Professional Documents

Culture Documents

ASNT MT Level III Notes

Uploaded by

Charles100%(4)100% found this document useful (4 votes)

1K views6 pagesAmerican Society of Nondestructive Testing Magnetic Particle Level III Notes.

Copyright

© Attribution Non-Commercial No-Derivs (BY-NC-ND)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAmerican Society of Nondestructive Testing Magnetic Particle Level III Notes.

Copyright:

Attribution Non-Commercial No-Derivs (BY-NC-ND)

Available Formats

Download as PDF, TXT or read online from Scribd

100%(4)100% found this document useful (4 votes)

1K views6 pagesASNT MT Level III Notes

Uploaded by

CharlesAmerican Society of Nondestructive Testing Magnetic Particle Level III Notes.

Copyright:

Attribution Non-Commercial No-Derivs (BY-NC-ND)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

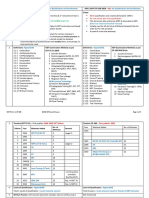

MT Level III Notes

MT Level III Notes

By: Charles Hansen ASNT Level III

MT Wave Forms

Charles Hansen ASNT Level III

Page 1|6

MT Level III Notes

Field Strength and Distribution in Symmetrical Objects

Charles Hansen ASNT Level III

Page 2|6

MT Level III Notes

Charles Hansen ASNT Level III

Page 3|6

MT Level III Notes

Impedance: Term used to refer to the total opposition to flow of current

represented by the combined effect of resistance, inductance and capacitance of a

circuit.

Magnetic Lines: Lines of force that form a path around a crack in a ring magnet

Earth field is weak, how weak? 0.3 gauss

Demagnetization is required: the object is to be electric arc welded, could

interfere with instruments in service, or could attract chips or particles in

service

Particle sizes for wet method testing ranges from: 1 to 25 micrometer

When magnetic material reaches its curie temperature, the material becomes:

paramagnetic

Which type of radiation can most damage human tissue? UV-B

Best technique for testing a large flat area? Prods

= Permeability = B/H

B = Flux Density measured in Gauss (SI Units measured in Tesla)

H = Magnetizing force measured in Oersted

Most common wattage of mercury vapor bulbs for fluorescent MT exams = 100 watts

Longitudinal field = amp turns (L/D), Yoke, Coil around part

Circular field= Prods, central conductor, head shot, passing current directly

through part

Parallel magnetization= should be avoided (field is established in a part when it

is placed next to a conductor carrying current.)

Multidirectional Magnetization: Useful when orientation of discontinuities are

unknown (Proper Sequence) Magnetize, apply particles, shut off current, and

inspect.

Vector field= produced by simultaneously imposing two magnetizing forces in two

directions where one is stronger than the other upon a magnetizeable article.

N*I = 45,000

L/D

N= number of turns

I= current (amps)

Advantage to demagnetize a part: Position East-West

Centistokes: unit of viscosity

Settling test: check concentration of particle for wet method

Calibrate MT Machine- Use shunt with calibrated ammeter

Ammeter: determine amperage being used

Fill Factor= 10% or 10:1

Gauss= 1 line of flux per square centimeter

= Flux Density

Charles Hansen ASNT Level III

Page 4|6

MT Level III Notes

Discontinuity= interruption or break in the normal physical structure

Indication= accumulation of particles

Plated parts can be reliably tested = 0.1mm (0.0004 in) thick

Retentivity or Remanent: retain magnetic field

Permeability: ease with which it can be magnetized

Inductance: The magnetism produced in a ferromagnetic body by some outside

magnetizing force.

Forging defects- laps, burst

Casting defects- shrinkage, gas, misruns, cold laps, sand inclusion, hot tears

Best Subsurface: Dry continuous HWDC with Prods (Deepest Penetration)

Best Surface and Subsurface: HW Rectified AC with Dry Particles (Most effective)

(Greatest Particle Mobility)

Best Surface: Wet Fluorescent Continuous AC (Shallowest Penetration)

Easier to demagnetize: Longitudinal fields

Harder to demagnetize: Circular fields

Skin affect: AC

Resistance to demagnetization: Greater in hard materials than soft materials

When a magnetic field is at 90 to the defect, it will cause an abrupt change in

the permeability of the part.

