Professional Documents

Culture Documents

The Oxidation of Niobium in The Temperature Range 450 176

Uploaded by

Ion AlbertoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Oxidation of Niobium in The Temperature Range 450 176

Uploaded by

Ion AlbertoCopyright:

Available Formats

The Oxidation of Niobium in the Temperature Range

450~176

J. S. Sheasby

Faculty of Engineering Science, The University of Western Ontario, London, Ontario, Canada

ABSTRACT

The oxidation properties of n i o b i u m were studied i n the t e m p e r a t u r e r a n g e

450~176

at oxygen pressures 1-760 Torr. P a r t i c u l a r emphasis was placed

on correlating the morphology of the reaction products with the oxidation

kinetics. During the initial, approximately parabolic oxidation period the

scale appears compact, and at the transition from parabolic to l i n e a r kinetics

the scale blisters and cracks. Scale formed d u r i n g l i n e a r oxidation grows i n a

series of crude layers. F r o m the relationships d e t e r m i n e d b e t w e e n the rate

of oxidation and the thickness of the oxide layers, it is deduced that the rate

of oxidation is controlled at all times by the diffusional properties of the

oxide layer in contact ,with the metal phase. The sensitivity of the rate of oxidation to oxygen pressure is ascribed to the pressure sensitivity of the u n d e r lying parabolic rate constant of formation of the n i o b i u m pentoxide, and to a

lesser extent to changes in the width of the oxide layers with the rate of

their formation. The inversion in the t e m p e r a t u r e coefficient of the oxidation

reaction as the t e m p e r a t u r e is lowered from 625~176

is associated with the

disappearance of layers of NbO and NbO2 from the reaction zone and the

appearance of a metastable platelet phase.

The oxidation behavior of n i o b i u m has been studied

b y m a n y workers, a n d the l i t e r a t u r e was reviewed

most recently by Seybolt (1). Niobium exhibits u n usual oxidation features, for at each t e m p e r a t u r e and

oxidation pressure the oxidation rate is found to follow a complex series of time laws. This paper describes

an investigation into the oxidation behavior of niob i u m in the t e m p e r a t u r e r a n g e 450~176

at oxygen

pressures n e a r atmospheric, for times from 2 m i n to

several hours. At times shorter than this, or for the

e q u i v a l e n t oxygen uptake at lower pressures, H u r l e n

(2) reports that the oxygen rate is time independent.

At reaction times longer than several hours a second

b r e a k a w a y reaction has been reported by Kolski (3)

and b y McLintock a n d Stringer (4).

The field u n d e r study is characterized b y a time

i n d e p e n d e n t rate (linear reaction rate law), which is

u s u a l l y preceeded by a short period of a p p r o x i m a t e l y

parabolic behavior. The linear reaction rate is pressure-sensitive and also decreases i n m a g n i t u d e as the

t e m p e r a t u r e is increased from 600 ~ to 625~ The m a jor part of the weight gain is associated with the form a t i o n of n i o b i u m - p e n t o x i d e although oxygen is also

consumed by the formation of lower or suboxides and

b y solution i n the m e t a l phase. Whereas there is good

a g r e e m e n t b e t w e e n previous studies on the rates of

oxidation and types of time laws observed at various

oxidation conditions, there is no agreement as to the

physical events and the n a t u r e of the rate controlling

steps associated with each stage. P a r t i c u l a r areas of

disagreement are: (i) the reaction products formed

d u r i n g parabolic oxidation, and the rate controlling

step; (ii) the m e c h a n i s m of the t r a n s i t i o n from p a r a bolic to linear oxidation kinetics; (iii) the r a t e - c o n trolling step d u r i n g l i n e a r oxidation; (iv) the mechanism of the rate inversion at 600~

Previous workers (2, 4, 5) have considered the high

pressure sensitivity of the oxidation rate and the

linear oxidation kinetics indicative of e q u i l i b r i u m

oxygen adsorption at an interface, followed by a phase

b o u n d a r y controlled reaction. However, Sheasby, W a l l work, and Smeltzer (6) have recently shown that in

the t e m p e r a t u r e r a n g e 720~176

the n i o b i u m p e n t oxide scale grows protectively, a n d that the parabolic

rate constant of its formation is pressure sensitive,

thus p e r m i t t i n g the pressure sensitive linear oxidation

kinetics to be rate controlled b y a b a r r i e r film mech-

anism. This paper describes the results of an investigation into this possibility.

Experimental

Specimens were cut in the form of squares approxi m a t e l y 1.1 cm 2 f r o m sheet 1 m m thick produced by

Fansteel. The specimens were prepared for oxidation

b y abrasion up to 600 grade silicon carbide paper, followed by electropolishing for 30 sec in a nitric acid

--30% hydrofluoric acid electrolyte at 24v using a

carbon cathode.

The kinetics of oxidation were e x a m i n e d using a

volumetric apparatus. E x p e r i m e n t a l r u n s were i n i t i ated by a d m i t t i n g oxygen to a specimen brought to

t e m p e r a t u r e u n d e r vacuum. Previous estimates of

specimen self-heating for this procedure gave a n

initial rise above the furnace t e m p e r a t u r e of about

30~ The specimens t h e n cooled to a steady value in

about 4 m i n to about 2~176 above the furnace t e m perature. For most of the experiments an oxygen

pressure of 380 Torr was used, and at this pressure a

1 cm m o v e m e n t of the m e r c u r y bead corresponds to

an oxygen u p t a k e of a p p r o x i m a t e l y 1.4 x 10 -5 g / c m 2.

At least two runs were made at each temperature, a n d

the rate constants so d e t e r m i n e d u s u a l l y agreed to

better t h a n 10%. After oxidation all the specimens

were e x a m i n e d metallographically. To obtain m i n i m u m loss of oxide the specimens were plunged while

still hot into c o l d - m o u n t i n g compound.

Experimental Results

Kinetic res~lts.---A series of specimens was oxidized at 380 Torr at a p p r o x i m a t e l y 25~ intervals over

the t e m p e r a t u r e r a n g e 450~176

to a weight gain of

about 0.01 g / c m 2. F u r t h e r specimens were oxidized

as r e q u i r e d for specific times, temperatures, and oxygen pressures.

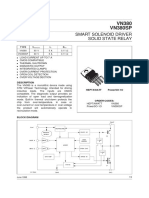

A typical weight gain curve in which initial protective behavior breaks away to a t i m e - i n d e p e n d e n t

reaction rate is shown in Fig. 1. A plot of (weight

gain) 2 vs. time for the protective period gives a good

fit to a straight line intersecting the time axis close

to the origin. The weight gain curves for the series of

specimens oxidized at 380 T o r t w e r e analyzed for

values of the reaction rate constants Kpv and Klv.

Where Kpv, the parabolic reaction rate constant, and

Klv, the l i n e a r reaction rate constant, are defined by

695

Downloaded on 2015-03-25 to IP 169.230.243.252 address. Redistribution subject to ECS terms of use (see ecsdl.org/site/terms_use) unless CC License in place (see abstract).

