Professional Documents

Culture Documents

ASME Sec IX Groove To Fillet Weld

Uploaded by

Azhar AliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASME Sec IX Groove To Fillet Weld

Uploaded by

Azhar AliCopyright:

Available Formats

ASME BPVC.

IX-2015

QW-202

TYPE OF TESTS REQUIRED

(c) Qualification for Fillet Welds. WPS qualification for

fillet welds may be made on grooveweld test coupons

using test specimens specified in (a) or (b). Filletweld

procedures so qualified may be used for welding all thicknesses of base metal for all sizes of fillet welds, and all diameters of pipe or tube in accordance with Table

QW-451.4. Nonpressureretaining fillet welds, as defined

in other Sections of the Code, may as an alternate be qualified with fillet welds only. Tests shall be made in accordance with QW-180. Limits of qualification shall be in

accordance with Table QW-451.3.

QW-202.1 Mechanical Tests. The type and number

of test specimens that shall be tested to qualify a groove

weld procedure are given in QW-451, and shall be removed in a manner similar to that shown in Figures

QW-463.1(a) through QW-463.1(f). If any test specimen

required by QW-451 fails to meet the applicable acceptance criteria, the test coupon shall be considered as

failed.

When it can be determined that the cause of failure is

not related to welding parameters, another test coupon

may be welded using identical welding parameters.

Alternatively, if adequate material of the original test

coupon exists, additional test specimens may be removed

as close as practicable to the original specimen location to

replace the failed test specimens.

When it has been determined that the test failure was

caused by an essential or supplementary essential variable, a new test coupon may be welded with appropriate

changes to the variable(s) that was determined to cause

the test failure. If the new test passes, the essential and

supplementary variables shall be documented on the

PQR.

When it is determined that the test failure was caused

by one or more welding related factors other than essential or supplementary essential variables, a new test coupon may be welded with the appropriate changes to the

welding related factors that were determined to cause

the test failure. If the new test passes, the welding related

factors that were determined to cause the previous test

failure shall be addressed by the organization to ensure

that the required properties are achieved in the production weldment.

Where qualification is for fillet welds only, the requirements are given in QW-202.2(c); and where qualification

is for stud welds only, the requirements are given in

QW-202.5.

QW-202.2

QW-202.3 Weld Repair and Buildup. WPS qualified

on groove welds shall be applicable for weld repairs to

groove and fillet welds and for weld buildup under the

following provisions:

(a) There is no limitation on the thickness of base metal or deposited weld metal for fillet welds.

(b) For other than fillet welds, the thickness range for

base metal and deposited weld metal for each welding

process shall be in accordance with QW-451, except there

need be no upper limit on the base metal thickness provided qualification was made on base metal having a

thickness of 11/2 in. (38 mm) or more.

QW-202.4 Dissimilar Base Metal Thicknesses. WPS

qualified on groove welds shall be applicable for production welds between dissimilar base metal thicknesses

provided:

(a) the thickness of the thinner member shall be within

the range permitted by QW-451

(b) the thickness of the thicker member shall be as

follows:

(1) For PNo. 8, PNo. 41, PNo. 42, PNo. 43, PNo.

44, PNo. 45, PNo. 46, PNo. 49, PNo. 51, PNo. 52,

PNo. 53, PNo. 61, and PNo. 62 metal, there shall be no

limitation on the maximum thickness of the thicker production member in joints of similar PNumber materials

provided qualification was made on base metal having a

thickness of 1/4 in. (6 mm) or greater.

(2) For all other metal, the thickness of the thicker

member shall be within the range permitted by

QW-451, except there need be no limitation on the maximum thickness of the thicker production member provided qualification was made on base metal having a

thickness of 11/2 in. (38 mm) or more.

More than one procedure qualification may be required

to qualify for some dissimilar thickness combinations.

Groove and Fillet Welds

(a) Qualification for Groove Full Penetration Welds.

Grooveweld test coupons shall qualify the thickness

ranges of both base metal and deposited weld metal to

be used in production. Limits of qualification shall be in

accordance with QW-451. WPS qualification for groove

welds shall be made on groove welds using tension and

guidedbend specimens. Notchtoughness tests shall be

made when required by other Section(s) of the Code.

