Professional Documents

Culture Documents

86050101

Uploaded by

GurkirtanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

86050101

Uploaded by

GurkirtanCopyright:

Available Formats

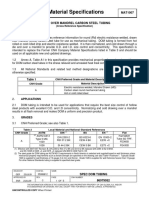

RAW MATERIALS / FERROUS

FNHA-2-A-551.00

MECHANICAL TUBING, COLD-DRAWN BUTTWELD ASTM A 512

1.

4.5.1 Mandrel Drawn; specify O.D. and I.D.

4.5.2 Sunk Drawn; specify O.D. and nominal wall

thickness.

SCOPE

This specification covers cold-drawn buttweld

carbon steel tubes for use as mechanical tubing.

2.

2.1

2.2

DRAWING SPECIFICATIONS

Versatile only:

Cold-drawn Buttweld ASTM A512, Soft

Annealed, MT 1020 Mechanical Tubing.

New Holland only:

CD Buttweld DOM ASTM A512, Type NORM MD - SR, Grade 1018,1020, incl. 1026.

3.

RELATED SPECIFICATIONS

3.1

REFERENCE STANDARD

ASTM A512 - Specification for Cold-Drawn

Buttweld Carbon Steel Mechanical Tubing.

Versatile Standard 2-A-009 - Tube Design.

4.

ORDERING INFORMATION

4.1

ASTM A512 Cold-drawn Buttweld Tubing.

4.2

Length; specify cut length or random.

4.6

Request Supplier Certification - if required.

5.

CHEMICAL REQUIREMENTS

Carbon, %

Manganese,%

Phosphorus,%

Sulfur, %

MT 1020

0.15/0.25

0.30/0.60

0.040 max.

0.045 max.

1018,1020 - 1026

0.14/0.28

0.30/0.90

0.040 max.

0.045 max.

6.

MECHANICAL REQUIREMENTS

6.1

MT 1020, Soft Annealed

Tensile Strength, min, ksi (MPa)*

50 (345)

Yield Strength, min, ksi (MPa)*

30 (207)

Elongation in 2", min %

32

Hardness, min, Rockwell B

50

* min not guaranteed per specification.

6.2

1018,1020 to 1026, Stress Relieved

min.

max.

Tensile Strength, ksi (MPa) 68 (469) 130 (896)

Yield Strength, ksi (MPa)

62 (427)

Elongation in 2", %

11

Hardness, Rockwell B or C B 73

C 20

4.3

Chemistry; specify MT 1020 or Grade

1018,1020, incl. 1026.

7.

4.4

SR.

Type; specify Soft Annealed or NORM-MD-

4.5

Dimensions

7.1

Diameter and Wall Thickness Tolerances see Table 1.

7.2

NAME

DIMENSIONS AND TOLERANCES

Cut Length Tolerances - see Table 2.

ALL

TH

115614

02-01

ALL

TH

115355

11-00

All

TH

114745

05-00

ALL

TH

114396

02-00

ALL

RLF

110229

7/97

ALL

RLF

107053

10/95

THE INFORMATION HEREON IS THE CONFIDENTIAL

STD ASTM A512 RD TUB

ENGINEERING

SPECIFICATION

ALL

RE

104739

1/95

AND PROPRIETARY PROPERTY OF NEW HOLLAND

FRAME NO.

REV

BY

ECN NO.

DATE

NORTH AMERICA, INC. AND/OR NEW HOLLAND

APP.

DRAWN

TH

2/94

CANADA, LTD. ANY USE, EXCEPT THAT FOR

KHH 1/95

CHECKED

WHICH IT MAY BE LOANED, IS PROHIBITED.

FRAME

OF

1

PART NUMBER

86050101

RAW MATERIALS / FERROUS

FNHA-2-A-551.00

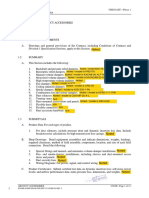

TABLE 1. Diameter and Wall Thickness Tolerances

Outside Diameter Range,

Outside Diam., inch (mm)

Inches (mm)

Over

Under

Inside Diam., inch (mm)

Over

Wall Thickness, %

Under

Over

Under

Sunk Drawn, specify O.D. and wall thickness

A

15

10

10

10

Up to 1/2 (12.7),excl.

