Professional Documents

Culture Documents

1993 - Adaptive Control of A Flexible-Link Robotic Manipulator With Unknown Payload Dynamics

Uploaded by

ademargcjuniorOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1993 - Adaptive Control of A Flexible-Link Robotic Manipulator With Unknown Payload Dynamics

Uploaded by

ademargcjuniorCopyright:

Available Formats

-fl-d

be F_uht. caNwW

TP13 - 15:40

Adaptive Control of a Flexible-Link Robotic Manipulator

with Unknown Payload Dynamics

Stephen M. Rock t

Lawrence J. Alder*

Stanford University Aerospace Robotics Laboratory

Stanford, Califoria 94305

Abstract

For many

applications, flexible-link robot

arm

practical to outfit the payload with sensrs that measure

the internal state of the payload. The sensory input for

controlling the robot-payload system will be based on the

robot system sensors only1.

The control approach that Is devloped and demonstrated experimentally in this paper is based on extensions to the self-tuning regulator solution of adaptive control. The approach is unique in that (1) it exploits the

closed-loop dynamic characteristic of the ca of systems beinginvestied in order to solve the persistent

d (2) itn orates the first experexctation p

imental, on-he d o Io of. W egenlue identification techique. The resut is a feasible, real-time

control that potentially can be implemented in future

space robotic systems.

may

handle payloads that are not simple rigid bodies. In space

applications, the RMS (remote manipulator system) will

contain fud or have

appendages. High-performance control schemes

for flexible-link manipulators require end-point feedback.

If the payload

are not accounted for in the control design, degraded performance or instaility are possible [1]. This paper presets technology that extends

be manipulating satelDtes that may

flexible

dynamics

the concept of end-point control to handle payloads with

nnknown internal dynamics.

innovaHigh-performance control is merged with

regulator aptive identification algorithm in a self-tn

proach. The identification of the payload is done using

recently developed subspace-fitting techniques. These

techniques allow real-time determiination of the order of

the payload dynamics. Sufficient excitation problems are

addressed by performing the identification closed loop.

Experimental results are presented.

an

2 Experimental Apparatus

Figure 1 shows a schematic diaram of the hardware.

The experiment repres a large spaced-based manipulator holding a payload that has intenal vibrating dynamics. The robot arm is a flexible beam wbich moves

in the horizontal plane. At one end of the beam, there

is a motor, and on the other end there is the payload

whki is a pad that floats on an airbearig. The pad

and air bearing prevent out of plane vibrations. Floating

the pad on a smooth granite table simulates the zero-g

environment of space in the horizontal plane. The pad

has a pendulum on it that represents the dynamics of the

payload. The pendulum can be locked in place resulting

in a rigid-body payload, or it be left free to oscillate producing a dynamic payload. Additionally, the pendulum

length can be manually adjusted; hence, the natural frequency of the pendulum is anunknown property of the

Introduction

Space-based robots

such

as the

shuttle Remote Ma-

nipulator System (RMS) and the proposed Space Sta

tion Remote Manipulator System (SSRMS) have been

and will be essential elements of future space explo-.

ration. These manipulators

are

long, light-weight, and

required to maipulate massive payloads. As a

consequence, structural flexibility in the links is significant. Further, the payloads manipulated by these large,

are

flexible-link robots may themselves include unknown internal dynamics: for example sloshing fuel or flexible appendages (e.g., vibrating solr panels on small satellite).

The goal of this research is to develop control techniques that provide precse high-bandwidth end-point

control of flexible-link maipulators, whfile simultaneously damping any internal oscilations of the payload.

The internal dynamics of the payload will not be known

apriori. Furthermore, it is assumed that it will not be

payload.

The sensed signals available for feedback are the hub

angle, the inertial position of the payload, and inertial

orientation of the paylad. The pendulum angle is also

sensed but is not used for feedback or identification, since

it would not be available on deployed systems. The pen-

dulum has a time coustant of 30 swonds corresponding

to a natural dampng ratio of less than 0.3%: the openloop response of the pendulum is shown in Figure 2. See

'Ph.D., Dept of Aeronautics & Astronautics.

tAsEoc.* Prof., Dept. of Aeronautics Astronautics.

'This includes vision sensng.

2n

igfl

references [2] and [3] for a more detailed description of

the hardware.

Figure 3: Self-Tuning Regulator

Thi paper focue on the idqntification apects of the

sef-tunng regulator. It is assumed that once the plant

has been identified correctly an appropriate controller

can be digned.

