Professional Documents

Culture Documents

2015 Flowserve Educational Services Course Catalog

Uploaded by

dford8583Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2015 Flowserve Educational Services Course Catalog

Uploaded by

dford8583Copyright:

Available Formats

SERVICES AND SOLUTIONS

2015 Flowserve Educational Services

Course Catalog

Experience In Motion

Welcome to Flowserve Educational Services

Our Instructors

Maximized plant asset availability and equipment reliability

Increased mean time between repair (MTBR)

Workforce development for increasing proficiency in the

installation, maintenance, and repair of pumping equipment

and systems

Some of the most respected experts in pumps, valves, and seals are

on our instructional team, with more than 100 years of combined

experience in all aspects of flow control, in every industry from water

treatment to aerospace. Because of this breadth of experience, our

trainers have dealt with many of the specific engineering, operational

or mechanical problems youve experienced, and in most cases are

able to recreate and then solve those problems in our unique, handson power labs. Whether its at the Flowserve Learning Resource

Center in Irving, Texas, at Flowserve locations around the world or

on-site at your location, our instructors are dedicated to sharing their

knowledge with you.

Flexible Programs to Meet Any Need

Proficiency

Whether customers require basic training or customized

programs, Flowserve offers an unparalleled global network of

training experts and facilities to accommodate any request.

Customers can choose the location, course content, and program

formats that optimize the use of human and financial resources

and deliver the most effective results.

Flowserve proficiency recognizes that you have completed a specific

training course and have attained a level of competence with the

material. It also allows for a progression to higher proficiency levels

as your expertise grows. Flowserve proficiency is offered in pumps,

mechanical seals and pumping system analysis. The closed-book

proficiency exams are given on the morning following the last class day.

They contain about 60 questions and can take up to four hours. You

must attain a grade of 80 percent to achieve proficiency at each level.

Flowserve proficiency documents are presented to and remain with you.

The documentation states the level of proficiency you have attained and

the number of formal training hours dedicated to each class.

Flowserve Educational Services provides companies around

the world with a wide range of innovative programs focused on

helping plant operators, reliability engineers and maintenance

personnel deepen their understanding of pumping systems.

Training programs from Flowserve are ideal for organizations

aiming to achieve:

Learning Resource Centers (LRC)

Flowserve has committed to the construction and support of the

pumping industrys largest and most sophisticated network of

Learning Resource Centers. These state-of-the-art facilities ensure

participants receive a balanced combination of hands-on training

and operating theory.

On-site Customer Training

Flowserve Educational Services provides the design, development,

and delivery of training tailored specifically around the people,

equipment and processes at a customers location. Unlike

off-the-shelf solutions, trainers and instructional designers

deliver individualized instruction on the concepts, processes

and equipment needed to maximize employee performance in

the customers environment. To optimize the learning experience,

on-site training is supported by use of remote hydraulic lab

technology and portable acrylic pump systems.

Educational Credits

For classes offered at Flowserve Learning Resource Centers, their

successful completion and an 80% and above score on the exams

will earn the participant Continuous Educational Units (CEU) or

Professional Development Hours (PDH), respectively.

The educational credit certificate will be issued by McNeese

State University.

flowserve.com

Please read the following information before

registering for any classes!

Available Course Offerings

Depending upon the role of the student, Flowserve offers courses

ranging from those for the generalist to those who have obtained

engineering degrees. A comprehensive catalog of technical

and maintenance courses provides plant engineers, operators,

reliability experts and maintenance technicians with the training

they need on the equipment they use every day on location or

at Flowserve Learning Resource Centers.

Track One Basics Level

For Operations Personnel (OP)

This track is for persons involved in day-to-day operations and

for those who do not have an engineering or related technical

degree. Persons who want to understand more about pump and

seal basics should sign up for these classes. For example, those

involved in purchasing, training, human resources and safety or

similar occupations would want to consider this track.

Track Two Intermediate Level

For Maintenance Personnel (MP)

This track is for maintenance personnel. These persons would

have experience in maintaining and servicing pumps and seals

used in the processing systems of the plant. It would be helpful for

enrollees to have a few years of hands-on involvement as well.

Track Three Advanced Level

For Reliability Personnel (RP) and

Engineering Personnel (EP)

This track is for those who have an engineering degree or similar

education and background. These offerings are advanced courses

that do NOT cover pump and seal basics and assume the student

already has an engineering foundation. Beginners should not

sign up for these classes and are encouraged to look at the basics

classes offered in Track One.

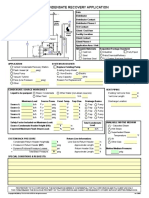

Course Registration Process

1. Get Organized

Carefully review the course descriptions, which can also

be obtained on our website in a more detailed format.

If you review courses on the website, note that some are

specifically designed for engineering, operations and

maintenance personnel. Since some of the courses are similar,

you may want to discuss your requirements with one of our

training coordinators or staff members.

2. Verify the Prerequisites

Some courses have prerequisites listed in the Course Description.

Please review them carefully. You must also have written and

spoken command of the English language, unless an alternate

language is listed.

3. Enroll in a Classroom Course or Purchase Online

Training

Simply follow the instructions below:

To register and purchase classroom courses and online training:

1. Go to www.Flowserve.com.

2. Click on the Services and Solutions tab at the top of the

page and then Education and Training.

3. Click on the Register button.

Classroom Courses:

1. You can view classroom course availability in different

regions by clicking on Classroom Courses and selecting

your preferred region.

2. To register, select Register in the Welcome area or log in

as a Guest in the box located on the top right side.

3. Note: If you are not the attendee, please register with

the attendees name.

To Enroll in a Classroom Course:

1. Click on Classroom Course to view all classes.

2. Click on your preferred region North America,

Europe, etc.

3. To view course description, click on subject title.

4. Click on down arrow to view available site locations

and dates.

5. Enter number of attendees.

6. To purchase, click on the Buy button.

Note: For Flowserve distributors and alliance customers,

please send an email to esg@flowserve.com for registrations or call

1-800-446-0401 and a customer care representative will assist you.

Online Training Courses:

1. Click on Online Courses to view all courses.

2. To view course description, click on subject title.

3. Enter number of purchases/attendees.

4. To purchase, click on the Buy button.

4. Make Travel Arrangements

Once your registration is processed, you will receive an email

notification of your class enrollment and location, along with

pertinent travel details to and from that location.

Since accommodations fill up quickly during the spring and fall,

we recommend that you book your hotel and airline reservations

as early as possible. When making travel arrangements,

please factor in your travel time to and from the airport to our

training facility for departures and arrivals. Please check with

your local training facility for information regarding departure

arrangements. We appreciate your flexibility and recommend

that you plan to remain at the course site until at least 4 p.m.

If possible, please purchase refundable tickets, since course

schedules sometimes change.

iStore Course Schedules and Locations

Payment and Cancellation Policy

Our courses are offered at various times throughout the year. For

our most current schedule, please visit: www.flowserve.com/

Services-and-Solutions/Education-and-Training.

Course payments should be made at the time of registration by

credit card, company check or purchase order (purchase order

number required). No fees will be charged for cancellation made

15 business days prior to the start of the class. There is a 100%

cancellation charge for cancellations less than 15 business days

prior to the start of the class. Additionally, there are no refunds

once the course begins.

Under Education and Training, click on the Register button to

view classroom sites, online training and create your account

to register. For additional training information, please call

1-800-446-0401 or email esg@flowserve.com. For technical

support related to iStore, please email esg@flowserve.com.

FLOWSERVE EDUCATIONAL SERVICES COURSE OFFERINGS AND LOCATIONS (AMERICAS & EUROPE)

Flowserve Facilities

Duration

Available On-Site

at Customer

Location

Centrifugal Pump Fundamentals

Mechanical Seal Fundamentals

Pump and Mechanical Seal Principles

Pump and Mechanical Seal Reliability

Pump System Analysis

Root Cause Analysis

Single-Stage Pump Repair

Multi-Stage Pump Repair

Pump and Seal Operator Training

Pump and Mechanical Seal Basics

Entry-level Vibration Training ISO Cat 1 Cert.

