Professional Documents

Culture Documents

ThyssenKrupp Industries India project specifications

Uploaded by

Sudhakar Karnan0 ratings0% found this document useful (0 votes)

20 views1 pageThis document provides specifications for designing drainage, firefighting, sewage, drinking water, and auxiliary systems for a coke handling system package project in Kerala, India. It requires the bidder to design the systems according to relevant codes and standards, considering total water and air consumption, pipe sizing, pump and compressor sizing, and pressure drops. Piping must allow for maintenance access and clearance for equipment removal. Pipes for water and air services should be run through conveyor galleries where possible and buried elsewhere. The document also specifies material requirements for pipes, valves, flanges, spray nozzles, deluge valves, and detector piping.

Original Description:

Informative

Original Title

Enq.spec_ds,Ff & Other Water, Ewage System_bpcl-kochi_part-1 6

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications for designing drainage, firefighting, sewage, drinking water, and auxiliary systems for a coke handling system package project in Kerala, India. It requires the bidder to design the systems according to relevant codes and standards, considering total water and air consumption, pipe sizing, pump and compressor sizing, and pressure drops. Piping must allow for maintenance access and clearance for equipment removal. Pipes for water and air services should be run through conveyor galleries where possible and buried elsewhere. The document also specifies material requirements for pipes, valves, flanges, spray nozzles, deluge valves, and detector piping.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views1 pageThyssenKrupp Industries India project specifications

Uploaded by

Sudhakar KarnanThis document provides specifications for designing drainage, firefighting, sewage, drinking water, and auxiliary systems for a coke handling system package project in Kerala, India. It requires the bidder to design the systems according to relevant codes and standards, considering total water and air consumption, pipe sizing, pump and compressor sizing, and pressure drops. Piping must allow for maintenance access and clearance for equipment removal. Pipes for water and air services should be run through conveyor galleries where possible and buried elsewhere. The document also specifies material requirements for pipes, valves, flanges, spray nozzles, deluge valves, and detector piping.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

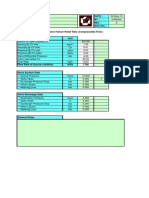

ThyssenKrupp Industries India

SPECIFICATIONS FOR DS/FF/SEWAGE/DW/AUXILIARY SYSTEMS

PROJECT: COKE HANDLING SYSTEM PACKAGE

(INTEGRATED REFINERY EXPANSION PROJECT), Kerala

CLIENT

: BHARAT PETROLEUM CORPORATION LIMITED, KOCHI

CONSULTANT

: ENGINEERS INDIA LIMITED, NEW DELHI

SPEC NO. : 7303-B00-01005

REVISION : 0

DATE

: 22.02.2014

W.O. NO.

: 3M0043

7.0 DESIGN REQUIREMENT:

Codes and Standards:

The bidder shall design the equipment / components of all the systems, total water & air consumption, sizing of

the piping, pumps & compressors, pressure drop in the piping, equipment as per relevant section of the

specifications enclosed and actual physical parameters of equipment involved.

For water & air services,

All isolation Valves (unless otherwise specified) will be of Forged /cast steel body Ball

Valve as per BS: 5351(full bore),

The layout of water pumps shall be such that it shall be possible to maintain any pump set without disturbing

the operating pump set. It shall be possible to remove the water pump and / or motor for maintenance by

disconnecting the pump coupling from the discharge piping. It should not be necessary to dismantle the

discharge piping for removing any pump. The pumps shall be of back pull out type.

The layout of water and air piping for dust suppression system shall be such that all valves are easily

accessible for maintenance. All water and air pipes shall be run in conveyor galleries. However, where it is

difficult to run air and water pipes in conveyor galleries particularly outside the switch gear room / control room

cum pump house before reaching nearest conveyor gallery and in stock yard areas, those are to be buried.

The overhead piping shall have a minimum working clearance of 2.5m head room over walkways and working

areas in buildings.

