Professional Documents

Culture Documents

Multy Crack Detection

Uploaded by

Arun Das PhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Multy Crack Detection

Uploaded by

Arun Das PhCopyright:

Available Formats

Technical Journal of Engineering and Applied Sciences

Available online at www.tjeas.com

2013 TJEAS Journal-2013-3-23/3484-3490

ISSN 2051-0853 2013 TJEAS

MULTY-CRACK DETECTION

Mehdi karimi1, Nima Haghshenas2, Behzad Masoumijalal3

1. Assistant Professor of Mechanical Engineering, Bu-Ali Sina University, Hamedan, Iran

2. M.Sc Student of Mechanical Engineering, Amirkabir University, Tehran, Iran

3. M.S Student of Civil Engineering, Islamic azad University, Hamedan, Iran

Corresponding author: Mehdi karimi

ABSTRACT: Crack is a type of damage that can lead to catastrophic failure when grows in a

structure. Therefore prediction of cracks is a very important problem. In this research, two methods

for crack detection in structures have been presented and compared. Some of the parameters

used for crack detection are mode shapes and natural frequencies. The structure used in this

research is a cantilever beam. The process of crack detection has been performed by using finite

element method and artificial neural network. In the method which was based on wavelet analysis

and finite element method, first some transverse cracks were assumed. Using finite element

method for identifies natural frequencies and first mode shapes. Then sym 4 wavelet transform

was used to analyze the mode shapes of the structure. Then a new technique based on local

maxima line of wavelet coefficient through different scales was applied. Subsequently, cracks

characteristics were computed with a good approximation. This technique was employed to

different numbers, locations of cracks and results were acquired. This technique has several

advantages to other common wavelet methods. Another method used in this research was based

on artificial neural network. Crack identification in the proposed method is consists of two steps. In

step 1, a radial basis neural network was used to detect the number of cracks of structure. In step

2, a back error propagation neural network was trained to detect the locations of cracks. Training

neural networks using obtained data from finite element method has been performed. Finally

obtained results from two methods were compared with each other.

Key words: multi-crack detection; finite element method; neural network; wavelet analysis

INTRODUCTION

One of the major types of faults that if develops, may cause catastrophic damages in structures are

crack. Recently some studies have been done on non-destructive crack identification methods. In last 5

decades researchers have shown great interest in vibration analysis method and so there are a lot of

investigations in this area. Dimarogonas reviewed methods of investigating cracked structures in 1996

(Adams and Cawley, 1979). Crack causes a local flexibility in the structure which affects the dynamic

behavior. For example it reduces the natural frequencies and changes the mode shapes. Analyzing

these effects can be used for crack detection (Binici, 2005). Dimarogonas et al modeled a crack using

local flexibility and calculated the equivalent stiffness utilizing fracture mechanic (Cam et al, 2008; Chang

et al, 2008). Adams et al developed an experimental technique to estimate the location and the depth of

a crack based on the changes of the natural frequencies (Chang and Chen, 2005). In another

investigation Dimarogonas presented methods which relate the depth of the crack to the changes of the

natural frequencies when the crack location is known (Chondros and Dimarogonas, 1980). These

methods can be used to identify cracks in different structures. Gudmunson presented a method to

predict the changes of the natural frequencies caused by faults such as cracks, notches, etc

(Dimarogonas, 1976). Shen et al Presented a method based on minimizing the difference between the

measured data the data obtained from an analytical data to identify cracks in an Euler-Bernoulli beam

(Dimarogonas, 1996). Masoud et al Investigated vibrational characteristics of a fixed-fixed beam with a

symmetric crack considering coupling effect of crack depth and axial load (Douka et al, 2003).

In recent years some studies have been done on multi-crack detection of structures. Sekhar (1982)

summarized different studies on double/multi-cracks and the respective influences, identification

methods in vibration structures as beams, rotors, pipes etc. Lee et al (2001) used finite element method

to solve forward problem in a multiple cracked beam. The inverse problem was solved iteratively for the

locations and sizes of the cracks using the Newton-Raphson method. Mazanoglu et al (2009) performed

Tech J Engin & App Sci., 3 (23): 3484-3490, 2013

a vibration analysis of multiple cracked non-uniform beams by the Rayleigh-Ritz approximation method.

