Professional Documents

Culture Documents

1 Repair & Maintenance

Uploaded by

willlycorreaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 Repair & Maintenance

Uploaded by

willlycorreaCopyright:

Available Formats

Service Manual of RS8160 Road Roller

SERVICE MANUAL

Version:0110

1 Repair & Maintenance

Service Manual for LG918 Wheel Loader

CONTENTS

1 Repair & Maintenance ......................................................................................... 1-1

11 Lubricant, Fuel and Other Liquids ...................................................................... 1-1

111 Lubricant ...................................................................................................... 1-1

112 Fuel .............................................................................................................. 1-1

113 Coolant......................................................................................................... 1-2

114 Selection of Oil ............................................................................................ 1-4

12 Repair................................................................................................................... 1-5

121 Notes before Repair ..................................................................................... 1-5

122 Periodic Maintenance .................................................................................. 1-8

123 Maintenance and Repair ............................................................................ 1-14

Service Manual for LG918 Wheel Loader

1 Repair &

Maintenance

Regular maintenance is necessary for high

performance of the machine. The viewpoint that the

machine doesnt need to be checked regularly if the

machine can be used normally is absolutely wrong.

Proper examination and maintenance not only can

extend the working life of the machine, but also find

the malfunctions and deal with them in time, in this

way, the maintenance time and cost can be reduced

significantly.

11 Lubricant,

Fuel

and

Other

Liquids

111 Lubricant

Lubricant can help to prevent the wear of fitting

surface and noise.

The connectors (pipe joint, connecting set) that

are not involved in this manual are only for

overhauling and not need to add lubricant. But

be sure to fill the lubricant if some parts are

difficult to operate after a long time using.

Clear the spilled lubricant after filling.

112 Fuel

Fuel pump is precise device, and it will not

work normally if the fuel is mixed with water

and other impurities.

1-1

Service Manual for LG918 Wheel Loader

Be careful to replace or fill the fuel. Never mix

it with impurities.

Related requirements in this manual must be

complied with when choosing fuel brand.

Fuel will freeze at low temperature (especially

below -15oC), so choose the fuel according to

ambient temperature.

To avoid condensed water from entering into

fuel tank, fill the fuel tank fully after work.

If the engine fails to absorb fuel during starting

process or the filter is just replaced, drain the

air in the circuit first.

113 Coolant

To avoid the incrustant from affecting the

performance of radiator or blocking the

radiator. Be sure to use the antifreeze specified

by SDLG all year round. Never use water as

coolant.

If the engine is overheated, cool the engine and

then fill the coolant.

Coolant should be filled to specified level. Too

low level will result in overheating of engine

and corrosion of cooling system.

If ambient temperature is above 30oC in

summer, park the wheel loader in shade

because the engine may overheat.

After operation, run the engine at idle for 5

minutes in order to prolong the service life of

engine and stop the engine until the water

temperature falls down.

Antifreeze agent is inflammable and you

should keep it away from flame when filling.

1-2

Antifreeze should be replaced every year.

Service Manual for LG918 Wheel Loader

Never use 100% antifreeze as coolant.

Choose different antifreeze according to

ambient temperature condition, recommended

range:

-25# is used for ambient temperature-15

-35# is used for ambient temperature-25

-45# is used for ambient temperature-35

ATTENTION

Never mix the different brands of oil. If there is

only one brand for selection and it is different

from the using one. Use it after draining all the

used oil out.

Due to the severe working conditions (high

temperature and high pressure) of the

wheel loader and dusty in external service

environment,

the

oil

is

easy

to

be

deteriorated. If so, replace the oil at once.

Fill the required volume of oil. Adding oil

too much or too little will cause failure.

Clean or replace filter when filling the oil.

Just after operating the engine, all kinds of

oil and coolant are hot. Do not open the cap

before it is cooled. After cooling, slowly

open the cab to release the internal

pressure.

1-3

Service Manual for LG918 Wheel Loader

114 Selection of Oil

Please use the oil specified by Shandong Lingong

Corp. and chose the oil according to the oil grades

as follows:

Table 1-1

Type

Recommended types and application standards

Qty.

