Professional Documents

Culture Documents

TSPS - PS - Float Switch

Uploaded by

Peter ManCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TSPS - PS - Float Switch

Uploaded by

Peter ManCopyright:

Available Formats

TEMPORARY SEWAGE PUMPING STATION

(ELECTRICAL & MECHANICAL WORKS)

opened to release the peak moment. Under normal operation, the pumping

system is automatically operated in the light of PLC and level sensing and

control system.

(e)

(3)

Starting Methods

(a)

(4)

Whenever more than one pump is in operation and the pump cut-off level is

reached, all sewage pumps in wet well are stopped sequentially and under

control by MACS system.

All pumps of the TSPS shall be star/ delta started by means of star/ delta

starters to limit the maximum starting current to within 2.5 times the rated

motor full load current.

Running Conditions

(a)

A delayed starting feature shall be provided to prevent the pumps from

starting simultaneously in particular on restoration of power supply.

(b)

Whenever abnormal condition is detected, the pump shall be tripped and an

audible and visual alarm shall be activated at the corresponding pump

control panel. The alarms shall be repeated to the MACS of TCSPS and

SWHSTW. The abnormal operating conditions shall include, but not limit

to, the following:(i)

(ii)

(iii)

(iv)

(v)

(vi)

No flow detection alarm is activated;

Thermal overload is detected in the pump motor windings;

Over-current of the pump motor;

Moisture or leakage detection sensor for submersible pump;

Temperature sensors for motor winding, motor bearing and pump

bearing; and

An Emergency Stop is pressed.

(c)

When there is a Low Level Alarm, all pumps at the wet well shall stop to

operate sequentially.

(d)

All necessary transducers, interfaces, controllers and accessories shall be

installed for the detection of the abnormalities listed in this sub-clause.

6.33.2 LEVEL SENSING AND CONTROL EQUIPMENT

(A)

20120731

The Contractor shall select, provide, deliver to work locations, install, test, commission and

be liable to defects during two-year Defects Liability Period of total four (4) sets of

hydrostatic level sensing and control equipment, seven (7) sets of ultrasonic level sensing

and control equipment, four (4) sets of level electrodes for sensing sewage levels and pump

control and one (1) set of float switches for sensing high sewage levels and pump control.

All types of sensing equipment shall be able to transmit continuous level signals to the

MACS of the TCSPS and SHWSTW, the switchboard and the local supervisory and control

panels at the TSPS under this Contract:

SW (E&M) / 40

TEMPORARY SEWAGE PUMPING STATION

(ELECTRICAL & MECHANICAL WORKS)

Location

Equipment

Measuring

Range

Qty

Inlet Chamber

Ultrasonic level and float switch sensing

and control equipment for inlet chamber

At least from

0 to 10 m

Each 1

set

Screen

Chambers

Ultrasonic level sensing and control

equipment for inlet screen control

At least from

0 to 10 m

4 sets

Wet Well

Hydrostatic level sensing and control

equipment complete with auto-flushing

system and ultrasonic level sensing and

control equipment backed up with level

electrodes for pump control

At least from

0 to 10 m

4 sets,

2 sets

and

4 sets

(B)

The hydrostatic level sensing equipment shall be complete with accessories for automatic

control of duty and standby sewage pumps and penstocks in wet well. Two hydrostatic

level sensors in one duty and one standby arrangement shall be provided at wet well. Two

ultrasonic level sensors at upstream and downstream arrangement of the screens shall be

provided for screen chambers as specified in the sub-clause (A) above. For the sensors at

wet well, sensor duty selection shall be available at the workstations of MACS at the TCSPS

and SHWSTW and also at the TSPS. Upon failure of the duty level sensor, the standby level

sensor shall take over the duties of the failed level sensor.

(C)

Each set of level sensing equipment comprising a sensor probe and a transmitter (or

controller as appropriate) shall be suitable for application in contaminated environment and

be recoverable from long-time standing in dryness.

(D)

A rigid stainless steel grade 316 tube shall be provided to protect and hold the hydrostatic

sensor body. The sensor body shall be suspended inside the tube by using its cable and an

A-clamp at the upper end of the tube. A stainless steel mesh guard shall be provided at the

lower end of the tube. An auto-flushing system shall be provided for periodic cleansing the

sensor body/head. The Contractor shall submit full details for the Engineer or his

Representatives review and approval.

