Professional Documents

Culture Documents

A Detailed Study On Analysis of Cylinder Head: Abstract

Uploaded by

IJARBESTOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Detailed Study On Analysis of Cylinder Head: Abstract

Uploaded by

IJARBESTCopyright:

Available Formats

ISSN (ONLINE): 2395-695X

ISSN (PRINT): 2395-695X

A Detailed Study on Analysis of Cylinder Head

Lijo. M. Raju1, Athul Kumar. A2, Bipin Kumar. B3, Akhil Joy4, Rohith Ambadi. S5

UG Scholars, Department of Mechanical and Automation Engineering 1, 2,3,4,5

PSN College of Engineering and Technology (Autonomous), Tirunelveli, India

Abstract - I.C motor cylinder is a standout amongst the most vital and complex part in the

motor. It is additionally some of the time alluded as the heart of motor. It is generally utilized

primarily as a part of car and mechanical fields subsequently, a nitty gritty review on its

static conduct is essential. This paper underlines on the static investigation of the cylinder

leader of a 4-stroke I.C motor. In the present work cylinder head is outlined utilizing

CATIAV5R20 and this model is broke down in ANSYS 14.5 and a review on its static conduct

is performed. Aluminum composite has been chosen as cylinder material for basic

examination. The hypothetical anxiety values got is contrasted and the anxiety values

acquired after the investigation in ANSYS 14.5.

Index Terms Cylinder Head, I.C Engine, CATIA V5R20, ANSYS 14.5, Static Analysis.

I. INTRODUCTION

https://www.ijarbest.com/Archive

This work by IJARBEST is licensed under Creative Commons Attribution 4.0 International License. Available at https://www.ijarbest.com/Archive

International Journal of Advanced Research in Basic Engineering Sciences and Technology (IJARBEST)

Vol. 3, Issue 1, January 2017

Piston is one of the most important components of engine. It is a part in motion which is present

in cylinder. In the engine the expansion of gas occurs in cylinder up to crankshaft through

connecting rod. The piston lasts this gas pressure and inertial forces at work and this may lead to

crack formation and piston wear. The study reports show that stress concentration is highest at

upper portion and this is one of the main reasons for crack formation and wear. This paper

describes stress distribution on piston head of an IC engine by using finite element method. It is

achieved by CAD and CAE software. Our main purpose is to study the static behavior of piston

head and analyze the stress distribution. By using CATIAV5R20 model of the piston head is

developed. Stress analysis is carried out by using ANSYS 14.5. The results obtained from ANSYS

14.5 are compared with the calculated theoretical stress values. Christo Ananth et al. [5] proposed

a system about Efficient Sensor Network for Vehicle Security. Today vehicle theft rate is very

high, greater challenges are coming from thieves thus tracking/ alarming systems are being

deployed with an increasingly popularity .As per as security is concerned today most of the

vehicles are running on the LPG so it is necessary to monitor any leakage or level of LPG in order

to provide safety to passenger. Also in this fast running world everybody is in hurry so it is

required to provide fully automated maintenance system to make the journey of the passenger

safe, comfortable and economical. To make the system more intelligent and advanced it is required

to introduce some important developments that can help to promote not only the luxurious but also

safety drive to the owner. The system Efficient Sensor Network for Vehicle Security, introduces

a new trend in automobile industry.

Lijo. M. Raju et al.

IJARBEST PUBLICATIONS

1

ISSN (ONLINE): 2395-695X

ISSN (PRINT): 2395-695X

International Journal of Advanced Research in Basic Engineering Sciences and Technology (IJARBEST)

Vol. 3, Issue 1, January 2017

II. MATERIAL PROPERTIES

Aluminum alloy is selected for the design and analysis of the piston head. Properties of

the aluminum alloy are mentioned below.

TABLE I: PARAMETERS AND VALUES

Parameter

Value

Density

2770 (Kg/m3)

Poisson Ratio

0.33

Young Modulus

7.1x1010 (Pa)

Thickness of the piston head by

t1 = D2q / [1600K (Tc-Te)] mm

considering the heat dissipation

III. CALCULATIONS

Bore diameter = 100 mm (D),

Stroke length = 120 mm (L),

Gas pressure = 5

MPa, BMEP = 0.5 MPa,

Fuel consumed =0.15 (Kg) / Brake Power (W),

Speed = 2200 rpm (N)

Step 1:

Brake power (BP) .in KW

BP = PLAN/ (100060) KW

Where, P = BEMP = 0.5 MPa

L = Stroke length m

A = Cross Section area m2

N = Speed rpm2

BP = 0.5120100 2200/ (1000460)

= 17.275 KW

Step 2:

Where, t1 = thickness of piston head mm

q = Heat flow J/s-m2

k = Heat conductivity W- mm/ (m2-0c)

Tc-Te = difference between the Temperature at centre and edges =222 K

q = K1CWBP/(A) J/s-m2

Lijo. M. Raju et al.

IJARBEST PUBLICATIONS

2

ISSN (ONLINE): 2395-695X

ISSN (PRINT): 2395-695X

International Journal of Advanced Research in Basic Engineering Sciences and Technology (IJARBEST)

Vol. 3, Issue 1, January 2017

Where, K1 = Constant which represents the amount of heat soaked by piston.

