Professional Documents

Culture Documents

Jack Up Test

Uploaded by

Germán AguirrezabalaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jack Up Test

Uploaded by

Germán AguirrezabalaCopyright:

Available Formats

SHAFT JACK UP TEST

September 22, 2012 by Nikos Kairis Leave a Comment

Proper shaft alignment is a key issue on ships, especially on large vessels such as bulk

carriers, tankers, container-ships and gas carriers. Any wrong alignment on the shaft can

result in undesirable vibrations and higher operating costs. As a result there may be

damages in stern tube bearings, propulsion system, M/E and eventually gear box.

The jack up test, enable us to determine the actual reaction in way of accessible bearing

and verify their influence coefficients. The accessible bearings are the intermediate

bearings and the forward or aft bush of shaft reduction gear always in relation to the

shaft arrangement.

The procedure of jack up test has some limitations:

Jack up tests can only measure whats happening at the intermediate bearing and

the engine coupling. But what we are really interested in is whats happening in

the stern tube. In particular, jack up tests tell us nearly nothing about the all

important pressure distribution within the aft bearing.

Jack up tests are completely static.

Jack up tests are limited to a couple of conditions. The rules require only three

conditions: in dock, cold along side at low draft, and one condition with the

engine hot.

Due to measurement errors and hysteresis effects, jack up tests are notoriously

inaccurate and unrepeatable.

These limitations are of less important nowadays because the last twenty years, naval

vessels have had their shafts aligned by dynamic strain gauging. The results are more

accurate and can almost cover all the important system variables, and can be taken with

the shaft operating for a large range of conditions including turning.

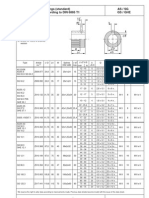

The required equipment is a dial gauge with magnetic support with an accuracy of

0,01mm and a total capacity of 3mm. The hydraulic jack is with a capacity of 20kN, a

minimum stroke of 20mm and a set of filler gauges. The jack is positioned at the

indicated positions.

During the lift of the shaft, it should not come in contact with the top part of the

bearing. Also during the lift of the shaft, it should not come in contact with any metallic

part of a shaft accessory as shaft seal, bulkhead seal, etc.

The jack is always placed below the shaft. The dial gauge is placed above the shaft,

opposite to the jack at 12 o clock.

First of all, it is wise to perform an initial lifting to the shaft in order to establish oil film

between shaft and bearing surface before reading the results. We adjust the dial gauge to

zero. We jack up the shaft by steps of 0,01 up to 0,3mm for jack load 1 and up to

0,1mm for jack load 2. At each step, we record the lift and the load at the jack. We pull

the shaft down by steps corresponding to the reverse direction of jacking up to zero

position. At each step we record the indication of the dial gauge and the load on the

jack. Finally we put all the data measurements to a table so as to draw the graph.

Jack Up Test Diagram

You might also like

- Naval ArchitectureDocument36 pagesNaval ArchitectureAnshuman SharmaNo ratings yet

- Sea-Water Lubricated Stern Tube BearingsDocument5 pagesSea-Water Lubricated Stern Tube BearingsfrancisNo ratings yet

- Waterjet Thesis - Rolls Royce PDFDocument170 pagesWaterjet Thesis - Rolls Royce PDFAmmy singhNo ratings yet

- Instruction Manual For Hydraulic Driven Deck MachineryDocument180 pagesInstruction Manual For Hydraulic Driven Deck MachineryBorysNo ratings yet

- Measuring Propeller Drop With The Help of Poker GaugeDocument2 pagesMeasuring Propeller Drop With The Help of Poker Gaugeas100% (1)

- Ship-Theory Propulsion 1Document29 pagesShip-Theory Propulsion 1Goutam Kumar SahaNo ratings yet

- M-38 Stern Tube SealsDocument246 pagesM-38 Stern Tube SealsMehmet AGAGÜNDÜZNo ratings yet

- 01 - System Description - Twin Stern RollerDocument16 pages01 - System Description - Twin Stern Rollermiguel100% (1)

- Tuning A Twin-Screw Rudder InstallationDocument6 pagesTuning A Twin-Screw Rudder Installationaeromexpower2009No ratings yet