Oiling location

Engine oil

Ambient temperature -15oC~40oC

CD

15W-40 diesel engine oil GB 11122

Ambient temperature -20oC~30oC

CD

10W-30 diesel engine oil GB 11122

13L

Engine

24L

Transmission

torque converter

Hydraulic

transmission 6# hydrodynamic drive oil

oil

Gear oil

Q/SH303 064

Heavy duty vehicle gear oil(GL-5) 85W-90

GB13895

Ambient temperature -10oC ~40oC L-HM46

anti-wear hydraulic oil GB11118.1

Ambient temperature -30oC ~40oC L-HM46

low-temperature hydraulic oil GB11118.1

Hydraulic oil Ambient temperature 0oC ~50oC L-HM68

anti-wear hydraulic oil GB11118.1

Fuel

Brake fluid

22.5+5L

Main drive and wheel

side brakes (export)

21.8+6L

Main drive and wheel

side brakes (domestic)

100L

Hydraulic oil tank

Caltex Superfine anti-grinding hydraulic oil

46

100L

Hydraulic oil tank

(E1805215AK601)

Min. ambient temperature4oC 0# common

diesel GB252

Min. ambient temperature-5oC

-10#

common diesel GB252

Min. ambient temperature-14oC

-20#

common diesel GB252

Min. ambient temperature-29oC

-35#

common diesel GB252

120L

Fuel tank

Motor vehicle brake fluid HZY3 (DOT3)

GB12981

Extreme wide temperature super anti-wear

hydraulic oil 46

box,

4L

Brake oil cup (if

installed)

E1805215AK601

Grease

2# or 3# common lithium-base grease

GB7324

Pin in the each joint

point of the working

device

Antifreeze

Ethylene glycol-based engine coolant

NB/SH/T0521

26L

Radiator

1-4

Service Manual for LG918 Wheel Loader

12 Repair

121 Notes before Repair

Park the wheel loader in maintenance position 1

(Refer to Page 9 in Safety & Environment)

Repair should be performed on solid and flat

ground.

Working device should on ground and bucket

should be laid flat.

Stop the engine and pull out the key.

All operation handles should be set in the

neutral position.

Press the parking brake button to keep the

wheel loader in the state of parking brake.

Put the blocks under the tires.

Lock the front and rear frame with frame lock

lever.

Turn off the battery main switch.

Hang warning tag

Attach the warning tag near the starting switch

before maintenance to prevent someone starting the

engine during maintenance.

Spare parts preparation

Use only parts specified by Shandong Lingong

Corp.

Oil and fuel preparation

Choose oil and fuel specified in this manual

according to ambient temperature.

Use specified oil and fuel

Keep containers of oil and fuel clean and use

specified oil and fuel.

Keep the wheel loader clean

Always keep the wheel loader clean. Especially

1-5

Service Manual for LG918 Wheel Loader

cleanness of oil filling parts, such as grease cups, oil

filling

ports,

and

prevent

impurities

from

infiltrating into those places.

Pay attention to the hot oil and coolant

It is very dangerous to drain hot oil and coolant or

remove the filters immediately after the engine just

stopped. Make sure the engine is cool. The

temperature of the oil drained is appropriately about

20oC~40oC. If it is lower than this temperature, be

sure to warm it up to this temperature before

draining it.

Check the oil and filters

After the oil is changed or filters are replaced, check

the replaced oil and filters. If large amounts of

metallic particles or impurities are found, consult

the maintenance personnel.

Fuel coarse filter

Do not remove the fuel coarse filter while fueling.

Oil replacement

Change oil in dust-free places to keep impurities out

of the oil.

Welding guide

Turn off the starting switch of the engine and

remove the battery cables.

Keep the distance between the grounding cable

and welding area more than 1m.

Avoid welding near the seal rings and

bearings.

Never weld any pipe or tube while there is fuel

gas or oil in them.

Fire prevention

Clean the parts with uninflammable cleaner or light

oil. Keep spark or cigarette light away from them.