696

J. Electroche~n. Soc.:

ELECTROCHEMICAL SCIENCE

July 1968

20

720~

IO

7 5 0 m m Hg.

16

x

"

Kp v Volumetric

Kp 9 KI. X Wc

=~

z

<[

jU

(~ 8

v:c

~4

/;

. . . . .

IO

20

30

40

TIME

rains

50

,o

G'0

e

1"O

Fig. 1. Oxidation of niobium at 720~

I'1

~o ~

1'2

1"3

.~

1"4

I O 3 / TOK

750 Torr

Fig. 4. Dependence of the derived and measured parabolic rate

constants of oxidation of niobium at 380 Torr on temperature.

the equations

w ~ = Kpvt + a

rate constant Kp~ are shown in Fig. 4. No other values

have been reported for these reaction conditions.

w = Klvt + b

respectively; w is the weight of oxygen absorbed at

time t, and a and b are reaction constants.

It was found that below a p p r o x i m a t e l y 610~ the

protective period is too short to obtain a parabolic

rate constant, and below 550~

after the initial deviations of a p p r o x i m a t e l y 10-rain duration, the reaction rate tends to decrease slowly as oxidation proceeds, Fig. 2. This latter behavior has been reported

previously b y A y l m o r e et al. (7) a n d b y Cox and

J o h n s t o n (8) a n d will be discussed later. Values of

the linear rate constant K/v agree well with previous

investigations (Fig. 3), and in particular a decrease in

reaction rate is noted as the oxidation t e m p e r a t u r e is

increased from 600 ~ to 622~ Values of the parabolic

8

x

'j/jj

/ //

Metallographic

results.--The

principal reaction

product i n the r a n g e 10-760 T o r t 450~176

is ~ - n i obium pentoxide as designated b y Terao (9). Layers

of NbO and NbO2 are present at the metal surface on

specimens reacted above 620~

Below 600~ these

oxides are absent and are replaced by a platelet phase

t e n t a t i v e l y identified as the suboxide NbOz as design a t e d b y N o r m a n (10). The appearance or n o n a p p e a r ance of the e q u i l i b r i u m d i a g r a m oxides NbO a n d

NbO2 depends on the time, t e m p e r a t u r e , a n d pressure

of oxidation, and also on the local radius of c u r v a ture of the m e t a l - o x i d e interface. For instance, as

shown i n Fig. 5, for a specimen reacted at 626~ in

380 Torr oxygen, NbO and NbOs are stable on the

m a i n faces of the specimen, b u t not at the specimen

corners. The reaction conditions necessary for the formation of NbO and NbO2 are the subject of a c u r r e n t

study and will be reported later.

I n cross section the n i o b i u m pentoxide layer tends to

be thicker at specimen corners a n d edges t h a n on the

.~/

, ~

/ .~'is

7./

x/

2'o

~o

;o

TIME

(rain.)

~o

Fig. 2. Oxidation of niobium at 520~

curve B, 380 Torr; curve C, 150 Torr.

,;0

120

Curve A, 760 Torr;

X SHEASBY

9 KOFSTAD

& COX

iO"~=

r

o

&

~ld 8

7oo'c

I

1"O

6oo%

I

I'.1

112

11~3

1"4

IO3/T(~

Fig. 3. Dependence of the linear rate of oxidation of niobium

at 380 Torr on temperature. X This investigation, interpolated

values of 9 Kofstad et al. (1.3), a,d a Cox et al. (7),

Fig. 5. Cross section of specimen oxidized at 380 Torr, 626~

for 65 rain., showing abnormal edge effect. Magnification A

(top) ca. i00X, B (bottom) ca. 525X.

Downloaded on 2015-03-25 to IP 169.230.243.252 address. Redistribution subject to ECS terms of use (see ecsdl.org/site/terms_use) unless CC License in place (see abstract).

Vol. 115, No. 7

OXIDATION

OF NIOBIUM

F R O M 450~176

697

Fig. 6. Cross section of specimen oxidized at 380 Torr, 575~

for 32.5 min, showing normal edge effect. Magnification 125X.

m a i n faces (Fig. 6), thus p r e v e n t i n g too literal an

i n t e r p r e t a t i o n of the reaction rate constants measured

b y the v o l u m e t r i c apparatus. The n i o b i u m - p e n t o x i d e

layer on all the specimens contains lenticular fissures

parallel to the metal surface giving the scale a l a m i n a r appearance. W h e n the scale is formed from niob i u m containing platelets these fissures or pores tend

to be aligned, r u n n i n g at an angle of about 60 ~ to

the metal surface and occurring i n pairs to give a

chevron p a t t e r n superimposed on the l a m i n a t i o n s

(Fig. 7). This chevron p a t t e r n of pores p r o b a b l y has

the same origin as the similar structure in t a n t a l u m

iaentoxide scales described and discussed b y S t r i n g e r

(11).

L a m i n a t i o n s in n i o b i u m pentoxide scale layers

formed from NbO a n d NbO2 are thicker t h a n those

formed from n i o b i u m c o n t a i n i n g platelets. L o w e r i n g

the oxidation pressure or raising the t e m p e r a t u r e

tends to increase the thickness of these laminations

so that above 725~ the oxide is not layered (6). W h e n

viewed in polarized light the oxide scales formed

at the higher t e m p e r a t u r e s are seen to be composed of c o l u m n a r crystals with the long axis n o r m a l

to t h e plane of the laminations, Fig. 8d. Similar structures have been observed in scales formed at lower

temperatures, b u t in general the layer widths and

oxide grain size are too small to m a k e observation

possible. The c o l u m n a r grains are continuous over

m a n y laminations, indicating that w h e n the oxide

layered r e n u c l e a t i o n of oxide crystals was not necessary. I n fact, in only r a r e instances in the several

h u n d r e d specimens examined, has a structure been

observed i n which n e w oxide grains appear to have

nucleated b e n e a t h a pore.

Several series of specimens were oxidized for v a r i ous lengths of time at specific t e m p e r a t u r e s and oxygen pressures. Photomicrographs of one such series

oxidized at 720~ in oxygen at 750 Torr for times of

13, 28, 68, and 100 rain are shown in Fig. 8 ( a - d ) , a n d

the associated weight gain curve in Fig. 1. The scale

is black d u r i n g the period of the first parabola and i n

cross section appears compact, Fig. 8a. Deviation from

the parabola is accompanied b y the appearance of

Fig. 7. Cross section of specimen oxidized at 750 Torr, 600~

for 120 min, showing chevron markings superimposed on the laminations. Magnification 100X.

Fig. 8. Cross sections of specimens oxidized at 720~ 760 Torr:

a, 13 min; b, 28 rain; c, 68 min; d, 100 min. Polarized light.

Magnifications 75X.

yellow blisters on the scale, which i n cross section are

seen to be regions w h e r e the scale has become detached from the metal a n d reacted with oxygen to

become stoichiometric, Fig. 8b. It is to be noted that

the pores act as barriers to f u r t h e r oxidation, a n d t h a t

u n t i l the oxide cracks b e t w e e n the blisters a second

layer does not form. G r o w t h of the n e w coherent layer

continues u n t i l it in t u r n blisters, a n d the cycle r e peats. The first two of three layers often form sufficiently in phase to be evident i n the kinetic curves.