Patil and Maiti (2004) detected multiple cracks by frequency measurements. Their procedure gave a

linear relationship explicitly between the changes in natural frequencies of the beam and the damage

parameters. Binici et al (1998) proposed a parametric study in order to investigate the effect of cracks

and axial force levels on the Eigen frequencies. A new method for natural frequency analysis of beam

with an arbitrary number of cracks has been developed by Khiem and Lien (2009) on the bases of the

transfer matrix. Ertugrul et al (1986) analyzed the vibrations of cracked beam as a result of impact

shocks to obtain information about the location and depth of cracks in cracked beams.

Also there are some studies have been done on crack identification in structures based on wavelet

transform method. Loutridis et al (2003) presented a method for crack identification in double-cracked

beams based on wavelet analysis. The location of the cracks was determined by the sudden changes in

the spatial variation of the transformed response. To estimate the relative depth of the cracks, an

intensity factor was established which correlated the size of the cracks to the coefficients of the wavelet

transform. Wavelet transform was used to analyze the fractional strain energy of each beam section by

Chang et al (2006). This method just requires the displacements of beam after damage. It was observed

that distributions of the wavelet coefficients can identify the damage position by showing a peak at the

position of the damage. Hang and Chen (2008) calculated the mode shapes of free vibration and natural

frequencies of the multiple cracked beams. The mode shapes were analyzed by wavelet transformation

to get the positions of the cracks. Then natural frequencies were used to predict the depth of the cracks

through the characteristic equation. Rucka and Wilde (1991) showed that continuous wavelet transform

are more suitable for damage detection in beams and plates than discrete wavelet transform. Because

continuous wavelet transforms provide precise resolution necessary for damage localization. Zamanian

and Ohadi (2009) proposed a method was based on local maxima lines of wavelet coefficients. They

showed that modified technique has ability of crack identification more obvious and clear than the

conventional methods in price of more computational effort.

In this research, two methods for crack detection in beams based on natural frequencies and mode

shapes by using wavelet analysis and two types of artificial neural network is presented and compared.

Modal Analysis

The beam investigated in this paper is a cantilever beam with one or more open crack. Table 1 gives the

beam's characteristics. In this section three natural frequencies of the structure are calculated for

different conditions of crack locations and depths using finite element method. Table 2 compares

between the some results obtained by finite element method in this study and the results obtained in

reference (Loutridis et al, 2004).

Wavelet Transform Analysis

One of the methods that in this study are used for crack identification is wavelet transform. Wavelet

transform is a new mathematical technique developed recently which consists in decomposing a signal into

elementary contributions called wavelets. By convoluting the signal with the wavelets, this decomposition

comprises an expansion of the signal over the wavelets. In the one dimensional case, it provides a two

dimensional unfolding of the signal resolving both in the position and scale as independent variables.

Wavelets are constructed from an analyzing function called mother wavelet by means of translations and

dilatations. Therefore, wavelet analysis acts as a mathematical micros cope which allows one to zoom in on

the fine structure of a signal or alternatively, to reveal large scale structures by zooming out.

Table1. Cantilever Beam Characteristics

Density

(Kg/m3)

Poisson

Ratio

7860

Length

(mm)

240

0.3

Thickness

(mm)

12

Elasticity

Modulus

(GPa)

210

Height

(mm)

20

3485

Tech J Engin & App Sci., 3 (23): 3484-3490, 2013

Table 2 .Comparison of Natural Frequencies between Present Study and (Loutridis et al, 2004)

Crack Location (mm)

Crack Depth (mm)

No

1

No

2

No

1

No

2

24

96

24

96

24

120

10

36

108

48

120

10

48

120

10

10

60

132

11

60

132

11

| ( )|

| |

| |

Where

()

Error

(%)