C = Calorific value of the fuel = 42000 KJ/Kg

W = fuel consumed = 0.15 Kg-hr/KW

A = d2/ (4) = (0.1)2/ (4) = 7.8510-3 m2

q = 0.05 (420001000) (0.15/3600)17.278/ (7.85410-3) = 192491 J/s-m2

t1 = 1002192491 / (1600460222) = 11.78 mm

Step 3: The thickness of the piston head using Grashofs formula

t1 = 0.43 D (P/t) mm

P = Gas pressure in MPa

t = Allowable tensile stress MPa

= 280/2.25

= 124.4 MPa

D = 100 mm

= 0.43100 (5/124)

= 8.7 mm = 9 mm

Adopt the greater value of the t1 i.e). t1 = 11.78 mm

Step 4: Piston ring properties

The radial thickness of the ring tr

tr = D(3Pr/ t) mm

Where, Pr is pressure exerted by fuel on cylinder wall in

N/mm2. Its value varies from 0.025 to 0.042N/mm2

= 100 (30.042/124)

= 3.187 mm

The distance from top to first groove tg

tg = 1t1 to 1.2t1

= 1.211.78

= 14 mm Number of rings i

i = 100/ (10h)

= 100/ (102.22) = 4 rings

The maximum thickness of piston barrel t3

t3 = 0.03D + b + 4.5 mm

Where, b is the depth of the ring grooves in mm

b = tr + 0.4 mm

= 3.187+0.4

Lijo. M. Raju et al.

IJARBEST PUBLICATIONS

3

ISSN (ONLINE): 2395-695X

ISSN (PRINT): 2395-695X

International Journal of Advanced Research in Basic Engineering Sciences and Technology (IJARBEST)

Vol. 3, Issue 1, January 2017

= 3.587 mm

t3 = 0.03100 + 3.587 + 4.5

= 11.08 mm

Thickness of the wall towards the open end of the piston t4

t4 = 0.25 t3 to 0.35t3

= 0.2511.08

= 3.32 mm

Diameter of the piston pin d = D2Pmax/ (4l1Pb)

Where, l1 = 1.5d

Pb is bearing pressure in MPa which is 15.7 for aluminum alloys.

= 10025/ [4 (1.5d) 15.7]

d = 40.83 mm

Step 5: Theoretical Stress Calculation

b = Mb/Wb MPa

Where Mb is the bending moment and

Wb is the moment of resistance to the bending

Mb = 1/3Pmaxr 3 MNm

Pmax = Maximum gas pressure in MPa.

This value varies between 2 to 5 MPa in case of aluminum alloys. [3]

ri = crown inner radius m

Wb = 1/3Gri2 m3

G = Thickness of piston crown m

ri = [D/2-(s+tr+dt)] m

dt = Radial clearance between piston rings and channel m

s = Thickness of the sealing part m

= [0.1/2-(0.005+0.0008+0.0031)] = 0.0413 m

Mb = 1/350.04133

= 1.17410-4 MNm

G = (0.08 to 0.1) D m

= 0.091100

= 9.1 mm

Wb = 1/30.04130.00912

= 1.1410-6 m3

b = 1.1710-4/1.1410-6

= 103 MPa

The theoretical stress value obtained is less than the allowable stress (103<124 MP a).

Hence the design is safe. Christo Ananth et al. [4] discussed about Improved Particle Swarm

Optimization. The fuzzy filter based on particle swarm optimization is used to remove the

high density image impulse noise, which occur during the transmission, data acquisition and

Lijo. M. Raju et al.

IJARBEST PUBLICATIONS

4

ISSN (ONLINE): 2395-695X

ISSN (PRINT): 2395-695X

International Journal of Advanced Research in Basic Engineering Sciences and Technology (IJARBEST)

Vol. 3, Issue 1, January 2017

processing. The proposed system has a fuzzy filter which has the parallel fuzzy inference

mechanism, fuzzy mean process, and a fuzzy composition process. In particular, by using noreference Q metric, the particle swarm optimization learning is sufficient to optimize the

parameter necessitated by the particle swarm optimization based fuzzy filter, therefore the

proposed fuzzy filter can cope with particle situation where the assumption of existence of

ground-truth reference does not hold. The merging of the particle swarm optimization with

the fuzzy filter helps to build an auto tuning mechanism for the fuzzy filter without any prior

knowledge regarding the noise and the true image. Thus the reference measures are not need

for removing the noise and in restoring the image. The final output image (Restored image)

confirm that the fuzzy filter based on particle swarm optimization attain the excellent quality

of restored images in term of peak signal-to-noise ratio, mean absolute error and mean square

error even when the noise rate is above 0.5 and without having any reference measures. Christo

Ananth et al. [6] discussed about Intelligent Sensor Network for Vehicle Maintenance System.

Modern automobiles are no longer mere mechanical devices; they are pervasively monitored

through various sensor networks & using integrated circuits and microprocessor based design

and control techniques while this transformation has driven major advancements in efficiency

and safety. In the existing system the stress was given on the safety of the vehicle, modification

in the physical structure of the vehicle but the proposed system introduces essential concept

in the field of automobile industry. It is an interfacing of the advanced technologies like

Embedded

Systems and the Automobile world. This Intelligent Sensor Network for Vehicle

Maintenance System is best suitable for vehicle security as well as for vehicles maintenance.