- Rudder and Rudder Stock Inspection in DDDocument12 pagesRudder and Rudder Stock Inspection in DDJORGENo ratings yet

- PART 1 Classification and SurveysDocument413 pagesPART 1 Classification and Surveys송성훈100% (1)

- MM-2-5 Seal & Stern T BRG PDFDocument76 pagesMM-2-5 Seal & Stern T BRG PDFndlong60No ratings yet

- Wear and Friction in A Controllable Pitch PropellerDocument187 pagesWear and Friction in A Controllable Pitch PropellerAgung HidayatullahNo ratings yet

- Propeller & Propulsion TerminologyDocument4 pagesPropeller & Propulsion TerminologyjmvNo ratings yet

- PropellerDocument15 pagesPropellerNavin Dipali100% (2)

- Marine Engineering & Naval Architecture DictionaryDocument848 pagesMarine Engineering & Naval Architecture Dictionaryandevari100% (1)

- Deckmachinery 210102001124Document16 pagesDeckmachinery 210102001124DILIP SURVENo ratings yet

- Rudder Drop & Tramel GuagrDocument6 pagesRudder Drop & Tramel GuagrSWASTIK MISHRANo ratings yet

- Protecciones EmdDocument8 pagesProtecciones EmdHANSELL MIRANDA ALVANo ratings yet

- Gravit 2Document15 pagesGravit 2Ivan MaltsevNo ratings yet

- Propulsion and ShaftingDocument31 pagesPropulsion and ShaftingPriscila KImNo ratings yet

- Common Damages On TailshaftDocument6 pagesCommon Damages On TailshaftStathis MoumousisNo ratings yet

- Bab 9 Shaft Propulsion Arrangement PDFDocument51 pagesBab 9 Shaft Propulsion Arrangement PDFAwan AJaNo ratings yet

- Propeller ElectricityDocument23 pagesPropeller ElectricitysoneraktasNo ratings yet

- Operation & Maintenance ManualDocument21 pagesOperation & Maintenance ManualMohammed BasionyNo ratings yet

- Design, Cavitation Performance, and Open-WaterDocument41 pagesDesign, Cavitation Performance, and Open-WateraminNo ratings yet

- StabilityDocument77 pagesStabilitybabissoul100% (2)

- Ship Wheel PDFDocument18 pagesShip Wheel PDFCarlos LuizNo ratings yet

- Propeller Tunnel DesignDocument3 pagesPropeller Tunnel DesignDanilo ContrerasNo ratings yet

- Propeller BasicsDocument2 pagesPropeller BasicsPavan KishoreNo ratings yet

- Rescue Boat Hook HRN.28 LTDocument10 pagesRescue Boat Hook HRN.28 LTTajana TovarovićNo ratings yet

- Propeller CatalogDocument156 pagesPropeller CatalogPoowadol NiyomkaNo ratings yet

- Sounding PipeDocument13 pagesSounding PipeSandeep KumarNo ratings yet

- Different Bulk Carriers ActivitiesDocument2 pagesDifferent Bulk Carriers ActivitiesKarina EcayNo ratings yet

- Telescopic AlignmentDocument37 pagesTelescopic AlignmentJeevana Sugandha Wijerathna100% (1)

- Accommodation Ladder NewDocument9 pagesAccommodation Ladder NewBrian Voyd RebitoNo ratings yet

- Windlas PDFDocument96 pagesWindlas PDFInfant RajNo ratings yet

- Becker Rudder BladeDocument38 pagesBecker Rudder Bladedwi maryadi100% (1)

- RudderDocument33 pagesRuddertribleprinceNo ratings yet

- Pa ManuelDocument82 pagesPa ManuelThanh Nghị BùiNo ratings yet

- Different Types of Rudder #SafkatDocument11 pagesDifferent Types of Rudder #SafkatSafkat Jubaer ShuvoNo ratings yet

- Group 2 WindlassDocument17 pagesGroup 2 WindlassUser NameNo ratings yet

- Radojcic - On High Speed Mono.2010.SYMPDocument19 pagesRadojcic - On High Speed Mono.2010.SYMPnavalarchmarine100% (1)

- Heel Leeway On Resistance and SideforceDocument10 pagesHeel Leeway On Resistance and SideforceklzsailingNo ratings yet