0.50

0.51

0.50

0.71

0.51

0.44

0.28

1.93

1.28

1.00

1.10

0.71

0.57

0.67

0.39

1.14

0.73

0.69

0.39

0.73

0.66

0.41

0.80

0.51

is the translation (factor a) and dilation (factor b) ( ):

(2)

with

(

The wavelet transform

(

Ref[13]

(HZ)

271.931

1649.858

4545.492

248.039

1654.086

4611.596

265.013

1625.863

4660.053

229.482

1405.505

4445.952

259.042

1536.825

4558.17

222.321

1527.623

4197.771

272.689

1624.409

4463.05

271.594

1476.876

4435.421

(1)

Relative to every basic wavelet

( )

Present

(HZ)

273.30

1658.3

4568.3

249.82

1662.6

4631.9

264.26

1657.4

4600.0

231.78

1421.1

4477.9

260.54

1547.2

4576.3

224.87

1538.9

4226.9

273.76

1636.3

4492.9

272.71

1488.8

4458.4

( ) is a basic wavelet if and if its Fourier transform ( ) satisfies:

A function

Natural Frequencies

( )

( )

) of function

( ) with respect to

is defined as their scalar product by:

(3)

Among available wavelets, Sym 4 has been chosen in this research. By replacing with a spatial coordinate

in previous equations, spatially distributed functions can be analyzed by wavelet transform. Considering the

spatial functions S distributed over ( ) the wavelet coefficients for the functions then can be written as:

(

( )

( )

(4)

Where is a spatial coordinate,

is the scale (dilation) factor and is the position (translation)

factor. The spatial functions used here are mode shapes of cracked beam and wavelet coefficients are

written as:

(

( )

( )

(5)

3486

Tech J Engin & App Sci., 3 (23): 3484-3490, 2013

Since the resulting coefficients from the wavelet transform of a spatial domain function can be

represented in a two dimensional positions scale map. Examination of the modulus of the wavelet transform

shows that many of these coefficients are very small in magnitude. Large magnitude components, termed

modulus maxima, will be present at positions where the maximum change in the mode shape has occurred.

Singularities (cracks) in the mode shape can therefore be identified by the presence of modulus maxima at

specific positions in the wavelet map.

Artificial Neural Network

In this section the process of crack detection has been performed by using finite element method

and combination of two types of artificial neural network including radial basis neural network and back error

propagation neural network. Crack identification in the proposed method is consists of two steps. In step 1, a

radial basis neural network was used to detect the number of cracks of structure. In step 2, a feed forward

back error propagation neural network was trained to detect the locations of cracks. Training neural networks

using obtained data from finite element method has been performed.

Back error propagation neural network

A schematic diagram of typical multilayer feed-forward neural-network architecture is shown in Fig 1.

The network usually consists of an input layer, some hidden layers and an output layer. The back e rror

propagation is the most widely used learning algorithm.

Figure1. Multilayer feed forward neural network

In this paper two back error propagation neural networks are employed for prediction of locations of

cracks, one of them for beam with two cracks and another for beam with one crack. These networks consist

of one input layer with 3 neurons, one hidden layer with 30 neurons and one output layer with two neurons

for beam with two cracks and one neuron for beam with one crack. The inputs of back error propagation

neural networks were first three natural frequencies of different conditions of cracks and output were

locations of cracks.

Radial basis neural network

The structure of Radial basis neural network is shown in Fig. 2. It includes four layers, the input

layer, hidden layer, summation layer and output layer. In this study a radial basis neural network was used to

detect the number of cracks in structure. The inputs of this neural network were f irst three natural

frequencies of different conditions of cracks and outputs were number of cracks.

3487

Tech J Engin & App Sci., 3 (23): 3484-3490, 2013

Figure2. Radial Basis Neural Network

RESULTS

In this section number and locations of cracks for some special cases are obtained by wavelet

transform method (Figs 3-8) and then are compared with results of artificial neural network method (Table 3).