Later, all traces of u n e v e n n e s s are lost and the reaction rate is linear.

Other series reacted at lower t e m p e r a t u r e s showed

similar relationships b e t w e e n the morphology of the

reaction product and the associated weight gain curve.

However, below 600~ the shortness of the period of

initial n o n l i n e a r behavior, combined with the u n c e r tainties introduced b y the t e c h n i q u e of starting the

reaction and overheating of the specimen w h e n first

introduced to oxygen, p r e v e n t s q u a n t i t a t i v e analysis

Downloaded on 2015-03-25 to IP 169.230.243.252 address. Redistribution subject to ECS terms of use (see ecsdl.org/site/terms_use) unless CC License in place (see abstract).

J. Electrochem. Soc.: E L E C T R O C H E M I C A L

698

of either the volumetric or the metallographic m e a surements.

Analysis.--Because of the correlation b e t w e e n

the morphology of the oxide scale with the variations

i n the w e i g h t - g a i n curve it is proposed that this oxidation reaction is an excellent example of the class

of oxidation reactions k n o w n as "paralinear." The

layered oxide scale emanates from the growth of the

oxide to a critical thickness, cracking, and regrowth.

Throughout this cycle the rate of reaction is controlled

by diffusion across the l a y e r of oxide that is in the

process of growing.

The c o l u m n a r g r a i n structure of the layered oxide

indicates that there is no pause in the oxidation reaction associated with the nucleation of n e w oxide layers, On the other hand, the layer of oxide in contact

with the m e t a l phase was not observed to be significantly thicker than the other layers, though cooling

cracks make this observation less certain. It follows

t h a t the l i n e a r oxidation rate Klo should be related b y

the m e a n layer w i d t h Wc to the u n d e r l y i n g parabolic

rate constant Kp for the reaction (12), according to

the equation

Kp = K~o x Wc

This parabolic rate constant should have the same

value as that of the parabolic oxidation at the start

of the reaction as m e a s u r e d either by the volumetric

apparatus (Kp,) or metallographically. F u r t h e r m o r e ,

e v e n though the local l i n e a r rate constants KIo and

l a m i n a t i o n thicknesses as d e t e r m i n e d m e t a l l o g r a p h i cally can v a r y from point to point on a specimen, the

parabolic rate constant derived using the equation

above should h a v e the same value.

Measurements of the w i d t h of l a m i n a t i o n s i n the

n i o b i u m pentoxide scale were made at several points

on all specimens. It must be emphasized that p a r t i c u l a r l y at the lower t e m p e r a t u r e s the scale layers are

not clearly defined m a k i n g it e x t r e m e l y difficult to

measure We with a n y accuracy. D e t e r m i n a t i o n s from

the specimen shown i n Fig. 6 are given in Table I

where it can be seen that the derived parabolic rate

constants t e n d to increase as the local linear rate

constant increases. The higher values are associated

with the curved regions of the specimen and could

have been caused by two effects. First, the scale could

have cracked closer to the m e t a l at these points, and

second, m e a s u r e m e n t s m a d e at 750~ showed that the

parabolic rate constant of oxidation on a convex

metal surface could be enhanced 30% above that on

a flat surface. A p a r t from sites of more e x t r e m e edge

oxidation, values of K p derived from metallographic

m e a s u r e m e n t s t a k e n from a r o u n d a specimen g e n e r ally agreed to within 30% of a m e a n value. The derived parabolic rate constants of all the specimens reacted at 360 Torr as a function of (1/T~

are shown

in Fig. 4. Two lines c a n be d r a w n on this plot, the

h i g h - t e m p e r a t u r e line corresponding to specimens

with layers of NbO, a n d the l o w - t e m p e r a t u r e line to

specimens w i t h platelets. The data points at about

610~

b e t w e e n the two lines, were obtained from

specimens in which platelets formed initially, and only

later i n the reaction did a l a y e r of NbO stabilize. I n

Table I. Scale measurements on a specimen oxidized at 575~

at an oxygen pressure of 380 Tarr for 32.5 rnin. Linear reaction

rate as determined volumetrically, KIv, 5.16 x 10 - 6 g.cm2/sec

No. of layers

19

25

30

34

43

50

63

111

Layer thickhess Wc,/~

2.4

2.2

2.2

2.1

1.9

1.9

1.7

1.8

Local linear rate

of oxidation, KI

g/crn'~/sec

3.6

4.4

5.2

5.8

6.7

7.4

8.3

x 1 0 -~

x 10-~

x 10 -~

x 10 -6

x 10 -~

x 10-~

x lO-e

1 X 10 -6

Parabolic rate constant

Kp = Kl Wc X 1.56

ge/cm4/sec

1.4

1.5

1.7

1.9

2.0

2.2

2.2

4.4

x

x

x

x

x

x

10-s

10-s

10 -s

l0 s

1 0 -s

1 0 -8

l O -s

1 0 -s

SCIENCE

J u l y 1968

certain specimens this dual oxidation behavior persisted to the end of the run, Fig. 5, a n d values of Kp

could be t a k e n corresponding to the two extremes.

Discussion

F r o m the morphological and kinetic evidence presented the oxidation behavior of n i o b i u m i n the temp e r a t u r e r a n g e 450~176

and pressure range 1-760

Torr agrees both q u a l i t a t i v e l y a n d q u a n t i t a t i v e l y with

a "repeated-parabolic" or " p a r a l i n e a r " scaling model.

Differences in scaling behavior as the t e m p e r a t u r e is

lowered are to a large extent caused by a decreased

plasticity of the oxide. Above about 750~ the oxide

does not layer, and consequently the o v e r - a l l reaction rate is essentially parabolic (6). At an oxygen

pressure of 380 Torr at 720~ the oxide grows protectively to a thickness of about 40~, and as the t e m p e r ature is lowered to 625~ the protective thickness is

reduced to about 13~. Below 600~ the ini,tial oxide

grows to a thickness of only a few microns before

failing, possibly because the platelets promote cracking. D u r i n g this period of oxidation the n i o b i u m pe.ntoxide scale layer is growing by a m e c h a n i s m in which

oxygen is the p r e d o m i n a t e diffusing species. This is

evidenced by the sustained appearance of polishing defects from the initial p r e p a r a t i o n on the free oxide

surface. Calculations show that in this phase of the

reaction less t h a n 5% of the weight gain of a specim e n is associated with oxygen solution in the m e t a l

phase and the formation of sub or lower oxides. This

value decreases as the reaction proceeds.