4

4

4

4

4

4

3

4

1

2

5

x

x

x

x

x

x

x (B)

x (B)

x

x

x

Vibration, Alignment and Balancing Basics

Vibration Category 2 Training

Vibration Category 3 Training

Pump and Seal Specialist 2

Troubleshooting and Operation for

Maintenance Staff

Product Training

Hydraulic Decoking

Ebullators

3

4

4

4

x

x

x

x

Custom (A)

MP/RP

Custom (A)

Custom (A)

Custom (A)

x

x

x

Custom

Custom

Custom

Course Description

Dallas

McNeese

Desio

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

South

America

TBD

Mexico

TBD

x

x

x

x

x

x

x

x

Typical

Attendee

RP/EP

RP/EP

ALL

RP/EP

RP/EP

ALL

MP/RP

MP/RP

OP

OP/MP

MP/RP

OP/MP

MP/RP

MP/RP

OP/MP

A. Customized depending on available customer equipment

B. Requires customer equipment for hands-on training

FLOWSERVE EDUCATIONAL SERVICES COURSE OFFERINGS AND LOCATIONS (ASIA PACIFIC)

Course Description

Flowserve Facilities

Singapore

CPTC

Suzhou,

China

Kawasaki,

Japan

Coimbatore,

India

Castlemaine,

Australia

Typical

Attendee

RP/EP

Centrifugal Pump Fundamentals

Mechanical Seal Fundamentals

Pump and Mechanical Seal Reliability*

OP/MP

Pump System Analysis

RP/EP

Root Cause Analysis

Single-Stage Pump Repair

Multi-Stage Pump Repair

*Formerly Pump and Seal Specialist 2 (PSS2)

Duration

Available

On-Site

at Customer

Location

RP/EP

ALL

MP/RP

flowserve.com

Legend

AA

Services Group

AA

Course

ESG

CPF

12412

IRV

LRC

Sample Course Code

Date

Location

Educational

Services Group

Course Acronym

Date

(MMDDYY)

Location

Facility Type

Element Description

(24 characters)

Facility Type

AA

Services Group

ESG

Educational

Course

Page

CPF

Centrifugal Pump Fundamentals

ELVT

Vibration Training

19

MSF

Mechanical Seal Fundamentals

MSPR

Multistage Pump Repair

10

PMSB

Pump and Mechanical Seal Basics

11

PMSP

Pump and Mechanical Seal Principles

12

PMSR

Pump and Mechanical Seal Reliability

13

POT

Pump and Seal Operator Training

14

PSA

Pump System Analysis

15

RCA

Root Cause Analysis

16

SSPR

Single-stage Pump Repair

17

VABB

Vibration/Alignment/Balancing Basics

18

B

Start Date

Date

(MMDDYY)

Location

BNG

Bangalore, India

CBT

Coimbatore, India

CHN

Chennai, India

CPTC

Chemical Process Technology Center

CSM

Castlemaine, Australia

DESIO

Desio, Italy

IRV

Irving, Texas, USA

KSW

Kashiwazaki, Japan

KWS

Kawasaki, Japan

LOU

McNeese University, Louisiana, USA

OSK

Osaka, Japan

SNG

Singapore

SZH

Suzhou, China

Facility Type

FMF

Flowserve Manufacturing Facility

LRC

Learning Resource Center

QRC

Quick Response Center

SAT

Satellite Location

CENTRIFUGAL PUMP FUNDAMENTALS (CPF) INTERMEDIATE LEVEL

Course Description

Course Objectives

An Intermediate Level course for engineers and

experienced reliability staff. This course provides an

in-depth understanding of centrifugal pump fundamentals. The

course is designed to provide a detailed explanation of how a

centrifugal pump is constructed and operated to achieve maximum

reliability. Selecting the right pump for a specific application

and identification of problems associated with pump operation

are determined through the use of pump curves and hydraulic

calculations.

Upon completion of this course, the participants will be able to:

Specific topics include:

Introduction to Pump Terms and Definitions

Basic Hydraulics

Net Positive Suction Head (NPSH), Recirculation, Cavitation

and Suction Conditions

Specific Speed, Suction Specific Speed

Performance Curves and Variable Operation

Viscosity

Centrifugal Pump Classification and Types

Bearings and Lubrication

Audience

This course is intended for individuals in the following fields:

applications engineering, reliability engineering and rotating

equipment engineering. Other experienced personnel requiring

knowledge of the design and operation of centrifugal pumps will

find this course helpful.

Understand how a centrifugal pump works

Understand the term head and how to calculate total system head

Be able to identify various pump types and components

Understand pump curves and generate a pump curve from data

collected at the pump

Understand the hydraulic loads created by a pump

Become familiar with affinity laws and how to apply them correctly

Become familiar with NPSH calculations and the effect suction

conditions have on pump performance

Be able to conduct the following calculations:

Total system head and Affinity Laws

NPSH available (NPSHA) for the system

Brake horsepower requirement

Viscosity corrections

Suction speed and suction specific speed

Become familiar with viscosity, specific gravity, and temperature

and their effect on pump performance and selection

Become familiar with basic vibration and how it relates to pump

performance

Prerequisites

It is recommended that participants have a bachelors or associates

degree and a basic math background. PMSB and PMSP are the

recommended prerequisites for other personnel.

Course Length

3 to 5 days. Varies by location.

Continued on next page

flowserve.com

North America Course Code Dallas LRC

Location

Code Name

Actual Dates

Duration

Dallas

ESG_CPF_012715_IRV_LRC_RES_ILT

01/27/2015 to 01/30/2015

Dallas

ESG_CPF_031015_IRV_LRC_RES_ILT

03/10/2015 to 03/13/2015

Dallas

ESG_CPF_042115_IRV_LRC_RES_ILT

04/21/2015 to 04/24/2015

Dallas

ESG_CPF_060215_IRV_LRC_RES_ILT

06/02/2015 to 06/05/2015

Dallas

ESG_CPF_071415_IRV_LRC_RES_ILT

07/14/2015 to 07/17/2015

Dallas

ESG_CPF_082515_IRV_LRC_RES_ILT

08/25/2015 to 08/28/2015

Dallas

ESG_CPF_092915_IRV_LRC_RES_ILT

09/29/2015 to 10/02/2015

Dallas

ESG_CPF_110315_IRV_LRC_RES_ILT

11/03/2015 to 11/06/2015

Dallas

ESG_CPF_120815_IRV_LRC_RES_ILT

12/08/2015 to 12/11/2015

McNeese

ESG_CPF_072115_LOU_SAT_RES_ILT

CPTC

ESG_CPF_010515_SNG_LRC_RES_ILT

01/05/2015 to 01/09/2015

Castlemaine

ESG_CPF_022315_CSM_LRC_RES_ILT

02/23/2015 to 02/27/2015

Suzhou

ESG_CPF_030215_SZH_LRC_RES_ILT

03/02/2015 to 03/06/2015

CPTC

ESG_CPF_030915_SNG_LRC_RES_ILT

03/09/2015 to 03/13/2015

Coimbatore

ESG_CPF_030915_CBT_LRC_RES_ILT

03/09/2015 to 03/13/2015

Suzhou

ESG_CPF_042015_SZH_LRC_RES_ILT

04/20/2015 to 04/24/2015

CPTC

ESG_CPF_051115_SNG_LRC_RES_ILT

05/11/2015 to 05/15/2015

Coimbatore

ESG_CPF_060815_CBT_LRC_RES_ILT

06/08/2015 to 06/13/2015

CPTC

ESG_CPF_081715_SNG_LRC_RES_ILT

08/17/2015 to 08/21/2015

Suzhou

ESG_CPF_081715_SZH_LRC_RES_ILT

08/17/2015 to 08/21/2015

CPTC

ESG_CPF_100515_SNG_LRC_RES_ILT

10/05/2015 to 10/09/2105

Suzhou

ESG_CPF_111615_SZH_LRC_RES_ILT

11/16/2015 to 11/20/2015

CPTC

ESG_CPF_113015_SNG_LRC_RES_ILT

11/30/2015 to 12/04/2015

North America Course Code McNeese University

07/21/2015 to 07/23/2015

Asia Pacific Course Code

South America Course Code

TBD*

TBD*

TBD*

TBD*

TBD*

Mexico Course Code

TBD*

Desio Course Code

Desio

ESG_CPF_012015_DESIO_LRC_RES_ILT

01/20/2015 to 01/23/2015

Desio

ESG_CPF_041415_DESIO_LRC_RES_ILT

04/14/2015 to 04/17/2015

Desio

ESG_CPF_050515_DESIO_LRC_RES_ILT

05/05/2015 to 05/08/2015

Desio

ESG_CPF_070715_DESIO_LRC_RES_ILT

07/07/2015 to 07/10/2015

Desio

ESG_CPF_091515_DESIO_LRC_RES_ILT

09/15/2015 to 09/18/2015

Desio

ESG_CPF_110315_DESIO_LRC_RES_ILT

11/03/2015 to 11/06/2015

*Please call the Flowserve Corporate office in Irving, Texas, for more information at +1 (972) 443-6500.

MECHANICAL SEAL FUNDAMENTALS (MSF) INTERMEDIATE LEVEL

Course Description

Course Objectives

An Intermediate Level course for engineers, technicians,

and experienced operators and maintenance staff. This

course explains the basic need for mechanical seal systems and

the theory behind how they work. Emphasis is placed not only on

the operation of mechanical seals, but also on the environment

where they operate (pump or other equipment) and the support

systems that help them survive. Additional topics include

materials of construction, fluid properties that affect seal selection,

seal specifications and reading seal drawings.

Upon completion of this course, the participants will be able to:

This course includes class time and laboratory exercises.