Magnetic domains: submicroscopic regions inside material

Medium: refers to particles that have the ability to be strongly attracted to

leakage fields.

**Permeability of Materials**

Diamagnetic: less than 1.0

Paramagnetic: 1.0 or slightly more

Ferromagnetic: many many times more than 1.0

MT particles need to have: High permeability / Low Retentivity

Human vision range is: 380nm to 770nm (violet to red)

Nm = nanometer - billionth of a meter

Black light = 365nm, outside of humans range

Fluorescent particles absorb 365nm (3650 angstroms) and release at 550nm (5500

angstroms) (Yellow/Green)

100 ft candles- Visible light for visible MT

Magnetic particle building from a discontinuity is strongest when the

discontinuity is orientated: 90 degrees to the magnetic flux flow.

Charles Hansen ASNT Level III

Page 5|6

MT Level III Notes

Strongest magnetic field in a coil is at the: inside edge

Field meter: equipment used to determine if a part has been demagnetized. They

read a maximum of 10 to 20G or 10 to 20 MT. (The positive corresponds to the

North pole on one end of the part, and the negative to the South pole on the

other end of the part.

Circular field is easiest to detect, but hardest to demagnetize

Longitudinal field is easier to demagnetize

Flux Indicator: small device, generally a metal strap or disk, containing

artificial discontinuity used to determine when the correct magnetizing condition

or magnetic field direction has been achieved.

Fill Factor: is given by 2 /2

Wet ferromagnetic particles have lower permeability and higher Retentivity

compared to dry powder.

Advantages of Magnetic Rubber: 1. Replica of the geometry is created. 2. A record

is created. 3. The indication can be viewed under a microscope.

Magnetic Rubber Inspection takes a long time because: curing the magnetizing

rubber solution.

Typical amperage output for mobile equipment is 1.5Ka to 4000 amperes.

Hall Effect probe: detects field strength because the field strength creates a

voltage difference between two sides of the sensor in proportion to the field

strength.

Quick Break: shuts off current at its maximum causing the collapsing magnetic

field to produce eddy currents that compensate for decreased flux density at the

ends of a part.

Cobalt glass filter provides peak transmission of what wavelength? 3650 angstroms

or 365nm

Advantages of batteries for MT: can be operated using low current line chargers.

Ketos Ring Test: provides information about particle concentration, magnetic

properties of the particles, and the functioning of the magnetizing machine.

Hall Effect probe sensitivity is increased using a ferrite ring because? Of

increased permeability and higher B value.

You should wear UV absorption eyewear while performing fluorescent MT, because if

light shines in your eye, a cloudy sensation may occur do to liquid in the eye

ball fluoresce.

Depth to width of a crack for detection.

Have seen 1:1 and 1:5.

Stringer: most likely subsurface discontinuity detectable by MT

Porosity: most difficult to detect by MT.

Contact pads used during a head shot are necessary to? reduce arcing and current

density through contact area.

Longer shots are required with magnetic rubber due to? Higher Viscosity

Charles Hansen ASNT Level III

Page 6|6

You might also like

- Q & A ASNT Level IIIDocument4 pagesQ & A ASNT Level IIISantosh Kumar100% (10)

- Level III UT Study NoteDocument3 pagesLevel III UT Study NoteAllen Situ83% (6)

- Basic Question Bank Asnt Level IiiDocument7 pagesBasic Question Bank Asnt Level Iiiabhi100% (10)

- MT Self-Study NoteDocument153 pagesMT Self-Study Notenewdao100% (5)

- Asnt Level Iii Basic Review:: Materials and Processes For NDT TechnologyDocument215 pagesAsnt Level Iii Basic Review:: Materials and Processes For NDT TechnologyTapan Kumar Nayak100% (7)

- Asnt Level III Study NoteDocument3 pagesAsnt Level III Study NoteAllen Situ80% (5)