After the onset of scale l a y e r i n g the reaction rate is

observed to be essentially linear. The excellent agreem e n t b e t w e e n the measured and calculated parabolic

rate constants above 625~ Fig. 4. confirms that the

rate of oxidation u n d e r these conditions is controlled

by the transport properties of the layer of oxide in

contact with the m e t a l phase. That is, the linear rate

of oxidation is not due to phase b o u n d a r y control, but

is the result of a repeated parabolic process. Below

625~ such direct confirmation of the oxidation m e c h anism is not available. However, the correlation of the

metallographic observations with inflections in the rate

curve, and the analysis of the enhanced oxidation at

specimen corners strongly supports the continued operation of a p a r a l i n e a r mechanism. There are no values

in the l i t e r a t u r e with which these calculated parabolic

rate constants can be directly compared, although they

appear to be a p p r o x i m a t e l y one order of m a g n i t u d e

faster t h a n those of G u l b r a n s e n and A n d r e w (13). It

is noted that below 625~ the oxides NbO a n d NbO2

are not present at the metal oxide interface as r e quired in their description of the oxidation reaction

by Cox and J o h n s t o n (8), b y Inouye (14), and b y

B l a c k b u r n (15).

The initial parabolic rate constants are k n o w n to

be sensitive to the oxidizing pressure (6). Further, it

has been observed both in this s t u d y and that of Kofstad and Kjollesdal (16), that the thickness of scale

laminations tends to increase as the oxidation pressure

is reduced. Hence the variation of both the l i n e a r rate

of reaction and the calculated parabolic rate is considered to e m a n a t e from these causes a n d not as a

result of phase b o u n d a r y control.

At t e m p e r a t u r e s below 550~

at some time well

after breakway, the rates of reaction tend to change

slowly to lower values. For example, in Fig. 2B, the

rate of reaction of a specimen reacted at 520~ at 380

Torr after 120 m i n has fallen to 0.6 that of the rate at

20 rain. This behavior has been reported previously

(7), and was considered to be due to a t h i c k e n i n g of

the b a r r i e r film. This could occur in two ways; the

average l a m i n a t i o n thickness Wc could increase, or the

l a m i n a t i o n thickness could r e m a i n constant b u t the

point at which a n e w l a m i n a t i o n forms could move

f u r t h e r from the metal-oxide interface. E x a m i n a t i o n

of oxidized specimens showed no evidence of a change

in l a m i n a t i o n w i d t h greater t h a n 0.85, whereas a

change of 0.6 is r e q u i r e d for the first mechanism. The

Downloaded on 2015-03-25 to IP 169.230.243.252 address. Redistribution subject to ECS terms of use (see ecsdl.org/site/terms_use) unless CC License in place (see abstract).

Vol. 115, No. ?

OXIDATION

OF

NIOBIUM

second m e c h a n i s m requires the l a m i n a t i o n of oxide

adjacent to the specimen to be up to 1.3 times thicker

t h a n the average. However, the l a m i n a t e d structure

is not sufficiently well defined, p a r t i c u l a r l y n e a r the

m e t a l - o x i d e interface where cooling effects are most

disruptive, for such a j u d g m e n t to be made. A n alternative m e c h a n i s m is proposed by Cox and J o h n s t o n

(8) to explain this reduction i n rate, in which the

reaction is p a r t i a l l y stifled b y restriction of the gas

flow due to the growth of the porous outer scale. In

growing the porous structure is altered so that the

restriction the scale presents to the gas attains a l i m i t ing value. S u b s e q u e n t oxidation would t h e n obey a

linear rate law and show a n almost linear dependence

of the rate on gas pressure. A central feature of t h e i r

a r g u m e n t s is that the pressure sensitivity of the reaction is a consequence of the porous plug character of

the scale, and not due to s u b s e q u e n t phase b o u n d a r y

or t r a n s p o r t steps. However, it can be seen in Fig. 2,

that oxidation is pressure sensitive from the start of

reaction, that is before a porous plug has been

formed. Hence it is considered that resistance to oxidation caused by the detached scale l a m i n a t i o n s is

only of secondary importance.

One of the most p r o m i n e n t characteristics of the

oxidation behavior of n i o b i u m is the decrease in reaction rate of specimens as the t e m p e r a t u r e is i n creased from 600~176

This behavior is most evident i n the values of the derived parabolic rate constant, where association with the lower t e m p e r a t u r e

line correlates with platelets in the specimen, and

association with the h i g h - t e m p e r a t u r e line correlates

with NbO (and p r o b a b l y NbO2) at the m e t a l - o x i d e

interface. The platelet phase has been considered in

some detail by Cox and Sheasby (17), concluding that

the platelets are a metastable phase, and that they

form d u r i n g reaction and not while the specimen is

being cooled to room temperature. These conclusions

are based on the following arguments.

1. Norman, Kofstad, a n d K r u d t a a (18) noted that

platelets only form from supersaturated solutions of

oxygen in niobium, and they could not prepare an

oxide with the same structure as the platelets by

m e l t i n g together the appropriate quantities of metal

and pentoxide.

2. On certain specimens reacted just above 600~

it is possible for platelets to form at one point on a

specimen and for layers of NbO and NbO2 to form at

another. The n i o b i u m pentoxide scale formed above

the platelet phase is always much thicker t h a n that

formed above the layers of lower oxides. Typical m i crohardness traces b e n e a t h two such regions are

shown in Fig. 9. Theoretical diffusion gradients were

i

]

i

i

i

630"C 750mm Hg.

-- - ??:'n:nder

NbO

37p

400 \ \

HARDNESS \ \

D.P.N.

T

300

--G

450~176

699

Fig. 10. Taper section of niobium oxidized at 600~ at an oxygen pressure of 750 Torr for 60 min, showing a band of platelets

in the metal phase; taper ratio approx. 10:1. Magnification 250X.

calculated assuming a linear rate of interface motion,

v a r y i n g only the hardness value corresponding to the

oxygen concentration at the metal-oxide interface to

optimize the fit to the e x p e r i m e n t a l points. As NbO is

the stable phase, the hardness of the metal in contact

with it, i.e., at zero depth on the b r o k e n curve, corresponds to the e q u i l i b r i u m level of saturation of oxygen in niobium. The hardness value u n d e r the platelet

phase extrapolates to a higher hardness v a l u e at the

surface, i n d i c a t i n g that the m e t a l is supersaturated

with oxygen in this region. As platelets are only found

w i t h i n the supersaturated zone they are a metastable

phase.

3. Platelets have n e v e r been observed b e n e a t h a

continuous l a y e r of NbO.

4. If platelets are present at the end of oxidation,

traces of their previous existence in the metal, as described by S t r i n g e r (11) for oxidized t a n t a l u m , are

observable in the layered n i o b i u m - p e n t o x i d e . Further,

p a r t i c u l a r l y in taper sections, it often appears that

the center of single platelets has been consumed by

the advancing m e t a l - o x i d e interface, Fig. 10. It is i m probable that platelets n u c l e a t i n g i n d e p e n d e n t l y d u r ing cooling would so often l i n e u p with each other on

either side of a region of pentoxide.

