Professional Documents

Culture Documents

Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 10

Uploaded by

Sudhakar KarnanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 10

Uploaded by

Sudhakar KarnanCopyright:

Available Formats

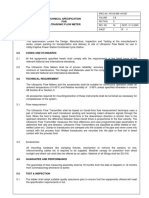

ThyssenKrupp Industries India

SPECIFICATIONS FOR DS/FF/SEWAGE/DW/AUXILIARY SYSTEMS

PROJECT: COKE HANDLING SYSTEM PACKAGE

(INTEGRATED REFINERY EXPANSION PROJECT), Kerala

CLIENT

: BHARAT PETROLEUM CORPORATION LIMITED, KOCHI

CONSULTANT

10.0

11.0

: ENGINEERS INDIA LIMITED, NEW DELHI

SPEC NO. : 7303-B00-01005

REVISION : 0

DATE

: 22.02.2014

W.O. NO.

: 3M0043

LIST OF MANDATORY SPARES:

HV Spray Nozzles

Quartzoid Bulb Detector :

10% of total nozzles used in each size/type with minimum drill holes.

10% of total used.

LIST OF O & M SPARES (Price to be valid- till 12 months from the date of satisfactory

commissioning of all systems):

Sprinkler

:

10 Nos.

Nozzles (Dry-fog)

:

20 Nos.

Nozzles (Plain water)

:

20 Nos.

Strainer Element

:

2 Nos.

Solenoid Valve (Dry-fog)

:

10 Nos.

Solenoid Valve (Sprinkling)

:

10 Nos.

Fire Hydrant System:

Fire Hydrant

:

5 Nos.

Hose (15m) with coupling

:

5 Nos.

Fire Monitor

:

1 No.

APPROVED VENDOR LIST:

The make of other items, which are not listed in Approved Vendor List: APPROVAL for the same is to

be taken from BPCL / EIL, prior to placement of order.

REFER ATTACHED APPROVED VENDOR LIST (A307-ID-28-41-VL-02).

12.0 QUALITY ASSURANCE PROGRAMME:

The quality assurance plan for manufacture and testing of equipment shall be prepared by supplier as per

format of TKII which shall be supplied during technical discussion and based on the requirements of client, and

same shall be submitted after the award of contract. The Quality assurance plans (including Field Quality Plan)

have got to be approved by BPCL / EIL / TKII. All testing & inspection shall be as per approved QAP.

TESTING AND INSPECTION

The details of the checks to be carried out in the various equipment / component are to be submitted by the

Contractor for Owners approval. However some indicative checks on different items are given in Minimum

Inspection Requirements which should necessarily form a part of the Quality Assurance Programme to be

agreed with by the Owner.

FIELD TEST AFTER ASSEMBLY / TRIAL RUN

Field test shall be performed to indicate free from vibration, noise, unbalance, leakage, satisfactory operation of

all interlocks for each individual equipment for complete systems and to establish the design performance of

equipment and systems, viz. Pressure availability, satisfactory operation of systems, guaranteed dust emission,

etc. Manufacturer shall submit the procedure of field test for various systems, for purchasers approval.

13.0

TRAINING OF POWER PLANT PERSONNEL:

13.1

The scope of service under training of Purchasers engineers shall include a training module in the

areas of Operation & Maintenance.

Such training should cover the following areas as a minimum in order to enable these personnel

to individually take the responsibility of operating and maintaining the supplied equipments in a manner

acceptable to the Purchaser:

13.2

The scope of services under training shall also necessarily include training of Purchaser's Engineering

personnel covering a suitable training module. This shall cover all disciplines viz, Mechanical,

Electrical, C&I, & QA etc. and shall include all the related areas like Design familiarization, training on

product design features of major equipment and systems, engineering, manufacturing, erection,

commissioning, training on operating features of equipment, quality assurance and testing, plant

visits and visits to manufacturer's works, exposure to various kinds of problems which

may be encountered in fabrication, manufacturing, erection, welding etc.

PREPARED BY: CHETAN

APPROVED.BY: D. MITRA.

