm.edu

Designing Plastic Parts for the Injection Molding Process

Plastic Material Selection

June 2-3, 2008

December 15-16, 2008

June 4-6, 2008

December 17-19, 2008

CEUs: 1.2

CEUs: 1.8

Course Description:

Course Outline:

Course Description:

Course Outline:

This program is offered to engineers and designers involved in the

design of injection molded plastic parts. You will get a fundamental

overview of plastic part design for the process of injection molding.

In order to design a high quality injection molded part, the designer

must select an appropriate plastic material formulation, develop a

functional design, and must work within the manufacturing limitations

associated with the injection molding process. This course will

cover the fundamentals of plastic materials behavior and selection,

engineering design, manufacturing considerations and assembly

methods. Ideally, the participants should have some knowledge of

plastic materials, injection molding and engineering principles,

although the basics will be introduced. The course is ideal for engineers

and designers who are accustomed to working with metals and

are faced with metal to plastic concerns.

An Introduction to Plastic Materials

Keeping up with new developments in materials is a full time proposition

that few designers and engineers can afford. With large firms cutting

back on internal technical support, end users are often reliant upon

processors and material manufacturers for recommendations.

Ignorance of new technologies can mean missed opportunities for

improved performance at a reduced cost, but sorting out the fact

from the fiction in the press release is a difficult task.

Defining the Fundamentals that Determine Plastic Properties

Molecular Weight The Foundation of Polymer Technology

Textbook Included:

Plastic Part Design for Injection Molding

by Robert Malloy

Course Instructor:

Prof. Nick R. Schott

University of Massachusetts-Lowell

Lowell, Massachusetts

Prof. Nick R. Schott completed his BS in Chemical Engineering

from UC Berkeley and then went on for an MS and PhD in

Chemical Engineering at the University of Arizona. Professor

Schott has been at the Univ. of Massachusetts Lowell for the past

34 years where he has taught courses in Plastics Product Design,

Plastics Injection Mold Design, Processing and Process Control. He

is an active researcher in these areas and also a worldwide lecturer on

these subjects. Professor Schott was named a fellow of the SPE in

1986 and is also a founding member of the SPE Product Design and

Development Division. He is an editor of various books and has

authored or co-authored numerous papers in the field of Plastics

Engineering.

Historical Development

Fundamental Concepts

Molecular Weight

Repeat Unit Structure

Morphology

Effect of additives

Mechanical Property Overview

Flow Property Overview

Advantages of Plastic Materials

Limitations of Plastic Materials

Review of Injection Molding Equipment

Review of the Injection Molding Process

Review of Injection Molds

Design Considerations for Injection Molded Parts

Mold Filling Considerations

Effect of Gate Location and Type

Molecular and Fiber Orientation

Mold Filling Pressure Drop

Flow Leaders and Flow Hesitation

Mold Filling Simulations

Runner Balancing and Family Molds

Weld or Knit Lines

Shrinkage and Warpage Considerations

Part Ejection Considerations

Mechanical Behavior pf Plastic Materials

Approaching Plastic Product Development

Establishing End Use Requirements

Conceptual Design

Initial Candidate Material Selection Procedures

Design Based Upon the Materials Selected

Final Materials Selection

Manufacturing Related Design Modifications

Prototyping and Testing

Production Tooling and Manufacturing

Plastic Part Prototyping Techniques

Assembly Techniques for Injection Molded Parts

Summary and Conclusion

This short course in material selection organizes the crowded landscape

by breaking the material selection process down to its fundamental

elements. It then uses this foundation to build a systematic approach

to determining cost effective solutions that combine the material

selection with the processing and design considerations.

Participants will learn to distinguish streams of data from truly

valuable information and will be able to ask the right questions

of their suppliers in order to arrive at viable material selections.

The emphasis of the course is on thermoplastics in the injection

molding process.