- ASNT Level 2 Magnetic Particle Testing Study GuideDocument55 pagesASNT Level 2 Magnetic Particle Testing Study Guidemikebowen89% (19)

- Basic Level Iii PDFDocument420 pagesBasic Level Iii PDFEslam Soliman90% (20)

- Basic Question ASNT L 3 PDFDocument23 pagesBasic Question ASNT L 3 PDFJosé Juan Jiménez Alejandro50% (2)

- BASIC - 5 - Question Asnt Level IIIDocument8 pagesBASIC - 5 - Question Asnt Level IIIabhi88% (8)

- ASNT III Study Material (ASNT Store)Document1 pageASNT III Study Material (ASNT Store)DESTINY SIMON0% (1)

- Basic Exam0001Document7 pagesBasic Exam0001shabbir62683% (6)

- VT Level III Study NoteDocument5 pagesVT Level III Study NoteAllen Situ100% (3)

- Asnt Level Iii Basic QuestionsDocument7 pagesAsnt Level Iii Basic Questionsabhi90% (10)

- SNT TC 1a Vs CP 189 14 08 17 Update PDFDocument8 pagesSNT TC 1a Vs CP 189 14 08 17 Update PDFvenkat100% (5)

- SNT TC-1A and CP-189 DifferenceDocument8 pagesSNT TC-1A and CP-189 Differencemahesh100% (2)

- ASNT Level III Study Guide Liquid PDFDocument96 pagesASNT Level III Study Guide Liquid PDFmohammed89% (19)

- Pirt Asnt NDT Leiii Exam Hints11cDocument3 pagesPirt Asnt NDT Leiii Exam Hints11celdobie30% (1)

- Supplement To Materials and Processes For NDT TechnologyDocument76 pagesSupplement To Materials and Processes For NDT TechnologyTC Capulcu Mustafa M100% (4)

- ASNT Level III Questions - HDDDocument28 pagesASNT Level III Questions - HDDMohammedBujair57% (7)

- ASNT Level III Study Guide Basic Flashcards - QuizletDocument9 pagesASNT Level III Study Guide Basic Flashcards - QuizletJayaneela Prawin100% (4)

- Pirt Asnt NDT Leiii Basic QB Solution11bDocument5 pagesPirt Asnt NDT Leiii Basic QB Solution11beldobie3100% (2)

- Comparison Between Snt-Tc-1a and CP 189Document3 pagesComparison Between Snt-Tc-1a and CP 189prabhakaran.S100% (5)

- 2 Lett 1 2 Lette 1 3 LetteDocument9 pages2 Lett 1 2 Lette 1 3 Lettemohamed100% (1)

- Asnt NDT Level Iii Basic RequirementsDocument2 pagesAsnt NDT Level Iii Basic RequirementsSantosh Kumar63% (16)

- Basic 5Document16 pagesBasic 5mohamedNo ratings yet

- asntRT IIIquestionsDocument3 pagesasntRT IIIquestionsjasminnee100% (3)

- Snt-Tc-1a-2016 QB - Key-003Document19 pagesSnt-Tc-1a-2016 QB - Key-003prabhakaran.S100% (8)

- Asnt Level III Basic Examination General Requirements 160410050536Document23 pagesAsnt Level III Basic Examination General Requirements 160410050536Mohammed MustafaNo ratings yet

- NDT Basic Examination-IDocument20 pagesNDT Basic Examination-IDenzil D'Souza67% (3)

- PT - Snt-Tc-1a 2006 (Study Test)Document8 pagesPT - Snt-Tc-1a 2006 (Study Test)DESTINY SIMON67% (3)

- ASNT Level II Study Guide Liquid Penetrant Testing MethodDocument49 pagesASNT Level II Study Guide Liquid Penetrant Testing MethodIsrael Riquelme100% (21)

- Acoustic Emission Testing Method: Questions AnswersDocument22 pagesAcoustic Emission Testing Method: Questions AnswersSadhasivam Velu100% (2)

- Snt-Tc-1a - 60 Questions PDFDocument14 pagesSnt-Tc-1a - 60 Questions PDFpremnath R75% (4)