(E)

The total performance of the level sensor, comprises the non-linearity including hysteresis,

non-reproducibility as well as the thermal change in the zero point, shall be better than 0.3%

of the measuring range or as agreed by the Engineers Representative.

(F)

The transmitters/controllers shall have analogue signal transmission of current outputs (4-20

mA) proportional to the water levels and the output signals shall be transmitted to the

programmable logic controller of the control system.

(G)

The transmitters/controllers shall have a local digital display to indicate the current water

levels in mPD. The transmitters/controllers shall also have diagnostic facilities to detect the

failure of the sensor and the transmitter/controller itself. Under any case, the readings of all

sensors shall be displayed at the same time at the MACS of TCSPS and SHWSTW, the

switchboard and the local supervisory panels.

(H)

The level transmitters/controllers shall be flush-mounted in an individual compartment at the

switchboard with window doors for the reading of level indicators of the transmitters.

Alternatively, the Contractor may offer for the Engineer's approval separate enclosures to be

20120731

SW (E&M) / 41

TEMPORARY SEWAGE PUMPING STATION

(ELECTRICAL & MECHANICAL WORKS)

pressure and surge from WSD supply at work location.

(N)

Control and Alarm

(1)

(2)

Inlet Chamber

(a)

One (1) set of ultrasonic level sensor and one (1) set of two float switch level

sensors shall be installed in the inlet chamber as shown in the relevant

Drawings. They shall detect the water level in the inlet chamber. The

ultrasonic level sensor shall be used to measure the sewage inflow and to

control the operation status of the penstocks in inlet chamber. The float

switches, control circuits and interface devices shall be taken as the last

resort to forcibly switch on the sewage pumps at high water level to

minimize the risk of overflow in case all sensors at wet well or the local PLC

in failure. A dedicated panel displaying a high water level signal and a low

water level signal both triggered by the float switches shall be provided in

TSPS and these two signals shall be repeated to the MACS of TCSPS and

SHWSTW.

(b)

The two float switches shall be installed at the upper and lower levels of the

inlet chamber to give an alarm and control the pump operation when they are

activated. The locations of the two float switches shall be 100 mm above the

high level alarm and 100 mm below low level alarm levels. These level

settings are required further verified and agreed with O&M team at work

location. These two float switches shall not be in operation unless the water

level is above the high level alarm or below low level alarm level and when

the ultrasonic level sensor does not operate the pump in accordance with the

control levels in sub-clause 6.33.1(D). The control of the pump operation by

float switches shall be independent of the PLC control and shall function

even when the UPS or PLC system fails to work.

Screen Chambers

(a)

(3)

Wet Wells

(a)

20120731

Two (2) sets of ultrasonic level sensors for each screen chamber shall be

installed as shown in the relevant drawings. The sensors shall detect the

water levels at upstream and downstream of screen in the screen chamber

and be used to control operation of the inlet screens and penstocks.

Four (4) sets of hydrostatic level sensors, two (2) sets of ultrasonic level

sensors and four (4) sets of level electrodes shall be installed in the wet wells

as shown in the relevant Drawings and they shall control the operation of the

sewage pumps under different conditions. For each wet well, one out of the

two sensors shall be able to be selected as the duty and standby level sensors

at MACS at TSPS and the Master Station of TCSPS and SHWSTW. Upon

the failure of the duty level sensor, the standby level sensor shall take over

the duties of the failed level sensor. Each pump shall be controlled by the

duty level sensor that assigned to its corresponding wet well. If the level

sensor of the other wet well is selected as the duty sensor, the PLC shall

confirm the opening status of the penstock between two wet well, otherwise,

warning signal shall be generated to restrict the control. Each sensor head

shall be regularly cleaned by an auto-flushing system which is composed of

SW (E&M) / 43

You might also like

- Outlet Management SystemDocument66 pagesOutlet Management SystemNaveen Nagisetti100% (2)

- A380-Level III - Ata 38 Water - WasteDocument40 pagesA380-Level III - Ata 38 Water - WasteAbolfazl Mazloomi100% (2)

- 2 PDFDocument10 pages2 PDFPeter ManNo ratings yet

- Business Law and The Regulation of Business 12th Edition Mann Test BankDocument25 pagesBusiness Law and The Regulation of Business 12th Edition Mann Test BankElizabethRuizrxka100% (60)

- Nevada Reply BriefDocument36 pagesNevada Reply BriefBasseemNo ratings yet

- CSCI5273 PS3 KiranJojareDocument11 pagesCSCI5273 PS3 KiranJojareSales TeamNo ratings yet