PAGE 10 OF 13

You might also like

- 08 FS EtpDocument18 pages08 FS EtpKatamaneni KoteswararaoNo ratings yet

- 16.0 Procedure For Preparation of Installation, Operation and Maintenance Instruction ManualDocument1 page16.0 Procedure For Preparation of Installation, Operation and Maintenance Instruction ManualSudhakar KarnanNo ratings yet

- SOW - Supply of High Pressure CleaningDocument8 pagesSOW - Supply of High Pressure CleaningLiberty MunyatiNo ratings yet

- 53 TS Fire Protection System For 400kV R1 010108Document95 pages53 TS Fire Protection System For 400kV R1 010108girish_motiyani100% (3)

- GEMSS-M-03 Rev 02-Condensate System Including Extraction Pumps and Condensate TankDocument7 pagesGEMSS-M-03 Rev 02-Condensate System Including Extraction Pumps and Condensate TankKaramSobhyNo ratings yet

- Hyd DamperDocument12 pagesHyd DampermailbkraoNo ratings yet

- Annexure NewDocument6 pagesAnnexure Newknp_rmgNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 9Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 9Sudhakar KarnanNo ratings yet

- Pneumatic Actuator Specs Including Hydrant Line POVs PDFDocument12 pagesPneumatic Actuator Specs Including Hydrant Line POVs PDFrka0503No ratings yet

- Pneumatic Actuator SpecsDocument13 pagesPneumatic Actuator Specsrka0503No ratings yet

- Volume - Ii Section - M0 Technical Specification: Specification For Compressed Air System GMR Energy LimitedDocument50 pagesVolume - Ii Section - M0 Technical Specification: Specification For Compressed Air System GMR Energy LimitedsuparnabhoseNo ratings yet

- Mist EliminatorDocument7 pagesMist EliminatorPrince ChaudharyNo ratings yet

- Functional Specifications FOR Test Separation Module: Onshore Engg Services, N Delhi Document No.: OESG/ARP/TSP/M002 REVDocument18 pagesFunctional Specifications FOR Test Separation Module: Onshore Engg Services, N Delhi Document No.: OESG/ARP/TSP/M002 REVAnonymous O0lyGOShYGNo ratings yet

- Maintenance EquipmentsDocument9 pagesMaintenance EquipmentsSuneed SkNo ratings yet

- Fire Detection & Protection SystemDocument26 pagesFire Detection & Protection Systemsheelamethu67% (3)

- DO10 ValveDocument6 pagesDO10 ValvetunradotNo ratings yet

- EIL Spec For Instrumentation WorksDocument85 pagesEIL Spec For Instrumentation WorksRatnam Sk93% (15)

- Pile Dynamic Analyzer TestingDocument4 pagesPile Dynamic Analyzer TestingYudha ArdiiansyahNo ratings yet

- Gateway SNMP Technical Manual enDocument68 pagesGateway SNMP Technical Manual enfrederic.verneyNo ratings yet

- Design PhilosophyDocument9 pagesDesign Philosophyabet133100% (1)

- Statement of ComplianceDocument82 pagesStatement of Complianceفاطمة قمرالدينNo ratings yet

- Plnat Water-Make Up P&idDocument58 pagesPlnat Water-Make Up P&idghostamirNo ratings yet

- ETP Spec.Document70 pagesETP Spec.Adam Michael GreenNo ratings yet

- Vi Precommissiong Final (Part B)Document6 pagesVi Precommissiong Final (Part B)Koushik Dey100% (1)

- Functional Specifications FOR Separation Module: Onshore Engg. Services New Delhi Document No.: OESG/ARP/SP/M0002 REVDocument17 pagesFunctional Specifications FOR Separation Module: Onshore Engg. Services New Delhi Document No.: OESG/ARP/SP/M0002 REVAnonymous O0lyGOShYGNo ratings yet

- Fire Fighting Pumping SystemDocument23 pagesFire Fighting Pumping Systemvirtech100% (1)

- TEI-I-111.15: Transmission Engineering StandardDocument12 pagesTEI-I-111.15: Transmission Engineering StandardArnieNo ratings yet

- Revised TS SalluDocument134 pagesRevised TS SalluShaswat AcharyaNo ratings yet

- 3PS MC 002 - 01Document26 pages3PS MC 002 - 01Viveck VivekNo ratings yet

- Tech Specs For ETPDocument26 pagesTech Specs For ETPNarayanan MenonNo ratings yet