Further it also supports advanced feature of GSM module interfacing. Through this concept in

case of any emergency or accident the system will automatically sense and records the

different parameters like LPG gas level, Engine Temperature, present speed and etc. so that at

the time of investigation this parameters may play important role to find out the possible

reasons of the accident. Further, in case of accident & in case of stealing of vehicle GSM

module will send SMS to the Police, insurance company as well as to the family members.

Christo Ananth et al. [7] discussed about an eye blinking sensor. Nowadays heart attack

patients are increasing day by day. Though it is tough to save the heart attack patients, we

can increase the statistics of saving the life of patients & the life of others whom they are

responsible for. The main design of this project is to track the heart attack of patients who are

suffering from any attacks during driving and send them a medical need & thereby to stop the

vehicle to ensure that the persons along them are safe from accident. Here, an eye blinking

sensor is used to sense the blinking of the eye. SpO2 sensor checks the pulse rate of the patient.

Both are connected to micro controller.

If eye blinking gets stopped then the signal is sent to the controller to make an alarm

through the buffer. If spO2 sensor senses a variation in pulse or low oxygen content in blood,

it may results in heart failure and therefore the controller stops the motor of the vehicle. Then

Tarang F4 transmitter is used to send the vehicle number & the mobile number of the patient

to a nearest medical station within 25 km for medical aid. The pulse rate monitored via LCD

.The Tarang F4 receiver receives the signal and passes through controller and the number gets

Lijo. M. Raju et al.

IJARBEST PUBLICATIONS

5

ISSN (ONLINE): 2395-695X

ISSN (PRINT): 2395-695X

International Journal of Advanced Research in Basic Engineering Sciences and Technology (IJARBEST)

Vol. 3, Issue 1, January 2017

displayed in the LCD screen and an alarm is produced through a buzzer as soon the signal is

received. Christo Ananth et al. [8] discussed about a system, GSM based AMR has low

infrastructure cost and it reduces man power. The system is fully automatic, hence the

probability of error is reduced. The data is highly secured and it not only solve the problem of

traditional meter reading system but also provides additional features such as power

disconnection, reconnection and the concept of power management. The database stores the

current month and also all the previous month data for the future use. Hence the system saves

a lot amount of time and energy. Due to the power fluctuations, there might be a damage in

the home appliances. Hence to avoid such damages and to protect the appliances,

the voltage controlling methodcan

be implemented. Christo Ananth et al. [9]

discussed about a project, in this project an automatic meter reading system is designed using

GSM Technology. The embedded micro controller is interfaced with the GSM Module. This

setup is fitted in home. The energy meter is attached to the micro controller. This controller

reads the data from the meter output and transfers that data to GSM Module through the serial

port. The embedded micro controller has the knowledge of sending message to the system

through the GSM module. Another system is placed in EB office, which is the authority office.

When they send unit request to the microcontroller which is placed in home. Then the unit

value is sent to the EB office PC through GSM module. According to the readings, the

authority officer will send the information about the bill to the customer. If the customer

doesnt pay bill on-time, the power supply to the corresponding home power unit is cut,

by sending the command through to the microcontroller. Once the payment of bill is done the

power supply is given to the customer.

Power management concept is introduced, in which during the restriction mode only

limited amount of power supply can be used by the customer.

In [10], the development in technology has given us all sophistications but equal amounts of

threats too. This has brought us an urge to bring a complete security system that monitors an

object continuously. Consider a situation where a cargo vehicle carrying valuable material is

moving in an area using GPS (an outdoor sensor) we can monitor it but the actual problem

arises when its movement involves both indoor (within the industry) and outdoor because GPS

has its limitations in indoor environment. Hence it is essential to have an additional sensor that

would enable us a continuous monitoring /tracking without cutoff of the signal. In this paper

we bring out a solution by combining Ultra wide band (UWB) with GPS sensory information

which eliminates the limitations of conventional tracking methods in mixed scenario(indoor

and outdoor).

The same method finds application in mobile robots, monitoring a person on grounds of

security, etc. Christo Ananth et al. [11] discussed about Nano robots Control Activation for

Stenosed Coronary Occlusion, this paper presents the study of Nano robots control activation

for stenosed coronary occlusion, with the practical use of chemical and thermal gradients for

biomedical problems. The recent developments on nanotechnology new materials allied with

electronics device miniaturization may enable Nano robots for the next few years. New

possibilities for medicine are expected with the development of Nano robots. It may help to

advance the treatment of a wide number of diseases: cardiovascular problems, neurosurgery,

Lijo. M. Raju et al.

IJARBEST PUBLICATIONS

6

ISSN (ONLINE): 2395-695X

ISSN (PRINT): 2395-695X

International Journal of Advanced Research in Basic Engineering Sciences and Technology (IJARBEST)

Vol. 3, Issue 1, January 2017

cancer, diabetes and new cell therapies.

The implementation of new methodologies to help on manufacturing analyses and system

design for the development of Nano scale molecular machine is one of the most important

fields for research. The use of 3D physically based simulation in conjunction with clinical data

may provide ways to design practical approaches for control and transducers development.

Christo Ananth et al.[12] discussed about E-plane and H-plane patterns which forms the basis

of Microwave Engineering principles.