The WPS shall be qualified for use with groove welds

within the range of essential variables listed.

(b) Qualification for Partial Penetration Groove Welds.

Partial penetration groove welds shall be qualified in accordance with the requirements of QW-451 for both base

metal and deposited weld metal thickness, except there

need be no upper limit on the base metal thickness provided qualification was made on base metal having a

thickness of 11/2 in. (38 mm) or more.

QW-202.5 Stud Welding. Procedure qualification

tests for stud welds shall be made in accordance with

QW-192. The procedure qualification tests shall qualify

the welding procedures for use within the range of the essential variables of Table QW-261. For studs welded to

other than PNo. 1 metals, five additional welds shall be

made and subjected to a macrotest, except that this is

not required for studs used for extended heating surfaces.

30

ASME BPVC.IX-2015

QW-450

QW-451

SPECIMENS

PROCEDURE QUALIFICATION THICKNESS LIMITS AND TEST SPECIMENS

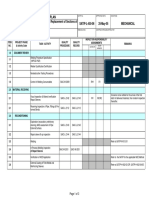

Table QW-451.1

Groove-Weld Tension Tests and Transverse-Bend Tests

Range of Thickness T of

Base Metal, Qualified,

in. (mm)

[Note (1)] and [Note (2)]

Thickness T of Test

Coupon, Welded,

in. (mm)

Min.

Max.

Maximum Thickness t of

Deposited Weld Metal,

Qualified, in. (mm)

[Note (1)] and [Note (2)]

Type and Number of Tests Required (Tension and

GuidedBend Tests) [Note (2)]

Tension,

QW-150

Side Bend,

QW-160

Face

Bend,

QW-160

Root

Bend,

QW-160

Less than 1/16 (1.5)

2T

2t

...

/16 (1.5)

2T

2t

[Note (5)]

/16 (5)

2T

2t

[Note (5)]

/4 (19) to less than 11/2 (38)

/4 (19) to less than 11/2 (38)

/16 (5)

/16 (5)

2T

2T

2t when t < 3/4 (19)

2T when t 3/4 (19)

2 [Note (4)]

2 [Note (4)]

4

4

...

...

...

...

11/2 (38) to 6 (150), incl.

/16 (5)

8 (200) [Note (3)]

2 [Note (4)]

...

...

1 /2 (38) to 6 (150), incl.

/16 (5)

8 (200) [Note (3)]

2t when t < 3/4 (19)

8 (200) [Note (3)] when

t 3/4 (19)

2 [Note (4)]

...

...

Over 6 (150) [Note (6)]

Over 6 (150) [Note (6)]

1.33T

1.33T

2t when t < 3/4(19)

1.33T when t 3/4 (19)

2 [Note (4)]

2 [Note (4)]

4

4

...

...

...

...

/16 to /8 (1.5 to 10), incl.

3

Over /8 (10), but less than

3

/4 (19)

/16 (5)

/16 (5)

NOTES:

(1) The following variables further restrict the limits shown in this table when they are referenced in QW-250 for the process under consideration: QW-403.9, QW-403.10, QW-404.32, and QW-407.4. Also, QW-202.2, QW-202.3, and QW-202.4 provide exemptions that

supersede the limits of this table.

(2) For combination of welding procedures, see QW-200.4.

(3) For the SMAW, SAW, GMAW, PAW, and GTAW welding processes only; otherwise per Note (1) or 2T , or 2t , whichever is applicable.

(4) see QW-151.1, QW-151.2, and QW-151.3 for details on multiple specimens when coupon thicknesses are over 1 in. (25 mm).

(5) Four sidebend tests may be substituted for the required face and rootbend tests, when thickness T is 3/8 in. (10 mm) and over.

(6) For test coupons over 6 in. (150 mm) thick, the full thickness of the test coupon shall be welded.

173

ASME BPVC.IX-2015

Table QW-451.2

Groove-Weld Tension Tests and Longitudinal-Bend Tests

Thickness t of

Range of Thickness T of Deposited Weld Metal

Qualified, in. (mm)

Base Metal Qualified, in.