- PTS 20158HDocument21 pagesPTS 20158HronelbarafaeldiegoNo ratings yet

- 22 56 13 - Solar CollectorsDocument23 pages22 56 13 - Solar Collectorsvaradarajck893No ratings yet

- Underground Pipe InstallationDocument15 pagesUnderground Pipe InstallationAbdul Abbas100% (1)

- 213110-Fire Pump SystemDocument19 pages213110-Fire Pump SystemGun WanNo ratings yet

- Technical Specifications - CompDocument57 pagesTechnical Specifications - CompAnonymous gr5Pr9AVNo ratings yet

- Sow TCP DST SWT 2023 - 2025 R0Document45 pagesSow TCP DST SWT 2023 - 2025 R0Marc LefrancqNo ratings yet

- B20 Residential ProjectDocument309 pagesB20 Residential ProjectChetlall JaspreetsinghNo ratings yet

- URS Lab Scale Counter Pressure Autoclave (Rev 1b)Document12 pagesURS Lab Scale Counter Pressure Autoclave (Rev 1b)puneetogupta100% (2)

- M 100 - General (1-6)Document6 pagesM 100 - General (1-6)Kingsley LimNo ratings yet

- 001 - Method Statement of Site Survey and TopographyDocument9 pages001 - Method Statement of Site Survey and Topographyahmed08839494100% (1)

- Tender Data SheetDocument3 pagesTender Data SheetgrrcNo ratings yet

- A307 T-1057 1001 TN Rev0Document2,089 pagesA307 T-1057 1001 TN Rev0VenkatRaghavendar100% (1)

- N 15862Document12 pagesN 15862Saleem BaigNo ratings yet

- PROJECT STANDARD and SPECIFICATIONS Off Shore Commissioning Procedures Rev01webDocument6 pagesPROJECT STANDARD and SPECIFICATIONS Off Shore Commissioning Procedures Rev01webselkhNo ratings yet

- STOD-GEN-AED-0000-ME-SPE-0005 - Functional Specification For Chemical InjectionDocument20 pagesSTOD-GEN-AED-0000-ME-SPE-0005 - Functional Specification For Chemical InjectionAHMED AMIRANo ratings yet

- SA02-16 - General Requirement RTUDocument60 pagesSA02-16 - General Requirement RTUhiryanizamNo ratings yet

- General RequirementsDocument4 pagesGeneral RequirementsJosh MazonNo ratings yet

- Ultrasonic Flow Meter SpecsDocument8 pagesUltrasonic Flow Meter SpecsAbhijit HavalNo ratings yet

- 2 SpecificationDocument20 pages2 Specificationprithvi614710No ratings yet

- 4.ELK20001 - Statement of WorkDocument26 pages4.ELK20001 - Statement of WorkSuneel PanditNo ratings yet

- Technical Proposal - Maintenance of Stacker & ReclaimerDocument18 pagesTechnical Proposal - Maintenance of Stacker & ReclaimerORE PROCESSING PLANT100% (2)

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AFrom EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Thermal Power Plant: Pre-Operational ActivitiesFrom EverandThermal Power Plant: Pre-Operational ActivitiesRating: 4 out of 5 stars4/5 (4)

- Industrial Agents: Emerging Applications of Software Agents in IndustryFrom EverandIndustrial Agents: Emerging Applications of Software Agents in IndustryPaulo LeitãoNo ratings yet

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsFrom EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsRating: 3.5 out of 5 stars3.5/5 (14)

- Module Learning Objectives: M.S Ramaiah School of Advanced Studies - BangaloreDocument1 pageModule Learning Objectives: M.S Ramaiah School of Advanced Studies - BangaloreSudhakar KarnanNo ratings yet

- Module Syllabus: M.S Ramaiah School of Advanced Studies - BangaloreDocument1 pageModule Syllabus: M.S Ramaiah School of Advanced Studies - BangaloreSudhakar KarnanNo ratings yet

- Autodesk® Inventor™ and Sheet Metal Manufacturing: From Drawing To FabricationDocument15 pagesAutodesk® Inventor™ and Sheet Metal Manufacturing: From Drawing To FabricationSudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 45Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 45Sudhakar KarnanNo ratings yet