- Magnetic Particle Inspection Levels 1, 2 & 3 Q & ADocument57 pagesMagnetic Particle Inspection Levels 1, 2 & 3 Q & Amikebowen90% (10)

- MT QB G Iii VietnamDocument18 pagesMT QB G Iii VietnamLalit Misra75% (4)

- UT-weld Defect ProfileDocument11 pagesUT-weld Defect ProfilephaninittNo ratings yet

- Basic 2Document15 pagesBasic 2mohamed100% (1)

- Asnt Level 3 Study Guide MTDocument4 pagesAsnt Level 3 Study Guide MTJulio Cesar Fernadez Estela0% (3)

- NDT Basic Questions PDFDocument7 pagesNDT Basic Questions PDFAnonymous gFcnQ4go71% (7)

- Asnt RT Level 3 Qns & AnsDocument64 pagesAsnt RT Level 3 Qns & AnsKartik Gulipalli95% (21)

- Magnetic Particle Testing NDT Level2 GulfndeDocument25 pagesMagnetic Particle Testing NDT Level2 GulfndeGulfnde India33% (3)

- Basic NDT QuestionsDocument15 pagesBasic NDT Questionsgbsubbu100% (3)

- Asnt MT Level Iii TipsDocument2 pagesAsnt MT Level Iii TipskingstonNo ratings yet

- Asnt VT Lii Questions and AnswersDocument10 pagesAsnt VT Lii Questions and Answerskevin desai50% (2)

- Asnt Level 3 Exam Penetrant TestDocument40 pagesAsnt Level 3 Exam Penetrant TestLora Boyd85% (33)

- ,DanaInfo Sinnot03.eagle - org+VT ASNT NDT LeveL - III - Doc 25 April 2011Document23 pages,DanaInfo Sinnot03.eagle - org+VT ASNT NDT LeveL - III - Doc 25 April 2011Ike Duaka100% (2)

- Asnt Level 3 UT ExamDocument1 pageAsnt Level 3 UT Examprem nautiyal100% (2)

- Pirt Asnt Leiii MT Spe 11aDocument12 pagesPirt Asnt Leiii MT Spe 11aeldobie3100% (1)

- Level III Basic Examination For SNT-TC-1A 1992Document8 pagesLevel III Basic Examination For SNT-TC-1A 1992mohamedNo ratings yet

- SNT-TC-1A and CP189 QuestionsDocument7 pagesSNT-TC-1A and CP189 Questionssafeer ahmad100% (3)

- ASNT Basic Level III Module 1 (Study Test)Document3 pagesASNT Basic Level III Module 1 (Study Test)DESTINY SIMONNo ratings yet

- NDE Level III Basic Sample QuestionsDocument3 pagesNDE Level III Basic Sample Questionskmohan6750% (2)

- Basic Exam Qustion SetDocument20 pagesBasic Exam Qustion SetsbmmlaNo ratings yet

- MT Level IIDocument13 pagesMT Level IIidealparrot89% (19)

- NDE 152 Final MT Review - STUDENT - SP18Document5 pagesNDE 152 Final MT Review - STUDENT - SP18donciriusNo ratings yet

- Magnetic Particle Testing: ASME BPVC Section V - Article 7 ASTM E-709, E-1444Document50 pagesMagnetic Particle Testing: ASME BPVC Section V - Article 7 ASTM E-709, E-1444hariNo ratings yet

- The Viability of Snail Shell Suso As An Additive in Making Cemented Pots Final DaftDocument29 pagesThe Viability of Snail Shell Suso As An Additive in Making Cemented Pots Final DaftRhaziela Eunika MalabagNo ratings yet

- DPP JF 11 To 20 FDocument50 pagesDPP JF 11 To 20 FAastikUdeniaNo ratings yet

- Chemical Composition of Callisia Fragrans Juice 1. Phenolic CompoundsDocument2 pagesChemical Composition of Callisia Fragrans Juice 1. Phenolic CompoundsLeTienDungNo ratings yet