[Note (1)] and

(mm) [Note (1)] and

[Note (2)]

[Note (2)]

Thickness T of Test

Coupon Welded, in. (mm)

Less than 1/16 (1.5)

1

/16 to 3/8 (1.5 to 10), incl.

Over 3/8 (10)

Min.

T

/16 (1.5)

3

/16 (5)

1

Type and Number of Tests Required (Tension and

GuidedBend Tests) [Note (2)]

Max.

Max.

Tension,

QW-150

Face Bend,

QW-160

Root Bend,

QW-160

2T

2T

2T

2t

2t

2t

2

2

2

2

2

2

2

2

2

NOTES:

(1) The following variables further restrict the limits shown in this table when they are referenced in QW-250 for the process under

consideration: QW-403.9, QW-403.10, QW-404.32, and QW-407.4. Also, QW-202.2, QW-202.3, and QW-202.4 provide exemptions

that supersede the limits of this table.

(2) For combination of welding procedures, see QW-200.4.

Table QW-451.3

Fillet-Weld Tests

Type of

Joint

Thickness of Test

Coupons as Welded, in.

Fillet

Per Figure QW-462.4(a)

Fillet

Per Figure QW-462.4(d)

Range Qualified

Type and Number of Tests Required

[Figure QW-462.4(a) or

Figure QW-462.4(d)] Macro

All fillet sizes on all base metal

thicknesses and all diameters

GENERAL NOTE: A production assembly mockup may be substituted in accordance with QW-181.1.1. When a production assembly

mockup is used, the range qualified shall be limited to the fillet weld size, base metal thickness, and configuration of the mockup. Alternatively, multiple production assembly mockups may be qualified. The range of thickness of the base metal qualified shall be no less than

the thickness of the thinner member tested and no greater than the thickness of the thicker member tested. The range for fillet weld sizes

qualified shall be limited to no less than the smallest fillet weld tested and no greater than the largest fillet weld tested. The configuration

of production assemblies shall be the same as that used in the production assembly mockup.

Table QW-451.4

Fillet Welds Qualified by Groove-Weld Tests

Thickness T of Test Coupon

(Plate or Pipe) as Welded

All groove tests

Range Qualified

All fillet sizes on all base metal

thicknesses and all diameters

Type and Number of Tests Required

Fillet welds are qualified when the groove

weld is qualified in accordance with

either Table QW-451.1 or Table

QW-451.2 (see QW-202.2)

GENERAL NOTE: Supplementary essential variables apply when notch toughness is required by other Sections.

174

You might also like

- Thickness Qualification Range For PQR and WPQDocument5 pagesThickness Qualification Range For PQR and WPQOuled BladiNo ratings yet

- Interview Ques & Ans - KNPCDocument8 pagesInterview Ques & Ans - KNPCStephen RajNo ratings yet

- TBE-Pressure Vessel Standard TemplateDocument4 pagesTBE-Pressure Vessel Standard TemplateSiva baalanNo ratings yet

- ASME P-Numbers PDFDocument1 pageASME P-Numbers PDFFahri Risfa ZulfiNo ratings yet

- Welder'S Work Record Log Sheet Welder's Name: S.M.W. Membership#Document1 pageWelder'S Work Record Log Sheet Welder's Name: S.M.W. Membership#satnamNo ratings yet

- Why use Pipe Supports: Types of Pipe Hangers and SupportsDocument25 pagesWhy use Pipe Supports: Types of Pipe Hangers and SupportsmurugesanNo ratings yet

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- B2020-TDC-VF-009 Vessel Fabrication R0Document5 pagesB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranNo ratings yet

- ASME Pressure Vessel JointDocument5 pagesASME Pressure Vessel JointRodrigo CarneiroNo ratings yet

- Types of Mill Test CertificateDocument2 pagesTypes of Mill Test CertificateMuhammadShabbirNo ratings yet

- WPS SummaryDocument33 pagesWPS SummaryMidhun K ChandraboseNo ratings yet

- Fluid Service CategoriesDocument5 pagesFluid Service CategoriesKodali Naveen Kumar100% (1)