Figure 1: Experimental System

SO

Identification Approach

In the general case, notg about the paylod is known

T

Im

apron; however, for this research the structure of the

payload model is assmed known. Specifically, in the

experiment the payload can either be a rigid body, or

it can include a sinl pendulum of unknown length. A

conequence of this is that the unknown properties of

the payload can be constructed from the exact open-loopeigenvalues of the system (payload plus arm). Thus, the

payload dynamics can be determined from identification

of eigenvaalues only.

To pursue this solution, an algorithm was developed

that is capable of identifying lightly damped eigenvalues

of a system (all of the open-loop eigenvalues of the expermental ystem are lightly damped). The algorithm is.

descibed in Appendix A and does not require kLowledge

of the system order.

A shortcoing of this approac-to identifying the payload is that all of the open-loop system modes must be

identified, which requires all of the modes to be excted.

If all of the modes are not identified, then it may not be

possible to distinguish a feible mode of the arm from

that of the payload ocillations. Since the payload may be

delicate, injecting excitation to guarantee that all modes

of the- arm are excited is unacceptable. To solve this

problem, a nominal controller is used, and the identification is performed dosed loop. The task of the nominal

controller is to damp the structural flexibility of the arm

so that the arm dynamics are not mistaken for the lightly

damped oscillatory dynamics of the payload.

For the experimental system, a nominal controller is

desiged using LQG synthesis techniques assuming that

the payload is a rigid body. Figure 4 shows how the

nominal controIler performs when the payload is dynamic. The nominal controIler yields a set of welldamped losed-loop system modes that have eigenvalues that are relatively insensitive to the presence of payload dyna ics Further, if the payload is dynamic, a

lightly damped or lightly unstable mode appears thathas an eigenvalue that is highly sensitive to the lengths

of the pendulum. Since the eigenvalue of the lightly

damped mode appears in a region of the s-plane that

is remote from the eigenvalues of the nominal set of con-

I1

*

3s

Figure 2: Pendulum Open-Loop Response

3 Adaptive Algorithm

Schmits [4] surveyed control design approaches appi

cable to high-order, lihtly-damped structures typical of

the las of systems dealt with here. Two conclusions

are drawn from that work. First, the ue of end-point

feedback is critial for high-performance end-point control of a flexible arm. The eond condusion is that linear

quadratic gausian (LQG) synthesis tools are effective in

generating control systems that exploit end-point feedback.

Extending the techniques of Schmitz to account for

dynamic payloads, it is possible to accurately position

the payload while simultaneously damping internal vibrations of the payload [3]. The results show that highperformance control is posible, but only if an accurate

model of the total system is available.

In this paper, an adaptive control algorithm will be

presented that merges the LQG controllers with a identification procedure that is able to provide the model fidelity that is required. The approach presented is based

on extensions to the self-tuning-regulator (STR) class of

adaptive controL The concept of a self-tuning regulator

is presented in Figure 3. It demonstrates the combination of two functions. First, an identification algorithm is

used to update the equations of motion of the plant. Second, a control design algorithm (either gain calculation

or scheduling) is used to modify the control law.

_8

trolled modes, the existence of payload dynamics can be

detected by determining the presence or absence of modal

content of the dosed-loop system in a 'critical region' of

the s-plne only. When a lightly damped or slightly Unstable cloed-loop mode is detected, it must be assCiated

with payoad dynamics. Thus, only natural excitation is

required to detect and identify the payload dynamics.

is1

- -

the pendulum is loked or it is sot excted; il either case,

it does not need to be controlled. If the pendulum becomes excited, the pole wi be detected in the cnrtial

region of the a-plne.

- - . - |

I

40

II

I

I

xK

II

I

2~~~~~~~~~~~

I

"I-%

i

10

1.2

X20

.15

L-

Figure 5: Closed-Loop Identification

-X3

.5

rugs)

Figure 4: Critical Region of S-Plane

This figure shows the locus of dosed-loop roots

of the system versus the open-loop frequency

of the payload. The controller is designed

suming the payload is a rigid body. The x's are

the location of the dosed-loop roots when the

payload is rigd. The lines show how the closedloop roots move as the open-loop frequency of

the payload is varied from 2.5 to 1.2 Hz. The

open-loop frequency of the payload is the frequency of the pendulum when the payload is

detached from the arm and floating on the airbearing. The dotted region in the s-plane is the

critical region. Once a pole is detected in the

critical region, the pendulum is known to exist,

The figure shows the eigenvalue identification

routine reporting the dosed-loop eigenvalues

of the system. Performing the identification

dosed-loop allows the poles that are sensitive to

the payload dynamics to be isolated. A mode

in the critical regon (dotted trapezoid)

the presence of payload dynamics.

signals

as-

and its frequency can be determined.