All piping shall be arranged to provide clearance for the removal of equipment requiring maintenance and for

easy access for valves & other piping accessories required for operation & maintenance. Layout drawings shall

also indicate orientation of valves and availability of access to valves and specialities.

Access walkways / space between equipment / steps etc., in the switch gear room /control room cum pump

house shall be minimum 1000 mm. Suitable hand railing shall be provided for personnel safety, wherever

required.

Wherever pipes / Cables cross roads / plant areas the minimum head room of 6 metres above road / grade

level shall be maintained.

Standards:

IS: 778 Gun Metal gate, globe & check valve for general purpose.

BS: 5150: Cast Iron gate valve for water works purposes.

BS: 5152: Cast Iron globe valve for water works purposes.

BS: 5312: Cast Iron check valve for water works purposes.

IS: 1239: Mild Steel tubes & fittings.

IS: 2379: Color for identification of pipe line.

IS: 2906: Sluice valve for water works purposes.

IS: 3589: Electrically welded steel pipes for water, gas & sewage (200 to 2000mm)

IS: 5312: Swing check valve reflux (non return) valve.

IS: 1520: Horizontal centrifugal pump for clean, cold fresh water.

IS: 5120: Centrifugal pump for clean, cold fresh water.

BS: 5169 & BS: 1123: Air receivers.

ANSI B 31.1: Code for pressure piping.

Hydraulic institute standards of U.S.A.

Material for Pipes, Valves & Joints please refer notes from P&ID for DWS, DFDS, SWS & PWDS system

(Drawing no. 3M0045 Q10 000 02) attached with this specification.

Material of Construction:

Pipes, fittings

Lot

Valves and flanges

Spray nozzles

Deluge valves

Detector piping

Nos.

Nos.

Nos.

Lot

PREPARED BY: CHETAN

CS for mains and

MS-GI (HVY) screwed piping for spray system upto 6diameter.

C.S.

Cu Alloy

C.I.

G.I.

APPROVED.BY: D. MITRA.

PAGE 6 OF 13

You might also like

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- A Guide to Ship Repair Estimates in Man-hoursFrom EverandA Guide to Ship Repair Estimates in Man-hoursRating: 4.5 out of 5 stars4.5/5 (5)

- Valve Procurement SpecsDocument39 pagesValve Procurement Specsjoseph.maquez24100% (2)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Bernoulli's EquationDocument14 pagesBernoulli's EquationMae Medalla DantesNo ratings yet

- Pipe, Valves & Fittings Specification GuideDocument136 pagesPipe, Valves & Fittings Specification GuideTefa MartinezNo ratings yet

- Basic Engineering, Standart Specification For Pipe, ValvesDocument196 pagesBasic Engineering, Standart Specification For Pipe, ValvesOzkr_sg100% (2)

- MechanicalDocument173 pagesMechanicalKerx EndranoNo ratings yet

- 2150 Attachment 13 - Minimum Piping DesiDocument24 pages2150 Attachment 13 - Minimum Piping Desidimdaliak_985662241100% (1)

- Hal Ahu BoqDocument16 pagesHal Ahu Boqmdalt9180100% (1)

- C1 The Basic of Plant Layout Design - Process Plant Layout and Piping DesignDocument81 pagesC1 The Basic of Plant Layout Design - Process Plant Layout and Piping Designdung100% (1)

- 06 PIPING Design Basis PDFDocument8 pages06 PIPING Design Basis PDFKatamaneni Koteswararao100% (2)

- Basic Engineering SpecificationDocument16 pagesBasic Engineering SpecificationOvaisNo ratings yet

- Equator 1Document48 pagesEquator 1sajkhdjksahdkjNo ratings yet

- Refrigerant Piping Sample-2Document4 pagesRefrigerant Piping Sample-2Hazrat AminNo ratings yet