Textbook Included:

Polymer Science and Technology

by Joel R. Fried

Course Instructor:

Mike Sepe

The Material Analyst

Dickten and Masch Manufacturing Company

Program Schedule Both Courses:

UWM reserves the right to amend the program should circumstances warrant such action.

In the event of course cancellation, the University of WisconsinMilwaukee will

reschedule the course, refund course fees or apply the fee payment to any other SCE

course offered in the next twelve months. Liability for course cancellation is specifically

limited to the amount of the pre-paid course fees and excludes any incidental or

consequential damages.

First Day Only:

7:30-8am

8:10am

Registration/Check In

Welcome

Seminar Format Each Day:

8am-12 Noon

Lecture and Discussion

12 Noon

Lunch

1-4:30pm

Lecture and Discussion

Michael Sepe brings over 30 years of experience in the plastics

industry, focused on injection molding and material testing. His

work includes hands-on plant experience coupled with business

management at several organizational levels. His primary interests

involve the integration of process technology and material testing

and analysis to competitively produce high quality products. He

teaches public courses on these subjects at several universities and

writes a monthly article for Injection Molding Magazine on material

analysis and its application to the solution of product performance

and processing problems. He has written contributing chapters for

a number of industry publications on material properties and injection

molding and has presented over 25 ANTEC papers on a variety of

topics related to the use of analysis to improve product quality.

Michael Sepe has authored a book on the use of dynamic mechanical

analysis as an engineering tool.

Last day adjournment at 3:30pm.

www.sce-eng.uwm.edu

The Relationship to Viscosity

The Relationship to Properties

New Technologies that Change the Rules

Methods of Polymerization Addition and Condensation Polymers

Polarity Why Nylons Absorb Water and Polyethylenes

Absorb Gasoline

Amorphous and Semi-Crystalline Polymers

The One Thing You Must Know About Polymer Structure

Detecting the Presence of Crystalline Structure

Effects on Processing

Effects on Properties

The Role of Polymer Blends

Property Evaluations Short Term

Tensile, Flexural, and Compressive Properties

Impact Properties Various Methods of Measurement

Thermal Properties

Other Properties Flammability, Wear Resistance, Optical, etc.

The Role of Material Property Databases and Selection Utilities

Property Evaluations Long Term

Effects of Temperature

Chemical Resistance Effects of Temperature and Time

Creep Resistance, Stress Relaxation, and Fatigue

Accelerated Testing Methods Advantages and Pitfalls

The Fundamental Equivalence of Temperature and Time

Environment Stress Crack Resistance

Radiation Resistance Weathering, Ultraviolet, Sterilization

Property Modifications

Fillers and Reinforcements

Impact Modifiers

Colorants

Stabilizers

Establishing the Cost / Performance Profile

Defining Application Requirements

Matching Requirements of A Cost Effective Material Family

Design Properties Versus Inherent Properties

Designing for manufacturing Wall Thickness,Viscosity,

& Process Selection

The Role of Simulation

Selecting A Material Supplier

Case Studies Successes and Failures

You might also like

- Hourly Report of Tata - Disc: Part: Tata Shift:-DATEDocument5 pagesHourly Report of Tata - Disc: Part: Tata Shift:-DATEazadsingh1No ratings yet

- 7,-Qad-28sample Inspection Report Mach. 74-100Document1 page7,-Qad-28sample Inspection Report Mach. 74-100azadsingh1No ratings yet

- Sheet Process: Technical Data ModificationDocument1 pageSheet Process: Technical Data Modificationazadsingh1No ratings yet

- Pdi 05 01.2015 Qad 28sample Inspection Report Mach. 74 100Document1 pagePdi 05 01.2015 Qad 28sample Inspection Report Mach. 74 100azad100% (1)

- Sheet Process: Technical Data ModificationDocument1 pageSheet Process: Technical Data Modificationazadsingh1No ratings yet