The identification procedure that applied to the experimental system is snmmarized in Figure 5. The procedure is split into detection and identification phases.

The detection is accomplished by evaluating the modal

content (e.g., the eigenvalues) of the system while under normal operation (cdosed-loop). The controller that

is running during the detection phase is the nominal

controller-no identification-specific inputs are required.

When evaluating the modal content, all of the closed-loop

eigenvalues might be found, but only the lightly damped

poles within the critical region of the s-plane are of interest (see Figure 4). If a pole appears within the critical

region, the payload is assumed to have internal dynamics.

If a pole is not detected in the critical region, then either

is

Once

pole

is

located in the critical

region,

its

ex-

act location can be used to identify the unknmown parameter (in this case, the length of the pendulum). For

the experimental system under nominal control, the location of the lightly damped mode is directly related to

the length of the pendulum. The relation between the

crtical eigenvalue and the pendulum length can be plotted (see Figure 4) and inverted graphically. Thus, once

the location of the pole is determined, the identification

of the pendulum length is accomplished using a straightforward table look-up. Then, appropriate controller is

designed based on the identification of the payload. The

new controller is then swapped into the control loop and

damps the oscillations of the payload.

an

Since no identification of the pendulum length is performed until a pole is detected in the critical region, the

payload is only identified when sufficent exctation exists naturally. There is no need to provide identificationspecific excitation.

The performance of the adaptive logic depends heavily on the ability of an identification algonrthm to provide

accurate estimates of the eigenvalues of the system. The

approach for accomplishing this utilizes a linear identification algorithm called ESPRIT which is described in

Appendix A.

Experimental Results

The result of two experimental tests are presented: the

disturbance response test, and the drop and slew test.

The payload natural frequency is different for each test.

The disturbance response test, shown in Figure 6,

demonstrate's the response of the adaptive algorithm to

large unmodelled disturbances for both rd and dynamic payloads. The pendulum is initially locked hanging straight down. An impulsive disturbance is applied

to the tip of the manipulator, and the controller rejects

the disturbance. As expected, no adaptation takes place.

This is in contrast to other adaptive algorithms that re-

10

12

14

16

I*s

10

12

14

16

1is

Figure 7: Drop and Slew

multaneously regulating the payload position. Note that

neither the identification nor control algonrthm is able

to sense the pendulum angle directly even though it is

plotted.

The drop and slew test, shown in Figure 7, demonstrates adaptation during a slew. It starts with the pendulum mechanically held at a 45 degree initial condition

so that the payload is initially a rigid body. For the

first two seconds, the controller is regulating the payload. The pendulum is then dropped just as the robot

is commanded to slew the payload to a new position on

the table. The adaptive algorithm detects and controls

the pendulum oscillations while simultaneously tracking

the slew command.

2

Ek"

spond unfavorably to unmodelled disturbances. The pendulum is then released; however, since the pendulum is

not oscllating, there is no need to identify or control it.

A second impulsive disturbance is then applied to the tip

of the manipulator. This disturbance excites the pendulum enabling the adaptive algorithm to identify the payload dynamics (natural frequency), select the proper controler, swap it in, and then damp the pendulum while si-

D~~~~~~~~~~~~~~~~ I~~~~~~~~~~~~~~~

the class of systems presented here, the identification, is

reduced to determining the eigenvalues of the system under nominal control. An eigenvalue identification routine based on ESPRIT is used to identify accurately any

lightly damped modes that are indicative of the payload

dynamics. Externally supplied exctation is not necessary

for payload identification: the approach does not identify

the payload dynamics unless they are excited naturally.

Experiments show the response of the system in disturbance rejection and slew. In all cases, the adaptation only occurs when there is natural exctation of the

payload dynamics. If the pendulum is not excited, the

controller does not need to account for it. Once the pendulum is excited, the algorithm first detects it and then

controls it. This adaptive approach has proven successful

in experimentally demonstrating precise high-bandwidth

end-point control while simultaneously damping internal

oscillations of a payload with unknown internal dynamics.