0.004 (0.10)

...

...

15

1/2 to 1 1/2 (12.7 to 38.1)

excl.

0.005 (0.13)

...

...

10

1 1/2 to 3 (38.1 to 76.2), incl.

0.010 (0.25)

...

...

Mandrel Drawn, specify O.D. and I.D. (wall thickness is for reference only)

Under 0.156(3.96)wall:

Up to 1/2 (12.7),excl.

1/2 to 1 1/2 (12.7 to 38.1)

excl.

0.004 (0.10)

0.010 (0.25)

12.5

12.5

10

10

0.005 (0.13)

0.005 (0.13)

0.005 (0.13)

0.005 (0.13)

Under 0.156(3.96)wall:

1 1/2 (38.1) and over

0.010 (0.25)

...

0.010 (0.25)

10

10

0.156 wall and over:

1 1/2 (38.1) and over

0.010 (0.25)

0.010 (0.25)

0.156 wall and over:

1/2 to 1 1/2 (12.7 to 38.1)

excl.

Except at the weld line, where the weld pad may exceed this figure.

Tubes with an inside diameter under 1/2 in.(12.7mm) may require more than 0.005 in.(0.13mm) I.D.

tolerance,and the producer should be consulted.

TABLE 2. Cut Length Tolerances

Length, feet

Diameter, up to 2 inches

Diameter, over 2 inches

Up to 4', incl.

+/- 1/32" (0.8mm)

+/- 3/64" (1.2mm)

Over 4' to 10', incl.

+/- 3/64" (1.2mm)

+/- 1/16" (1.6mm)

Over 10' to 24', incl.

+/- 1/8" (3.2mm)

+/- 1/8" (3.2mm)

Over 24'

+/- 1/8" (3.2mm)

+/- 1/8" (3.2mm)

NAME

PART NUMBER

STD ASTM A512 RD TUB

ENGINEERING SPECIFICATION

REV.

K

FRAME

2

OF

2

86050101

You might also like

- Specification of F1267Document7 pagesSpecification of F1267pLangpLingpLungNo ratings yet

- C955 09Document4 pagesC955 09jacr27No ratings yet

- A269Document5 pagesA269Jeffrey StokesNo ratings yet

- A Dimensional Engineering Process For ShipbuildingDocument11 pagesA Dimensional Engineering Process For ShipbuildingWJccnNo ratings yet

- As 4041Document22 pagesAs 4041vivek_pandey100% (2)

- TUBE, UNS S31600/S31603, SMLS, AnnealedDocument2 pagesTUBE, UNS S31600/S31603, SMLS, AnnealedTuấn Dương QuốcNo ratings yet

- Session5 Automotive PackagingDocument72 pagesSession5 Automotive PackagingShivprasad Savadatti100% (1)

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesFrom EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Land Based SensorsDocument40 pagesLand Based SensorsJ.MichaelLooneyNo ratings yet

- Ansi MH2Document14 pagesAnsi MH2Mohamed Ma'mounNo ratings yet

- Material Specifications: Low Carbon Steel, Hot Rolled Sheet and StripDocument5 pagesMaterial Specifications: Low Carbon Steel, Hot Rolled Sheet and Striptim0% (1)

- A449-14 Standard Specification For Hex Cap Screws, Bolts and Studs, Steel, Heat Treated, 120 - 105 - 90 Ksi Minimum Tensile Strength, General UseDocument7 pagesA449-14 Standard Specification For Hex Cap Screws, Bolts and Studs, Steel, Heat Treated, 120 - 105 - 90 Ksi Minimum Tensile Strength, General UseislamakthamNo ratings yet

- Astm A890-A890m-12Document4 pagesAstm A890-A890m-12Sankar Ganesh100% (3)

- XML JavascriptDocument62 pagesXML Javascriptanon-506495No ratings yet

- Astm 608 PDFDocument6 pagesAstm 608 PDFIslam FawzyNo ratings yet

- Astm A792 PDFDocument6 pagesAstm A792 PDFOswaldo Enrique Adame67% (3)

- Astm 366Document2 pagesAstm 366Acas NandingNo ratings yet

- Astm A210Document3 pagesAstm A210Rajan SteeveNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Notes On Cronbach's AlphaDocument10 pagesNotes On Cronbach's AlphaSyed Umar Shirazi Hashmi100% (1)