- QW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Document1 pageQW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Deepanshu KhatriNo ratings yet

- Fit Up ReportDocument41 pagesFit Up ReportFendik NewbieNo ratings yet

- QW-451 Procedure Qualification Thickness Limits and Test SpecimensDocument2 pagesQW-451 Procedure Qualification Thickness Limits and Test SpecimensmiteshNo ratings yet

- Welding Standard Tolerances GuideDocument2 pagesWelding Standard Tolerances GuidewahyuNo ratings yet

- PQR Asme Ix - CompletedDocument3 pagesPQR Asme Ix - CompletedCarlos Nombela Palacios100% (1)

- Pressure Vessel Dimension Inspection PDFDocument17 pagesPressure Vessel Dimension Inspection PDFEqubal KhanNo ratings yet

- Fabrication Procedure for Rolling Shell PlatesDocument10 pagesFabrication Procedure for Rolling Shell PlatesMuhammad Yunus NurdinNo ratings yet

- Blind Thickness Calculation: Refer Section 304.5.3 ASME B31.3 Diam, NB Class Diam, DGDocument1 pageBlind Thickness Calculation: Refer Section 304.5.3 ASME B31.3 Diam, NB Class Diam, DGVarun MalhotraNo ratings yet

- Plant Piping Pressure Testing: (Exam For Inspectors Performing Test PKG & Sis Sheet Calculation Reviews)Document3 pagesPlant Piping Pressure Testing: (Exam For Inspectors Performing Test PKG & Sis Sheet Calculation Reviews)aslam.ambNo ratings yet

- Yerp Design Manual Engineering Verification ChecklistDocument3 pagesYerp Design Manual Engineering Verification ChecklistZeshanNo ratings yet

- Pressure Vessel Repair ProcedureDocument7 pagesPressure Vessel Repair ProcedureAndy UgohNo ratings yet

- Welders Qualification, According To Asme Sec IxDocument47 pagesWelders Qualification, According To Asme Sec Ixravi00098No ratings yet

- Head InspectionDocument7 pagesHead Inspectionpriti kumariNo ratings yet

- SAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsDocument2 pagesSAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsAnonymous S9qBDVkyNo ratings yet

- Madina Group W.L.L. Procedure Qualification Record 152Document38 pagesMadina Group W.L.L. Procedure Qualification Record 152MAT-LIONNo ratings yet

- ASME SECTION IX INTERPRETATIONSDocument95 pagesASME SECTION IX INTERPRETATIONSnizam1372No ratings yet

- Heat Treatment Requirement As Per ASME B31.3Document2 pagesHeat Treatment Requirement As Per ASME B31.3Siddiqui Abdul Khaliq67% (3)

- Hydrotesting of PipelineDocument14 pagesHydrotesting of PipelineJWC Sales & Services :100% (1)

- Saudi Aramco Typical Inspection PlanDocument3 pagesSaudi Aramco Typical Inspection PlanAnonymous S9qBDVkyNo ratings yet

- Shell Rolling ProcedureDocument26 pagesShell Rolling ProcedureKingston Rivington100% (1)

- Pressure Vessel Fabrication & Inspection: Poyyara ConsultantsDocument76 pagesPressure Vessel Fabrication & Inspection: Poyyara ConsultantsgopidhanNo ratings yet

- WPQ WELDER QUALIFICATION 16MM PLATE SMAWDocument1 pageWPQ WELDER QUALIFICATION 16MM PLATE SMAWniket0No ratings yet

- 6-15-0003 Rev 4Document9 pages6-15-0003 Rev 4cynideNo ratings yet

- Example of Tank Field ErectionDocument12 pagesExample of Tank Field Erectionfazeel mohammedNo ratings yet

- Storage Tank Test & Inspection Report enDocument10 pagesStorage Tank Test & Inspection Report enMarketing CTNNo ratings yet

- API-653 Now Permits Lap-Welded Patch Plates For Shell Repairs - Carmagen EngineeringDocument2 pagesAPI-653 Now Permits Lap-Welded Patch Plates For Shell Repairs - Carmagen Engineeringmohsen_267100% (1)