Students will assemble and disassemble pumps and seals as

well as operate pumps and monitor performance. Both team and

individual hands-on exercises are included.

Audience

This course is intended for maintenance and engineering

personnel that require a detailed explanation of mechanical

seal design, operation and maintenance. Engineers and other

reliability staff will find this to be a foundational class for

understanding complex problems relating to mechanical

seals and sealing systems.

Describe basic construction of a pump and its purpose

Describe the function of a seal within a pump

Discuss construction and design of various mechanical seals and

outline performance factors

Describe fluid principles and concepts relating to seal operations

Differentiate among various seal designs and configurations and

describe operations and appropriate applications

Understand various API/ANSI Piping Plans and select appropriate

plans based upon application and seal design

Discuss benefits and limitations of seal construction materials

according to application

Utilize a seal assembly drawing to locate key components and

measurements

Perform equipment condition checks and install a mechanical seal

Prerequisites

There are no prerequisites for this course, but it is recommended

students have a basic understanding of centrifugal pumps. PMSB is

helpful for those new to centrifugal pumps.

Course Length

3 to 5 days. Varies by location.

Continued on next page

flowserve.com

North America Course Code Dallas LRC

Location

Code Name

Actual Dates

Duration

Dallas

ESG_MSF_030315_IRV_LRC_RES_ILT

03/03/2015 to 03/06/2015

Dallas

ESG_MSF_041415_IRV_LRC_RES_ILT

04/14/2015 to 04/17/2015

Dallas

ESG_MSF_060915_IRV_LRC_RES_ILT

06/09/2015 to 06/12/2015

Dallas

ESG_MSF_072115_IRV_LRC_RES_ILT

07/21/2015 to 07/24/2015

Dallas

ESG_MSF_090115_IRV_LRC_RES_ILT

09/01/2015 to 09/04/2015

Dallas

ESG_MSF_102015_IRV_LRC_RES_ILT

10/20/2015 to 10/23/2015

Dallas

ESG_MSF_121515_IRV_LRC_RES_ILT

12/15/2015 to 12/18/2015

McNeese

ESG_MSF_091515_LOU_SAT_RES_ILT

CPTC

ESG_MSF_011215_SNG_LRC_RES_ILT

01/12/2015 to 01/16/2015

Suzhou

ESG_MSF_030215_SZH_LRC_RES_ILT

03/02/2015 to 03/06/2015

Coimbatore

ESG_MSF_031615_CBT_LRC_RES_ILT

03/16/2015 to 03/20/2015

CPTC

ESG_MSF_042015_SNG_LRC_RES_ILT

04/20/2015 to 04/24/2015

Suzhou

ESG_MSF_051815_SZH_LRC_RES_ILT

05/18/2015 to 05/22/2015

CPTC

ESG_MSF_082415_SNG_LRC_RES_ILT

08/24/2015 to 08/28/2015

Suzhou

ESG_MSF_082415_SZH_LRC_RES_ILT

08/24/2015 to 08/28/2015

CPTC

ESG_MSF_101215_SNG_LRC_RES_ILT

10/12/2015 to 10/16/2015

Castlemaine

ESG_MSF_110915_CSM_LRC_RES_ILT

11/09/2015 to 11/12/2015

Suzhou

ESG_MSF_112315_SZH_LRC_RES_ILT

11/23/2015 to 11/27/2015

CPTC

ESG_MSF_120715_SNG_LRC_RES_ILT

12/07/2015 to 12/11/2015

North America Course Code McNeese University

09/15/2015 to 09/17/2015

Asia Pacific Course Code

South America Course Code

TBD*

TBD*

TBD*

TBD*

TBD*

Mexico Course Code

TBD*

Desio Course Code

Desio

ESG_MSF_012715_DESIO_LRC_RES_ILT

01/27/2015 to 01/30/2015

Desio

ESG_MSF_033115_DESIO_LRC_RES_ILT

03/31/2015 to 04/03/2015

Desio

ESG_MSF_051215_DESIO_LRC_RES_ILT

05/12/2015 to 05/15/2015

Desio

ESG_MSF_063015_DESIO_LRC_RES_ILT

06/30/2015 to 07/03/2015

Desio

ESG_MSF_090815_DESIO_LRC_RES_ILT

09/08/2015 to 09/11/2015

Desio

ESG_MSF_111015_DESIO_LRC_RES_ILT

11/10/2015 to 11/13/2015

*Please call the Flowserve Corporate office in Irving, Texas, for more information at +1 (972) 443-6500.

MULTISTAGE PUMP REPAIR (MSPR) INTERMEDIATE LEVEL

North America Course Code Dallas LRC

Location

Code Name

Actual Dates

Duration

Dallas

Dallas

ESG_MSPR_022415_IRV_LRC_ESG_ILT

02/24/2015 to 02/27/2015

ESG_MSPR_042815_IRV_LRC_ESG_ILT

04/28/2015 to 05/01/2015

Dallas

ESG_MSPR_070715_IRV_LRC_ESG_ILT

07/07/2015 to 07/10/2015

Dallas

ESG_MSPR_091515_IRV_LRC_ESG_ILT

09/15/2015 to 09/18/2015

Dallas

ESG_MSPR_120115_IRV_LRC_ESG_ILT

12/01/2015 to 12/04/2015

Desio

ESG_MSPR_042715_DESIO_LRC_RES_ILT

Desio

ESG_MSPR_092915_DESIO_LRC_RES_ILT

Desio Course Code

04/27/2015 to 04/30/2015

09/29/2015 to 10/02/2015

Asia Pacific Course Code

Suzhou

10

ESG_MSPR_071315_SNG_LRC_RES_ILT

07/13/2015 to 07/17/2015

Course Description

Course Objectives

An Intermediate Level course for maintenance staff.

This course instructs participants on the proper procedures for

the preparation, rigging, disassembly, inspection and reassembly

of multistage centrifugal pumps equivalent to those used in most

industries. The pumps addressed include both horizontally split and

radially split pumps. Participants will be introduced to maintenance

and troubleshooting techniques that will enable them to diagnose,

predict and prevent common problems associated with these

pumps. They also will be instructed in the proper installation of

mechanical seal assemblies and the mechanical seal piping plans

that apply to multistage pumps. Additional topics covered include:

design, installation and effective operation of multistage centrifugal pumps, as well as the use of associated tools and measuring

equipment. Class time is divided into 40% classroom-based

lecture and 60% hands-on lab activities where students take part in

the disassembly and reassembly of actual pumps.

Upon completion of this course, the participants will be able to:

Audience

Course Length

Service, maintenance, machine repair, or engineering staff of an

industrial plant, institution or public utility which use multistage

pumps and related equipment. Individuals should have direct

involvement or responsibility for multistage pump installation,

performance and maintenance.

4 to 5 days. Varies by location.

Identify typical multistage pump designs and associated

applications

Demonstrate in logical order the major tasks for the disassembly/

assembly of a multistage centrifugal pump

Demonstrate routine maintenance and overhaul procedures

Inspect and determine when to replace and/or repair pump

components

Describe various troubleshooting procedures

Prerequisites

It is recommended that participants complete the SSPR course or

have equivalent field experience before attending this class.

Personal Protective Equipment

Safety toe shoes are required for this class.

flowserve.com

PUMP AND MECHANICAL SEAL BASICS (PMSB) BASICS LEVEL

North America Course Code McNeese University

Location

Code Name

McNeese

ESG_PMSB_051915_LOU_SAT_ESG_ILT

Actual Dates

Duration

05/19/2015 to 05/20/2015

Mexico Course Code

TBD*

TBD*

TBD*

*Please call the Flowserve Corporate office in Irving, Texas, for more information at +1 (972) 443-6500.

Course Description

Course Objectives

A Basics Level course for operators, craftsmen, and

entry-level engineers and technicians. This course

provides participants with the knowledge and skills needed to

understand the basics of pumps and mechanical seals. The course

curriculum is designed to provide a basic explanation of the parts

of the pump and mechanical seal and how they function together

to achieve maximum reliability.

Upon completion of this course, the participants will be able to:

Concepts and theory are taught in a classroom setting and then

reinforced with hands-on exercises using portable laboratories.

The class does not cover the disassembly and repair of centrifugal

pumps or mechanical seals.

Specific topics include:

Introduction to Pump Terms and Definitions

Construction of the Pump and the Function of Each Part

Basic Hydraulics, Head and Flow

Performance Curves

Net Positive Suction Head and Cavitation

Single Mechanical Seals

Dual Mechanical Seals

Basic Systems

Basic Troubleshooting

Demonstrate a basic understanding of how a centrifugal pump works

Explain pressures within a centrifugal pump and how mechanical

seals are affected by pump operation

Identify mechanical seal piping plans, their purpose and when

each is used

Review troubleshooting processes for determining causes

Prerequisites

It is recommended that participants have basic hands-on skills and

some experience with rotating equipment.