. . . , . .2

0m

A Eigenvalue Identification

~. .I

Ii

This appendix describes the subspace-fitting technique

called ESPRIT. Reference [5] presents the algorithm in

the context of direction of arrival determination for signal processing. The algorithm is presented here in the

context of linear system identification.

The subspace-fitting technique is inherently digital.

Suppose that the system is linear time-invariant and is

described in state-space form by

(1)

Xk+1 = AXk + BUk

(2)

Y, = Cxj, + DUk

where xk is the state of the linear system at time k, Uk is

the input to the linear system, and Yk is the observed

Output (xk E xnxl, uk E JIQXI and yk E lRyxl)

Since the states are not measured, the system matrices

are identifiable only to within- an arbitrary non-singular

20\

-400

LOCKED

6hOB

-1

10

12

14

16

Is

a0

Figure 6: Disturbance Response

Conclusions

In this research, a new approach to identification is

developed that utiliz a nominal controller in order to

isolate the dynamic effects related to the uncertain parameters from the other known system dynamics. For

20U1

shift invariant property. Compute the singular value decomposition of YUL:

state (similarity) transformation. The identifiability of

the system matrices is also limited by the excitation of

the system from the inputs or initial conditions.

The algorithm requires a window of data. The length

of the data, N, must be selcted. A slding window kngth

size M C N/2 must also be chosen.

The first step in the procedure is to take the input and

output data and form the Hankel matrices

Yi

YN-M+l

YN-M+2

Y= [Y2

Y2

Y3

I

...

...

...

_ Ym

Ym+i

...e

YN

[Ui

U2

...

VJ= [U2 2U3

=~

U

...

_- Um

...

...

...

..

UmW+l

(10)

YUL = PEQT.

Let P. be the matrix contaning the first n left singular

vectors of YU'. It can be shown from Equation 9 and 10

that there exists a full rank n x n matrix T such that

P. -= FT.Expanding the rows of this equation yields

(3)

UNM+1]

UN-M+2

...

...

(4)

...

UN

p,

Thus,

CAM-I

T= [

CA

CAm-

(12)

system.

rT = [ CT (CA)T ... (CAM-' )T ]

=

D

CB

CAB

CAM-2B

1

ID

C:,B

CAh

f-3B

To find A, form

(6)

(7)

Xl -M+i]

[XI X2

CA2

first row by A, etc. P. is r in some new coordinate

where

- [

Hence, there is a matrix A that is the state-transition

matrix of the system in some coordinate frame such that

the second row of P, can be found by multiplying the

(5)

Y = rx + HU

[CA[A

[Pi

P2

PM-i

(11)

...

..

..

P.l

P. with last row deleted

P.2 s P. with first row deleted

and observe that

-(8)

P1iA A P.2

(13)

(14)

(15)

The approximation is due to the fact P.1 and P.2 are

created from noisy data. A is computed by solving the

least squares problem or more accurately the total least

squares problem (see [5]) that is posed by Equation 15.

From A the eigenvalues of the system can be found.

Thus Y e utmMx(N-M+1) And U E JRqMx(N-M+1) r E

ixamMxnn Xi Ir x(N-M+1) and H E R!mMxMAq, Note

that U and Y are the only matrces that are formed from

measured data.

The second step of the procedure is to find a matrix

UL such that UUL = 0. The matrix UL can be fond

from the ingular value decomposition of U. Once U'

has been calculated, YU1 can be formed from Equation 5. Thus,

yu" = rxul'.

References

[1] Daniel M. Rovuer and Robert H. Cannon, Jr. Experiments toward on-line identification and control

of a very lexible one-link manipulator. International Journal of Robotics Research, 6(4):3-19, Win-

(9)

ter 1987.

[2] L. J. Alder and S. M. Rock. Control of a flexible robotic manipulator with unknown payload dynamics: Initial experiments. In Proceedings of the

ASME Winter Annual Meeting, Atlanta GA, December 1991.

[3] Lawrence Alder. Control of a Flexible-Link Robotic

Arm Manipulating An Unknown Dynamic Payload.

PhD thesis, Stanford University, Stanford, CA 94305,

February 1993.

[4] Robert H. Cannon, Jr. and Eric Schmitz. Initial experiments on the end-point control of a flexible oneink robot. The International Journal of Robotics Research, 3(3):62-75, FaUl 1984.

[5] R. H. Roy. ESPRIT - Estimation of Signal Parameters via Rotational Invariance Techniques. PhD

thesis, Stanford University, Stanford, CA., August

1987.