The wavelet analysis is conducted on beam fundamental mode shape (Figs 3, 6) assumed as a

spatially distributed signal by the sym 4 wavelet. For a special case the wavelet transform modulus

computed from the first mode shape. Then the one-dimensional CWT of mode shapes is performed for

scales = l - 25. The modulus maxima value grows with the increase of the scale and clearly points to the

location of crack (Fig 4, 7).

Table 3 .Comparison of actual and predicted number and crack locations for cantilever

NO

Parameter

Actual Data

Number of Cracks

2

120

48

Cracks Location(mm)

Locations Error (%)

2

Number of cracks

Cracks Location(mm)

Locations Error (%)

Figure 3. Fundamental Vibration Mode Shape of

The Multiple Cracked Beam x1 = 0.483 (m),

a1 = 0.01(m), X2 = 0.1194 (m) and a2 = 0.008(m)

1

24

Predicted Data

Wavelet

2

119.4

48.3

0.5

0.6

1

26

8.3

ANN

2

111.93

48.05

6.73

0.1

1

24.15

0.63

Figure 6. Fundamental Vibration Mode Shape of

The Single Cracked Beam x1 = 0.26(m) and

a1 = 0.01(m)

3488

Tech J Engin & App Sci., 3 (23): 3484-3490, 2013

Figure 4. Wavelet Coefficients (Sym 4 Wavelet

Transform) In Multiple Cracked Beam x1 = 0.483

(m), a1 = 0.01(m), x2 = 0.1194 (m) and a 2 = 0.008(m)

Figure 5. Maxima Line of Wavelet Coefficients

(Sym 4 Wavelet Transform) In Multiple Cracked

Beam x1 = 0.483 (m), a 1 = 0.01(m), x2 = 0.1194 (m)

and a2 = 0.008(m)

Figure7. Wavelet Coefficients (Sym 4 Wavelet

Transform) In Single Cracked Beam x1 = 0.26(m)

and a1 = 0.01(m)

Figure 8. Maxima Line of Wavelet Coefficients

(Sym 4 Wavelet Transform) In Single Cracked

Beam x1 = 0.26 (m) and a 1 = 0.01(m)

The new techniques find local maxima of wavelet coefficients in multiple scales and then create a

line like path based on these maxima by connecting these points (Fig 5-8).

CONCLUTION

Two methods for crack detection in structures based on mode shapes and natural frequencies have

been presented and compared. The structure used in this research was a cantilever beam with rectangular

cross section. Firstly, a new method based on local maxima line of wavelet coefficient through different

scales and finite element method was applied. The advantage of this technique is that the crack detection

process is more clear and

comfortable than previous works. After this analysis, the process of crack identification has bee n performed

by using finite element method and combination of two types of artificial neural network including radial basis

neural network and back error propagation neural network. These techniques were employed to different

numbers and locations of cracks and results were acquired. Finally it is shown that cracks characteristics

from both of the methods were computed with good approximations.

REFERENCES

Adams AD, Cawley P.1979.The location of defects in structures from measurements of natural frequencies, Journal of Strain Analysis, 14,

49-57.

3489

Tech J Engin & App Sci., 3 (23): 3484-3490, 2013

Binici B.2005.Vibration of beams with multiple open cracks subjected to axial force. Journal of Sound and Vibration.287, 277-295.

Cam E, Sadettin O, Murat L. 2008. An analysis of cracked beam structure using impact echo method, NDTand E International. 38, 368373.

Chang CC, Chang SM, Huang HY, Yeh JY. 2008. Application of the wavelet analysis to strain energy damage detection method. Journal of

Professional Mechanical Engineers.1, 23-26.

Chang CC, Chen LW. 2005. Detection of the location and size of cracks in the multiple cracked beams by spatial wavelet based approach.

Mechanical Systems and Signal processing. 19 139-155.

Chondros TG, Dimarogonas AD.1980. Identification of cracks in welded joints of complex structures. Journal of sound and vibration, 69,

531 -538.

Dimarogonas AD. 1976. Vibration Engineering, West Publishers, St Paul, Minesota.

Dimarogonas AD. 1996. Vibration of cracked structures: a state of the art review. Engineering Fracture Mechanics 55, 831-857.