The presence of platelets in the reaction zone can

therefore be t a k e n as evidence that the metal is

supersaturated with oxygen with respect to NbO, the

n e x t stable phase on the e q u i l i b r i u m diagram. It follows that in these circumstances the n i o b i u m - p e n t o x i d e

adjacent to the metal phase will be supersaturated

with niobium. The oxidation rate has been shown to

be controlled by the diffusional properties of the

n i o b i u m - p e n t o x i d e layer in contact w i t h the m e t a l

phase. Hence it is proposed that the increase in oxidation rate observed above the platelet phase is due to

the enhanced oxygen concentration gradient present in

the n i o b i u m - p e n t o x i d e u n d e r these conditions.

Nb205

Under platelets

175,u Nb205

\ ~ \

~ \ \

FROM

Acknowledgments

The author is grateful to Mr. E. K o h n for his assistance with the e x p e r i m e n t a l work. The research was

supported by the National Research Council of Canada

a n d The U n i v e r s i t y of W e s t e r n Ontario.

Manuscript received Feb. 16, 1968..

\\

A n y discussion of this paper will appear in a Discussion Section to be published in the J u n e 1969 JOURNAL.

200

| (~- ~

20

DEPTH JJ

REFERENCES

A. U. Seybolt, Advances in Physics, 12, 1 (1963).

T. Hurlen, J. Inst. Metals, 89, 273 (1960-61).

T. L. Kolski, Trans. ASM, 55, 119 (1962).

C. H. McLintock and J. Stringer, J. Less Com~non

Metals, 2, 233 (1960).

5. D. W. Bridges a n d W. M. Fassell, This Journal, 103,

326 (1956).

6. J. S. Sheasby, G. R. W a l l w o r k and W. W. Smeltzer,

ibid., 113, 1225 (1966).

1.

2.

3.

4.

60

Fig. 9. Microbordness gradients under two different regions of

the same specimen.

Downloaded on 2015-03-25 to IP 169.230.243.252 address. Redistribution subject to ECS terms of use (see ecsdl.org/site/terms_use) unless CC License in place (see abstract).

700

J. Electrochem. Soc.: E L E C T R O C H E M I C A L

7. D. W. Aylmore, S. J. Gregg, a n d W. B. Jepson,

ibid., 107, 495 (1960).

8. B. Cox and T. Johnston, Trans. Met. Soc. AIME,

227, 36 (1963).

9. N. Terao, Japan, J. Appl. Physics, 2, 156 (1963).

1O. N. Norman, J. Less Common Metals, 4, 52 (1962).

11. J. Stringer, ibid., 11, 111 (1966).

12. J. Stringer, Met. Rev., 11, 113 (1966).

13. E. A. G u l b r a n s e n a n d K. F. A n d r e w , This JournaL,

105, 4 (1955).

SCIENCE

J u l y 1968

14. H. Inouye, " C o l u m b i u m Metallurgy," p. 649, Metals

Society, AIME, Conf. 1960.

15. P. E. Blackburn, This Journal, 109, 1142 (1962).

16. P. Kofstad a n d H. Kjollesdal, Trans. Met. Soc.

AIME, 221, 285 (1961).

17. G. W. Cox, Ph.D. Thesis, U n i v e r s i t y of N.S.W.

(1963).

18. N. Norman, P. Kofstad, a n d O. J. K r u d t a a , J. Less

Common Metals, 4, 124 (1962).

Insulator-Induced Conduction

Jerry M. Cantril and H. A. Pohl*

Department o$ Physics, Oklahoma State University, Stillwater, Oklahoma

ABSTRACT

The presence of i n s u l a t i n g particles, even those of higher resistivity t h a n

the liquid, was found to increase electrical conduction in several dielectrical

liquids. We believe this to be a general effect which will occur if the particles have a higher dielectric constant t h a n the liquid. I n particular, we observed i n several highly purified liquids (C C14 and toluene) that the c u r r e n t

conducted across a cylindrical electrode system was considerably e n h a n c e d

w h e n highly purified solids (e.g., p o l y v i n y l chloride, quartz, or sulfur) were

held against the smaller i n n e r electrode by dielectrophoretic force. A theory

for the effect is given. It emphasizes the effect of local field concentration

(field-focussing) by the particles. This "focussing" of the field in the liquid

acts to enhance carrier concentration and conduction since the conduction is i n

the n o n o h m i c space-charge-limited regime.

Solid particles with a dielectric polarization higher

t h a n that of the s u r r o u n d i n g liquid m e d i u m are pulled

dielectrophoretically into regions of highest field

strength. This effect has been used to accomplish

separations of solid particles in n o n u n i f o r m electric

fields (1-4). The present study has sought to i n q u i r e

e x p e r i m e n t a l l y as to what effect the deposition of solid

m a t e r i a l might have on electrical conduction t h r o u g h

the liquid.

The effects of particles on electrical conduction processes in liquids are as yet incompletely known. Conductive particles such as iron or wet particles such as

moist clay are k n o w n to play a n i m p o r t a n t role in dielectric b r e a k d o w n of liquids (6, 7). The role of i n sulating material particles in conduction in dielectric

liquids is less well known, especially at voltages well

below b r e a k d o w n values. Electrophoretic p h e n o m e n a

i n v o l v i n g the charging of particles and their subseq u e n t discharge after migration to an electrode are

well recognized (6,7). K o k (6) has expressed the

opinion that particles, themselves of a n insulating n a ture, have a negligible effect on c u r r e n t flow in liqquid dielectrics a n d t h a t their effect would be indistinguishable from the b a c k g r o u n d ionic current. Pohl

and Schwar (3) have suggested that rotational

B r o w n i a n motion of suspended particles m a y enhance

c u r r e n t flow by rotationally t r a n s p o r t i n g deposited

ions from the m e d i u m on the surface of the particles.

The effect on conduction due to i n s u l a t i n g particles

resting at an electrode has not been studied. I n the

case of p u r e l y ohmic conduction one would expect

the presence of particles of lower conductivity t h a n

the liquid to block c u r r e n t flow. Yet the earlier experiments of Pohl and Schwar had indicated that the

opposite might occur, and that the presence of i n s u l a t ing particles could enhance c u r r e n t flow in dielectric

liquids. The present work was u n d e r t a k e n to e x a m i n e

more q u a n t i t a t i v e l y the e x p e r i m e n t a l facts and to derive a theoretical u n d e r s t a n d i n g of them.

A somewhat distantly related p h e n o m e n o n is k n o w n

to occur in glow discharge tubes. W h e n the cathode is

entirely covered with a t h i n film of i n s u l a t i n g m a t e r i a l

* Electrochemical Society Active Member.

(5) a c u r r e n t increase is observed. The explanation

proposed was that a positive space charge was formed

either inside or at the surface of the i n s u l a t i n g m a t e riM, the positive charge being supplied by positive

ions from the gas plasma i n the tube. The r e s u l t a n t

high field in the i n s u l a t i n g layer pulled electrons

t h r o u g h it, some of which are emitted with high velocity into the conducting gas. This effect, as we shall

see, is different in an essential w a y from that which

we shall discuss for particles. The particles produce a

t h r e e - d i m e n s i o n a l p e r t u r b a t i o n in the electric field,

the film produces only a o n e - d i m e n s i o n a l one, a n d

different mechanisms are calIed into play.