- Pex SpecsDocument24 pagesPex SpecsYazan TamimiNo ratings yet

- Rowan University Design Guide 2013Document2 pagesRowan University Design Guide 2013zeliteNo ratings yet

- Piping BasisDocument32 pagesPiping Basislowermine100% (2)

- T - Proc - Notices - Notices - 020 - K - Notice - Doc - 16303 - 980084027 PDFDocument11 pagesT - Proc - Notices - Notices - 020 - K - Notice - Doc - 16303 - 980084027 PDFMuhammadSiddiqueNo ratings yet

- DRAWINGS STANDARD SPECIFICATIONS BawanaDocument172 pagesDRAWINGS STANDARD SPECIFICATIONS Bawanaenjoyguruji83% (6)

- Plumbing System - RevDocument4 pagesPlumbing System - RevLuis Gabriel BautistaNo ratings yet

- SEWAGE FORCE MAIN INSTALLATION REQUIREMENTSDocument9 pagesSEWAGE FORCE MAIN INSTALLATION REQUIREMENTSMarlon A. MendozaNo ratings yet

- PLUMBING SPECIALTIES TITLEDocument19 pagesPLUMBING SPECIALTIES TITLEadel rihanaNo ratings yet

- FS HpuDocument11 pagesFS Hpuscribd_thakurNo ratings yet

- Process Design Manual LurgiDocument25 pagesProcess Design Manual LurgiMarcelo Peretti91% (11)

- General Notes On PRDSDocument6 pagesGeneral Notes On PRDSmkbeast60No ratings yet

- Essar Steel PlantDocument62 pagesEssar Steel PlantKrishnadev C.SNo ratings yet

- Piping LayoutDocument16 pagesPiping Layoutsanmiguel000100% (1)

- 6 Annexure 6 Technical Specification of Piping-2021-07!07!04!12!52Document23 pages6 Annexure 6 Technical Specification of Piping-2021-07!07!04!12!52mech1kingNo ratings yet

- Air-Cooled Condenser Piping Design RequirementsDocument3 pagesAir-Cooled Condenser Piping Design RequirementsHoney TiwariNo ratings yet

- 22 11 17 - Gas Pipe and AppurtenancesDocument7 pages22 11 17 - Gas Pipe and AppurtenancesTeguh SetionoNo ratings yet

- Piping Layout UDLDocument24 pagesPiping Layout UDLLegend Anbu100% (1)

- AED Design Requirements - Water Tanks and System Distribution - Sep09 PDFDocument23 pagesAED Design Requirements - Water Tanks and System Distribution - Sep09 PDFAvonodOiratulcNo ratings yet

- Fire Pumps - MSTDocument58 pagesFire Pumps - MSTwafikmh4No ratings yet

- CH 11 - IrrigationDocument13 pagesCH 11 - IrrigationRohit BaliNo ratings yet

- Irrigation System for Residential ComplexDocument8 pagesIrrigation System for Residential ComplexuddinnadeemNo ratings yet

- QCS-2010 Section 19 Part 2 Water DistributionDocument12 pagesQCS-2010 Section 19 Part 2 Water Distributionbryanpastor106100% (1)

- Ac Units Technical Specifications Annex ADocument44 pagesAc Units Technical Specifications Annex Aengr.genaNo ratings yet

- P.O. Number: 7200018725Document6 pagesP.O. Number: 7200018725sethu1091No ratings yet

- Pipe Rack PipingDocument28 pagesPipe Rack Pipingardikurniawan100% (2)

- MechanicalDocument173 pagesMechanicalapi-38592580% (1)

- HEI Typ Specs For Steam Surface Condensers Data SheetDocument5 pagesHEI Typ Specs For Steam Surface Condensers Data Sheetraden_aditiya39No ratings yet

- Section IDocument58 pagesSection IARAVINDRAJ V RNo ratings yet

- Steam Line Mechanical DistributionDocument25 pagesSteam Line Mechanical DistributionNAYEEMNo ratings yet