Course Length

Two days (16 hours)

Audience

This course is intended for those individuals starting their

careers in the following fields: pump maintenance, applications

engineering, reliability engineering and rotating equipment

engineering. Other personnel requiring knowledge or a refresher

on the basics of pumps and mechanical seals will benefit

from this training. Participants should have direct involvement

or responsibility for pump and mechanical seal installation,

operation, troubleshooting or maintenance.

11

PUMP AND MECHANICAL SEAL PRINCIPLES (PMSP) INTERMEDIATE LEVEL

North America Course Code Dallas LRC

Location

Code Name

Actual Dates

Duration

Dallas

Dallas

ESG_PMSP_021015_IRV_LRC_ESG_ILT

02/10/2015 to 02/13/2015

ESG_PMSP_032415_IRV_LRC_ESG_ILT

03/24/2015 to 03/27/2015

Dallas

ESG_PMSP_051915_IRV_LRC_ESG_ILT

05/19/2015 to 05/22/2015

Dallas

ESG_PMSP_070715_IRV_LRC_ESG_ILT

07/07/2015 to 07/10/2015

Dallas

ESG_PMSP_081815_IRV_LRC_ESG_ILT

08/18/2015 to 08/21/2015

Dallas

ESG_PMSP_100615_IRV_LRC_ESG_ILT

10/06/2015 to 10/09/2015

Dallas

ESG_PMSP_111715_IRV_LRC_ESG_ILT

11/17/2015 to 11/20/2015

McNeese

ESG_PMSP_031715_LOU_SAT_ESG_ILT

North America Course Code McNeese University

03/17/2015 to 03/19/2015

Mexico Course Code

TBD*

TBD*

TBD*

*Please call the Flowserve Corporate office in Irving, Texas, for more information at +1 (972) 443-6500.

Course Description

Course Objectives

An Intermediate Level course for engineers, technicians,

and experienced operators and maintenance staff.

This course provides participants with the knowledge and skills

needed to understand the basics of pumps, pumping systems and

mechanical seals. The course curriculum is centered on pump

and mechanical seal design, operation and maintenance, and is

made up of approximately 60% classroom and 40% laboratory

time. Concepts and theory are taught in a classroom setting

and then reinforced with hands-on exercises in the laboratories.

Participants utilize the laboratories (static displays and operational

pumps) to perform pump and seal settings through learning

experiments. Working in teams, attendees will be involved in

interactive discussions while they assemble, disassemble, test,

and document a variety of operational pumps and mechanical seals.

Upon completion of this course, the participants will be able to:

When combined with PMSR this course forms an excellent

curriculum for pump engineers and technicians.

Audience

Facility personnel who require basic understanding of centrifugal

pumps, pumping systems hydraulics and mechanical seals

are encouraged to attend this course. Specifically, millwrights,

mechanics, machinery technicians, engineers and maintenance

supervisors, as well as experienced operators, will benefit from

this training. Participants

should have direct

involvement or responsibility

for pump and mechanical

seal installation, operation,

troubleshooting or

maintenance.

12

Identify and describe basic centrifugal pump design

Identify and describe the basics of pumping system hydraulics

Identify classic cavitation, recirculation and Net Positive Suction

Head (NPSH)

Describe acceptable and preferred regions of pump operation,

including minimum flow, best efficiency point and runout

Describe impeller design as it relates to specific speed and suction

specific speed

Describe pump and system interaction

Identify and describe centrifugal pump types and designs

Identify and describe basic seal configurations

Describe how a mechanical seal operates

Describe the limitations of single mechanical seals

Identify and describe common mechanical seal piping plans

Prerequisites

PMSB or hands-on skills and some experience with rotating

equipment. Basic math skills are helpful.

Course Length

3 to 4 days. Varies by

location.

flowserve.com

PUMP AND MECHANICAL SEAL RELIABILITY (PMSR) INTERMEDIATE LEVEL

North America Course Code Dallas LRC

Location

Code Name

Actual Dates

Duration

Dallas

Dallas

ESG_PMSR_022415_IRV_LRC_ESG_ILT

02/24/2015 to 02/27/2015

ESG_PMSR_042815_IRV_LRC_ESG_ILT

04/28/2015 to 05/01/2015

Dallas

ESG_PMSR_062315_IRV_LRC_ESG_ILT

06/23/2015 to 06/26/2015

Dallas

ESG_PMSR_081115_IRV_LRC_ESG_ILT

08/11/2015 to 08/14/2015

Dallas

ESG_PMSR_102715_IRV_LRC_ESG_ILT

10/27/2015 to 10/30/2015

McNeese

ESG_PMSR_111715_LOU_SAT_ESG_ILT

North America Course Code McNeese University

11/17/2015 to 11/19/2015

Mexico Course Code

TBD*

TBD*

TBD*

Asia Pacific Course Code

Coimbatore

ESG_PMSR_020915_CBT_LRC_RES_ILT

02/09/2015 to 02/13/2015

CPTC

ESG_PMSR_032315_SNG_LRC_RES_ILT

03/23/2015 to 03/27/2015

Suzhou

ESG_PMSR_040615_SZH_LRC_RES_ILT

04/06/2015 to 04/10/2015

Coimbatore

ESG_PMSR_050415_CBT_LRC_RES_ILT

05/04/2015 to 05/08/2015

CPTC

ESG_PMSR_052515_SNG_LRC_RES_ILT

05/25/2015 to 05/29/2015

Suzhou

ESG_PMSR_062915_SZH_LRC_RES_ILT

06/29/2015 to 07/03/2015

CPTC

ESG_PMSR_072715_SNG_LRC_RES_ILT

07/27/2015 to 07/31/2015

CPTC

ESG_PMSR_091415_SNG_LRC_RES_ILT

09/14/2015 to 09/18/2015

Suzhou

ESG_PMSR_092115_SZH_LRC_RES_ILT

09/21/2015 to 09/25/2015

Coimbatore

ESG_PMSR_101915_CBT_LRC_RES_ILT

10/19/2015 to 10/23/2015

CPTC

ESG_PMSR_110215_SNG_LRC_RES_ILT

11/02/2015 to 11/06/2015

CPTC

ESG_PMSR_121415_SNG_LRC_RES_ILT

12/14/2015 to 12/18/2015

*Please call the Flowserve Corporate office in Irving, Texas, for more information at +1 (972) 443-6500.

Course Description

An Intermediate Level course for engineers, technicians,

and experienced operators and maintenance staff. This

course gives participants a better understanding of the interrelated

functions of the centrifugal pump, mechanical seal and complete

pumping system. Participants learn how to find and address

causes of poor pump and seal reliability. Course curriculum

centers on pump and seal troubleshooting and solutions.

Concepts and theory are taught in a classroom setting and then

reinforced with hands-on exercises in laboratories. This course

is 60% classroom and 40% laboratory time. Participants use

our laboratories pumps to perform exercises that demonstrate

the principles presented in the classroom. Working in teams, all

are involved in interactive discussions while they analyze and

document findings from the operation of laboratory equipment.

When combined with RCA this class forms an excellent curriculum

for reliability staff.

The target audiences are experienced operations and maintenance

personnel and entry-level engineering staff with one to three years of

plant experience.

Course Objectives

Upon completion of this course, the participants will be able to:

Explain how the interrelationship of centrifugal pumps, mechanical

seals and process systems affect equipment reliability

Evaluate symptoms to determine causes of failures associated with

centrifugal pumps and mechanical seals

Identify practical corrective procedures that can improve centrifugal

pump and mechanical seal reliability

Prerequisites

PMSP is a suggested prerequisite for this course for maintenance

and operations personnel. CPF and MSF are suggested prerequisites

for reliability and engineering personnel.

Audience

Course Length

This course builds upon information presented in PMSP.

3 to 5 days. Varies by location.

13

PUMP AND SEAL OPERATOR TRAINING (POT) BASICS LEVEL

North America Course Code McNeese University

Location

Code Name

McNeese

ESG_POT_052015_LOU_SAT_ESG_ILT

Actual Dates

Duration

05/20/2015

Course Description

A Basics Level course for operators, craftsmen, and

entry-level engineers and technicians. The purpose of this

program is to teach principles and procedures that will optimize

pump and seal life through proper operation. Participants will

identify causes of rotating equipment failure through operation and

discuss methods to make corrections.

Participants will interpret the sights and sounds of potential failure

and identify corrective actions. They will review proper start-up

and shutdown procedures and identify the purposes and functions

of critical pump and seal components.

Audience

All people or supervisors involved with the routine operation

of mechanically sealed equipment. Others who would benefit

include engineers responsible for the reliability of mechanical

seals and pumps.

Course Objectives

Upon completion of this course, the participants will be able to:

Explain how centrifugal pumps and mechanical seals operate

Identify causes of rotating equipment failure through improper

operation

Describe the function and operation of auxiliary equipment

Describe proper start-up and shutdown of equipment

Describe troubleshooting procedures which identify and correct

potential rotating equipment damage or failure

Prerequisites

It is recommended that participants have some experience with

rotating equipment.