- Pdi 05 01.2015 Qad 28sample Inspection Report Mach. 74 100Document1 pagePdi 05 01.2015 Qad 28sample Inspection Report Mach. 74 100azad100% (1)

- 8654Document43 pages8654azadsingh1No ratings yet

- Cost Machine Shop-April 2015Document18 pagesCost Machine Shop-April 2015azadsingh1No ratings yet

- Oee Machineshop March15Document8 pagesOee Machineshop March15azadsingh1No ratings yet

- Cost-Machine Shop Mar-15 (Ram-Assy)Document7 pagesCost-Machine Shop Mar-15 (Ram-Assy)azadsingh1No ratings yet

- Copy of Crank Shaft Cycle TimeDocument1 pageCopy of Crank Shaft Cycle Timeazadsingh1No ratings yet

- Eat Right For Your Blood TypeDocument5 pagesEat Right For Your Blood Typekingcobra00791% (58)

- Item Code: Minimum Inventory in Store/monthDocument1 pageItem Code: Minimum Inventory in Store/monthazadsingh1No ratings yet

- Injection Molding GuideDocument33 pagesInjection Molding Guidethangkhungpro0% (1)

- PQCS Welding ProcessDocument22 pagesPQCS Welding Processazadsingh1No ratings yet

- Non-Conformity Report & Corrective Action: Description of Non-ConformanceDocument1 pageNon-Conformity Report & Corrective Action: Description of Non-Conformanceazadsingh1No ratings yet

- Pqcs SampleDocument3 pagesPqcs Sampleazadsingh1100% (1)

- Process ChartDocument1 pageProcess Chartazadsingh1No ratings yet

- Aluminum Foundry TechniqueDocument51 pagesAluminum Foundry Techniqueazadsingh1No ratings yet

- Projet ReportDocument4 pagesProjet Reportazadsingh1No ratings yet

- Power MillDocument158 pagesPower Millazadsingh1100% (3)

- Happy Steels (P) LTD.: Qualification CriteriaDocument2 pagesHappy Steels (P) LTD.: Qualification Criteriaazadsingh1No ratings yet

- Trident Auto ProfileDocument17 pagesTrident Auto Profileazadsingh1No ratings yet

- PreDocument3 pagesPreazadsingh1No ratings yet

- FMEA1Document25 pagesFMEA1azadsingh1No ratings yet

- Supplier: Parveen Enterprises Customer - MEDICAMEN Biotech Limited Quotation - PE-01Document2 pagesSupplier: Parveen Enterprises Customer - MEDICAMEN Biotech Limited Quotation - PE-01azadsingh1No ratings yet

- Excels Keyboard Shortcuts: Menu Equivalent Comments AllDocument5 pagesExcels Keyboard Shortcuts: Menu Equivalent Comments Allazadsingh1No ratings yet

- Age CharacterCalculationDocument1 pageAge CharacterCalculationAnonymous gwldee5No ratings yet

- Part Submission WarrantDocument2 pagesPart Submission Warrantazadsingh1100% (1)

- Presstool Design Tutorial - MisumiDocument166 pagesPresstool Design Tutorial - Misumiazadsingh1No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Theories of Congruent Communication by Haim GinottDocument11 pagesTheories of Congruent Communication by Haim GinottAdam AriffNo ratings yet

- Blogs, Wikis, Podcasts, and Other Powerful Web Tools For Classrooms (Gnv64)Document185 pagesBlogs, Wikis, Podcasts, and Other Powerful Web Tools For Classrooms (Gnv64)Vag Kats33% (3)

- Transverse Myelitis Case StudyDocument25 pagesTransverse Myelitis Case Studyapi-234211889No ratings yet

- LIS MCQsDocument5 pagesLIS MCQsMomi Zaidi86% (7)

- ELC231 Course BriefingDocument10 pagesELC231 Course BriefingMUHAMMAD FARIS BIN ROZAIDINo ratings yet