- Typical Specification For Steam Surface Condensers Appendix ADocument5 pagesTypical Specification For Steam Surface Condensers Appendix Ahappale2002No ratings yet

- Guidelines For Piping Design & ErectionDocument55 pagesGuidelines For Piping Design & ErectionKartik Varma Namburi100% (2)

- DE - Ch9 - Piping Design and SpecificationsDocument9 pagesDE - Ch9 - Piping Design and SpecificationsMy TvNo ratings yet

- Standard Specification For Hot Insulation (Piping & Equipment)Document62 pagesStandard Specification For Hot Insulation (Piping & Equipment)Wade Coleman89% (9)

- Subsea Valve Actuator Functional SpecDocument11 pagesSubsea Valve Actuator Functional Specscribd_thakurNo ratings yet

- 23 21 13 Hydronic Piping Systems QA QCDocument5 pages23 21 13 Hydronic Piping Systems QA QCAsmara KanthiNo ratings yet

- Engineering Appendix Three Pumping Stations Version 12 November 2012Document16 pagesEngineering Appendix Three Pumping Stations Version 12 November 2012Mohamed Abou El hassanNo ratings yet

- Project Standard Specification: Drainage and Vent Piping 15420 - Page 1/8Document8 pagesProject Standard Specification: Drainage and Vent Piping 15420 - Page 1/8adel rihanaNo ratings yet

- Jacobs (HPCL) Standard On Pressure Vessel & He PDFDocument52 pagesJacobs (HPCL) Standard On Pressure Vessel & He PDFAnit100% (1)

- Design Basis for Piping PresentationDocument50 pagesDesign Basis for Piping Presentationrajachem100% (1)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- DFMA Introduction 3Document1 pageDFMA Introduction 3Sudhakar KarnanNo ratings yet

- DFMA Introduction 2Document1 pageDFMA Introduction 2Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 44Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 44Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 40Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 40Sudhakar KarnanNo ratings yet

- Autodesk® Inventor™ and Sheet Metal Manufacturing: From Drawing To FabricationDocument15 pagesAutodesk® Inventor™ and Sheet Metal Manufacturing: From Drawing To FabricationSudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 38Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 38Sudhakar KarnanNo ratings yet

- Lean OverviewDocument29 pagesLean OverviewSudhakar KarnanNo ratings yet

- Module Syllabus: M.S Ramaiah School of Advanced Studies - BangaloreDocument1 pageModule Syllabus: M.S Ramaiah School of Advanced Studies - BangaloreSudhakar KarnanNo ratings yet

- Module Learning Objectives: M.S Ramaiah School of Advanced Studies - BangaloreDocument1 pageModule Learning Objectives: M.S Ramaiah School of Advanced Studies - BangaloreSudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 45Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 45Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 42Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 42Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 43Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 43Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 37Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 37Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 39Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 39Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 33Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 33Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 34Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 34Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 35Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 35Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 35Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 35Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 34Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 34Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 32Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 32Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 28Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 28Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 31Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 31Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 25Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 25Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 30Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 30Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 27Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 27Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 22Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 22Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 29Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 29Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 26Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 26Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 24Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 24Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 23Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 23Sudhakar KarnanNo ratings yet

- Reality Check: Enver Karakas, Elliott Group, Cryodynamic Products, USADocument4 pagesReality Check: Enver Karakas, Elliott Group, Cryodynamic Products, USAptonnelNo ratings yet

- Reductores Excentricos-ConcentricosDocument1 pageReductores Excentricos-ConcentricosRobertoNo ratings yet

- MAST2776B Process Instrumentation TS Lesson 4 Rev.00Document60 pagesMAST2776B Process Instrumentation TS Lesson 4 Rev.00Hassan Al-HasanNo ratings yet

- PN16 Flange TablesDocument3 pagesPN16 Flange TablesMichael VillaluzNo ratings yet

- Isometri HydrantSprinkle - 0818040024 - Fikri Ari PDocument6 pagesIsometri HydrantSprinkle - 0818040024 - Fikri Ari PFikri Ari PratomoNo ratings yet