Note that the column space of YU' is contained in

the column space of r. The matrix r has n columns.

Thus, performing a singular value decomposition of YU'

should yield n or less non-zero singular values. However,

since the data has noise, the last mM-nsingular values

will not be exactly zero but will be sificantly smaller

than the firt a. The large drop in the singular values

of YUL determines the number of excited poles of the

system, n.

Once the order of the system has been determined, the

next step is to find the A matrix that is of the proper

order that best fits the data. To find A, note that the ohservability matrix r poses a shift invariant structure.

This means that the second row of r can be found by

multiplying the first row by A, and the third row can

be fond by multiplying the second row by A, and so

on. However, r is unknown. Fortunately, rcan be computed in a different coordinate system maintaining the

2082

You might also like

- 307 Bsi PinoutDocument5 pages307 Bsi Pinoutmohhizbar0% (1)

- H-DC-0023 (AP) Economy Manual Dishwashing LiquidDocument1 pageH-DC-0023 (AP) Economy Manual Dishwashing LiquidShiraz Khan83% (6)

- Brochure Integrated Container Terminal Planning Optimization EN PDFDocument10 pagesBrochure Integrated Container Terminal Planning Optimization EN PDFHerum ManaluNo ratings yet

- Revisd Load Calculations Orchid HospitalDocument11 pagesRevisd Load Calculations Orchid Hospitalsubstationlover100% (1)

- Optimal Control of Inverted Pendulum Using Fuzzy Logic, PID & LQR ControllerDocument8 pagesOptimal Control of Inverted Pendulum Using Fuzzy Logic, PID & LQR Controllershekhar yadavNo ratings yet

- Rotary Inverted PendulumDocument8 pagesRotary Inverted PendulumEduardo BittencourtNo ratings yet

- Multi-Sensor Switching Strategy For Automotive Longitudinal ControlDocument6 pagesMulti-Sensor Switching Strategy For Automotive Longitudinal ControlMarioNo ratings yet

- Design of A Simple and Robust Control System For A Single-Link Flexible Robot ArmDocument6 pagesDesign of A Simple and Robust Control System For A Single-Link Flexible Robot ArmDilek METİNNo ratings yet

- Modeling and Control of A Rotary Inverted PendulumDocument6 pagesModeling and Control of A Rotary Inverted PendulumsalmanNo ratings yet

- A Student Guide To Clasical ControlDocument5 pagesA Student Guide To Clasical ControlSusana Vázquez VallínNo ratings yet

- Mechanical Structural Analysis AND Design Optimization: OF Industrial RobotsDocument29 pagesMechanical Structural Analysis AND Design Optimization: OF Industrial RobotsAhsan AmjadNo ratings yet

- MMARDocument6 pagesMMARManar HosnyNo ratings yet

- Modeling and Simulation of Inverted Pendulum System Using Matlab: OverviewDocument4 pagesModeling and Simulation of Inverted Pendulum System Using Matlab: OverviewMuhammad Zubair SheikhNo ratings yet

- Second Order Sliding Mode Control of Underactuated Mechanical Systems I: Local Stabilization With Application To An Inverted PendulumDocument15 pagesSecond Order Sliding Mode Control of Underactuated Mechanical Systems I: Local Stabilization With Application To An Inverted PendulumVandana TakNo ratings yet

- (1987 J.J. Slotine, W. Li) On The Adaptive Control of Robot Manipulators PDFDocument12 pages(1987 J.J. Slotine, W. Li) On The Adaptive Control of Robot Manipulators PDFbagus setyaji100% (1)

- This Study Addresses The Robust Fault Detection Problem For Continuous-Time Switched Systems With State Delays.Document5 pagesThis Study Addresses The Robust Fault Detection Problem For Continuous-Time Switched Systems With State Delays.sidamineNo ratings yet

- Low-Cost Accelerometers For Robotic Manipulator PerceptionDocument7 pagesLow-Cost Accelerometers For Robotic Manipulator PerceptionAbbé BusoniNo ratings yet

- Students Guide To Classical ControlDocument5 pagesStudents Guide To Classical ControlmixarimNo ratings yet

- State Observer - Wikipedia, The Free EncyclopediaDocument6 pagesState Observer - Wikipedia, The Free EncyclopediaNhà Của CọpNo ratings yet

- IN Electronics and Communication Engineering: Sheth Dhrumil HDocument5 pagesIN Electronics and Communication Engineering: Sheth Dhrumil HSachin ShendeNo ratings yet