- Butt JointsDocument21 pagesButt JointsRaj1-23No ratings yet

- Pressure Vessel Plate InspectionDocument5 pagesPressure Vessel Plate InspectionSadashiw PatilNo ratings yet

- Storage Tank Shell Banding Quality Control and Inspection Report FormDocument1 pageStorage Tank Shell Banding Quality Control and Inspection Report FormAlif Rahmat FebriantoNo ratings yet

- QM 05. Line PipesDocument2 pagesQM 05. Line Pipesmohamed elmasryNo ratings yet

- Fabrication Engineer Job Duties and ResponsibilitiesDocument2 pagesFabrication Engineer Job Duties and ResponsibilitiesRAKHEE RICHHARIA100% (1)

- QW 406 Asme CodeDocument3 pagesQW 406 Asme CodeMardeOpamenNo ratings yet

- Whats Different in B31.1 PDFDocument30 pagesWhats Different in B31.1 PDFhirenkumar patel100% (2)

- Vaccum Test MethodDocument4 pagesVaccum Test MethodMahmud AlamNo ratings yet

- SAIC-W-2006 Rev 0Document4 pagesSAIC-W-2006 Rev 0philipyap100% (2)

- Welding Questionaire: Duties and Responsibilities of Welding InspectorDocument32 pagesWelding Questionaire: Duties and Responsibilities of Welding Inspectorshaynad binsharafNo ratings yet

- Sa 672Document7 pagesSa 672lalitaliNo ratings yet

- Quality Control Manual GuideDocument99 pagesQuality Control Manual Guidedoyenofcastle100% (4)

- Sample ASME QC Manual For U, U2, S&PPDocument53 pagesSample ASME QC Manual For U, U2, S&PPKingston RivingtonNo ratings yet

- Shell and Tube Heat Exchanger TPIDocument9 pagesShell and Tube Heat Exchanger TPIpstechnical_43312697No ratings yet

- Api 570 - 02 Asme B 31.3Document12 pagesApi 570 - 02 Asme B 31.3Mohammad RawoofNo ratings yet

- Notes Api650Document6 pagesNotes Api650MasoodMiyanNo ratings yet

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 pagesWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNo ratings yet

- Asme B31.3 Open & Closed Book (165 Q&A) (For Api 570 & Si Examinations)Document28 pagesAsme B31.3 Open & Closed Book (165 Q&A) (For Api 570 & Si Examinations)nani356No ratings yet

- Asme 9 DatosDocument47 pagesAsme 9 Datosvichu_villamarNo ratings yet

- ASME IX Temper Bead WeldingDocument4 pagesASME IX Temper Bead WeldingAhmadiBinAhmadNo ratings yet

- Asme Section IxDocument71 pagesAsme Section Ixranjitkumar1977100% (1)

- ASME Section IX WPS questions on welding procedure qualificationsDocument35 pagesASME Section IX WPS questions on welding procedure qualificationsdhasdj100% (1)

- HIC Testing RequirementsDocument2 pagesHIC Testing RequirementsAzhar AliNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAzhar AliNo ratings yet

- Saep 135Document8 pagesSaep 135Anonymous 4IpmN7OnNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAli RazaNo ratings yet

- Layout Drawings With Highlight (Section Wise)Document1 pageLayout Drawings With Highlight (Section Wise)Azhar AliNo ratings yet

- Lightning Protection System Design and Installation SpecificationDocument16 pagesLightning Protection System Design and Installation SpecificationAzhar AliNo ratings yet

- SECTION 07720 Roof Accessories Rev 0Document22 pagesSECTION 07720 Roof Accessories Rev 0Azhar AliNo ratings yet

- SECTION 07910 Preformed Joint Seals Rev 0Document16 pagesSECTION 07910 Preformed Joint Seals Rev 0Azhar AliNo ratings yet

- SECTION 13420 Instruments Rev 0Document43 pagesSECTION 13420 Instruments Rev 0Azhar AliNo ratings yet