IV. STRUCTURAL ANALYSIS

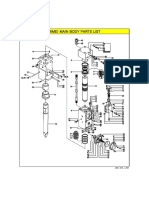

A. Restraining the Model at Piston Pin Holes

Cylinder stick gaps are considered as settled support. Thus frictionless support is

connected and it is limited at its gaps.

Fig 1. Restraining the model at piston pin holes

B. Applying Pressure on Top Surface

For static basic investigation the weight of size 5 MPa is connected on the top surface of

the cylinder head. The gas burning weight for aluminum compound is 5 MPa.

Lijo. M. Raju et al.

IJARBEST PUBLICATIONS

7

ISSN (ONLINE): 2395-695X

ISSN (PRINT): 2395-695X

International Journal of Advanced Research in Basic Engineering Sciences and Technology (IJARBEST)

Vol. 3, Issue 1, January 2017

Fig 2. Applying the pressure on top surface of piston head

V. RESULTS

The model is fathomed in the wake of applying the weight and results are acquired for VonMises push and basic misshaping which are demonstrated as follows. The estimation of

auxiliary distortion got is 0.7314 mm and stress esteem acquired is 103.32 MPa.

Fig 3. Results obtained for Structural deformation of piston head

Lijo. M. Raju et al.

IJARBEST PUBLICATIONS

8

ISSN (ONLINE): 2395-695X

ISSN (PRINT): 2395-695X

International Journal of Advanced Research in Basic Engineering Sciences and Technology (IJARBEST)

Vol. 3, Issue 1, January 2017

Fig 4. Results obtained for stress in Cylinder head

VI. CONCLUSION

As the Engine barrel is a champion among the most imperative and complex part in the engine.

It is also as a rule implied as the heart of engine. It is for the most part used principally as a piece

of auto and mechanical fields along these lines, a bare essential audit on its static lead is

fundamental. This paper underlines on the static examination of the chamber pioneer of a 4-stroke

I.C engine. In the present work chamber head is laid out using CATIAV5R20 and this model is

penniless down in ANSYS 14.5 and a survey on its static lead is performed. Aluminum composite

has been picked as barrel material for fundamental examination. The theoretical tension qualities

got is differentiated and the uneasiness values procured after the examination.

REFERENCES

[1] W.M. Thomas, E.D. Nicholas, J.C. Needham, M.G. Murch, P. Temple-Smith, C.J. Dawes, Method of

operating on a workpiece, in, United States Patent, 5,460,317, The Welding Institute, Cambridge, GB, 1995.

[2] E. Bousquet, A. Poulon-Quintin, M. Puiggali, O. Devos, M. Touzet, Relationship between microstructure,

microhardness and corrosion sensitivity of an AA 2024-T3 friction stir welded joint, Corrosion Science, 53

(2011) 3026-3034.

[3] M. Ericsson, R. Sandstrm, Influence of welding speed on the fatigue of friction stir welds, and comparison

with MIG and TIG, International Journal of Fatigue, 25 (2003) 1379-1387.

[4] Christo Ananth, Vivek.T, Selvakumar.S., Sakthi Kannan.S., Sankara Narayanan.D, Impulse Noise Removal

using Improved Particle Swarm Optimization, International Journal of Advanced Research in Electronics

and Communication Engineering (IJARECE), Volume 3, Issue 4, April 2014,pp 366-370

[5] Christo Ananth, I.Uma Sankari, A.Vidhya, M.Vickneshwari, P.Karthiga, Efficient Sensor Network for

Vehicle Security, International Journal of Advanced Scientific and Technical Research (IJST), Volume 2,

Issue 4, March-April 2014,pp 871-877

[6] Christo Ananth, C.Sudalai@UtchiMahali, N.Ebenesar Jebadurai, S.Sankari@Saranya, T.Archana,

Intelligent sensor Network for Vehicle Maintenance system, International Journal of Emerging Trends in

Engineering and Development (IJETED), Vol.3, Issue 4, May 2014, pp- 361-369

Lijo. M. Raju et al.

IJARBEST PUBLICATIONS

9

ISSN (ONLINE): 2395-695X

ISSN (PRINT): 2395-695X

International Journal of Advanced Research in Basic Engineering Sciences and Technology (IJARBEST)

Vol. 3, Issue 1, January 2017

[7] Christo Ananth, S.Shafiqa Shalaysha, M.Vaishnavi, J.Sasi Rabiyathul Sabena, A.P.L.Sangeetha, M.Santhi,

Realtime Monitoring Of Cardiac Patients At Distance Using Tarang Communication, International Journal

of Innovative Research in Engineering & Science (IJIRES), Volume 9, Issue 3,September 2014,pp-15-20

[8] Christo Ananth, G.Poncelina, M.Poolammal, S.Priyanka, M.Rakshana, Praghash.K., GSM Based AMR,

International Journal of Advanced Research in Biology, Ecology, Science and Technology (IJARBEST),

Volume 1,Issue 4,July 2015, pp:26-28

[9] Christo Ananth, Kanthimathi, Krishnammal, Jeyabala, Jothi Monika, Muthu Veni, GSM Based Automatic

Electricity Billing System, International Journal Of Advanced Research Trends In Engineering And

Technology (IJARTET), Volume 2, Issue 7, July 2015, pp:16-21

[10] Christo Ananth, S.Silvia Rachel, E.Edinda Christy, K.Mala, Probabilistic Framework for the Positioning Of

a Vehicle in a Combined Indoor-Outdoor Scenario, International Journal of Advanced Research in