Course Length

One day (8 hours)

14

flowserve.com

PUMP SYSTEM ANALYSIS (PSA) ADVANCED LEVEL

North America Course Code Dallas LRC

Actual Dates

Duration

ESG_PSA_020315_IRV_LRC_RES_ILT

02/03/2015 to 02/06/2015

ESG_PSA_050515_IRV_LRC_RES_ILT

05/05/2014 to 05/08/2015

Dallas

ESG_PSA_072815_IRV_LRC_RES_ILT

07/28/2015 to 07/31/2015

Dallas

ESG_PSA_092215_IRV_LRC_RES_ILT

09/22/2015 to 09/25/2015

Dallas

ESG_PSA_120115_IRV_LRC_RES_ILT

12/01/2015 to 12/04/2015

CPTC

ESG_PSA_041315_SNG_LRC_RES_ILT

04/13/2015 to 04/17/2015

Suzhou

ESG_PSA_070615_SZH_LRC_RES_ILT

07/06/2015 to 07/10/2015

Coimbatore

ESG_PSA_071315_CBT_LRC_RES_ILT

07/13/2015 to 07/17/2015

CPTC

ESG_PSA_080315_SNG_LRC_RES_ILT

08/03/2015 to 08/07/2015

CPTC

ESG_PSA_112315_SNG_LRC_RES_ILT

11/23/2015 to 11/27/2015

Desio

ESG_PSA_021015_DESIO_LRC_RES_ILT

02/10/2015 to 02/13/2015

Desio

ESG_PSA_060915_DESIO_LRC_RES_ILT

06/09/2015 to 06/12/2015

Desio

ESG_PSA_101315_DESIO_LRC_RES_ILT

10/13/2015 to 10/16/2015

Location

Code Name

Dallas

Dallas

Asia Pacific Course Code

Desio Course Code

Course Description

Audience

An Advanced Level course for engineers and

experienced maintenance and reliability staff. This course

provides an in-depth understanding of pump system analysis. The

course is designed to provide a detailed comprehension of how

to perform system evaluation and calculation to achieve optimum

system reliability.

This course is intended for senior maintenance personnel,

reliability engineers, rotating equipment engineers/specialists and

management personnel requiring knowledge of how to analyze

centrifugal pumping systems.

Specific topics include:

Total Energy in an Incompressible Liquid

Pump Total Head

Energy and Hydraulic Gradient

System Head Curves

System Head Curves for Branch-line Systems

Friction Head Losses Through Valves and Fittings

Pump Selection Criteria

Controlling Centrifugal Pumps

Measurements Using Controlling Systems

Machine Protection

Seal Flushing and Cooling

Parallel Operation and Series Operation

Variable Speed vs. Valve Control

Pump Nozzle Loads

Calculation of NPSHA

Driver Selection and Pump Critical Speeds

Suction and Discharge Piping

Course Objectives

Upon completion of this course, the participants will be able to:

Understand system curves

Calculate Total System Head

Be able to select the right pump for an application

Understand how the pump is controlled by flow control systems

Understand the influence of nozzle loads on system reliability

Assess suction conditions and be able to calculate the NPSHA

of a system

Define and understand the power requirement for a system

Understand critical speeds of pumps

Evaluate and analyze suction and discharge piping issues

Prerequisites

It is recommended that participants have already completed CPF

and have a minimum of three years of experience in pumps and

mechanical seals.

Course Length

4 to 5 days. Varies by location.

15

ROOT CAUSE ANALYSIS (RCA) INTERMEDIATE LEVEL

North America Course Code Dallas LRC

Location

Code Name

Actual Dates

Duration

Dallas

Dallas

ESG_RCA_021015_IRV_LRC_RES_ILT

02/10/2015 to 02/13/2015

ESG_RCA_041415_IRV_LRC_RES_ILT

04/14/2015 to 04/17/2015

Dallas

ESG_RCA_061615_IRV_LRC_RES_ILT

06/16/2015 to 06/19/2015

Dallas

ESG_RCA_081815_IRV_LRC_RES_ILT

08/18/2015 to 08/21/2015

Dallas

ESG_RCA_102015_IRV_LRC_RES_ILT

10/20/2015 to 10/23/2015

Dallas

ESG_RCA_121515_IRV_LRC_RES_ILT

12/15/2015 to 12/18/2015

McNeese

ESG_RCA_011315_LOU_SAT_ESG_ILT

Kawasaki

ESG_RCA_030215_KWS_LRC_RES_ILT

03/02/2015 to 03/06/2015

Singapore

ESG_RCA_051815_SNG_LRC_RES_ILT

05/18/2015 to 05/22/2015

Suzhou

ESG_RCA_061515_SZH_LRC_RES_ILT

06/15/2015 to 06/19/2015

Singapore

ESG_RCA_090715_SNG_LRC_RES_ILT

09/07/2015 to 09/11/2015

Coimbatore

ESG_RCA_111615_CBT_LRC_RES_ILT

11/16/2015 to 11/20/2015

North America Course Code McNeese University

01/13/2015 to 01/15/2015

Asia Pacific Course Code

Desio Course Code

Desio

ESG_RCA_021715_DESIO_LRC_RES_ILT

02/17/2015 to 02/20/2015

Desio

ESG_RCA_052615_DESIO_LRC_RES_ILT

05/26/2015 to 05/29/2015

Desio

ESG_RCA_102015_DESIO_LRC_RES_ILT

10/20/2015 to 10/23/2015

*Please call the Flowserve Corporate office in Irving, Texas, for more information at +1 (972) 443-6500.

Course Description

An Intermediate Level course for engineers, technicians

and reliability staff. This course provides an in-depth

understanding of Root Cause-mapping techniques. The course is

designed to provide detailed comprehension of how to perform

RCA to achieve the maximum bottom-line results, the resolution

of identified causes.

Specific topics include:

Introduction to and Purpose of Root Cause Analysis (RCA)

Elements of Root Cause Analysis

Define the Problem

Investigate Causes

Execute the Solution

Centrifugal Pump Failure Analysis and Troubleshooting

Mechanical Seal Failure Analysis and Troubleshooting

Case Studies used to exercise the skill and knowledge of

troubleshooting and RCA

When combined with PMSR this class forms an excellent

curriculum for reliability staff.

Audience

This course is intended for senior maintenance personnel,

16

reliability engineers, rotating equipment engineers/specialists and

management personnel requiring knowledge of identifying the

causes of centrifugal pump and mechanical seal failures.

Course Objectives

The objective of this course is to teach the participant how to identify,

analyze and eliminate a problem. Participants will have the requisite

skills and knowledge necessary to correctly select, accurately analyze

and obtain resolution to undesirable events. They will understand

how to perform all the facets of a complete and accurate Root Cause

Analysis using cause-mapping techniques.

Upon completion of this course, the participants will be able to:

Recognize, identify and describe a problem

Gather relevant and discard non-relevant information

Evaluate and analyze the problem symptoms and information to

arrive at the root cause of a problem

Define solutions to correct the problem

Prerequisites

There are no prerequisites for this class; however, students new

to centrifugal pumps will benefit from PMSB or PMSP.

Course Length

3 to 5 days. Varies by location.

flowserve.com

SINGLE-STAGE PUMP REPAIR (SSPR) BASICS LEVEL

North America Course Code Dallas LRC

Location

Code Name

Actual Dates

Duration

Dallas

Dallas

ESG_SSPR_031015_IRV_LRC_RES_ILT

03/10/2015 to 03/12/2015

ESG_SSPR_050515_IRV_LRC_RES_ILT

05/05/2015 to 05/07/2015

Dallas

ESG_SSPR_072815_IRV_LRC_RES_ILT

07/28/2015 to 07/30/2015

Dallas

ESG_SSPR_110315_IRV_LRC_RES_ILT

11/03/2015 to 11/05/2015

Singapore

ESG_SSPR_042715_SNG_LRC_RES_ILT

Singapore

ESG_SSPR_081115_SNG_LRC_RES_ILT

Asia Pacific Course Code

04/27/2015 to 04/30/2015

08/11/2015 to 08/14/2015

Desio Course Code

Desio

ESG_SSPR_042115_DESIO_LRC_RES_ILT

04/21/2015 to 04/23/2015

Desio

ESG_SSPR_092215_DESIO_LRC_RES_ILT

09/22/2015 to 09/24/2015

Course Description

Course Objectives

A Basics Level course for maintenance staff. This course

Upon completion of this course, the participants will be able to:

will provide participants with the knowledge and skills needed to

repair and maintain centrifugal pumps and understand the basics

of pumps, pumping systems and mechanical seal design. The

course is comprised of approximately 50 percent classroom and

50 percent laboratory time. Concepts and theory are taught in a

classroom setting and then reinforced with hands-on exercises.