- Saep 32 PDFDocument15 pagesSaep 32 PDFRami ElloumiNo ratings yet

- SECTION 13112 Sacrificial Anode CP of Submerged and Buried Underground Structures Rev 0 PDFDocument26 pagesSECTION 13112 Sacrificial Anode CP of Submerged and Buried Underground Structures Rev 0 PDFHafed BaccoucheNo ratings yet

- SECTION 13111 Impressed Current CP of Submerged and Buried Metallic Structures Rev 0Document33 pagesSECTION 13111 Impressed Current CP of Submerged and Buried Metallic Structures Rev 0Azhar Ali100% (1)

- SECTION 13113 Impressed Current CP of Reinforced Concrete Structures Rev 0 PDFDocument46 pagesSECTION 13113 Impressed Current CP of Reinforced Concrete Structures Rev 0 PDFHafed BaccoucheNo ratings yet

- SECTION 13850 Detection and Alarm Rev 0Document25 pagesSECTION 13850 Detection and Alarm Rev 0Azhar AliNo ratings yet

- SECTION 13450 Central Control Rev 0Document36 pagesSECTION 13450 Central Control Rev 0Azhar AliNo ratings yet

- SECTION 13860 Fire Detection and Alarm System Rev 0Document13 pagesSECTION 13860 Fire Detection and Alarm System Rev 0Azhar AliNo ratings yet

- SECTION 16510 Interior Luminaires Rev 0Document23 pagesSECTION 16510 Interior Luminaires Rev 0Ahmed HashimNo ratings yet

- Guideline Specification for Indicators, Recorders and ControllersDocument18 pagesGuideline Specification for Indicators, Recorders and ControllersAzhar AliNo ratings yet

- Power Cable SpecificationsDocument49 pagesPower Cable SpecificationsAhmed HashimNo ratings yet

- SECTION 16075 Electrical Identification Rev 0Document26 pagesSECTION 16075 Electrical Identification Rev 0Ahmed HashimNo ratings yet

- SECTION 13430 Boxes, Panels and Control Centers Rev 0Document19 pagesSECTION 13430 Boxes, Panels and Control Centers Rev 0Azhar AliNo ratings yet

- SECTION 16710 Communication Circuit Rev 0Document32 pagesSECTION 16710 Communication Circuit Rev 0Ahmed HashimNo ratings yet

- SECTION 16450 Panelboards Rev 0Document14 pagesSECTION 16450 Panelboards Rev 0Ahmed HashimNo ratings yet

- SECTION 16110 Residential Wiring Connections, Rev 0Document12 pagesSECTION 16110 Residential Wiring Connections, Rev 0Ahmed HashimNo ratings yet

- SECTION 16130 Raceway and Boxes Rev 0Document19 pagesSECTION 16130 Raceway and Boxes Rev 0Ahmed HashimNo ratings yet

- SECTION 16440 Switchboards, Panelboards & Control Centers Rev 0Document32 pagesSECTION 16440 Switchboards, Panelboards & Control Centers Rev 0Ahmed HashimNo ratings yet

- SECTION 16140 Wiring Devices Rev 0Document18 pagesSECTION 16140 Wiring Devices Rev 0Ahmed HashimNo ratings yet

- SECTION 02840-1 Delineators Rev 0Document14 pagesSECTION 02840-1 Delineators Rev 0Azhar AliNo ratings yet

- SECTION 02891 Traffic Signs Rev 0Document37 pagesSECTION 02891 Traffic Signs Rev 0Azhar Ali100% (1)

- SECTION 02840-2 Guardrail Rev 0Document11 pagesSECTION 02840-2 Guardrail Rev 0Saldarriaga FranciscoNo ratings yet

- Detail of Engineer Facilities Quantity Rate Diff in Amount BOQ Actual Origional Up Lifted BOQ Qty's Actual Qty'sDocument2 pagesDetail of Engineer Facilities Quantity Rate Diff in Amount BOQ Actual Origional Up Lifted BOQ Qty's Actual Qty'sfluretNo ratings yet

- Terminal CabinetDocument66 pagesTerminal CabinetChristine May CagaraNo ratings yet