Management, Architecture, Technology and Engineering (IJARMATE), Volume 2, Special Issue 13, March

2016, pp: 46-59

[11] Christo Ananth, R.K. Shunmuga Priya, T.Rashmi Anns, S.Kadhirunnisa, NANOROBOTS CONTROL

ACTIVATION FOR STENOSED CORONARY OCCLUSION, International Journal of Advanced

Research in Management, Architecture, Technology and Engineering (IJARMATE), Volume 2, Special Issue

13, March 2016, pp: 60-76

[12] Christo Ananth, S.Esakki Rajavel, S.Allwin Devaraj, M.Suresh Chinnathampy. "RF and Microwave

Engineering (Microwave Engineering).", ACES Publishers, Tirunelveli, India, ISBN: 978-81-910-747-5-8,

Volume 1,June 2014, pp:1- 300.

[13] M. Jariyaboon, A.J. Davenport, R. Ambat, B.J. Connolly, S.W. Williams, D.A. Price, The effect of welding

parameters on the corrosion behaviour of friction stir welded AA2024T351, Corrosion Science, 49 (2007)

877-909.

[14] R.A. Prado, L.E. Murr, D.J. Shindo, K.F. Soto, Tool wear in the friction-stir welding of aluminum alloy

6061+20% Al2O3: a preliminary study, ScriptaMaterialia, 45 (2001) 75-80.

[15] S. Benavides, Y. Li, L.E. Murr, D. Brown, J.C. McClure, Low-temperature friction-stir welding of 2024

aluminum, ScriptaMaterialia, 41 (1999) 809-815.

Lijo. M. Raju et al.

IJARBEST PUBLICATIONS

10

You might also like

- Engine Mechanical Section ContentsDocument136 pagesEngine Mechanical Section ContentsJose Figueroa60% (5)

- Stress Analysis of Piston Using Pressure Load and Thermal LoadDocument8 pagesStress Analysis of Piston Using Pressure Load and Thermal LoadInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Silver Knights Cad Cae ReportDocument23 pagesSilver Knights Cad Cae ReportSg_manikandanNo ratings yet

- Winch DesignDocument132 pagesWinch Designzeek7767% (3)

- John Deere 1640 2040 2040SDocument1,448 pagesJohn Deere 1640 2040 2040Sbga187583% (6)

- Housing Designs & Seal Options PDFDocument27 pagesHousing Designs & Seal Options PDFmimi_chan_17100% (1)

- 0000 Design by Optimization of An Axial-Flux Permanent-Magnet Synchronous MotorDocument5 pages0000 Design by Optimization of An Axial-Flux Permanent-Magnet Synchronous MotorAnonymous hWj4HKIDOF100% (1)

- MAN B&W Diesel Operating InstructionsDocument366 pagesMAN B&W Diesel Operating Instructionspostolache marius100% (3)

- ENGINEERING MCQs GUIDEDocument45 pagesENGINEERING MCQs GUIDEthejaraju_r50% (4)

- Catalogo BendixDocument132 pagesCatalogo BendixCristian Muñoz100% (1)

- Ex215 - 4 - WORKSHOP MANUAL ENGINE PDFDocument205 pagesEx215 - 4 - WORKSHOP MANUAL ENGINE PDFkhaled boulahlib83% (6)

- Sauer compressor maintenance scheduleDocument18 pagesSauer compressor maintenance scheduleSebastian Przybylowicz100% (1)

- Impact Analysis On Car BumperDocument5 pagesImpact Analysis On Car Bumperkailashparmar1No ratings yet

- 6 Speed FWD & 4WD Automatic Transmission Overhaul Kits & PartsDocument4 pages6 Speed FWD & 4WD Automatic Transmission Overhaul Kits & PartsMaria Margarita Granada Ríos100% (3)

- Bombas IMO CEP SeparadorasDocument36 pagesBombas IMO CEP SeparadorasAngi España MejiaNo ratings yet

- JSB165 Main Body and Parts ListsDocument5 pagesJSB165 Main Body and Parts ListsO.LedesmaNo ratings yet

- LPG CO2 System Data Sheets PDFDocument156 pagesLPG CO2 System Data Sheets PDFRazaulKareem83% (12)

- 400-440A Parts ListDocument35 pages400-440A Parts ListJoel Maximo Javines Mangaoang100% (2)

- Structure Analysis of Cast Iron For Dry Clutch of Amphibious VehicleDocument4 pagesStructure Analysis of Cast Iron For Dry Clutch of Amphibious VehicleseventhsensegroupNo ratings yet

- Customized Spring and Damper of An AtvDocument6 pagesCustomized Spring and Damper of An AtvIAEME PublicationNo ratings yet

- 73 ThermalDocument10 pages73 ThermalShashank DubeyNo ratings yet

- Ijmet 08 01 016Document6 pagesIjmet 08 01 016Shri Hari .SNo ratings yet

- An Sys PaperDocument13 pagesAn Sys PaperHitesh Kumar PrajapatiNo ratings yet

- Ijet V2i5p22 PDFDocument6 pagesIjet V2i5p22 PDFInternational Journal of Engineering and TechniquesNo ratings yet