- ASTM A1063 / A1063M - 11aDocument4 pagesASTM A1063 / A1063M - 11avargas35No ratings yet

- ASTM A792-10 Specification GalvalumeDocument6 pagesASTM A792-10 Specification GalvalumeSaurabh Gupta0% (1)

- A 1008 - A 1008M - 02 Qtewmdgtmdjfmq - PDFDocument7 pagesA 1008 - A 1008M - 02 Qtewmdgtmdjfmq - PDFTiến Lượng NguyễnNo ratings yet

- Steel Sheet, 55 % Aluminum-Zinc Alloy-Coated by The Hot-Dip ProcessDocument6 pagesSteel Sheet, 55 % Aluminum-Zinc Alloy-Coated by The Hot-Dip ProcessJosé Ramón GutierrezNo ratings yet

- CNH Mat 1007 - 07-2009Document5 pagesCNH Mat 1007 - 07-2009rgi178No ratings yet

- ALLOY 6082: Understanding Extruded Aluminum AlloysDocument0 pagesALLOY 6082: Understanding Extruded Aluminum Alloysetamil87No ratings yet

- DS DSL990 FR en Us 16831Document2 pagesDS DSL990 FR en Us 16831Rahul JadhavNo ratings yet

- SECTION 07 71 00 Roof SpecialtiesDocument12 pagesSECTION 07 71 00 Roof SpecialtiesJuanPaoloYbañezNo ratings yet

- A 814 - A 814m - 01 Qtgxnc9bode0ts1sruqDocument7 pagesA 814 - A 814m - 01 Qtgxnc9bode0ts1sruqsachinguptachdNo ratings yet

- Summary of Chain Link Fence UpdatesDocument11 pagesSummary of Chain Link Fence UpdatesAnonymous vh1f95o8No ratings yet

- Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater TubesDocument4 pagesElectric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater TubesSriniramu SriniramuNo ratings yet

- A-355 - 89 (R94)Document2 pagesA-355 - 89 (R94)José Ramón GutierrezNo ratings yet

- A 1011 - A 1011M - 03 Qtewmtetmdm - PDFDocument7 pagesA 1011 - A 1011M - 03 Qtewmtetmdm - PDFTiến Lượng NguyễnNo ratings yet

- A794A794M-12 Standard Specification For Commercial Steel (CS), Sheet, Carbon (0.16 % Maximum To 0.25 % Maximum), Cold-RolledDocument3 pagesA794A794M-12 Standard Specification For Commercial Steel (CS), Sheet, Carbon (0.16 % Maximum To 0.25 % Maximum), Cold-Rolledtjt4779No ratings yet

- A 1008 - A 1008M - 01 Qtewmdgtmdfb PDFDocument7 pagesA 1008 - A 1008M - 01 Qtewmdgtmdfb PDFTiến Lượng NguyễnNo ratings yet

- Mat 1031Document4 pagesMat 1031Emir AkçayNo ratings yet

- A 313 - A 313M - 98 Qtmxmy9bmzezts1sruq - PDFDocument7 pagesA 313 - A 313M - 98 Qtmxmy9bmzezts1sruq - PDFTiến Lượng NguyễnNo ratings yet

- A 1008 - A 1008M - 00 Qtewmdgtmda - PDFDocument7 pagesA 1008 - A 1008M - 00 Qtewmdgtmda - PDFTiến Lượng NguyễnNo ratings yet

- 8202 2Document10 pages8202 2Yang WuNo ratings yet

- A 1008 - A 1008M - 04 Qtewmdgvqtewmdhnlvjfra - PDFDocument9 pagesA 1008 - A 1008M - 04 Qtewmdgvqtewmdhnlvjfra - PDFMarcos Verissimo Juca de PaulaNo ratings yet

- Aa10112 1518422243Document5 pagesAa10112 1518422243johnrajraj608No ratings yet

- Un 2004-03 - Ud-Au-000-Eb-00009 PDFDocument3 pagesUn 2004-03 - Ud-Au-000-Eb-00009 PDFManjeet SainiNo ratings yet

- Alloy/Steel Bolting Materials For Low-Temperature ServiceDocument7 pagesAlloy/Steel Bolting Materials For Low-Temperature ServiceJosé Ramón GutierrezNo ratings yet