- Robust Adaptive Control in The Presence of Unmodeled Actuator DynamicsDocument18 pagesRobust Adaptive Control in The Presence of Unmodeled Actuator DynamicsJovan BoskovicNo ratings yet

- Optimal Control of Nonlinear Systems To Given OrbitsDocument14 pagesOptimal Control of Nonlinear Systems To Given OrbitsMi Đỗ Hoàng NgânNo ratings yet

- K. H PT T. 1: The Funoamental Concepts Robust Compliant Mbtion For Lrqbot Manipulators H. P. Her C AnDocument10 pagesK. H PT T. 1: The Funoamental Concepts Robust Compliant Mbtion For Lrqbot Manipulators H. P. Her C AnAlex George NegoitaNo ratings yet

- LolaDocument5 pagesLolaAriff FirdausNo ratings yet

- Sliding Mode ControlDocument2 pagesSliding Mode ControlCrazyGamer SLNo ratings yet

- End-Effector Trajectory Tracking in Flexible Arms Comparison of Approaches Based On Regulation TheoryDocument17 pagesEnd-Effector Trajectory Tracking in Flexible Arms Comparison of Approaches Based On Regulation Theoryoscar201140No ratings yet

- Composite Robust Control of A Laboratory Flexible ManipulatorDocument6 pagesComposite Robust Control of A Laboratory Flexible ManipulatorinfodotzNo ratings yet

- Back SteppingDocument7 pagesBack Steppinggigapis845No ratings yet

- Stabilization of Inverted Pendulum On Cart Based On Pole Placement and LQRDocument5 pagesStabilization of Inverted Pendulum On Cart Based On Pole Placement and LQRCitra AlfaNo ratings yet

- Tip Position Control of A Flexible One Arm Robot With Predictive Adaptive Output Feedback Implemented With Lattice Filter Parameter IdentifierDocument6 pagesTip Position Control of A Flexible One Arm Robot With Predictive Adaptive Output Feedback Implemented With Lattice Filter Parameter IdentifierChuxoMéndezNo ratings yet

- SWING UP AND STABILIZATION OF ROTARY INVERTED PENDULUM Jirı MertlDocument6 pagesSWING UP AND STABILIZATION OF ROTARY INVERTED PENDULUM Jirı MertldiemtrieuNo ratings yet

- Control and Estimation For Cooperative Manipulator Tasks: 1 MotivationDocument19 pagesControl and Estimation For Cooperative Manipulator Tasks: 1 MotivationHelmi Ab MajidNo ratings yet

- Magnetic Torquer Attitude Control Via Asymptotic Periodic LQRDocument13 pagesMagnetic Torquer Attitude Control Via Asymptotic Periodic LQRKanu GovilaNo ratings yet

- Robot Manipulator Control and Computational Cost: Technical Reports (CIS)Document40 pagesRobot Manipulator Control and Computational Cost: Technical Reports (CIS)Mauricio RamosNo ratings yet

- Isma'09 62649 PDFDocument6 pagesIsma'09 62649 PDFVignesh RamakrishnanNo ratings yet

- Modeling and Controller Designing of Rotary Inverted Pendulum (RIP) - Comparison by Using Various Design MethodsDocument8 pagesModeling and Controller Designing of Rotary Inverted Pendulum (RIP) - Comparison by Using Various Design Methodskyaw phone htetNo ratings yet

- Swing: The Control Problem For The AcrobotDocument7 pagesSwing: The Control Problem For The AcrobotVictor PassosNo ratings yet

- Laboratory Experimental Testing of InertersDocument6 pagesLaboratory Experimental Testing of Inertersนิติพล ไชยวงศ์No ratings yet

- Gac Wedge EaaiDocument14 pagesGac Wedge EaaijinxichangeNo ratings yet

- Control Law Comparison For Attitude Control of A SpacecraftDocument7 pagesControl Law Comparison For Attitude Control of A Spacecrafthossein_AUNo ratings yet

- KF and LQG Controller Design ExamplesDocument6 pagesKF and LQG Controller Design ExamplesRao ZubairNo ratings yet

- Tuning of Type-1 Servo System Using Swarm Intelligence For SIMO ProcessDocument4 pagesTuning of Type-1 Servo System Using Swarm Intelligence For SIMO ProcessAnonymous WkbmWCa8MNo ratings yet