- Math Lesson PlanDocument4 pagesMath Lesson Planapi-340862505No ratings yet

- New York Times War and Memory LessonDocument39 pagesNew York Times War and Memory Lessonapi-218930601No ratings yet

- ICEP CSS - PMS Institute, Lahore (MCQ'S Gender Studies)Document22 pagesICEP CSS - PMS Institute, Lahore (MCQ'S Gender Studies)Majid Ameer AttariNo ratings yet

- Aruna ReddyDocument14 pagesAruna ReddyVinay ChagantiNo ratings yet

- Govt: Girls Degree College Julagram District Malakand: Service Experience CertificateDocument66 pagesGovt: Girls Degree College Julagram District Malakand: Service Experience CertificateIjaz KhanNo ratings yet

- Api111 Syllabus 0819Document6 pagesApi111 Syllabus 0819qaz333No ratings yet

- The Folklore of Language Teaching. Thomas F. Magner (1965)Document6 pagesThe Folklore of Language Teaching. Thomas F. Magner (1965)Turcology TiranaNo ratings yet

- QF EheaDocument200 pagesQF Eheajose_dias_58No ratings yet

- Close Reading in Elementary SchoolDocument1 pageClose Reading in Elementary Schoolapi-373975702No ratings yet

- Jared M. Hansen: 1803 Anna ST Bellevue, NE 68005 Phone: C: (402) 709-1615 H: (402) 293-1565Document2 pagesJared M. Hansen: 1803 Anna ST Bellevue, NE 68005 Phone: C: (402) 709-1615 H: (402) 293-1565dcfan402No ratings yet

- Optional Exams 2019-20: Smt. Sulochanadevi Singhania SchoolDocument1 pageOptional Exams 2019-20: Smt. Sulochanadevi Singhania SchoolRamanand YadavNo ratings yet

- Bahay Pag-AsaDocument8 pagesBahay Pag-AsaVenna Grace OquindoNo ratings yet

- Sptve - Techdrwg 8 - q1 - m9Document12 pagesSptve - Techdrwg 8 - q1 - m9MirtelShane-Ara Agustin SalesNo ratings yet

- Dissertation Michael Curtin - g00313894Document33 pagesDissertation Michael Curtin - g00313894api-350526786No ratings yet

- Monitoring and Evaluation of Online LearningDocument8 pagesMonitoring and Evaluation of Online LearningFadjar Eko NovantoNo ratings yet

- Teaching English With TechnologyDocument13 pagesTeaching English With TechnologyFaizah Eza KesumaNo ratings yet

- DMD 3062 - Final Year Project IDocument10 pagesDMD 3062 - Final Year Project IShafiq KhaleedNo ratings yet

- 3248 s12 Ms 1Document5 pages3248 s12 Ms 1mstudy123456No ratings yet

- Psumt Newsletter FallDocument3 pagesPsumt Newsletter Fallapi-251592269No ratings yet

- Evaluation Rating Sheet For Non Print LR MaterialsDocument8 pagesEvaluation Rating Sheet For Non Print LR MaterialsMica BernabeNo ratings yet

- Benchmarking E-Learning Phase 1 BELA OverviewDocument10 pagesBenchmarking E-Learning Phase 1 BELA OverviewPaul BacsichNo ratings yet

- (DOC) UNIQUE - Gina Cruz - Academia - EduDocument18 pages(DOC) UNIQUE - Gina Cruz - Academia - EduAbelardo Ramos DiasNo ratings yet

- AO1.2 - Poster EssayDocument5 pagesAO1.2 - Poster EssayHeart EspineliNo ratings yet

- Curriculum Vitae: EducationDocument3 pagesCurriculum Vitae: EducationSomSreyTouchNo ratings yet

- Post Doctoral Research Fellow-Research Fellow - PDDocument5 pagesPost Doctoral Research Fellow-Research Fellow - PDpauloquioNo ratings yet