1-6

Service Manual for LG918 Wheel Loader

Seals

When replacing O-ring or sealing gaskets, clean the

sealing surfaces first, and make sure the O-ring or

sealing gaskets are in the correct assembly position.

Check the frame

After a long time of stone shoving and transporting

operation, check the frame for damage and check

whether the connecting nuts and bolts are loose and

damaged.

Notes for washing machine

Wash machine after complete cooling of the

engine.

Do not splash water on electric components.

Checking in raining and snowing circumstances

Clean the machine immediately after working in

rain and snow. Lubricate and coat anti-rust oil to

more parts.

Dusty circumstances

Do the following items when the machine works in

dusty circumstances:

Inspect and clean the air filter frequently to

avoid blocking.

Clean the radiator frequently to avoid blocking.

Clean and replace the fuel filter frequently.

Clean the electric components, especially the

starting motor

and

generator,

to

avoid

accumulation of dust affecting dissipation of

heat.

Refer to the bring-in Operation and Maintenance

Manual of Diesel Engine for replacing and

maintaining air filter.

1-7

Service Manual for LG918 Wheel Loader

122 Periodic Maintenance

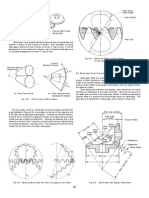

Refer to Fig. 1-1 for periodic maintenance points.

Fig. 1-1

Every 10 Hours (Daily) Maintenance

1.

Check the sealing performance of working

device, steering system and brake system.

2.

Check the flexibility and reliability of the

brakes.

3.

Check whether the electric circuits are correct

and the electric components are normal.

4.

Check the oil level in the fuel tank and the

coolant level in the water tank.

5.

Add grease to the engine fan shaft, hinge joints

between front and rear frames, transmission

1-8

Service Manual for LG918 Wheel Loader

shafts, hinge joints of oscillating frame and

working device.

6.

Check if there are other abnormalities.

7.

Open the gasholder (if installed) water drain

valve to drain water.

8.

Refer

to

Operation

and

Maintenance

Manual of Diesel Engine for maintaining the

engine.

Every 50 Hours (Weekly) Maintenance

1.

Carry out the periodic maintenance of every 10

hours with this maintenance operation at the

same time.

2.

Check oil level in transmission box and

hydraulic oil tank.

3.

Check and tighten all connecting bolts of each

transmission shaft.

4.

Check and tighten all connecting bolts of the

rim and brake caliper.

5.

Check and tighten all connecting bolts of

bucket teeth.

6.

Check and lubricate the accelerator controller,

parking brake and gearshift control system. In

addition, do the extra maintenance in the first

50 hours as follows:

Check and clean the air vent of the

transmission box.

Check if there is leakage in the hydraulic

system.

Check and clean the air vent of the

hydraulic tank.

Check and clean the oil returning filter

element of the hydraulic tank.

1-9

Check and clean the pilot filter element of

Service Manual for LG918 Wheel Loader

the hydraulic tank (if installed).

Check if there is leakage in the brake

system.

Clean strainer of booster pump oil storage

cup, clean the air vent (if installed).

Check brake fluid level and add if

necessary.

Every 100 Hours Maintenance

1.

Carry out the periodic maintenance of every 10

and 50 hours with this maintenance operation

at the same time.

2.

Clean the radiator components.

3.

Clean fuel tank filling filter.

4.

In addition, do the extra maintenance in the

first 100 hours as follows:

Check

and

clean

the

air

vent

of

transmission box.

Clean transmission oil sump. Replace oil

absorption filter element in transmission

oil sump. Replace the filter elements in

torque converter-transmission box oil

circuit.

Replace

transmission

oil.

(Do

the

maintenance every 500h thereafter)

Replace the gear oil in the front and rear

axles. (Do the maintenance every 1000h

thereafter)

Every 250 Hours (Monthly) Maintenance

1.

Carry out the periodic maintenance of every 10,

50 and 100 hours with this maintenance

operation at the same time.

2.

Check the storage battery. Clean surface and

terminals of the battery then coat Vaseline on

1-10

Service Manual for LG918 Wheel Loader

them.