- Atoyac: Flistnllhf-20Document85 pagesAtoyac: Flistnllhf-20BorysNo ratings yet

- Steeringgearsandrudders Propellers 180905170942 PDFDocument142 pagesSteeringgearsandrudders Propellers 180905170942 PDFWajihNo ratings yet

- My Notes On Savitsky Method PDFDocument25 pagesMy Notes On Savitsky Method PDFy_596688032No ratings yet

- Design of Ship RuddersDocument82 pagesDesign of Ship RuddersGerard Sarg100% (1)

- Propeller Fitting InstructionsDocument7 pagesPropeller Fitting Instructionsrubens0001No ratings yet

- Schilling Rudder - Wikipedia, The Free EncyclopediaDocument3 pagesSchilling Rudder - Wikipedia, The Free EncyclopediaAhmad HajivandNo ratings yet

- MgpsDocument2 pagesMgpsSumeet SawantNo ratings yet

- Rudders Maintenance ManualDocument33 pagesRudders Maintenance ManualDawid DobrzańskiNo ratings yet

- MAIB - Collision Due To Anchor DragDocument16 pagesMAIB - Collision Due To Anchor DragBinh Pham100% (1)

- StabilityGuide FA UKDocument54 pagesStabilityGuide FA UKosamaNo ratings yet

- Rudder SizingDocument6 pagesRudder SizingNeo ZaoNo ratings yet

- Latvia Marine Engineering Test PaperDocument90 pagesLatvia Marine Engineering Test PaperkrishnaNo ratings yet

- Rudder DesignDocument19 pagesRudder DesignRamkumar100% (1)

- Marine Rudders, Hydrofoils and Control Surfaces: Principles, Data, Design and ApplicationsFrom EverandMarine Rudders, Hydrofoils and Control Surfaces: Principles, Data, Design and ApplicationsNo ratings yet

- Planing Is BunkumDocument12 pagesPlaning Is BunkumGermán AguirrezabalaNo ratings yet

- Passenger Comfort On Board Motor YachtsDocument11 pagesPassenger Comfort On Board Motor YachtsGermán AguirrezabalaNo ratings yet

- Taking The Mystery Out of Speed PredictionsDocument9 pagesTaking The Mystery Out of Speed PredictionsGermán AguirrezabalaNo ratings yet

- Fishing Boats - Donald BlountDocument22 pagesFishing Boats - Donald BlountGermán AguirrezabalaNo ratings yet

- Mooring BuoyDocument3 pagesMooring BuoyGermán AguirrezabalaNo ratings yet

- Deflection Measuringsystemfor Floating DrydocksDocument6 pagesDeflection Measuringsystemfor Floating DrydocksGermán AguirrezabalaNo ratings yet

- Safety of Floating Drydocks in Accordance With Mil-Std-1625aDocument10 pagesSafety of Floating Drydocks in Accordance With Mil-Std-1625aGermán AguirrezabalaNo ratings yet

- Marine Propulsion For Small CraftsDocument71 pagesMarine Propulsion For Small CraftsGermán Aguirrezabala100% (1)

- Manual EVK SealDocument18 pagesManual EVK Sealpanamajack26No ratings yet

- Boat Data BookDocument5 pagesBoat Data BookGermán Aguirrezabala100% (1)

- ICOMIA Standard 36 88Document2 pagesICOMIA Standard 36 88Germán AguirrezabalaNo ratings yet

- Speed Boat DevelopmentsDocument18 pagesSpeed Boat DevelopmentsGermán AguirrezabalaNo ratings yet

- Multiple Vessel Dry Docking PDFDocument5 pagesMultiple Vessel Dry Docking PDFGermán AguirrezabalaNo ratings yet

- RablDocument2 pagesRablGermán AguirrezabalaNo ratings yet

- Valspeq 3.80 User Manual EnglishDocument269 pagesValspeq 3.80 User Manual EnglishFaizan AhmedNo ratings yet

- ST 010 ISBT 128 Standard Product Description Code Database v6.0.0Document34 pagesST 010 ISBT 128 Standard Product Description Code Database v6.0.0Patrick Ramos100% (1)

- Ga AsDocument7 pagesGa Aspippo pappiNo ratings yet

- QR 390 Manual Partes Quincy 390Document31 pagesQR 390 Manual Partes Quincy 390ramiro alvarezNo ratings yet