- Hot Rolled Coil - Drawing & Forming Steel Grades PDFDocument3 pagesHot Rolled Coil - Drawing & Forming Steel Grades PDFSunitSGalimathNo ratings yet

- Astm B163 PDFDocument12 pagesAstm B163 PDFSuellen FerreiraNo ratings yet

- Tdoct2014b EngDocument2 pagesTdoct2014b Engmahmoud abuelmgdNo ratings yet

- A308Document4 pagesA308alirioNo ratings yet

- JDM A24 Spec for ERW Steel Mechanical TubingDocument5 pagesJDM A24 Spec for ERW Steel Mechanical Tubingrgi178No ratings yet

- Applicable Standard Mech Documents ReviewDocument27 pagesApplicable Standard Mech Documents ReviewArun CPNo ratings yet

- Mil PRF 13789eDocument9 pagesMil PRF 13789eOm Parkash SharmaNo ratings yet

- Section 233300-Air Duct Accessories (Kbe Damper)Document12 pagesSection 233300-Air Duct Accessories (Kbe Damper)Li LiuNo ratings yet

- C 955 - 01 Qzk1ns1sruqDocument6 pagesC 955 - 01 Qzk1ns1sruqHumberto GutierrezNo ratings yet

- A 822 - 90 r00 Qtgymi9bodiyts1sruqDocument5 pagesA 822 - 90 r00 Qtgymi9bodiyts1sruqsachinguptachdNo ratings yet

- Steel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsDocument3 pagesSteel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsTamil funNo ratings yet

- Att 2 - EdsDocument30 pagesAtt 2 - Eds정동현No ratings yet

- C 955 - 03Document4 pagesC 955 - 03Tarek FennicheNo ratings yet

- Engineering Material Specification: Controlled Document at Page 1 of 7Document7 pagesEngineering Material Specification: Controlled Document at Page 1 of 7Reginaldo SantosNo ratings yet

- Rosemount 1195 Integral Orifice Primary Element: Product Data SheetDocument18 pagesRosemount 1195 Integral Orifice Primary Element: Product Data Sheetابزار دقیقNo ratings yet

- Aa10112 BhelDocument6 pagesAa10112 Bhelmini p shendeNo ratings yet

- Mat1140 PDFDocument4 pagesMat1140 PDFGustavo C. FerreiraNo ratings yet

- Stainless steel tubing specificationDocument2 pagesStainless steel tubing specificationTuấn Dương QuốcNo ratings yet

- Asme2b sb-152Document6 pagesAsme2b sb-152kkskasdkk12No ratings yet

- 016 - 98-IND-B10 May 2016Document8 pages016 - 98-IND-B10 May 2016GurkirtanNo ratings yet

- 98-Ind-B2 Dec2098Document3 pages98-Ind-B2 Dec2098GurkirtanNo ratings yet

- 001 - 98-Ind-B10 DEC 2009Document2 pages001 - 98-Ind-B10 DEC 2009GurkirtanNo ratings yet

- 010 - 98-Ind-B10 May 2014Document2 pages010 - 98-Ind-B10 May 2014GurkirtanNo ratings yet

- QM CertificateDocument1 pageQM CertificateGurkirtanNo ratings yet

- Adhesives and Tapes Design GuideDocument108 pagesAdhesives and Tapes Design GuideGurkirtanNo ratings yet

- Web TranscritsDocument2 pagesWeb TranscritsGurkirtanNo ratings yet

- Course Outline QM Certication UOMDocument6 pagesCourse Outline QM Certication UOMGurkirtanNo ratings yet

- Probabity and Stat Binomial CalcualtionDocument2 pagesProbabity and Stat Binomial CalcualtionGurkirtanNo ratings yet

- 10 MathsDocument11 pages10 MathsZubair MohammedNo ratings yet

- Continuing Education: Course Registration FormDocument1 pageContinuing Education: Course Registration FormGurkirtanNo ratings yet

- ISO 9001 2015 Transition Internal Auditor Course CertificateDocument1 pageISO 9001 2015 Transition Internal Auditor Course CertificateGurkirtanNo ratings yet