The present experiments were conducted with p a r ticles held to an electrode in a n o n u n i f o r m field b y the

action of dielectrophoretic force. Great care was

t a k e n with regard to p u r i t y of the liquids and the

suspended particles. A c o m b i n a t i o n of exhaustive recycled sorption and electrical de-ionization was used

in a sealed test cell to achieve v e r y high p u r i t y and a

high degree of reproducibility. The experiments,

broadly speaking, were done using a slightly modified

form of dielectrophoretic technique with cylindrical

geometry (1-4). P o l y v i n y l chloride (PVC), sulfur, and

silicon dioxide were used as solids, carbon tetrachloride and carbon t e t r a c h l o r i d e - t o l u e n e m i x t u r e s were

used as liquids.

Experimental

Test system.--A schematic diagram of the test syst e m is shown in Fig. 1. The cell was designed so that

the purification system was i n t e g r a l w i t h it. The p u r i fication system comprised two parts; a sorption bed

of 6-12 mesh silica gel in the lefthand c h a m b e r of the

P y r e x glass cell, and a set of three concentric cylindrical stainless steel electrodes in the r i g h t h a n d c h a m ber. The latter electrodes were connected as shown to

a 45v battery. The central c h a m b e r served as the test

chamber. The sintered glass filter b e n e a t h the central

test c h a m b e r had a m a x i m u m pore size of 40-60~,

while that u n d e r the sorption bed had a m a x i m u m

pore size of 170-200~. The whole ceil was 21.6 cm high

and 14.0 cm wide. The chambers were constructed of

Downloaded on 2015-03-25 to IP 169.230.243.252 address. Redistribution subject to ECS terms of use (see ecsdl.org/site/terms_use) unless CC License in place (see abstract).

You might also like

- Brumm 1992Document14 pagesBrumm 1992bensNo ratings yet

- Fluxing Reactions of Sulphate and Carbonates (N Cement Clinkering. I. SystemsDocument7 pagesFluxing Reactions of Sulphate and Carbonates (N Cement Clinkering. I. SystemsQuách Hồng HàNo ratings yet

- (23 176 of Polycrystalline Nickel: On The Mechanism of Low-Temperature OxidationDocument5 pages(23 176 of Polycrystalline Nickel: On The Mechanism of Low-Temperature OxidationPaty ChiluisaNo ratings yet

- 10 1002@pssb 2221880227Document10 pages10 1002@pssb 2221880227Ruan JunNo ratings yet

- The Diffusivity of Hydrogen in NB Stabilized Stainless SteelDocument6 pagesThe Diffusivity of Hydrogen in NB Stabilized Stainless Steelmehrshad_mjNo ratings yet

- Electrical Properties in LaSrTiO A Potential AnodeDocument7 pagesElectrical Properties in LaSrTiO A Potential AnodeyohahaNo ratings yet

- On The Role of Ions in PECVD Deposition of SiO2Document19 pagesOn The Role of Ions in PECVD Deposition of SiO2hoodacctNo ratings yet

- TGA Limestone DegradationDocument18 pagesTGA Limestone DegradationTammie HendersonNo ratings yet

- High-efficiency CO2-to-fuels electrolysisDocument6 pagesHigh-efficiency CO2-to-fuels electrolysisEvonne ChingNo ratings yet

- 1 s2.0 S016727389700427X MainDocument9 pages1 s2.0 S016727389700427X MainMandal RupeshNo ratings yet

- Acidity and Basicity of Metal Oxide Surfaces 1 II. Determination by Catalytic Decomposition of IsopropanolDocument9 pagesAcidity and Basicity of Metal Oxide Surfaces 1 II. Determination by Catalytic Decomposition of Isopropanolnguyennha1211No ratings yet

- Effect of Electrolyte Temperature On The Polarization Characteristics of An Ai-Li-Cu-Mg Alloy Innaoh C Thakur and R BalasubramaniamDocument9 pagesEffect of Electrolyte Temperature On The Polarization Characteristics of An Ai-Li-Cu-Mg Alloy Innaoh C Thakur and R Balasubramaniamkk ooNo ratings yet

- Potassium Nitrate Decomposition Paper PURCHASED Fro Acs - Org Michaelstarr1969Document4 pagesPotassium Nitrate Decomposition Paper PURCHASED Fro Acs - Org Michaelstarr1969michaelstarr1969No ratings yet

- DR EN Diffusion and Solution at High Pe Res in 316L Stainless Steel and Nickel-Base Heat-Resistant Alloys N. Kishimoto, - MumDocument9 pagesDR EN Diffusion and Solution at High Pe Res in 316L Stainless Steel and Nickel-Base Heat-Resistant Alloys N. Kishimoto, - MumRitu Raj RamanNo ratings yet

- AkineticsandsurfaceWGS-Ross-1973 ImportDocument8 pagesAkineticsandsurfaceWGS-Ross-1973 ImportleonardoNo ratings yet

- Thermal characteristics of radioactive graphite-CuO-Na2CO3-K2CO3-NaCl-KCl systemDocument6 pagesThermal characteristics of radioactive graphite-CuO-Na2CO3-K2CO3-NaCl-KCl systemСергей АлексеевNo ratings yet

- J. Electrochem. Soc. 1954 Belle 339 42Document4 pagesJ. Electrochem. Soc. 1954 Belle 339 42Sutanwi LahiriNo ratings yet

- Molecular Orbital of Chemisorbed Carbon Monoxide: GeohgeDocument6 pagesMolecular Orbital of Chemisorbed Carbon Monoxide: GeohgeLuis M. MolinaNo ratings yet

- Electrochemical Impedance Models For Molten Salt Corrosion: C.L. Zeng, W. Wang, W.T. WuDocument15 pagesElectrochemical Impedance Models For Molten Salt Corrosion: C.L. Zeng, W. Wang, W.T. WuVictor SabNo ratings yet

- Kinetic Study of The Catalytic Reforming of Methane With Carbon Dioxide To Synthesis Gas Over Ni - La2O3 Catalyst PDFDocument8 pagesKinetic Study of The Catalytic Reforming of Methane With Carbon Dioxide To Synthesis Gas Over Ni - La2O3 Catalyst PDFMarcus NguyễnNo ratings yet

- Calcination of Nickel-Alumina CatalystsDocument4 pagesCalcination of Nickel-Alumina CatalystsAnonymous 4PuFzAR100% (1)

- Reith Oxidation of Na2so3Document7 pagesReith Oxidation of Na2so3cmegmhiNo ratings yet

- Jurnal Perancangan AlatDocument6 pagesJurnal Perancangan AlatFreeQueenNo ratings yet

- Oxidation of CopperDocument21 pagesOxidation of CopperAmeen ShahidNo ratings yet

- Interaction of Fluorine and NickelDocument30 pagesInteraction of Fluorine and NickelrrandommNo ratings yet