3.

Check whether connecting bolts of frames and

working devices are loose. Check whether

welding seams are cracked.

4.

Check whether the connections between front

and rear axles, engine, transmission box and

frame are loose.

5.

Check the tire pressure. Inflation pressure of

front tires should be (0.33~0.35)MPa, while

that of rear tires should be (0.27~0.29)MPa.

6.

In addition, do the extra maintenance in the

first 250 hours as follows:

Check if there is leakage in the brake

system.

Clean strainer of booster pump oil storage

cup, clean the air vent.

Check Brake fluid level and add if

insufficient. Replace it if necessary.

Every 500 Hours (Seasonally) Maintenance

1.

Carry out the periodic maintenance of every 10,

50, 100 and 250 hours with this maintenance

operation at the same time.

2.

Check and adjust the brake clearance of

parking brake system.

3.

Check the wear condition of brake discs and

friction discs. Replace them if necessary.

4.

Clean the silencer of the brake electromagnetic

valve.

5.

Check and clean the air vent of transmission

box.

6.

Clean the oil sump of transmission box.

7.

Replace transmission oil filter.

8.

Replace the transmission oil. Replace it at least

1-11

Service Manual for LG918 Wheel Loader

once a year.

9.

In addition, do the extra maintenance in the

first 500 hours as follows:

Check if there is leakage in the hydraulic

system.

Check and clean the air vent of hydraulic

tank.

Replace the oil-return filter element of

hydraulic tank and pilot filter element (if

installed).

Check the quantity and cleanness of

hydraulic oil. Filter the oil if possible. Add

them if insufficient and replace them if

necessary.

Every 1000 Hours (Biannually) Maintenance

1.

Carry out the periodic maintenance of every 10,

50, 250 and 500 hours with this maintenance

operation at the same time.

2.

Replace the gear oil in the front and rear axles.

3.

Check and clean strainer of booster pump oil

storage cup (if installed), clean the air vent,

and replace the brake fluid.

4.

Check if there is leakage in the hydraulic

system. Check and clean the air vent of

hydraulic tank. Clean hydraulic oil tank,

replace the oil return filter element of

hydraulic tank and pilot filter element. (If

installed). Replace hydraulic oil.

5.

Check the clearance and wear condition of

pin-sleeve fitting in each hinge joint.

Every 2000 Hours (Yearly) Maintenance

1.

Carry out the periodic maintenance of every 10,

50, 100, 250, 500 and 1000 hours with this

1-12

Service Manual for LG918 Wheel Loader

maintenance operation at the same time.

2.

Replace antifreeze every 2000 working hours

or once a year, whichever comes first.

3.

Check performance of the torque converter

and transmission box, differentials of front and

rear axles and the wheel side reducers.

4.

Check the sealing performance of multitandem

valve and hydraulic tank by measuring the

natural sedimentation volume of the cylinder,

and measure the system pressure.

5.

Check the welding seams of rim and other

stress areas and adjust the deformation.

The maintenance principles listed above are the

basic requirements. The maintenance time should

be determined by the closer one between two the

maintenance schedules. If the working condition is

very severe, please shorten the maintenance cycle

and increase the maintenance times according to

the real conditions.

1-13

Service Manual for LG918 Wheel Loader

123 Maintenance and Repair

Brake check

Observe whether its appearance is normal, such as

oil leakage.

Draining drive axle oil

If you cannot make sure whether the fuel is cooled,

please wear protective cloth in case of burning.

1.

Make sure the draining plug is at lowest

position and you can rotate the wheel if

necessary. (Refer to Fig. 1-2)

1

Fig. 1-2

1 Wheel side oil drain plug (keep it at

the lowest place while draining)

2.

Place the container under the main reducer and

aside the hub to drain the oil. Check and clean

the plug and O-ring, replace them if necessary.

( Refer to Fig. 1-3)

1

Fig. 1-3

1 Oil drain plug of axle housing

Draining of oil in the hydraulic tank

1.

After the engine is cooled, wear protective

cloth.

2.