- Abrasive Cut Off Machine Mini ProjectDocument49 pagesAbrasive Cut Off Machine Mini ProjectdurendranNo ratings yet

- Comparative Analysis of Vehicle Suspension System in Matlab-Simulink and Msc-Adams With The Help of Quarter Car ModelDocument8 pagesComparative Analysis of Vehicle Suspension System in Matlab-Simulink and Msc-Adams With The Help of Quarter Car ModelHemanth KrishnaNo ratings yet

- Finite Element Analysis of Connecting Rod Using Ansys: Nikhil U.Thakare, Nitin D. Bhusale, Rahul P.Shinde, Mahesh M.PatilDocument5 pagesFinite Element Analysis of Connecting Rod Using Ansys: Nikhil U.Thakare, Nitin D. Bhusale, Rahul P.Shinde, Mahesh M.Patilaravindan476No ratings yet

- 1.steam Turbine Rotor GroovesDocument7 pages1.steam Turbine Rotor GroovesRaheem JunaidiNo ratings yet

- Prediction of Optimal Cutting Parameters For High Speed Dry Turning of Inconel 718 Using GonnsDocument12 pagesPrediction of Optimal Cutting Parameters For High Speed Dry Turning of Inconel 718 Using GonnsIAEME PublicationNo ratings yet

- Piston Strength Analysis Using FEM: Swati S Chougule, Vinayak H KhatawateDocument8 pagesPiston Strength Analysis Using FEM: Swati S Chougule, Vinayak H KhatawateRam TirumalasettiNo ratings yet

- CFD Analysis of Flow Through Muffler To Select Optimum Muffler Model For Ci EngineDocument8 pagesCFD Analysis of Flow Through Muffler To Select Optimum Muffler Model For Ci EngineAnonymous Clyy9NNo ratings yet

- Experimental Investigation of Laser Surface Texturing On Piston Rings For Reduction of Friction PowerDocument7 pagesExperimental Investigation of Laser Surface Texturing On Piston Rings For Reduction of Friction PowerfuturemukundNo ratings yet

- Design of Braking System For Electric Golf-CartDocument6 pagesDesign of Braking System For Electric Golf-Cartfariezulhakimi68No ratings yet

- Productionofnylon - 2Document15 pagesProductionofnylon - 2IAEME PublicationNo ratings yet

- Piston Head Analysis - AnsysDocument5 pagesPiston Head Analysis - Ansyssamar kadamNo ratings yet

- Ijesrt: International Journal of Engineering Sciences & Research TechnologyDocument8 pagesIjesrt: International Journal of Engineering Sciences & Research TechnologyJohn RobinsonNo ratings yet

- Influence of Load on Tribological Conditions in Medium-Speed Diesel EngineDocument10 pagesInfluence of Load on Tribological Conditions in Medium-Speed Diesel EngineSyed Danish FayazNo ratings yet

- Optimization of Car Rim Using OptiStructDocument6 pagesOptimization of Car Rim Using OptiStructsujaydsouza1987No ratings yet

- 5.accidental Car Impact Analysis and CFDDocument6 pages5.accidental Car Impact Analysis and CFDprojectzfourNo ratings yet

- Thermal AnalysisDocument3 pagesThermal AnalysisMathew JohnNo ratings yet

- A Study of Mesh Sensitivity For Crash Simulations - Comparison of Manually and Batch Meshed ModelsDocument8 pagesA Study of Mesh Sensitivity For Crash Simulations - Comparison of Manually and Batch Meshed Modelscharan2kNo ratings yet

- design and manufacture of spur gear in f1Document15 pagesdesign and manufacture of spur gear in f1safaa723227No ratings yet

- Effi CycleDocument6 pagesEffi CycleHar ShaNo ratings yet

- Abrasive Cut Off Machine Mini ProjectDocument48 pagesAbrasive Cut Off Machine Mini ProjectdurendranNo ratings yet

- Paperpdf 1589980240Document4 pagesPaperpdf 1589980240akashpchauhan1127No ratings yet

- Design Optimization of Power Screw JackDocument7 pagesDesign Optimization of Power Screw JackTd DammikaNo ratings yet

- 2020 SpringerDocument10 pages2020 SpringerBrandt GadorNo ratings yet

- Ijmet: ©iaemeDocument7 pagesIjmet: ©iaemeIAEME PublicationNo ratings yet

- Air Flow Analysis For Defroster and Ventilation System of A Passanger CarDocument4 pagesAir Flow Analysis For Defroster and Ventilation System of A Passanger CarSai PatilNo ratings yet

- Helical Gear DesignDocument12 pagesHelical Gear DesignRoozbeh PNo ratings yet

- Design and Analysis of Crankshaft Used in Aerospace Applications and Comparision Using Different Materials.Document8 pagesDesign and Analysis of Crankshaft Used in Aerospace Applications and Comparision Using Different Materials.Innovative Research PublicationsNo ratings yet

- DC Motor Brush Noise Reduction MultibodyDocument2 pagesDC Motor Brush Noise Reduction MultibodyfrecciaaaNo ratings yet

- Static and Thermal Analysis of Piston With Different Thermal CoatingsDocument13 pagesStatic and Thermal Analysis of Piston With Different Thermal CoatingsPinsteritNo ratings yet