- Robustness Study of The Dynamic Inversion Based Indirect Adaptive Control of Flight Vehicles With Uncertain Model DataDocument6 pagesRobustness Study of The Dynamic Inversion Based Indirect Adaptive Control of Flight Vehicles With Uncertain Model DataDivya KrishnanNo ratings yet

- Research Article: Adaptive Barrier Control For Nonlinear Servomechanisms With Friction CompensationDocument11 pagesResearch Article: Adaptive Barrier Control For Nonlinear Servomechanisms With Friction CompensationSanjeev Kumar PandeyNo ratings yet

- Terminal Sliding ModesDocument4 pagesTerminal Sliding ModesAldin BeganovicNo ratings yet

- Adaptive Output Feedback Control Based On Neural Networks 2009 IFAC ProceediDocument6 pagesAdaptive Output Feedback Control Based On Neural Networks 2009 IFAC ProceediKeneni AlemayehuNo ratings yet

- Crane State Space ModelDocument12 pagesCrane State Space ModelSarojakanti SahooNo ratings yet

- 4-Dimensional Control of Remotely Piloted: VehicleDocument6 pages4-Dimensional Control of Remotely Piloted: VehicleFawaz PartoNo ratings yet

- Design of Robust Fuzzy Controllers For Aerospace ApplicationsDocument5 pagesDesign of Robust Fuzzy Controllers For Aerospace ApplicationsRitesh SinghNo ratings yet

- Position Control: 1999 John Wiley & Sons, IncDocument31 pagesPosition Control: 1999 John Wiley & Sons, IncKenpachi ZarakiNo ratings yet

- Mechanical Systems and Signal Processing: Zhi-Cheng QiuDocument19 pagesMechanical Systems and Signal Processing: Zhi-Cheng QiuLakshmi Ganesh SudikondaNo ratings yet

- Chaos Exp 2 To Word PDF TYARDocument9 pagesChaos Exp 2 To Word PDF TYARnishrish sihagNo ratings yet

- Wang 2011Document4 pagesWang 2011ArunavaNo ratings yet

- XMM Attitude and OrbitDocument5 pagesXMM Attitude and OrbitThomas VoirinNo ratings yet

- Research Article: Optimal On-Off Attitude Control For The Brazilian Multimission Platform SatelliteDocument17 pagesResearch Article: Optimal On-Off Attitude Control For The Brazilian Multimission Platform SatelliteSimone DascanioNo ratings yet

- A Control Engineers Quide To Sliding Mode ControlDocument14 pagesA Control Engineers Quide To Sliding Mode ControlyalllikNo ratings yet

- Supplementary Material For: Controlled Flight of A Biologically Inspired, Insect-Scale RobotDocument14 pagesSupplementary Material For: Controlled Flight of A Biologically Inspired, Insect-Scale RobotsamanNo ratings yet

- Swigup Acrobot Spong PDFDocument7 pagesSwigup Acrobot Spong PDFJ.a. Tenshi ExecutionerNo ratings yet

- Chapter 7 Buku NelsonDocument6 pagesChapter 7 Buku Nelsoncatia asdosNo ratings yet

- Abstract PrepDocument3 pagesAbstract PrepSyed MamnoonNo ratings yet

- Fateh 2009Document7 pagesFateh 2009Daniel CarvalhoNo ratings yet

- Modeling and Simulation of Inverted Pendulum System Using Matlab: OverviewDocument4 pagesModeling and Simulation of Inverted Pendulum System Using Matlab: OverviewShoaib chishtyNo ratings yet

- Energetic Processes in Follow-Up Electrical Control Systems: International Series of Monographs on Electronics and InstrumentationFrom EverandEnergetic Processes in Follow-Up Electrical Control Systems: International Series of Monographs on Electronics and InstrumentationNo ratings yet

- 1980 - Stable Adaptive Controller Design, Part II - Proof of Stability (Narendra)Document9 pages1980 - Stable Adaptive Controller Design, Part II - Proof of Stability (Narendra)ademargcjuniorNo ratings yet

- 1978 - Stable Adaptive Controller Design-Direct Control (Narendra)Document14 pages1978 - Stable Adaptive Controller Design-Direct Control (Narendra)ademargcjuniorNo ratings yet

- 1980 - Global Stability of Parameter-Adaptive Control SystemsDocument7 pages1980 - Global Stability of Parameter-Adaptive Control SystemsademargcjuniorNo ratings yet

- 1997 - Adaptive Predictive Control - Limits of StabilityDocument21 pages1997 - Adaptive Predictive Control - Limits of StabilityademargcjuniorNo ratings yet