- 1b RAF60 IntroductionDocument3 pages1b RAF60 Introductionwhwy99No ratings yet

- 119E2423G001Document1 page119E2423G001Eduard MachadoNo ratings yet

- Type sp2Document11 pagesType sp2Mamiherintsoa Issaia RanaivoarimananaNo ratings yet

- (ICSLX-0621-THL1175-601) - FRESH WATER SERVICE PIPING DIAGRAM - rev.00-BVDocument2 pages(ICSLX-0621-THL1175-601) - FRESH WATER SERVICE PIPING DIAGRAM - rev.00-BVaz marine servicesNo ratings yet

- Parallel Pump Curves TA2538 X 4, 1760 RPM : L/Sec 200 300 400 500 600 700 800 900 1000 1100 1200Document1 pageParallel Pump Curves TA2538 X 4, 1760 RPM : L/Sec 200 300 400 500 600 700 800 900 1000 1100 1200Rubi AbionNo ratings yet

- Legend: Hydraulic/Hydrostatic Schematic With Two Speed Option 319 (S/N 563311001 AND ABOVE)Document2 pagesLegend: Hydraulic/Hydrostatic Schematic With Two Speed Option 319 (S/N 563311001 AND ABOVE)Леонид ЮртаевNo ratings yet

- Curvas de Operación Bombas CentrifugasDocument10 pagesCurvas de Operación Bombas CentrifugasAleidinNo ratings yet

- BVA Remote Valves CatalogDocument1 pageBVA Remote Valves CatalogTitanplyNo ratings yet

- 6060 Hydraulic Oil CoolingDocument9 pages6060 Hydraulic Oil Coolingedison barrionuevoNo ratings yet

- Fire Pump Casing Relief Valve BrochureDocument2 pagesFire Pump Casing Relief Valve Brochureramon duldulaoNo ratings yet

- Instrument Connection BOQ Samples GuideDocument4 pagesInstrument Connection BOQ Samples Guidenas_mech8208No ratings yet

- EC 10003 12 Vol1 A Series PDFDocument89 pagesEC 10003 12 Vol1 A Series PDFParvezNo ratings yet

- Presentation 1Document41 pagesPresentation 1Gianna Alvarez BalibagNo ratings yet

- Domestic Pump Guide for Bungalow HomesDocument10 pagesDomestic Pump Guide for Bungalow HomesCollins Obari AdiyeNo ratings yet

- Ufgs 21 13 13.00 20Document24 pagesUfgs 21 13 13.00 20Ashraf Adel Nashed ZakiNo ratings yet

- Control Valve Failure Relief Rate - Gas ServiceDocument3 pagesControl Valve Failure Relief Rate - Gas ServiceSaeid Rahimi Mofrad100% (1)

- 2020 3 3 Company Catalogue MPL FLOW en V1Document24 pages2020 3 3 Company Catalogue MPL FLOW en V1LASCARZAMFIRESCUNo ratings yet

- K91.51 Fig F112 en FinalDocument1 pageK91.51 Fig F112 en FinaladrianioantomaNo ratings yet

- Series Pipeline Systems Series Pipeline Systems: A A Y YDocument9 pagesSeries Pipeline Systems Series Pipeline Systems: A A Y YPigpug PigpugNo ratings yet

- Accessories: Spare Parts and AccessoriesDocument1 pageAccessories: Spare Parts and AccessoriesHafiz Muhammad Azeem NoorNo ratings yet

- Mec MG100 2 - 3DDocument3 pagesMec MG100 2 - 3Ddragos manole100% (1)

- Hydraulic Winch Operation ManualDocument11 pagesHydraulic Winch Operation ManualMohammed MostafaNo ratings yet

- Ref 1Document5 pagesRef 1zhyhhNo ratings yet

- Valve - WikipediaDocument10 pagesValve - WikipediaaravindNo ratings yet