- Probabity and StatDocument2 pagesProbabity and StatGurkirtanNo ratings yet

- Quality Toolkit User GuideDocument127 pagesQuality Toolkit User GuideGurkirtanNo ratings yet

- Probabity and StatDocument2 pagesProbabity and StatGurkirtanNo ratings yet

- Astm CompDocument4 pagesAstm CompGurkirtanNo ratings yet

- ElectricDocument42 pagesElectricAbd ZouhierNo ratings yet

- Kent Supplies-11022016123456Document1 pageKent Supplies-11022016123456GurkirtanNo ratings yet

- ElectricDocument42 pagesElectricAbd ZouhierNo ratings yet

- Chapter 3 - Methods of Analysis: N N N N A A A ADocument15 pagesChapter 3 - Methods of Analysis: N N N N A A A AvampakkNo ratings yet

- Lecture 10 - Dry Etching PDFDocument7 pagesLecture 10 - Dry Etching PDFSiddhant ModiNo ratings yet

- Babcock University Bookshop An Babcock University BookshopDocument11 pagesBabcock University Bookshop An Babcock University BookshopAdeniyi M. AdelekeNo ratings yet

- Heliosit OrthodonticDocument20 pagesHeliosit OrthodonticAndhika Galih PrasetyoNo ratings yet

- Monitor AOC 24P3CW EnglishDocument32 pagesMonitor AOC 24P3CW Englishflorinf_uNo ratings yet

- Hydraulic Filter ReportDocument6 pagesHydraulic Filter ReportSandrock_01sr2No ratings yet

- Zebralette User GuideDocument24 pagesZebralette User GuideGiacomo TimbrelloNo ratings yet

- SVCE Seminar Report Format (FINAL)Document6 pagesSVCE Seminar Report Format (FINAL)Vinod KumarNo ratings yet

- RWM61 Data SheetDocument3 pagesRWM61 Data SheetBarth XaosNo ratings yet

- SK EngineeringDocument16 pagesSK EngineeringOmkar waghuleNo ratings yet

- Guide For Dynamic Report Generator - EndsfsdfsdfsdfsdfDocument15 pagesGuide For Dynamic Report Generator - Endsfsdfsdfsdfsdfmtech structuresNo ratings yet

- PI ControllerDocument5 pagesPI Controllerdanuega1No ratings yet

- Prescurtari PDFDocument67 pagesPrescurtari PDFהוד אנדרוNo ratings yet

- Sand, Salt, IronDocument1 pageSand, Salt, IronKevin ChoyNo ratings yet

- Materials Refractive Index and Extinction CoefficientDocument276 pagesMaterials Refractive Index and Extinction CoefficientDr-Mandeep SinghNo ratings yet

- S4M Service ManualDocument522 pagesS4M Service ManualRafał Krzysztof Kowalski100% (1)

- Ups Lyonn Modelo: Ult St5-100 KS: 10KVA A 120KVADocument1 pageUps Lyonn Modelo: Ult St5-100 KS: 10KVA A 120KVASebastian Matias CruzNo ratings yet

- Echotrac Mkiii: Operator'S ManualDocument48 pagesEchotrac Mkiii: Operator'S ManualKhắc PhongNo ratings yet

- 0580 w13 QP 41Document20 pages0580 w13 QP 41Haider AliNo ratings yet

- VDVDVXVCFDBCVCDocument390 pagesVDVDVXVCFDBCVCHafiz Rahmat UllahNo ratings yet

- Rudolf Steiner - Warmth Course GA 321Document119 pagesRudolf Steiner - Warmth Course GA 321Raul PopescuNo ratings yet

- Experiment No 02Document5 pagesExperiment No 02Farhan AliNo ratings yet

- Faculty of Engineering and Computing Sciences: Annexure-IDocument2 pagesFaculty of Engineering and Computing Sciences: Annexure-IAkshay MehtaNo ratings yet

- Swat Luu: User ManualDocument13 pagesSwat Luu: User ManualgjferreiraNo ratings yet

- Materials and Techniques Used For The "Vienna Moamin": Multianalytical Investigation of A Book About Hunting With Falcons From The Thirteenth CenturyDocument17 pagesMaterials and Techniques Used For The "Vienna Moamin": Multianalytical Investigation of A Book About Hunting With Falcons From The Thirteenth CenturyAirish FNo ratings yet