- Syllabus New PDFDocument107 pagesSyllabus New PDFmassNo ratings yet

- Implementation 3-Axis CNC Router For Small Scale Industry: Telkom Applied Science School, Telkom University, IndonesiaDocument6 pagesImplementation 3-Axis CNC Router For Small Scale Industry: Telkom Applied Science School, Telkom University, IndonesiaAnonymous gzC9adeNo ratings yet

- Chapter 4 (Digital Modulation) - Review: Pulses - PAM, PWM, PPM Binary - Ask, FSK, PSK, BPSK, DBPSK, PCM, QamDocument7 pagesChapter 4 (Digital Modulation) - Review: Pulses - PAM, PWM, PPM Binary - Ask, FSK, PSK, BPSK, DBPSK, PCM, QamMuhamad FuadNo ratings yet

- Creating Flight Plan and User Waypoint Files For The Flight1 GTNDocument6 pagesCreating Flight Plan and User Waypoint Files For The Flight1 GTNJosé A. Montiel QuirósNo ratings yet

- HSC Chemistry SkillsDocument9 pagesHSC Chemistry SkillsMartin KarlowNo ratings yet

- Nivel Liquido Dodge 62teDocument4 pagesNivel Liquido Dodge 62teMario Do' HirchsNo ratings yet

- As / SG Gs / Ghe Dimensions For Couplings (Standard) Bore With Keyway According To DIN 6885 T1Document1 pageAs / SG Gs / Ghe Dimensions For Couplings (Standard) Bore With Keyway According To DIN 6885 T1hadeNo ratings yet

- Domus Ventilation Guide 2019Document96 pagesDomus Ventilation Guide 2019Regie CayasNo ratings yet

- SRX5400-SRX5800 Services Gateway DSDocument12 pagesSRX5400-SRX5800 Services Gateway DSAnonymous rSFHGQIBdFNo ratings yet

- Fortinet Configuration Report: Hostname: "FG3600-Internet"Document21 pagesFortinet Configuration Report: Hostname: "FG3600-Internet"rizkymulyawan89No ratings yet

- Code PICDocument6 pagesCode PICsongbao527No ratings yet

- ' ' Shail Ahmad: Privet of India Acres N Inches List of ClientDocument3 pages' ' Shail Ahmad: Privet of India Acres N Inches List of Clientapi-243316402No ratings yet

- Chapter 19 Malicious LogicDocument16 pagesChapter 19 Malicious LogicAnita Sofia KeyserNo ratings yet

- Business Value of Bim in Middle EastDocument52 pagesBusiness Value of Bim in Middle EastshahbazdgNo ratings yet

- Ancient Civilizations AssignmentDocument3 pagesAncient Civilizations Assignmentapi-240196832No ratings yet

- 2.0 Intro To Small Basic GraphicsDocument18 pages2.0 Intro To Small Basic GraphicspatoturboNo ratings yet

- AcknowledgementDocument4 pagesAcknowledgementPurna GuptaNo ratings yet

- Improvements in Offshore Pipeline Cathodic ProtectionDocument6 pagesImprovements in Offshore Pipeline Cathodic ProtectionEddy Norman Benites DelgadoNo ratings yet

- Analysis and Design of Bridge Substructures PDFDocument195 pagesAnalysis and Design of Bridge Substructures PDFsuheilbugs100% (1)

- ALL SYSTEMS GO by Zenovia AndrewsDocument225 pagesALL SYSTEMS GO by Zenovia AndrewsTanya Gillie100% (3)

- Types of CameraDocument18 pagesTypes of CameraVijay Ravi100% (1)

- Surface Roughness TesterDocument1 pageSurface Roughness TesterRenju NairNo ratings yet

- History of Gun PowderDocument32 pagesHistory of Gun PowderHerbert GongonNo ratings yet

- Teco VFD Operating ManualDocument69 pagesTeco VFD Operating ManualStronghold Armory100% (1)

- Swaroop (1) ResumeDocument4 pagesSwaroop (1) ResumeKrishna SwarupNo ratings yet

- Rigmaster 304 Stainless Steel Fluorescent LuminairesDocument2 pagesRigmaster 304 Stainless Steel Fluorescent LuminairesErikaGaitanGonzalezNo ratings yet