- Mali Bert 1997Document17 pagesMali Bert 1997Sudip BiswasNo ratings yet

- The Corrosion Behavior of 316L Stainless Steel in H S Environment at High TemperaturesDocument14 pagesThe Corrosion Behavior of 316L Stainless Steel in H S Environment at High Temperaturesthomas_v501925No ratings yet

- Kinetic Study of Third-Order Reactions of Nitric OxideDocument10 pagesKinetic Study of Third-Order Reactions of Nitric OxideSaviaNo ratings yet

- To Steam Electrolysis For Hydrogen ProductionDocument5 pagesTo Steam Electrolysis For Hydrogen ProductionAndres CamposNo ratings yet

- CO2 ReductionDocument6 pagesCO2 ReductionMarc LabataNo ratings yet

- Bolt ReliefDocument5 pagesBolt ReliefBob212121212No ratings yet

- AC Catalst PTDocument5 pagesAC Catalst PTJarretNo ratings yet

- Sodium Sulphate ConductivityDocument13 pagesSodium Sulphate Conductivitysandypu08No ratings yet

- Thermal properties and structure of LaSrCo1-xMnxO4 mixed oxidesDocument11 pagesThermal properties and structure of LaSrCo1-xMnxO4 mixed oxidesMahmoud ȜliNo ratings yet

- Dynamic Effect NPDocument4 pagesDynamic Effect NPPurwojatmiko HandokoNo ratings yet

- A Secondar Cooling Pattern For Preventing Surface Cracks of Continuous Casting SlabDocument9 pagesA Secondar Cooling Pattern For Preventing Surface Cracks of Continuous Casting SlabDarkprogNo ratings yet

- Absortion of H in SteelDocument7 pagesAbsortion of H in SteelAlberto SerranoNo ratings yet

- J. Krudtaa Central Institute For Industrial Research, Blindern, Oslo (Norway)Document9 pagesJ. Krudtaa Central Institute For Industrial Research, Blindern, Oslo (Norway)Milla GomesNo ratings yet

- 1984 - MORSE - MICHALOPOULOS - Chem - Rev - Spectroscopic Studies of The Jet-Cooled Nickel DimerDocument7 pages1984 - MORSE - MICHALOPOULOS - Chem - Rev - Spectroscopic Studies of The Jet-Cooled Nickel DimerAlejandra AwimbaweNo ratings yet

- 1967-Swisher - Solubility, Permeability and Diffusivity of Oxygen in Solid IronDocument6 pages1967-Swisher - Solubility, Permeability and Diffusivity of Oxygen in Solid IronDavid Hernández EscobarNo ratings yet

- The Mechanism of The Oxidation of Propene To AcroleinDocument9 pagesThe Mechanism of The Oxidation of Propene To AcroleinLeonardo BrunelliNo ratings yet

- Optical and Thermodynamic Properties of HgBa2CuO4+δ SuperconductorDocument30 pagesOptical and Thermodynamic Properties of HgBa2CuO4+δ SuperconductorpetrNo ratings yet

- Isothermal Compressibility of Aqueous Sodium Chloride, Magnesium Chloride, Sodium Sulfate, and Magnesium Sulfate Solutions From 0 To 45.deg. at 1 AtmDocument8 pagesIsothermal Compressibility of Aqueous Sodium Chloride, Magnesium Chloride, Sodium Sulfate, and Magnesium Sulfate Solutions From 0 To 45.deg. at 1 AtmMawareNo ratings yet

- Effect of Temperature On The Initial, Thermal Oxidation of ZirconiumDocument11 pagesEffect of Temperature On The Initial, Thermal Oxidation of ZirconiummmkzNo ratings yet

- 1 s2.0 0010938X9190045Q MainDocument12 pages1 s2.0 0010938X9190045Q MainDang MinhNo ratings yet

- National Academy of SciencesDocument6 pagesNational Academy of SciencesGenevieve HirschfeldNo ratings yet

- 支持信息 NiFe MOFs增强BiVO4光阳极的水氧化活性和稳定性 PDFDocument18 pages支持信息 NiFe MOFs增强BiVO4光阳极的水氧化活性和稳定性 PDFNing ZhangNo ratings yet

- ARTICLE Onthehigh TemperatureoxidationofnickelDocument26 pagesARTICLE Onthehigh TemperatureoxidationofnickelJimyVillaNo ratings yet

- Study of Ti-6Al-4V Alloy Spectral Emissivity Characteristics During Thermal Oxidation ProcessDocument8 pagesStudy of Ti-6Al-4V Alloy Spectral Emissivity Characteristics During Thermal Oxidation ProcessGiustNo ratings yet

- On The Mechanism of Oscillations in The Beating Mercury HeartDocument5 pagesOn The Mechanism of Oscillations in The Beating Mercury HeartGustavo Koiti YoshimuraNo ratings yet

- Thermal Conductivity of Multiwalled Carbon NanotubesDocument6 pagesThermal Conductivity of Multiwalled Carbon NanotubesAyad DariNo ratings yet

- Georgia Tech Sponsored ResearchDocument51 pagesGeorgia Tech Sponsored ResearchChristian SmallenNo ratings yet

- Cao Thermal ConductivityDocument4 pagesCao Thermal ConductivityKoteswara RaoNo ratings yet

- FKNJNDocument6 pagesFKNJNIlham Mahrojan SulaimanNo ratings yet

- Thermal Oxidation of SiDocument8 pagesThermal Oxidation of SiPrabal TiwariNo ratings yet

- Synthesis and Thermoelectric Properties of CoFe2-xCr xO4 NanoparticlesDocument3 pagesSynthesis and Thermoelectric Properties of CoFe2-xCr xO4 NanoparticlesRaveendra SannegowdaNo ratings yet

- Catalytic Reforming of Methane With Carbon Dioxide Over Nickel Catalysts II. Reaction KineticsDocument26 pagesCatalytic Reforming of Methane With Carbon Dioxide Over Nickel Catalysts II. Reaction KineticsDiego LVNo ratings yet

- CO Oxidation Studied Using Fast' XPS and A Molecular Beam ReactorDocument4 pagesCO Oxidation Studied Using Fast' XPS and A Molecular Beam ReactorDwi WidyawatiNo ratings yet

- Palandri, 1993 (J. Anal. Appl. Pyrolysis)Document12 pagesPalandri, 1993 (J. Anal. Appl. Pyrolysis)Alberto Moreno GomezNo ratings yet

- Pumps, Channels and Transporters: Methods of Functional AnalysisFrom EverandPumps, Channels and Transporters: Methods of Functional AnalysisNo ratings yet

- Analyse EDS 20190503Document352 pagesAnalyse EDS 20190503Ion AlbertoNo ratings yet

- Graphene Nanoplatelets Enhance PropertiesDocument2 pagesGraphene Nanoplatelets Enhance Propertiessujit_sekharNo ratings yet

- Faure2015 PDFDocument25 pagesFaure2015 PDFIon AlbertoNo ratings yet

- How To Use Image-JDocument198 pagesHow To Use Image-JHai Anh NguyenNo ratings yet