Connect the hose to hydraulic oil draining port

and the other end should be diverted to empty

container (Place an empty container aside and

the total volume of the tank is 128L, refer to

1

Fig. 1-4

1 Oil drain port of hydraulic tank

Fig. 1-4)

3.

Open the valve and drain oil to the empty

container.

4.

1-14

Disconnect the hose.

Service Manual for LG918 Wheel Loader

Draining

of

hydrodynamic

drive

oil

(transmission oil) in transmission box

Do the maintenance after the machine is cooled.

Open the draining plug and drain the oil to the

empty container. (Refer to Fig. 1-5)

Fig. 1-5

1 Oil drain port of transmission box

Engine oil draining

Do the maintenance after the machine is cooled.

Place the empty container under the engine and

open the oil drain plug. (Refer to Fig. 1-6)

1

Fig. 1-6

1 Oil drain plug

Replacement of fuel filter

1.

Remove filter with filter wrench (Refer to Fig.

1-7)

2.

Coat the seal of new filter with engine oil. And

tighten it according to the guide in the manual.

3.

Deflate the fuel system after replacing the

filter.

1

Fig. 1-7

1 Coarse fuel filter

1-15

Service Manual for LG918 Wheel Loader

Replacement of engine oil filter

Maintenance it after it is cooled.

1.

Replace the engine oil filter.

2.

Apply new engine oil on the new filter. (Refer

to Fig. 1-8), tighten it according to the

requirements described in the manual.

1

Fig. 1-8

1 Engine oil filter

Replacement of engine air filter

1.

Replace the main filter at least once a year, or

replace it when the filter is blocked and alarm.

During replacing, clean the filter cover hood,

because it is used to contain the particle that is

not filtered by filter.

2.

Check and ensure that all the hoses and

connectors from air filter to engine manifold

have no leakage problem. Check and tighten

the clamps.

Fig. 1-9

1 Air filter

3.

Replace the safety filter at least every other

year or when the main filter is replaced 3 times.

(Refer to Fig. 1-9)

Replacement of transmission oil filter

Overhaul the machine after it is cooled.

1.

Drain the oil out and then remove the filter.

(Refer to Fig. 1-10)

2.

Install new filter and tighten it according to the

instructions described in the manual.

1

Fig. 1-10

1 Transmission oil filter

1-16

Service Manual for LG918 Wheel Loader

Clean the oil absorption filter screen of

transmission box

1.

Remove the cover and clean the internal parts.

Check and ensure the parts are not damaged.

2.

Install a new gasket between cover hood and

transmission box

3.

Reassemble the absorption screen. (Refer to

Fig. 1-11)

1

Fig. 1-11

1 Oil absorption filter screen

Engine oil filling

Fill the engine oil of specified volume (Refer to

Fig. 1-12)

1

Fig. 1-12

1 Engine oil filling port

1-17

Service Manual for LG918 Wheel Loader

Transmission belt checking

Check tension of belt and check whether the

draw-in rod is worn. (Refer to Fig. 1-13)

1

Fig. 1-13

1 Belt

Replacement of vent filter of hydraulic tank

Replace the filter. (Refer to Fig. 1-14)

Replacement of oil-return filter of hydraulic

tank

Fig. 1-14

1 Oil return flange

2 Upper oil absorption flange

3 Hydraulic oil filling port

4 Vent filter

1.

Remove the filter cap. (Refer to Fig. 1-14)

2.

Remove the filter.

3.

Install the new filter.

4.

Check the seal ring in cover hood when

installing it.

Hydraulic oil filling

1.

Fill the hydraulic oil to the specified level.

(Refer to Fig. 1-14)

2.

Control the oil level by using oil level pointer.

Transmission oil filling

Fill about 24L.

1

Fig. 1-15

1 Filling port of transmission oil

1-18

Service Manual for LG918 Wheel Loader

Drive axle gear oil filling

1.

Keep the wheel side draining plug in tire

horizontal shaft position.

2.

Fill specified gear oil via the oil draining ports

on the two wheel sides of drive axle and the

filling port in the middle of axle housing.

3.

1

Fill the oil until the level gets the edge of oil

level plug.