- Dam InstrumentationDocument9 pagesDam InstrumentationDheeraj ThakurNo ratings yet

- Untitled 04Document6 pagesUntitled 04eoictiNo ratings yet

- Liquid Level Control System V2Document14 pagesLiquid Level Control System V2Shisanu SenNo ratings yet

- Lab ReportDocument13 pagesLab ReportHemal MenukaNo ratings yet

- Report - Pump Room AutomationDocument12 pagesReport - Pump Room AutomationtanujgateNo ratings yet

- Compañía Minera Suyamarca S.A.C Inmaculada Project Process Control PhilosophyDocument29 pagesCompañía Minera Suyamarca S.A.C Inmaculada Project Process Control PhilosophyHeiner PalaciosNo ratings yet

- Panching Water Treatment Plant O&M ManualDocument15 pagesPanching Water Treatment Plant O&M Manualcaseysoh3804No ratings yet

- Panching Water Treatment Plant O&M ManualDocument30 pagesPanching Water Treatment Plant O&M Manualcaseysoh3804No ratings yet

- Specification Substation AutomationDocument258 pagesSpecification Substation Automationmspd2003100% (1)

- General Electric Systems Technology Manual Feedwater Control SystemDocument24 pagesGeneral Electric Systems Technology Manual Feedwater Control SystemVikas AhlawatNo ratings yet

- Flow Control Trainer: Experiment No: 03Document3 pagesFlow Control Trainer: Experiment No: 03Musa KhanNo ratings yet

- NTPC Korba Dry Fly Ash System Observation ReportDocument3 pagesNTPC Korba Dry Fly Ash System Observation ReportVenkatesh RaoNo ratings yet

- Calibration RigDocument5 pagesCalibration RigBijoy AyyagariNo ratings yet

- Test Procedures For Solar System (Check For Commitioning List)Document19 pagesTest Procedures For Solar System (Check For Commitioning List)Aziz LuluNo ratings yet

- Design Memorandum For LP Chemcial Dosing System (Rev-1)Document12 pagesDesign Memorandum For LP Chemcial Dosing System (Rev-1)suparnabhoseNo ratings yet

- TLS-350R UST Monitoring and Leak Detection System 577013-368 Rev. BDocument32 pagesTLS-350R UST Monitoring and Leak Detection System 577013-368 Rev. BShalvaTavdgiridzeNo ratings yet

- M-1-40 WATER TREATMENT - VNGDC-TD-M-01-DSC-DC-0001-new UpdateDocument3 pagesM-1-40 WATER TREATMENT - VNGDC-TD-M-01-DSC-DC-0001-new UpdateEurotech purchasing04No ratings yet

- Coupled Tanks - User ManualDocument22 pagesCoupled Tanks - User Manualpinkpanter100% (1)

- Automatic Liquid Level Control of Tank SystemDocument9 pagesAutomatic Liquid Level Control of Tank SystemFatahillah AtaNo ratings yet

- Electrohydraulic controls troubleshooting guideDocument4 pagesElectrohydraulic controls troubleshooting guidechandushar1604No ratings yet

- L.A.C.T. Unit DesignDocument3 pagesL.A.C.T. Unit DesignBill Gu100% (2)

- Bus Bar ProtectionDocument8 pagesBus Bar ProtectionSiva Koti ReddyNo ratings yet

- BP107 (A4) 1Document4 pagesBP107 (A4) 1Huda TajuddinNo ratings yet

- Gestra Level Control Monitoring LimitationDocument7 pagesGestra Level Control Monitoring LimitationVoicu StaneseNo ratings yet

- MBR Instruments Locations QuantityDocument1 pageMBR Instruments Locations QuantityHemantk8731No ratings yet

- ICSS Loop Test Presentation UpdatedDocument31 pagesICSS Loop Test Presentation UpdatedHashemAliHashem50% (2)

- TLS-350 UST Monitoring SystemDocument29 pagesTLS-350 UST Monitoring SystemShalvaTavdgiridzeNo ratings yet

- Annexure-I (Sprinkler System)Document5 pagesAnnexure-I (Sprinkler System)ashilvantNo ratings yet

- Rotary Displacement Flowmeter Design: GeneralDocument7 pagesRotary Displacement Flowmeter Design: Generaljose mirandaNo ratings yet