Douka E, Loutridis S, Trochidis A. 2003.Crack identification in beams using wavelet analysis, international journal of solids and structures,

40, 3557-3569.

Goudmunson P, 1982. Eigenfrequency change of structures: a state of the art review. Engineering Fracture Mechanics, 55, 831-857.

Khiem NT, Lien TV.2001. A simplified method for natural frequency analysis of a multiple cracked beam. Journal of Sound and Vibration.

245, 737-751.

Lee J. 2009.Identification of multiple cracks in a beam using natural frequencies. Journal of Sound and Vibration.320, 482-490.

Loutridis S, Douka E, Trochidis A.2004. Crack identification in double-cracked beams using wavelet analysis. Journal of Sound and

Vibration.277, 1025-1039.

Masoud A, Jarrad MA, Al-Maamory M. 1998.Effect of crack depth on the natural frequency of a prestressed fixed-fixed beam. Journal of

sound and vibration 214, 201-212.

Mazanoglu K, Yesilyurt I, Sabuncu M. 2009. Vibration analysis of multiple-cracked non-uniform beams. Journal of Sound and

Vibration.320, 977- 989.

Paipetis SA, Dimarogonas AD. 1986. Analytical method in rotor dynamics, Elsevier applied science, London.

Patil DP, Maity SK. 2003.Detection of multiple cracks using frequency measurements. Engineering Fracture Mechanics. 70, 1553-1572.

Rucka M, Wilde K. 2006.Application of continuous wavelet transform in vibration based damage detection method for beams and plates.

Journal of Sound and Vibration. 297, 536-550.

Sekhar AS. 2008. Multiple cracks effects and identification. Mechanical Systems and Signal Processing.22, 845-878.

Shen MHH, Taylor JE. 1991. An identification problem for vibrating cracked beams. Journal of sound and vibration, 150-457, 84.

Zamanian AH, Ohadi A. 2009. Crack identification in Timoshenko beam using local maxima lines of wavelet coefficients. The Sixteenth

International Congress on Sound and Vibration, Krakow, Poland.

3490

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Finite Element Modelling of Reinforced Concrete Frame PDFDocument109 pagesFinite Element Modelling of Reinforced Concrete Frame PDFArun Das PhNo ratings yet

- Comparitive Study of Linear and Geometric Nonlinear Load-Deflection Behavior of Flexural Steel MembersDocument6 pagesComparitive Study of Linear and Geometric Nonlinear Load-Deflection Behavior of Flexural Steel MembersArun Das PhNo ratings yet

- Prediction of Location of Multi Cracks in A Cantilever BeamDocument2 pagesPrediction of Location of Multi Cracks in A Cantilever BeamArun Das PhNo ratings yet

- Aee Paper3 Civil Engg 2003Document8 pagesAee Paper3 Civil Engg 2003balkelabalNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 2gr-Fse Cooling - Cooling System - On-Vehicle Inspection PDFDocument1 page2gr-Fse Cooling - Cooling System - On-Vehicle Inspection PDFJohn LockeNo ratings yet

- Air Standard CycleDocument93 pagesAir Standard CycleJonathan CerdanNo ratings yet

- Ne6 3911gb-MidlumDocument234 pagesNe6 3911gb-MidlumDinu GabrielNo ratings yet

- Chapter 5 - Exhaust SystemsDocument26 pagesChapter 5 - Exhaust SystemsVin KenNo ratings yet

- MINI Clubman Mobile Vehicle RepairDocument5 pagesMINI Clubman Mobile Vehicle RepairJamal NoorNo ratings yet

- Pre-Concreting Checklist Ditch Concrete KM 2 SAR P205-P203 Leftt SideDocument2 pagesPre-Concreting Checklist Ditch Concrete KM 2 SAR P205-P203 Leftt SideMvomoNo ratings yet

- SY16 Maintenance ManualDocument148 pagesSY16 Maintenance ManualAndres SorinNo ratings yet