- Structural analysis of connecting rod and crankshaft for 150cc engineDocument13 pagesStructural analysis of connecting rod and crankshaft for 150cc engineGurpreet SinghNo ratings yet

- " Design and Front Impact Analysis of Rollcage ": July 2012Document7 pages" Design and Front Impact Analysis of Rollcage ": July 2012shounakNo ratings yet

- Plagiarism Checker X Originality Report: Similarity Found: 30%Document7 pagesPlagiarism Checker X Originality Report: Similarity Found: 30%pramo_dassNo ratings yet

- Bright Hub EngineeringDocument5 pagesBright Hub EngineeringTaha ZiaNo ratings yet

- Design of Flywheel for Punching MachineDocument15 pagesDesign of Flywheel for Punching MachineGujar SnehaNo ratings yet

- I JR Et 20150404003 JJJDocument9 pagesI JR Et 20150404003 JJJSuresh YadavNo ratings yet

- U 02530863088Document3 pagesU 02530863088TobiasOliveiraNo ratings yet

- Fileserve PDFDocument5 pagesFileserve PDFsrknotesNo ratings yet

- Uphill Braking System SeminarDocument16 pagesUphill Braking System SeminarRaj NadafNo ratings yet

- Structural Analysis of Disc Brake RotorDocument4 pagesStructural Analysis of Disc Brake RotorseventhsensegroupNo ratings yet

- Design and Analysis of Carbon Fiber / Epoxy Resin Brake RotorDocument6 pagesDesign and Analysis of Carbon Fiber / Epoxy Resin Brake RotorIOSRjournalNo ratings yet

- Milestone No. 01 - CAE LABDocument9 pagesMilestone No. 01 - CAE LABMuhammad Junaid Rajput FatimaNo ratings yet

- Modification of Mini ProjectDocument23 pagesModification of Mini Projectvishal mishraNo ratings yet

- Optimization of Gear To Improve Performance of GearboxDocument4 pagesOptimization of Gear To Improve Performance of Gearboxijaert100% (1)

- Study On Groove Shape in Park Lock SystemDocument7 pagesStudy On Groove Shape in Park Lock SystemIJRASETPublicationsNo ratings yet

- Project HelpDocument13 pagesProject HelpVishal MirashiNo ratings yet

- Study of Front-Body of Formula-One Car For Aerodynamics Using CFDDocument7 pagesStudy of Front-Body of Formula-One Car For Aerodynamics Using CFDInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- 10 DesigningDocument10 pages10 Designingshank100No ratings yet

- Quantification of Rate of Air Pollution by Means of Statistical Data Collections From HospitalsDocument9 pagesQuantification of Rate of Air Pollution by Means of Statistical Data Collections From HospitalsIJARBESTNo ratings yet

- Segmentation and Automatic Counting of Red Blood Cells Using Hough TransformDocument8 pagesSegmentation and Automatic Counting of Red Blood Cells Using Hough TransformIJARBESTNo ratings yet

- Performance Analysis of PAPR Reduction in MIMO-OFDMDocument8 pagesPerformance Analysis of PAPR Reduction in MIMO-OFDMIJARBESTNo ratings yet

- A New Bit Split and Interleaved Channel Coding For MIMO DecoderDocument7 pagesA New Bit Split and Interleaved Channel Coding For MIMO DecoderIJARBESTNo ratings yet

- High Speed and Low Power ASIC Using Threshold LogicDocument8 pagesHigh Speed and Low Power ASIC Using Threshold LogicIJARBESTNo ratings yet

- Analysis of Modulation Strategies For Two-Stage Interleaved Voltage Source Inverter Employed For PV ApplicationsDocument12 pagesAnalysis of Modulation Strategies For Two-Stage Interleaved Voltage Source Inverter Employed For PV ApplicationsIJARBESTNo ratings yet

- Simulation of An Adaptive Digital Beamformer Using MatlabDocument9 pagesSimulation of An Adaptive Digital Beamformer Using MatlabIJARBESTNo ratings yet

- Multipath Routing Protocol For Effective Local Route RecoveryDocument14 pagesMultipath Routing Protocol For Effective Local Route RecoveryIJARBESTNo ratings yet

- Review of Integrated Power Factor Correction (PFC) Boost Converter Topologies For Telecommunication SystemsDocument11 pagesReview of Integrated Power Factor Correction (PFC) Boost Converter Topologies For Telecommunication SystemsIJARBESTNo ratings yet

- Ijarbest Journal - Call For Editors - Aeronautical EngineeringDocument1 pageIjarbest Journal - Call For Editors - Aeronautical EngineeringIJARBESTNo ratings yet

- Simulation and Implementation of Electric Bicycle Employing BLDC DriveDocument25 pagesSimulation and Implementation of Electric Bicycle Employing BLDC DriveIJARBESTNo ratings yet

- Fermentation Process For Manufacturing of Wine From Emblica Officinalis FruitsDocument7 pagesFermentation Process For Manufacturing of Wine From Emblica Officinalis FruitsIJARBESTNo ratings yet

- A Survey On Question and Answer System by Retrieving The Descriptions Using Local Mining and Global LearningDocument8 pagesA Survey On Question and Answer System by Retrieving The Descriptions Using Local Mining and Global LearningIJARBESTNo ratings yet