- Long Span Roof StructureDocument7 pagesLong Span Roof StructureDarwin Robain67% (3)

- Accurex Hood SpecsDocument42 pagesAccurex Hood SpecsaudithanNo ratings yet

- MARAFIQ Pipe Specification Rev 1Document17 pagesMARAFIQ Pipe Specification Rev 1jaseelNo ratings yet

- Metal Casting Process Unit - 1Document146 pagesMetal Casting Process Unit - 1sudhakarNo ratings yet

- Tailored Vertical Platform Lifts for Homes and BuildingsDocument20 pagesTailored Vertical Platform Lifts for Homes and Buildingsshem4funNo ratings yet

- CASHCLA DESIGN DRAWINGS FOR CALIFORNIA GOLD PROPERTIES RESIDENCEDocument7 pagesCASHCLA DESIGN DRAWINGS FOR CALIFORNIA GOLD PROPERTIES RESIDENCEAngelo MoralNo ratings yet

- Design and Analysis of Injection Mould with Hot Runner SystemDocument17 pagesDesign and Analysis of Injection Mould with Hot Runner SystemKiran KumarNo ratings yet

- Aloha Stadium Corrosion Review Final ReportDocument302 pagesAloha Stadium Corrosion Review Final ReportHonolulu Star-Advertiser100% (1)

- Material Quantity and Cost ComputationDocument46 pagesMaterial Quantity and Cost ComputationMylfie Dultra100% (2)

- Plumbing Plans ComparisonDocument1 pagePlumbing Plans ComparisonEnriqueta VelazquezNo ratings yet

- Retaining Wall Block, Size, Style and Color OptionsDocument1 pageRetaining Wall Block, Size, Style and Color Optionsmax3731No ratings yet

- Laying of DWC PipesDocument56 pagesLaying of DWC Pipessatyam50% (2)

- PCCP Pipe SpecificationsDocument22 pagesPCCP Pipe SpecificationsChief Engineer Hydro Project & Quality ControlNo ratings yet

- CHECKLIST FOR METAL AND GLAZINGDocument2 pagesCHECKLIST FOR METAL AND GLAZINGajit karandikar50% (2)

- Tools AND Equipment: Submitted byDocument4 pagesTools AND Equipment: Submitted byChan Chan GamoNo ratings yet

- The "Carbon Footprint" of Aluminum and Magnesium Die Casting Compared To Injection Molded ComponentsDocument40 pagesThe "Carbon Footprint" of Aluminum and Magnesium Die Casting Compared To Injection Molded ComponentsPaolo BartoliNo ratings yet

- Polymer Processing TechniquesDocument9 pagesPolymer Processing TechniquesShalini VirdiNo ratings yet

- Glass (Enamel) Material and Enameling TechnologyDocument12 pagesGlass (Enamel) Material and Enameling TechnologyshahinNo ratings yet

- Bug Holes in PrecastDocument5 pagesBug Holes in PrecastMichel DaoustNo ratings yet

- Manual Cutting Machine 1Document4 pagesManual Cutting Machine 1H 5895No ratings yet

- Tavistock BrochureDocument140 pagesTavistock BrochureCreepersBKNo ratings yet

- Section 1Document9 pagesSection 1ognjenristicNo ratings yet

- Mascrete LH - FinalDocument12 pagesMascrete LH - FinalOng Tai BoonNo ratings yet

- "Tech Notes": Stone Matrix Asphalt (SMA)Document4 pages"Tech Notes": Stone Matrix Asphalt (SMA)abdikarim_omarNo ratings yet

- Rewari PIPE ERECTION SpecificationDocument71 pagesRewari PIPE ERECTION Specificationkselvan_1100% (1)

- Building Construction (9019) PDFDocument7 pagesBuilding Construction (9019) PDFMani Deep50% (2)

- Mechanics of Composite Materials - 2017 PDFDocument2 pagesMechanics of Composite Materials - 2017 PDFJAGANNATH PRASADNo ratings yet

- Masterair 721 v1Document2 pagesMasterair 721 v1tally3tallyNo ratings yet