- Tablas Medidas Tubos de Acero API5L - ASTM A53 - A106Document6 pagesTablas Medidas Tubos de Acero API5L - ASTM A53 - A106Reinaldo AndaraNo ratings yet

- Characteristics of DC Motor: 1. Torque-Armature Current CharacteristicsDocument8 pagesCharacteristics of DC Motor: 1. Torque-Armature Current CharacteristicsBilbo BagginsNo ratings yet

- BlowerGB 2Document6 pagesBlowerGB 2Kiyarash BarmakizadehNo ratings yet

- Chapter - 7 Part I STDDocument75 pagesChapter - 7 Part I STDBelkacem Achour100% (1)

- Cooling Tower SolutionDocument38 pagesCooling Tower SolutionThabangNo ratings yet

- Mobiscreen Ms 702 - Ms 703 - Ms 952 - Ms 953 Evo: Feed HopperDocument2 pagesMobiscreen Ms 702 - Ms 703 - Ms 952 - Ms 953 Evo: Feed HopperTEKLEWEYNI TsegayNo ratings yet

- L3548 4 07Document2 pagesL3548 4 07Héctor Hugo Sánchez GómezNo ratings yet

- Swimming EquipmentsDocument45 pagesSwimming EquipmentsHaymanAHMEDNo ratings yet

- (Hyundai Sonata 2005-2011, (Kia Forte 2009-2010, K5 2010-2011, Lotze 2010)Document4 pages(Hyundai Sonata 2005-2011, (Kia Forte 2009-2010, K5 2010-2011, Lotze 2010)marran almarranyNo ratings yet

- of MotorvaneDocument3 pagesof MotorvaneJeevan BabuNo ratings yet

- Flue Gas Analyzer O&M Manual ROENDocument2,353 pagesFlue Gas Analyzer O&M Manual ROENAnonymous bSpP1m8j0nNo ratings yet

- IRN 15 18.5 KW (20 25 HP) IRN 22 30 KW (30 40 HP) : Operation and Maintenance ManualDocument172 pagesIRN 15 18.5 KW (20 25 HP) IRN 22 30 KW (30 40 HP) : Operation and Maintenance ManualNikolay VelchevNo ratings yet

- Building Utilities Reviewer ComprehensiveDocument3 pagesBuilding Utilities Reviewer ComprehensiveReynald HarrisNo ratings yet

- Fabrication of Turbocharger For Two Wheeler: Ahir Nischal A, Sofia Ali A, Darshan S Shah, Sneh R PrajapatiDocument8 pagesFabrication of Turbocharger For Two Wheeler: Ahir Nischal A, Sofia Ali A, Darshan S Shah, Sneh R PrajapatiDeepak sutarNo ratings yet

- Scheda Autoclave VT - Med ResDocument2 pagesScheda Autoclave VT - Med Resengomar nadyNo ratings yet

- Minishover Komatsu SK820-5E0Document260 pagesMinishover Komatsu SK820-5E0Jose A. Basanta H.100% (1)

- Item Code Item Name Item Class Brand Model Code Warehouse Group Warehouse Code Location Code Sales Price Available QtyDocument8 pagesItem Code Item Name Item Class Brand Model Code Warehouse Group Warehouse Code Location Code Sales Price Available Qtyrahmat agungNo ratings yet

- Is.7396.1.1985 Surge Shaft DesignDocument26 pagesIs.7396.1.1985 Surge Shaft DesignVanu Vamalai100% (1)

- Elmex P ListDocument47 pagesElmex P Listbasantjain12345No ratings yet

- PDFDocument44 pagesPDFRebecca Hartman75% (4)

- Technical Diagram enDocument4 pagesTechnical Diagram enJamil Ahmed100% (2)

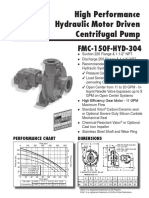

- FMC-150F-HYD-304 - 04-13 Bomba AceDocument2 pagesFMC-150F-HYD-304 - 04-13 Bomba AceEmerson GomesNo ratings yet

- ControlFlow GateValveDocument37 pagesControlFlow GateValveclaudio godinezNo ratings yet