- DR FCC PDFDocument7 pagesDR FCC PDFAle SanzNo ratings yet

- Analyze The Cases and Answer The QuestionsDocument31 pagesAnalyze The Cases and Answer The QuestionsJohn Lloyd PedresoNo ratings yet

- Model Answer Final Revision Chapter 4 FinalDocument50 pagesModel Answer Final Revision Chapter 4 FinalAhmed BasemNo ratings yet

- TIMBERDocument13 pagesTIMBERAbigail FababaerNo ratings yet

- Assay of Magnesium HydroxideDocument8 pagesAssay of Magnesium HydroxiderahulNo ratings yet

- Screw Compressors ReviewDocument19 pagesScrew Compressors ReviewCarlos Maldonado AlmeidaNo ratings yet

- Cambridge IGCSE™: Chemistry 0620/52Document8 pagesCambridge IGCSE™: Chemistry 0620/52Sridharan VijayalakshmiNo ratings yet

- ThermodynamicsDocument660 pagesThermodynamicsGiridharan SharmaNo ratings yet

- Synthesis and Characterization of Nano Banana Fibre Reinforced Polymer Nano CompositesDocument133 pagesSynthesis and Characterization of Nano Banana Fibre Reinforced Polymer Nano CompositesBoopathi RajaNo ratings yet

- CO2+R3N+H2O R3NH+ +HCO3 - : Base Catalyzed MechanismDocument5 pagesCO2+R3N+H2O R3NH+ +HCO3 - : Base Catalyzed MechanismsammarNo ratings yet

- Paul DiracDocument6 pagesPaul DiracLeonNo ratings yet

- Australia To See Fastest Energy Transition in The World Due To - 2020 - Focus oDocument1 pageAustralia To See Fastest Energy Transition in The World Due To - 2020 - Focus oBagoes IdchaNo ratings yet

- J Chroma 2017 12 056Document9 pagesJ Chroma 2017 12 056AnisaNo ratings yet

- Decomposition of Hydrogen Peroxide FinalDocument35 pagesDecomposition of Hydrogen Peroxide FinalDuaa Raja100% (1)

- Unit 1: Atomic Structure: AP ChemistryDocument39 pagesUnit 1: Atomic Structure: AP ChemistrykawarriorNo ratings yet

- Vasco 6000 EsiteDocument2 pagesVasco 6000 EsiteBruno GomesNo ratings yet

- RADIOIMMUNOASSAYDocument4 pagesRADIOIMMUNOASSAYJansen MunioNo ratings yet

- Prediction of The Optimal Micro Hardness and Crystalline Size of Nanostructure Via Machining and Neuro-Fuzzy TechniqueDocument5 pagesPrediction of The Optimal Micro Hardness and Crystalline Size of Nanostructure Via Machining and Neuro-Fuzzy TechniqueSrdjan SuknovicNo ratings yet

- KU SPH 101 Electricity and Magnetism 1 NotesDocument107 pagesKU SPH 101 Electricity and Magnetism 1 NotesCallum Fallen100% (1)

- C184 E037bDocument48 pagesC184 E037bNeyda Flores VasquezNo ratings yet

- New Holland TM Electrical System Duplicated From Main ManualDocument456 pagesNew Holland TM Electrical System Duplicated From Main ManualRoong RuangNo ratings yet

- Completion Fluid Services Liquid Viscosifier: DescriptionDocument2 pagesCompletion Fluid Services Liquid Viscosifier: DescriptionpaimanNo ratings yet

- SM5 Meter Specifications Sheet: PerformanceDocument2 pagesSM5 Meter Specifications Sheet: Performancehendro saputroNo ratings yet

- EXP-10 Pressure Drop in Packed BedDocument23 pagesEXP-10 Pressure Drop in Packed BedZakwan HanifNo ratings yet

- Process Intensification, Transforming Chemical EngineeringDocument13 pagesProcess Intensification, Transforming Chemical EngineeringseelampremNo ratings yet

- Himma2018-Review N2 - MembraneDocument35 pagesHimma2018-Review N2 - MembranefaezNo ratings yet

- Right Hand RuleDocument14 pagesRight Hand RuleTyra Christine Victorio FloresNo ratings yet