Participants will use static displays and operational pumps to

perform pump and seal settings. Working in a team, they will

assemble, disassemble, and document a variety of operational

pumps and mechanical seals. Seminar texts and demonstrations

are generic to all vendors hardware.

Describe centrifugal pump operation and why they fail

Describe basic hydraulics and its impact on pump performance

Describe pump and system interaction

Explain basic functions of mechanical seals, how they work and

why they fail

Demonstrate accurate reading of precision measurement tools

Accurately interpret mechanical seal assembly drawings

Properly disassemble and inspect a centrifugal pump

Accurately measure critical pump dimensions using precision

instruments

Demonstrate proper bearing removal and installation

Audience

This course is for mechanics, millwrights and technicians in

facilities with single-stage centrifugal pumps. Attendees should

have direct involvement or supervisory responsibilities for pump

maintenance.

Prerequisites

It is recommended that participants have basic math skills and have

knowledge of safe work practices. The ability to read mechanical

drawings and use hand, measurement and power tools are a plus.

Personal Protective Equipment

Safety toe shoes are required for this class.

Course Length

3 to 4 days. Varies by location.

17

VIBRATION, ALIGNMENT AND BALANCING BASICS (VABB) INTERMEDIATE LEVEL

Desio Course Code

Location

Code Name

Desio

ESG_VABB_100615_DESIO_LRC_RES_ILT

Actual Dates

Duration

10/06/2015 to 10/09/2015

Course Description

An Intermediate Level course for reliability and

maintenance staff. This course is used to impart knowledge and

increase understanding about rotating equipment health and how

vibration analysis is used to determine condition of rotating

machinery. It will prepare personnel to more effectively interface

with customers and consultants who may be confused by industry

terms and jargon.

Audience

This course is intended for operating personnel, maintenance

personnel, and for those who wish to gain a general understanding

of vibration, alignment and balancing.

Course Objectives

Upon completion of this course, participants will have an

understanding of:

Maintenance practices

Vibration fundamentals

Vibration measurement

Spectrum analysis

Alignment and misalignment

Balancing of machines

18

Prerequisites

It is recommended that participants have already completed

PMSP and MSF.

Course Length

Four days (32 hours)

flowserve.com

VIBRATION TRAINING / ISO CATEGORY 1 CERTIFICATION (ELVT) BASICS LEVEL

Desio Course Code

Location

Code Name

Desio

ESG_ELVT_051915_DESIO_LRC_RES_ILT

Actual Dates

Duration

05/19/2015 to 05/22/2015

Course Description

A Basics Level course for maintenance and reliability

staff. The course focuses on periodic, single-channel data

collection and analysis for condition-based maintenance

programs. A foundation is established for in-depth understanding

of spectrum and waveform relationships.

Audience

This course is intended for personnel who are new to vibration

monitoring and analysis, and for personnel who have limited

vibration analysis experience.

Course Objectives

Upon completion of this course, participants will have an

understanding of:

Prerequisites

There are no prerequisites for this course.

Course Length

Four days (32 hours)

1X

Amplitude

Maintenance practices

Condition monitoring

Principles of vibration

Data acquisition

Equipment knowledge

Basic vibration analysis

ISO standards

1.5X

2.8X

2X

1.8X

3X

3.8X

Frequency (Orders)

19

Essentials: Site-Specific Information for Dallas, Texas

Hotel Arrangements

You are responsible for your hotel reservations and expenses.

Unless you are planning to stay at the hotel on Friday night,

plan on checking out before arriving at the training center Friday

morning. For the convenience of our Dallas trainees, we have made

arrangements with the Marriott Dallas/Fort Worth Airport to receive

a discounted rate. If you decide to book with this hotel, please call

1-800-228-9290 to make a reservation. A minimum of three (3)

nights must apply. The main address is:

Dallas Learning Resource Center

The Dallas Learning Resource Center is located in the heart of the

Dallas/Fort Worth Metroplex. This convenient location is within

minutes of the Dallas/Fort Worth International Airport.

Address

Dallas Learning Resource Center

8440 Freeport Parkway

Irving, Texas 75063 USA

Phone: +972 929 8800

Fax: +972 929 6501

Toll-Free: +888 489 2647

Reservations: +800 228 9290

Arrival at DFW Airport

Upon arrival at DFW Airport, please proceed to Baggage Claim.

The Marriott has a shuttle that departs and arrives on the sidewalk

outside of Baggage Claim.

4343 West Royal Lane

Suite 106

Irving, Texas 75063

Phone: +800 446 0401

Fax: +972 915 1600

Flight Arrangements

You are responsible for your own airfare and flight arrangements.

Since most classes begin at 8 a.m., please consider arriving

one day prior to your class. If youre flying out of the Dallas/Fort

Worth area on the last day of class, please make sure your flight

reservations are for a departure no earlier than 4 p.m.

Attire

The proper dress code for Flowserve students is business casual/

casual. Jeans, Dockers or casual pants and shirts are acceptable

for men; slacks or jeans are fine for women. To ensure your safety

in the labs, please refrain from wearing shorts, tank tops or opentoed shoes. Students will need to bring safety toe shoes for Singlestage Pump Repair (SSPR) and Multistage Pump Repair (MSPR).

Meals

We provide lunch for full-day classes; you are responsible for all

other meals.

20

Arrival at Love Field Airport

If you choose to fly into Love Field Airport, you must arrange for

a taxi or rental car.

flowserve.com

Essentials: Site-Specific Information for McNeese

The Institute for Industry Education Collaboration (IIEC)

The Institute for Industry Education Collaboration provides a

framework for McNeese State University to organize and expand

existing industry-university collaborations to enhance economic

development and cultural growth in this region and beyond. As

the liaison between industry and higher education, the IIEC seeks

to establish relationships with a strong emphasis on economic

development.

McNeese Learning Resource Center

The McNeese State University is a satellite facility for students

local to the Lake Charles, Louisiana, area.

The IIEC in collaboration with Flowserve has brought Flowservespecific courses to the Gulf Coast Flowserve satellite training site. At

this training facility, practicing engineers and technicians will receive

specialized hands-on training in pumps, valves and seals.

For registration and course information, please contact Educational

Services at the Flowserve Irving, Texas, facility.

Address

McNeese University

The College of Engineering & Engineering Technology

ETL 111

Beauregard Dr.

Lake Charles, Louisiana 70609

Phone: +337 475 5875

Fax: +337 475 5237

Part of the University of Louisiana system, McNeese State

University offers best practices and maintenance training

programs to Flowserve customers, distributors and employees

in the Lake Charles, Louisiana, area. The College of Engineering

& Engineering Technology is one of six colleges within the

university. It consists of two departments: Engineering and

Engineering Technology. Both Engineering and Engineering

Technology programs are nationally accredited by the

Accreditation Board for Engineering and Technology (ABET) Inc.

21

Essentials: Site-Specific Information for Desio

Airports

Milan Malpensa Airport

Linate Airport

Orio Al Serio Airport

Hotels

Desio Learning Resource Center

Based on the applied learning principles that drove the design

of the Learning Resource Center in Dallas, Texas, the LRC in

Desio-Milan, Italy, also offers best practices and maintenance

training programs to Flowserve customers, distributors and

employees. The LRC specializes in hands-on training in pumps,

valves and seals for engineers, operators, craftsmen and other

plant professionals.

The Desio LRC is equipped with:

One classroom which can conveniently host 24 people

One static/power lab

Test loop and control room

Address

Desio Learning Resource Center

Via Rossini, 90/92 20033 Desio (MI), Italy

Telephone Number: +39 0362 612535

Fax: +39 0362 303396

Transportation

The Desio LRC is located just 30 minutes from the Milan Main

Station or approximately 40 minutes by car from either Milan

Malpensa Airport or Linate Airport.

Taxi

Flowserve recommends:

Autonoleggio Vigan

Special fair rates have been negotiated.

Email address: autonoleggiovigano@libero.it

or

Easy Taxi

Email address: info@easytaxi.it

Link to reservations and special fair rates is:

http://www.easytaxi.it/aziende/flow-training

22

Flowserve recommends:

Hotel Royal Falcone Monza

Special rates have been negotiated.

C.so Milano 5, 20900 Monza (MB)

Phone: +39 039 2300187

Fax: +39 039 2300129

Website: http://www.royalfalcone.com/english/

Attire

The proper dress code for Flowserve students is business casual/

casual. Jeans, Dockers or casual pants and shirts are acceptable

for men; slacks or jeans are fine for women. To ensure your safety in

the labs, please refrain from wearing shorts, tank tops or open-toed

shoes. Students will need to bring safety toe shoes for Singlestage Pump Repair (SSPR) and Multistage Pump Repair (MSPR).

flowserve.com

Essentials: Site-Specific Information for Singapore

and Chemical Process Technology Center (CPTC)

Transportation

Singapore has a number of transportation services, including airport

shuttles, taxis, rental cars, buses and subway trains (MRT).