- Lean OverviewDocument29 pagesLean OverviewSudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 39Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 39Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 44Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 44Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 37Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 37Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 38Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 38Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 42Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 42Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 29Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 29Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 34Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 34Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 12Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 12Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 14Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 14Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 28Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 28Sudhakar KarnanNo ratings yet

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 23Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 23Sudhakar KarnanNo ratings yet

- Heizer Om10 ModbDocument48 pagesHeizer Om10 ModbbsaNo ratings yet

- Anganwadi Estimate AnthwarDocument12 pagesAnganwadi Estimate AnthwarK KARTHIKNo ratings yet

- Analisis Kesehatan Dan Keselamatan Kerja Pada Industri Furnitur Kayu Dengan Metode Job Safety AnalysisDocument10 pagesAnalisis Kesehatan Dan Keselamatan Kerja Pada Industri Furnitur Kayu Dengan Metode Job Safety Analysisyendri putri febriyantiNo ratings yet

- APD Presentation A320FamilyDocument57 pagesAPD Presentation A320FamilydianaddqNo ratings yet

- Garlic Processing MachineDocument13 pagesGarlic Processing MachineMani GandanNo ratings yet

- Ductwork Order FormDocument5 pagesDuctwork Order FormShaun SullivanNo ratings yet

- Iabse PresentationDocument8 pagesIabse Presentationukyo0801No ratings yet

- Cat Delta ConectoresDocument90 pagesCat Delta ConectoresArgenis TRNo ratings yet

- Scientific American Architects and Builders Edition 1890 Jul-DecDocument240 pagesScientific American Architects and Builders Edition 1890 Jul-DecNickiedeposieNo ratings yet

- Brother Sewing Machine InstructionsDocument56 pagesBrother Sewing Machine InstructionsDwaine Webb100% (1)

- 6 TKA 155a Technical SpecificationDocument3 pages6 TKA 155a Technical Specificationar2925No ratings yet

- Functional SafetyDocument4 pagesFunctional SafetyMsKarolyNo ratings yet

- EM531 531 RathodH 2Document60 pagesEM531 531 RathodH 2Santosh Kumar SurineediNo ratings yet

- Introduction To Information Technology: ITP 101 (4 Units)Document7 pagesIntroduction To Information Technology: ITP 101 (4 Units)standalonembaNo ratings yet

- Buscar Filtro - Wix FiltersDocument1 pageBuscar Filtro - Wix FiltersRodolfo PerezNo ratings yet

- Mysql WP DRBDDocument25 pagesMysql WP DRBDNasim AkhtarNo ratings yet

- Iecee Od-2025-B-2016Document21 pagesIecee Od-2025-B-2016krivitskiNo ratings yet

- NACA SeriesDocument31 pagesNACA SeriesAli OkumuşNo ratings yet

- J910 DT03 P0ZEN 040001 SQCP 0010 (Quality Control Procedure Index) - Rev.0Document3 pagesJ910 DT03 P0ZEN 040001 SQCP 0010 (Quality Control Procedure Index) - Rev.0Budi SetiawanNo ratings yet

- Kojima - JapanDocument5 pagesKojima - JapanSam HoNo ratings yet

- Audi A6 Qu (1) - 3.0 TdiDocument4 pagesAudi A6 Qu (1) - 3.0 TdiStanescu CatalinNo ratings yet

- GC Compact PDFDocument39 pagesGC Compact PDFalessandro2000No ratings yet

- System Manager 7.4 User GuideDocument158 pagesSystem Manager 7.4 User GuidemasterboloNo ratings yet

- Advacned ITT Question BankDocument7 pagesAdvacned ITT Question BankKunal BhandariNo ratings yet

- JJ104 Workshop Technology Chapter2 Hand ToolsDocument12 pagesJJ104 Workshop Technology Chapter2 Hand ToolsAh TiangNo ratings yet

- PFMEADocument6 pagesPFMEAAcep GunawanNo ratings yet

- Bazooka CS1Bazooka CS1204 Manual204 ManualDocument8 pagesBazooka CS1Bazooka CS1204 Manual204 ManualSvasta SvastarijaNo ratings yet

- Bio - CIO RhodesDocument1 pageBio - CIO Rhodesgunit007No ratings yet