- Ijarbest Journal - Call For Editors - Aeronautical EngineeringDocument1 pageIjarbest Journal - Call For Editors - Aeronautical EngineeringIJARBESTNo ratings yet

- Ijarbest Journal - Call For Editors - Aeronautical EngineeringDocument1 pageIjarbest Journal - Call For Editors - Aeronautical EngineeringIJARBESTNo ratings yet

- Ijarbest Journal - Call For Editors - Aeronautical EngineeringDocument1 pageIjarbest Journal - Call For Editors - Aeronautical EngineeringIJARBESTNo ratings yet

- Ijarbest Journal - Call For Editors - Aeronautical EngineeringDocument1 pageIjarbest Journal - Call For Editors - Aeronautical EngineeringIJARBESTNo ratings yet

- Ijarbest Journal - Call For Editors - GeneticsDocument1 pageIjarbest Journal - Call For Editors - GeneticsIJARBESTNo ratings yet

- Ijarbest Journal - Call For Editors - Aeronautical EngineeringDocument1 pageIjarbest Journal - Call For Editors - Aeronautical EngineeringIJARBESTNo ratings yet

- Ijarbest Journal - Call For Editors - Aeronautical EngineeringDocument1 pageIjarbest Journal - Call For Editors - Aeronautical EngineeringIJARBESTNo ratings yet

- Ijarbest Journal - Call For Editors - Aeronautical EngineeringDocument1 pageIjarbest Journal - Call For Editors - Aeronautical EngineeringIJARBESTNo ratings yet

- Ijarbest Journal - Call For Editors - Aeronautical EngineeringDocument1 pageIjarbest Journal - Call For Editors - Aeronautical EngineeringIJARBESTNo ratings yet

- Ijarbest Journal - Call For Editors - Aeronautical EngineeringDocument1 pageIjarbest Journal - Call For Editors - Aeronautical EngineeringIJARBESTNo ratings yet

- Ijarbest Journal - Call For Editors - GeosciencesDocument1 pageIjarbest Journal - Call For Editors - GeosciencesIJARBESTNo ratings yet

- Ijarbest Journal - Call For Editors - Aeronautical EngineeringDocument1 pageIjarbest Journal - Call For Editors - Aeronautical EngineeringIJARBESTNo ratings yet

- Ijarbest Journal - Call For Editors - Aeronautical EngineeringDocument1 pageIjarbest Journal - Call For Editors - Aeronautical EngineeringIJARBESTNo ratings yet

- Ijarbest Journal - Call For Editors - Food Science and TechnologyDocument1 pageIjarbest Journal - Call For Editors - Food Science and TechnologyIJARBESTNo ratings yet

- Ijarbest Journal - Call For Editors - Aeronautical EngineeringDocument1 pageIjarbest Journal - Call For Editors - Aeronautical EngineeringIJARBESTNo ratings yet

- Ijarbest Journal - Call For Editors - Aeronautical EngineeringDocument1 pageIjarbest Journal - Call For Editors - Aeronautical EngineeringIJARBESTNo ratings yet

- John Deere 27Czts Compact Excavator Service Repair Manual (TM2053)Document17 pagesJohn Deere 27Czts Compact Excavator Service Repair Manual (TM2053)laopaodunNo ratings yet

- 2005 Acura 1.7ELDocument255 pages2005 Acura 1.7ELDEIDRE ANTONIETA BERNAL MORALESNo ratings yet

- 03 Indicator DiagramDocument37 pages03 Indicator DiagramnareshNo ratings yet

- Pages From Iom LPG Comp - Ie101hDocument8 pagesPages From Iom LPG Comp - Ie101hRamius HamdaniNo ratings yet

- Allis Chalmers I40 I400 Tractor Parts CatalogDocument20 pagesAllis Chalmers I40 I400 Tractor Parts Catalogjames100% (45)

- Thermal Engineering Lab ManualDocument64 pagesThermal Engineering Lab ManualERKATHIR86% (7)

- Controllable Pitch Propeller Pneumatics SystemDocument69 pagesControllable Pitch Propeller Pneumatics SystemBahari Prabowo Aji100% (1)

- Rod DropDocument7 pagesRod DropBabay HermawanNo ratings yet

- Machine Design Document SummaryDocument14 pagesMachine Design Document SummaryJeevanandam ShanmugaNo ratings yet

- BCM - Mechanical UNIT IV NOTESDocument22 pagesBCM - Mechanical UNIT IV NOTESKARTHICK MNo ratings yet

- Centro Matic PDFDocument52 pagesCentro Matic PDFfendixNo ratings yet

- Ac 43-11, Reciprocating Engine Overhaul, Terminology and StandardsDocument4 pagesAc 43-11, Reciprocating Engine Overhaul, Terminology and Standardsbobbyo56No ratings yet

- TP01 5Document1 pageTP01 5oussamaNo ratings yet

- The New SL-V Injector: SolutionsDocument8 pagesThe New SL-V Injector: SolutionsalvaroleivazNo ratings yet

- Overview Neumatic Cylinders of RexrothDocument26 pagesOverview Neumatic Cylinders of RexrothFrnd BrCrdsNo ratings yet

- Man Rider - Fa150 Kgi PartsDocument24 pagesMan Rider - Fa150 Kgi PartsLIVIANo ratings yet

- Catalytic ConverterDocument26 pagesCatalytic ConverterYash PatelNo ratings yet