Grand Park City Hall Hotel to CPTC is approximately 35 minutes by

car. Return transfer services will be arranged from Grand Park City

Hall Hotel to the CPTC.

Hotels

Singapore offers a wide range of hotels with various ratings.

Flowserve recommends:

Singapore Learning Resource Center

Located in the heart of Jurong Island, Singapore, the CPTC is the

location where most of the Flowserve laboratory exercises are

conducted. The lab exercises provide participants an opportunity

to work with equipment which they will encounter in similar work

environments.

The CPTC is equipped with:

A classroom that can accommodate 20 participants

Static lab stations

Power lab stations

Cutaway pump and mechanical seal models

Address

Singapore Learning Resource Center

Flowserve Pte Ltd

10 Tuas Loop

Singapore 637345

Phone: +65 6771 0600, +65 6771 0632

Grand Park City Hall Hotel (4 stars)

10 Coleman Street

Singapore 179809

Phone: +65 6336 3456, Fax: +65 6339 9311

www.parkhotelgroup.com

A special Flowserve rate is available when registering at this hotel.

Airport

Singapore Changi International Airport

Weather and Attire

Singapore is a tropical country with temperatures ranging from

27C 32C all year long.

The proper dress code for Flowserve students is business casual/

casual. Jeans, Dockers or casual pants and shirts are acceptable

for men; slacks or jeans are fine for women. To ensure your safety

in the labs, please refrain from wearing shorts, tank tops or opentoed shoes.

CPTC

Flowserve Lab

81 Jurong Island Highway

Singapore 627837

23

Essentials: Site-Specific Information for China

Weather and Attire

Suzhou is a historical tourist city famous for its gardens, handicraft

embroideries, silks and other traditional delicacies. It offers

distinctive seasonal changes. Temperatures vary by season from

-2C in the winter to an average of 32C in the summer.

The proper dress code for Flowserve students is business casual/

casual. Jeans, Dockers or casual pants and shirts are acceptable

for men; slacks or jeans are fine for women. To ensure your safety

in the labs, please refrain from wearing shorts, tank tops or opentoed shoes. Students will need to bring safety toe shoes for Singlestage Pump Repair (SSPR) and Multistage Pump Repair (MSPR).

Hotels

China Learning Resource Center

The Suzhou Learning Resource Center is located in the Flowserve

Suzhou facility that includes three buildings, with a ground area of

14 000 square meters. This learning environment is supplemented

with spacious classrooms and state-of-the-art laboratories

where real-world equipment models are utilized to assist in the

visualization of situations found in daily work environments

through hands-on experience.

The LRC is equipped with:

Two classrooms that can accommodate 12 and 18 participants,

respectively

Cutaway pump and mechanical seal models

Innovative power lab stations that provide a wide variety of

experiments, including:

Pumps in series or parallel operation

Vibrations

Cavitation

Submergence

NPSH considerations

API piping plan set-ups

Address

Suzhou Learning Resource Center

FSG Suzhou Manufacturing Plant

No. 26 Lisheng Road, Suzhou Industrial Park

Suzhou 215021, Jiangsu Province, P.R. China

Phone: +86 512 6255 2388

Fax: +86 512 6255 3702

24

Suzhou offers a wide range of hotels with various ratings.

Flowserve recommends:

Grand Metro Park (Suzhou) Hotel (4 stars)

1355 Jijinhu Avenue, Suzhou Industrial Park, 210521

Phone: +86 512 62800666; Fax: +86 512 62920777

www.metroparkhotels.com/suzhou

A special Flowserve rate is available when registering at this hotel.

Airports and Transportation

Suzhou is one of the major cities in the Yangtze River Delta and

is located in the heart of many traffic routes. It can be reached

conveniently by buses, railways, etc. A subway train is under

construction and will be available in 2014. If you are traveling via air,

the following airports are suggested for your convenience:

Shanghai Hongqiao Airport (1.5-hour drive to Suzhou, mostly for

domestic trips and overseas trips to Japan and Korea)

Shanghai Pudong Airport (2.5-hour drive to Suzhou, mostly for

overseas trips)

Wuxi Airport (1-hour drive to Suzhou, for domestic trips only)

Airport shuttles to Suzhou are also available. Pickup services at a

special Flowserve rate are available to hotel registrants.

The Grand Metro Park Suzhou Hotel is within an approximately

5- to 10-minute walking distance of the Suzhou LRC. Morning

transportation services can be arranged from the hotel to the LRC

every morning.

flowserve.com

Essentials: Site-Specific Information for

Latin America

Hotels

So Paulo offers a wide range of hotels with various ratings.

Flowserve recommends:

Hotel Mercury So Caetano do Sul (4 stars)

(10 minutes by taxi to the LRC)

Hotel Mercury Santo Andre (4 stars)

(15 minutes by taxi to the LRC)

Website: www.mercure.com.br

Hotel IBIS Santo Andre (3 stars)

(15 minutes by taxi to the LRC)

Website: www.ibis.com.br

Latin America Learning Resource Center

Based on the applied learning principles that drove the design of

the Learning Resource Center in Dallas, Texas, the LRC in So

Caetano do Sul - So Paulo, Brazil, also offers best practices

and maintenance training programs to Flowserve customers,

distributors and employees in Latin America.

Attire

The proper dress code for Flowserve students is business casual/

casual. Jeans, Dockers or casual pants and shirts are acceptable

for men; slacks or jeans are fine for women. To ensure your safety

in the labs, please refrain from wearing shorts, tank tops or opentoed shoes.

The LRC specializes in hands-on training in pumps and seals

for engineers, operators and other plant professionals. The So

Caetano do Sul LRC is equipped with:

A classroom that can conveniently host 15 people

One static/power lab

Address

Latin America Learning Resource Center

Rua Tocantins, 128

CEP-09580-130 - So Caetano do Sul - So Paulo - Brazil

Phone: +55 11 2169-6338

Fax: +55 11 2169-6329

Airports and Transportation

The So Caetano do Sul LRC is located 75 minutes by car from

the Andre Franco Montoro International Airport (Old Guarulhos

International Airport) and approximately 30 minutes by car

from the Congonhas Airport (the Downtown Airport with local

inbound/outbound flights and also includes some flights to/from

Argentina).

25

Essentials: Site-Specific Information for Mexico

Airport and Transportation

The Flowserve LRC is located in the Flowserve facility in Tlaxcala,

Mexico. If you arrive at Mexico City International Airport, you will

need to take the Mexico - Puebla highway and then Puebla - Tlaxcala

highway to the Tlaxcala LRC, located about two hours from the airport.

While at training, Flowserve provides transportation from the LRC to

the hotel and back. You will be picked up at the hotel lobby at 7:30

every morning. Please be punctual.

Hotels

Flowserve recommends:

Mexico Learning Resource Center

Located in Tlaxcala, Mexico, the Learning Resource Center is the

location where training and laboratory exercises are conducted.

The Mexico LRC has developed several technical and maintenance

courses that enhance participants knowledge of fluid management

systems and rotational equipment. The lab exercises provide

participants an opportunity to work with equipment they will

encounter in similar work environments.

Our trainers have several years of experience working in fields

relevant to the training and will be a valuable resource to our

participants. At the end of the training, the participants will

undergo field and written testing in order to be appropriately

certified.

Safety

During laboratory exercises, participants must always wear

their personal safety equipment (safety glasses, earplugs and

shoes). You must not drive any equipment without the trainers

instructions. In the event of an evacuation, participants must meet

at assigned meeting points in each classroom.

Address

Mexico Learning Resource Center

Manzana 3, Lotes 2, 4, 6 y 8

Parque Industrial Xiloxoxtla, Tlaxcala

Santa Isabel Xiloxoxtla, Tlaxcala, Mxico 90180

Contact Information

No Altamirano

Human Resources and Official Coordinator

Phone: +52 246 46 5 2616

Mobile: +52 246 49 080 19

Email: naltamirano@flowserve.com

26

Hotel Mision San Francisco (5 stars)

(10 minutes from the LRC)

Plaza de la Constitucin Num. 17

Col. Centro Tlaxcala, Tlax. (Centro Histrico de la Cd. de Tlaxcala)

Phone: +52 246 46 2 60 22

www.hotelesmision.com

Hotel Mision Atlihuetzia (5 stars)

(20 minutes from the LRC)

Carretera Tlaxcala Apizaco Km 10

Santa Maria Atlihuetzia, Tlaxcala

Phone: +52 246 46 1 0000

www.hotelesmision.com

Schedule

Training is conducted during the week from Monday to Friday. The

training starts at 8 a.m. every morning and ends at 5 p.m. Lunch will

be served at 1 p.m. every afternoon at the Flowserve facility.