- RFQ - Pumping SystemDocument6 pagesRFQ - Pumping Systemrkpatel40No ratings yet

- Project PLCDocument18 pagesProject PLCnarendramohan22No ratings yet

- Annex 4-Draft Electrical Design Theme Phase 2-MariusDocument7 pagesAnnex 4-Draft Electrical Design Theme Phase 2-Mariusmarius barbuNo ratings yet

- Custody Transfer SystemDocument8 pagesCustody Transfer SystempriyoNo ratings yet

- Mechatronics AssignmentDocument3 pagesMechatronics AssignmentParin PatelNo ratings yet

- Flowmeter Calibration ProcedureDocument8 pagesFlowmeter Calibration ProcedureShesadri ChakrabartyNo ratings yet

- OLTC SpecificationDocument5 pagesOLTC Specificationamulya00428No ratings yet

- M.tech Lab ManualDocument94 pagesM.tech Lab ManualSHINUMMNo ratings yet

- Metso Column CellDocument10 pagesMetso Column CellmektanNo ratings yet

- Kyle Form 4C Recloser Control Technical SpecificationsDocument7 pagesKyle Form 4C Recloser Control Technical SpecificationsCarolina UrrutiaNo ratings yet

- E21valve Remote Control SystemDocument13 pagesE21valve Remote Control System백승훈No ratings yet

- Loughborough University Process Control Lab ManualDocument16 pagesLoughborough University Process Control Lab Manualabmuqeet2No ratings yet

- Isolate, Test and Return High-Pressure Water Mist SystemDocument3 pagesIsolate, Test and Return High-Pressure Water Mist SystemnellaiNo ratings yet

- SUB-AUX-LV-AC-BOARDDocument2 pagesSUB-AUX-LV-AC-BOARDjm.mankavil6230No ratings yet

- Brewery Distance LearningDocument3 pagesBrewery Distance LearningRomel AganNo ratings yet

- Liquid Flow Meter Proving and LACT UnitsDocument4 pagesLiquid Flow Meter Proving and LACT UnitsDayo IdowuNo ratings yet

- Drum Level Commissioning ProcedureDocument11 pagesDrum Level Commissioning ProcedureS.KAMBANNo ratings yet

- 38 Water WasteDocument100 pages38 Water Wastefourj747No ratings yet

- Centralize Manifold Room and Medical Gases PipelineDocument12 pagesCentralize Manifold Room and Medical Gases PipelineRanjan ShahNo ratings yet

- Automatic Water Pump ControllerDocument5 pagesAutomatic Water Pump Controllershannali50% (2)

- SCADADocument57 pagesSCADAkailasamvv100% (1)

- Mahyroto 01 (Ing)Document41 pagesMahyroto 01 (Ing)Nicoleta CosteaNo ratings yet

- Philosophy of OperationDocument30 pagesPhilosophy of Operationfehmi-fjr4696No ratings yet

- PRACTICES MANUAL FOR PROCESS UNIT CONTROL LOOPSDocument18 pagesPRACTICES MANUAL FOR PROCESS UNIT CONTROL LOOPSAdjie PranatamaNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Some Power Electronics Case Studies Using Matlab Simpowersystem BlocksetFrom EverandSome Power Electronics Case Studies Using Matlab Simpowersystem BlocksetNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Masterseal Plus CatalogueDocument8 pagesMasterseal Plus CataloguePeter ManNo ratings yet

- ISO Cert of Ecfit FittingDocument1 pageISO Cert of Ecfit FittingPeter ManNo ratings yet

- Radiation Assignment SolutionDocument7 pagesRadiation Assignment SolutionPeter ManNo ratings yet

- Thermal Dynamics Example Set 3Document14 pagesThermal Dynamics Example Set 3Peter ManNo ratings yet

- Heat - Work - Lecture NotesDocument20 pagesHeat - Work - Lecture NotesPeter ManNo ratings yet

- AMA294T3 SolnDocument10 pagesAMA294T3 SolnPeter ManNo ratings yet

- ProblemDocument20 pagesProblemLucas LentzNo ratings yet

- Friction FactorDocument30 pagesFriction FactorSomnath JagtapNo ratings yet

- Mathematics II - SolutionDocument6 pagesMathematics II - SolutionPeter ManNo ratings yet

- Mathematics II - SolutionDocument6 pagesMathematics II - SolutionPeter ManNo ratings yet

- AMA 294 Midterm Review: Eigenvalues, Diagonalization, Complex NumbersDocument1 pageAMA 294 Midterm Review: Eigenvalues, Diagonalization, Complex NumbersPeter ManNo ratings yet