- Suspended Sludge and Biofilm ShapedDocument7 pagesSuspended Sludge and Biofilm ShapedIon AlbertoNo ratings yet

- Shaffer 1999Document5 pagesShaffer 1999Ion AlbertoNo ratings yet

- How To Process XRD Files in EVADocument6 pagesHow To Process XRD Files in EVAIon AlbertoNo ratings yet

- Analyse EDS 20190503Document352 pagesAnalyse EDS 20190503Ion AlbertoNo ratings yet

- Theoretical Models of Single Droplet Drying Kinetics: A ReviewDocument18 pagesTheoretical Models of Single Droplet Drying Kinetics: A ReviewIon AlbertoNo ratings yet

- The Principles and Practice of Electron MicrosDocument496 pagesThe Principles and Practice of Electron MicrosIon Alberto100% (1)

- Wayne CSAT-2 GFE June 18th 2013Document17 pagesWayne CSAT-2 GFE June 18th 2013Ion AlbertoNo ratings yet

- Simultaneous Removal of Aniline, Nitrogen and PhosphorusDocument8 pagesSimultaneous Removal of Aniline, Nitrogen and PhosphorusIon AlbertoNo ratings yet

- Paper 22241 Manuscript 3762 FinalDocument6 pagesPaper 22241 Manuscript 3762 FinalIon AlbertoNo ratings yet

- High Resistance Sns Sandwich TypeDocument3 pagesHigh Resistance Sns Sandwich TypeIon AlbertoNo ratings yet

- SiC Graphene NanoplateletsDocument7 pagesSiC Graphene NanoplateletsIon AlbertoNo ratings yet

- Anammox For Nitrogen Removal From Anaerobically Pre-TreatedDocument10 pagesAnammox For Nitrogen Removal From Anaerobically Pre-TreatedIon AlbertoNo ratings yet

- MCM41Document9 pagesMCM41Ion AlbertoNo ratings yet

- Simultaneous Removal of Aniline, Nitrogen and PhosphorusDocument8 pagesSimultaneous Removal of Aniline, Nitrogen and PhosphorusIon AlbertoNo ratings yet

- Synthesis and Performance of Iron Oxide-Based Porous CeramsiteDocument9 pagesSynthesis and Performance of Iron Oxide-Based Porous CeramsiteIon AlbertoNo ratings yet

- ConcreteDocument54 pagesConcreteMuhammad SafdarNo ratings yet

- 2012-Applied Clay Science-Z.zhang, Et Al.,-Potential Application of GeopolymersDocument6 pages2012-Applied Clay Science-Z.zhang, Et Al.,-Potential Application of GeopolymersIon AlbertoNo ratings yet

- Removal of Fluorescent Dissolved Organic MatterDocument6 pagesRemoval of Fluorescent Dissolved Organic MatterIon AlbertoNo ratings yet

- Detailed Programme ICSFSDocument4 pagesDetailed Programme ICSFSIon AlbertoNo ratings yet

- CeramicsDocument27 pagesCeramicsIon Alberto100% (1)

- Self HealingDocument22 pagesSelf HealingIon AlbertoNo ratings yet

- Glazes and Glazes CoatingDocument343 pagesGlazes and Glazes CoatingMar Yam80% (10)

- 5.lorentz lc100-m36 en 140603Document3 pages5.lorentz lc100-m36 en 140603Aliredha HamaidhanNo ratings yet

- Everyday Practical Electronics 1999-01Document86 pagesEveryday Practical Electronics 1999-01Wagner SilvaNo ratings yet

- SemiconductorDocument69 pagesSemiconductorSatheshNo ratings yet

- FreeRTOS V7.1.0 release notes with new ports and demosDocument32 pagesFreeRTOS V7.1.0 release notes with new ports and demoslna_cooolmadina5742No ratings yet

- ECE320 Chapter 3 PDFDocument23 pagesECE320 Chapter 3 PDFAhsan NisarNo ratings yet

- Motor ControlDocument36 pagesMotor Controldebraj1061100% (3)

- Power Electronics, Smart Grid and Renewable Energy SystemsDocument8 pagesPower Electronics, Smart Grid and Renewable Energy SystemsLuis Angel Garcia ReyesNo ratings yet

- 101Document11 pages101Superb HMNo ratings yet

- VN380 Smart Solenoid Driver SpecificationsDocument10 pagesVN380 Smart Solenoid Driver SpecificationsAdan Pérez EchevarríaNo ratings yet

- Datasheet 2Document2 pagesDatasheet 2Dung TranNo ratings yet

- UHF Power MOS Transistor: Important NoticeDocument16 pagesUHF Power MOS Transistor: Important NoticexoxovasNo ratings yet

- ES PaperDocument22 pagesES PaperRaghu Nath SinghNo ratings yet

- Q & A During L&T VisitDocument4 pagesQ & A During L&T VisitHarshitkumarNo ratings yet

- 1396767621physics Experiments 2013-14 Sec ADocument17 pages1396767621physics Experiments 2013-14 Sec AtishaprakashNo ratings yet

- IEEE STD C57.123-2002 IEEE Guide For Transformer Loss MeasurDocument35 pagesIEEE STD C57.123-2002 IEEE Guide For Transformer Loss MeasurkoolxiaNo ratings yet

- Complete Power ElectronicsDocument386 pagesComplete Power ElectronicsAnandu DipukumarNo ratings yet

- Handbook of Semiconductor Wafer Cleaning TechnologyDocument11 pagesHandbook of Semiconductor Wafer Cleaning Technologynothing4free0% (1)

- Compact smart relay data sheetDocument6 pagesCompact smart relay data sheetMircea MurarNo ratings yet

- Littelfuse Varistor LA Datasheet PDFDocument16 pagesLittelfuse Varistor LA Datasheet PDFjesusNo ratings yet

- Ponyprog Circuit For AVR& PIC16F84Document6 pagesPonyprog Circuit For AVR& PIC16F84tiensinh1No ratings yet

- MPPT Power PsocDocument14 pagesMPPT Power PsocgubiliNo ratings yet

- EDC 2 MarksDocument16 pagesEDC 2 Marksdr mbaluNo ratings yet

- Sgr15n40l / Sgu15n40lDocument8 pagesSgr15n40l / Sgu15n40lttmelonNo ratings yet

- All About OpampDocument46 pagesAll About OpampVamsi BobbaNo ratings yet

- Silicon N-Channel Power MOSFET CS4145 A8H Technical SpecificationsDocument10 pagesSilicon N-Channel Power MOSFET CS4145 A8H Technical SpecificationsHidayat KhanNo ratings yet

- Nano ChemistryDocument15 pagesNano ChemistryJani Basha100% (1)

- AT90USB1286Document39 pagesAT90USB1286Alan_88No ratings yet

- HVDC Terminal StationDocument28 pagesHVDC Terminal Stationmaka27No ratings yet

- Features: CMOS Voltage ConvertersDocument12 pagesFeatures: CMOS Voltage ConvertersAlexNo ratings yet

- Dry ContactsDocument2 pagesDry ContactsDiwakar MishraNo ratings yet