Medical Services

In case of illness, please contact the local human resources or LRC

personnel immediately. You will be directed to our on-site medical

doctor for a checkup.

flowserve.com

Notes

27

Dallas Learning Resource Center

4343 West Royal Lane

Suite 106

Irving, TX 75063 USA

Toll Free: +1 800 446 0401

Telephone: +1 972 915 1600

Desio Learning Resource Center

Via Rossini, 90/92

20033 Desio (MI) Italy

Phone: +39 0362 612535

Fax: +39 0362 303396

Singapore Learning Resource Center

Flowserve Private Limited

10 Tuas Loop

Singapore 637345

Phone: +65 6771 0600, +65 6771 0632

Chemical Processing Technology Center

Flowserve Lab

81 Jurong Island Highway

Singapore 627837

China Learning Resource Center

FSG Suzhou Manufacturing Plant

No. 26 Lisheng Road, Suzhou Industrial Park

Suzhou 215021, Jiangsu Province, P.R. China

Phone: +86 512 6255 2388

Fax: +86 512 6255 3702

Bulletin FSG-106g (E) October 2014. 2014 Flowserve Corporation

To find your local Flowserve representative:

For more information about Flowserve Corporation,

visit www.flowserve.com or call +1 937 890 5839.

flowserve.com

Latin America Learning Resource Center

Rua Tocantins, 128

CEP-09580-130 - So Caetano do Sul

So Paulo - Brazil

Phone: +55 11 2169-6338

Fax: +55 11 2169-6329

Mexico Learning Resource Center

Manzana 3, Lotes 2, 4, 6 y 8

Parque Industrial Xiloxoxtla, Tlaxcala

Santa Isabel Xiloxoxtla,

Tlaxcala, Mxico 90180

You might also like

- Accor - Door To Opportunity Procedure ManualDocument33 pagesAccor - Door To Opportunity Procedure ManualsarjeetarkanNo ratings yet

- Working at Heights Online Course OntarioDocument7 pagesWorking at Heights Online Course Ontariojcipchajd100% (2)

- Navedtra 14310 PDFDocument346 pagesNavedtra 14310 PDFskylancer-3441No ratings yet

- Accounting NotesDocument3 pagesAccounting NoteswangxjjNo ratings yet

- REsume For Teacher JobDocument4 pagesREsume For Teacher JobBavisetti Venkat100% (2)

- Tracer Survey of Agriculture GraduatesDocument12 pagesTracer Survey of Agriculture GraduateskitkatiktakNo ratings yet

- Pumps & MotorsDocument370 pagesPumps & MotorsStefano SquadraniNo ratings yet

- Resume For Student PilotDocument7 pagesResume For Student Pilotgt72k5e5100% (1)

- Hydraulics 130106180852 Phpapp02Document257 pagesHydraulics 130106180852 Phpapp02hagh_mostafa2787No ratings yet

- Work at Height Rescue Course SingaporeDocument8 pagesWork at Height Rescue Course Singaporebcqta9j6100% (2)

- Pumpsmotors PDFDocument256 pagesPumpsmotors PDFfalcon724No ratings yet

- Facilitator GuideDocument59 pagesFacilitator Guideapi-430578422No ratings yet

- Rotating Equipment Specialist Program: Providing Quality Customer Support WorldwideDocument2 pagesRotating Equipment Specialist Program: Providing Quality Customer Support Worldwidepiping777No ratings yet

- Chairman Message:: Eng. Ahmed El Gayar Chairman & CEO AFCDocument66 pagesChairman Message:: Eng. Ahmed El Gayar Chairman & CEO AFCAbu Qir FertilizerNo ratings yet

- Script..Demo Achilles AdlawanDocument3 pagesScript..Demo Achilles AdlawanAchilles Gem J. AdlawanNo ratings yet

- Working at Heights Refresher Course OnlineDocument8 pagesWorking at Heights Refresher Course Onlinelozuzimobow3100% (2)

- ASHRAE Certification Programs Frequently Asked Questions: (Last Revised 9 March 2011)Document4 pagesASHRAE Certification Programs Frequently Asked Questions: (Last Revised 9 March 2011)Vincent DavidsonNo ratings yet

- P2 P Training Guide v2.0.3Document6 pagesP2 P Training Guide v2.0.3Timothy MunhengaNo ratings yet

- Comprehensive Master's ExaminationDocument8 pagesComprehensive Master's ExaminationHazem FarwatiNo ratings yet

- Aircraft Reliability and Maintenance Cost NadeemDocument4 pagesAircraft Reliability and Maintenance Cost NadeemSyedNadeemAhmedNo ratings yet

- Training Specialist ResumeDocument4 pagesTraining Specialist Resumejgsjzljbf100% (2)

- HR PPT FinalDocument41 pagesHR PPT Finalbaweja1No ratings yet

- 2014 Technician Training CatalogDocument29 pages2014 Technician Training CatalogCamilo Andres Tabares100% (1)

- Trainig Center - Technical Rescue Training Hurdles and Solutions How To Fund and Run Handson Training CenterDocument9 pagesTrainig Center - Technical Rescue Training Hurdles and Solutions How To Fund and Run Handson Training CenterGaudencio BoniceliNo ratings yet

- Access Course CourseworkDocument7 pagesAccess Course Courseworknjoqvnjbf100% (2)

- Technical ProposalDocument27 pagesTechnical Proposalshivam03454No ratings yet

- ULC College Algebra and Problem Solving Course Syllabus Course OverviewDocument5 pagesULC College Algebra and Problem Solving Course Syllabus Course OverviewUser nameNo ratings yet

- Training - FAQ - EN - ALEDocument8 pagesTraining - FAQ - EN - ALEPedro FrançaNo ratings yet

- Course Guide V02 GBDocument4 pagesCourse Guide V02 GBcreatorusNo ratings yet

- OLM Users Guide ManagersDocument18 pagesOLM Users Guide Managersoracle.7760% (1)

- Vocational TrainingDocument11 pagesVocational Traininglaisa13abgaoNo ratings yet

- Welcome Kit DeveloperDocument5 pagesWelcome Kit DeveloperjosephjanisNo ratings yet

- Hydraulics PDFDocument257 pagesHydraulics PDFMuhtiarNo ratings yet

- t2174-360-03 SG-Ins Lec ENDocument318 pagest2174-360-03 SG-Ins Lec ENTaru LucianNo ratings yet

- 2012 SABS Training BrochureDocument58 pages2012 SABS Training Brochuredarl1No ratings yet

- CTP Study GuideDocument11 pagesCTP Study GuideicebumpNo ratings yet

- Work at Height Assessor Course SingaporeDocument8 pagesWork at Height Assessor Course Singaporeafjwdprlzaxewj100% (2)

- Guidance For C.WEMDocument6 pagesGuidance For C.WEMHesham TaherNo ratings yet

- T3904-390-02 SG-Ins Lec EN PDFDocument383 pagesT3904-390-02 SG-Ins Lec EN PDFBrunoPanuto100% (1)

- SWBT Guide Reviewer For InterviewDocument4 pagesSWBT Guide Reviewer For InterviewMARJORIE BIBONNo ratings yet

- OMESOL Training Catalogue Global-1Document47 pagesOMESOL Training Catalogue Global-1pkgarg_iitkgpNo ratings yet

- Mat 170 Course SyllabusDocument5 pagesMat 170 Course SyllabuskrishNo ratings yet

- EOC Trainees Manual - UpdatedDocument56 pagesEOC Trainees Manual - UpdatedMa. Cristina RanadaNo ratings yet

- Work at Height Course For AssessorsDocument4 pagesWork at Height Course For Assessorsujsqjljbf100% (2)

- Hydraulic Principles: Continuing Education Professional Development CourseDocument288 pagesHydraulic Principles: Continuing Education Professional Development CourseMahmoud I. MahmoudNo ratings yet

- Pumping PrinciplesDocument384 pagesPumping PrinciplesMahmoud I. Mahmoud100% (1)

- FLP2443 Diploma For Ship & Port Agents HA101Document6 pagesFLP2443 Diploma For Ship & Port Agents HA101Mohamed Salah El DinNo ratings yet

- Fast Track BrochureDocument6 pagesFast Track BrochureNagendra Singh RanawatNo ratings yet

- Jee Course Brochure 2013Document36 pagesJee Course Brochure 2013Victor IkeNo ratings yet

- Work at Height Course For WorkersDocument5 pagesWork at Height Course For Workersvepybakek1t3100% (2)

- C.S. Foundation Programme - Study and ExaminationDocument12 pagesC.S. Foundation Programme - Study and ExaminationSathya PramodNo ratings yet

- CPIM - StructureDocument4 pagesCPIM - StructureManeesh JhaNo ratings yet

- Yokogawa Training Centre UaeDocument32 pagesYokogawa Training Centre UaeSerdar AksoyNo ratings yet

- Facilitating ScriptDocument7 pagesFacilitating ScriptRonald Sillana100% (1)

- HydraulicsDocument300 pagesHydraulicsChitranjan Kumar100% (2)

- Refrigerating Machine Operator: Passbooks Study GuideFrom EverandRefrigerating Machine Operator: Passbooks Study GuideNo ratings yet