- 2M542 ManualDocument9 pages2M542 ManualzivcaniNo ratings yet

- Approval Process Handbook 2019-20Document1 pageApproval Process Handbook 2019-20Arvind SharmaNo ratings yet

- A Ground-Motion Transfer Function Matrix Between Two Nearby Rock and Soil Sites: A System Identification ProblemDocument13 pagesA Ground-Motion Transfer Function Matrix Between Two Nearby Rock and Soil Sites: A System Identification ProblemRicardo Angelo Quispe MendizábalNo ratings yet

- Productguide - Chemicals Aceites FleetriteDocument12 pagesProductguide - Chemicals Aceites FleetriteJose AlbertoNo ratings yet

- Pt. Amanah Nusantara Sejahtera - Hydrotest ProcedureDocument5 pagesPt. Amanah Nusantara Sejahtera - Hydrotest ProcedureDoris AbadiNo ratings yet

- CKD Sab SVB Catalogue en Cc770a PDFDocument58 pagesCKD Sab SVB Catalogue en Cc770a PDFvanNo ratings yet

- 20488B 00Document14 pages20488B 00dentisyNo ratings yet

- KZP Sub-Contractor Bill-LRDocument20 pagesKZP Sub-Contractor Bill-LRhelalNo ratings yet

- 2gr TorqueDocument3 pages2gr TorqueDouglasArayaNo ratings yet

- CDB2043 - CH 03 - StoichiometryDocument36 pagesCDB2043 - CH 03 - StoichiometryAqilah HanimNo ratings yet

- ESP32 S2 DevKit Lipo - Rev - B1Document1 pageESP32 S2 DevKit Lipo - Rev - B1Inventor TestNo ratings yet

- Repuestos TK30Document108 pagesRepuestos TK30Juan Esteban GiraldoNo ratings yet

- Water ShowDocument9 pagesWater ShowFaizal SattuNo ratings yet

- UAES 473F Engine Electronic Fuel Injection Section PDFDocument81 pagesUAES 473F Engine Electronic Fuel Injection Section PDFjardenNo ratings yet

- Brosur SikaDocument7 pagesBrosur SikachaerulNo ratings yet

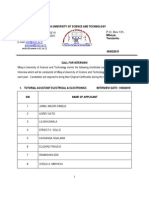

- Call For Interview Phase V - Mbeya University.Document13 pagesCall For Interview Phase V - Mbeya University.Rashid BumarwaNo ratings yet

- Module 3 - Loci of Points and Straight LinesDocument41 pagesModule 3 - Loci of Points and Straight LinesEngr Fazal Akbar100% (3)

- DocumentDocument32 pagesDocumentmnasiriqbal786No ratings yet

- Physical Properties of Undisturbed Tropical Peat Soil at Pekan District, Pahang, West MalaysiaDocument12 pagesPhysical Properties of Undisturbed Tropical Peat Soil at Pekan District, Pahang, West MalaysiaHanim YunusNo ratings yet

- 1 a.PMMA Shiphandling and ManDocument373 pages1 a.PMMA Shiphandling and ManTOtzkie Tapales Arpay100% (6)

- Fluke T3 Voltage and Continuity TesterDocument2 pagesFluke T3 Voltage and Continuity Testerkoko MeNo ratings yet

- Kuo H-H Et Al. INTERFERENCE-COLORED FINISHES FOR AUTOMOTIVE ALUMINUM ALLOYSDocument8 pagesKuo H-H Et Al. INTERFERENCE-COLORED FINISHES FOR AUTOMOTIVE ALUMINUM ALLOYSkaka**No ratings yet

- SECTION 307-01: Automatic Transaxle/Transmission - 6R80 2012 F-150 Workshop Manual General ProceduresDocument3 pagesSECTION 307-01: Automatic Transaxle/Transmission - 6R80 2012 F-150 Workshop Manual General ProceduresPriscilla Kelly Freitas dos SantosNo ratings yet

- Reference To Foxpro FunctionsDocument19 pagesReference To Foxpro FunctionsGanapatibo GanapatiNo ratings yet

- Module 2 - Important Theory Portions: - Friction - Characteristics of FrictionDocument8 pagesModule 2 - Important Theory Portions: - Friction - Characteristics of FrictionHima SNo ratings yet

- An Introduction To Project Logistics Management: ArticleDocument9 pagesAn Introduction To Project Logistics Management: ArticleCh Tushar BhatiNo ratings yet