- AngendaDocument1 pageAngendaPeter ManNo ratings yet

- Chapter 6 Performance Review and Appraisal - ReproDocument22 pagesChapter 6 Performance Review and Appraisal - ReproPrecious SanchezNo ratings yet

- Gustilo Vs Gustilo IIIDocument1 pageGustilo Vs Gustilo IIIMoon BeamsNo ratings yet

- CXS 310-2013 - PomegranateDocument5 pagesCXS 310-2013 - PomegranateFranz DiazNo ratings yet

- Zellner Bayesian AnalysisDocument4 pagesZellner Bayesian AnalysisfoopeeNo ratings yet

- Claim Form - Group Health InsuranceDocument5 pagesClaim Form - Group Health Insurancevizag mdindiaNo ratings yet

- Chapter 2 FlywheelDocument24 pagesChapter 2 Flywheelshazwani zamriNo ratings yet

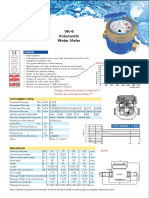

- Baylan: VK-6 Volumetric Water MeterDocument1 pageBaylan: VK-6 Volumetric Water MeterSanjeewa ChathurangaNo ratings yet

- Group 1 RRLDocument19 pagesGroup 1 RRLAngelo BolgarNo ratings yet

- Computer Application in Business NOTES PDFDocument78 pagesComputer Application in Business NOTES PDFGhulam Sarwar SoomroNo ratings yet

- JAM 2020 Information Brochure: Admission to M.Sc., Joint M.Sc.-Ph.D., M.Sc.-Ph.D. Dual Degree and Integrated Ph.D. ProgrammesDocument51 pagesJAM 2020 Information Brochure: Admission to M.Sc., Joint M.Sc.-Ph.D., M.Sc.-Ph.D. Dual Degree and Integrated Ph.D. ProgrammesVaibhav PachauleeNo ratings yet

- Distribution Requirements PlanningDocument8 pagesDistribution Requirements PlanningnishantchopraNo ratings yet

- West Systems Fiberglass Boat Repair & MaintenanceDocument91 pagesWest Systems Fiberglass Boat Repair & MaintenanceDonát Nagy100% (2)

- Mecafix 120: Description Technical DataDocument1 pageMecafix 120: Description Technical DataJuan Carlos EspinozaNo ratings yet

- SAPGLDocument130 pagesSAPGL2414566No ratings yet

- CV of Prof. D.C. PanigrahiDocument21 pagesCV of Prof. D.C. PanigrahiAbhishek MauryaNo ratings yet

- SSPC Paint 25 BCSDocument6 pagesSSPC Paint 25 BCSanoopkumarNo ratings yet

- Ab Initio Interview Questions - HTML PDFDocument131 pagesAb Initio Interview Questions - HTML PDFdigvijay singhNo ratings yet

- Gilette Case - V3Document23 pagesGilette Case - V3Vidar Halvorsen100% (3)

- تقرير سبيس فريم PDFDocument11 pagesتقرير سبيس فريم PDFAli AkeelNo ratings yet

- G.R. No. 122039 May 31, 2000 VICENTE CALALAS, Petitioner, Court of Appeals, Eliza Jujeurche Sunga and Francisco Salva, RespondentsDocument56 pagesG.R. No. 122039 May 31, 2000 VICENTE CALALAS, Petitioner, Court of Appeals, Eliza Jujeurche Sunga and Francisco Salva, RespondentsJayson AbabaNo ratings yet

- RAMA - 54201 - 05011381320003 - 0025065101 - 0040225403 - 01 - Front - RefDocument26 pagesRAMA - 54201 - 05011381320003 - 0025065101 - 0040225403 - 01 - Front - RefMardiana MardianaNo ratings yet

- LogDocument85 pagesLogJo NasNo ratings yet

- Personal Selling ProcessDocument21 pagesPersonal Selling ProcessRuchika Singh MalyanNo ratings yet

- Supply AnalysisDocument5 pagesSupply AnalysisCherie DiazNo ratings yet

- Payment Solutions For Travel Platform: SabreDocument2 pagesPayment Solutions For Travel Platform: Sabrehell nahNo ratings yet

- What Is PID - TutorialDocument5 pagesWhat Is PID - Tutorialsocrates19582405No ratings yet

- SM 2021 MBA Assignment Forecasting InstructionsDocument3 pagesSM 2021 MBA Assignment Forecasting InstructionsAmit Anand KumarNo ratings yet