Fig. 1-16

1 Filling port of axle housing

Replacement of internal circulation filter and

external circulation filter in the cab

1.

Open the side cover. (Refer to Fig. 1-17)

2.

Rotate the fixing parts aside and then remove

external circulation filter and put it aside.

3.

Rotate the fixing parts aside, and then remove

the

lower

shell.

Remove

the

internal

circulation filter and put it aside.

Fig. 1-17

4.

Install new filters, shell and new prefilter and

then close the cover.

Transmission oil level checking

Before the checking, make sure the oil temperature

is about 50oC and engine is running idly. It is

normal if there is oil overflowing when open the

oil level checking plug. (Refer to Fig. 1-18)

1

Fig. 1-18

1 Transmission oil level checking plug

1-19

Service Manual for LG918 Wheel Loader

Hydraulic oil level checking

Keep the boom at the lowest position. Check the

oil level via the bar-type oil pointer.

1

Fig. 1-19

1 Bar-type oil pointer

Engine oil level checking

Oil level should be between max mark and min

mark on the oil dipstick.

1

Fig. 1-20

1 Engine oil dipstick

Coolant level checking

Start and run the engine for several minutes, shut

down the engine and wait until the coolant is

cooled.

Open water tank cap to check coolant level, oil

level should be in specified range.

If you fill the coolant, do not open the cover when

the coolant is hot. Wait until it is cooled.

1

Fig. 1-21

1 Water tank cap

1-20

Service Manual for LG918 Wheel Loader

Checking of battery, cable and connectors

Touch the liquid of battery will cause severe

chemical burning.

Wear protective gloves, goggle and clothes when

maintaining the battery.

1.

Open the battery cover. Open one hood each

time.

Fig. 1-22

2.

Check and clean the connectors of cable and

terminals and bolts of battery, and coat the

external surface with grease as anticorrosion,

such as Vaseline. (Refer to Fig. 1-22)

3.

Check the liquid level, and the green color

means normal.

Radiator cleaning

1.

Open the engine hood.

2.

Clean the fins of radiator with compressed air

along the rotating direction. (Refer to Fig.

1-23)

Install the grid shield device.

If not being dealt properly, the fins of radiator

may be damaged.

Fig. 1-23

1-21

You might also like

- Analise de Falhas e ServiCos Lg918 To Lg968 Eng Rev1 2011Document60 pagesAnalise de Falhas e ServiCos Lg918 To Lg968 Eng Rev1 2011AUTOMAQ SERVICENo ratings yet

- Service Manual for LG936L Wheel Loader Engine SystemDocument55 pagesService Manual for LG936L Wheel Loader Engine Systemမင်း လွင်No ratings yet

- LG Axle Service Manual of Edition in 2020. 5Document89 pagesLG Axle Service Manual of Edition in 2020. 5technical trainer 011c100% (1)

- HDF50!70!7 (S) Service ManualDocument518 pagesHDF50!70!7 (S) Service ManualHubert Chavez100% (4)

- LG936L Wheel Loader Parts CatalogDocument256 pagesLG936L Wheel Loader Parts CatalogTiago CamposNo ratings yet

- LG936 g2xDocument141 pagesLG936 g2xdimaqdcNo ratings yet

- Daewoo Fault PDFDocument4 pagesDaewoo Fault PDFBabei Ionut-MihaiNo ratings yet

- SM 5184 Espanol-Cmp 15-30Document464 pagesSM 5184 Espanol-Cmp 15-30Junior NogueiraNo ratings yet

- L60F, L70F, L90F: Volvo Wheel LoadersDocument36 pagesL60F, L70F, L90F: Volvo Wheel Loadersامین پارساNo ratings yet

- VMT 860 Brochure Issue 2Document16 pagesVMT 860 Brochure Issue 2Florin Paraschivescu100% (1)

- Eefedofdefc - Pub - Service Mansadfeafual For Weichai Wp6stage 3pdf PDFDocument204 pagesEefedofdefc - Pub - Service Mansadfeafual For Weichai Wp6stage 3pdf PDFgaurav champawatNo ratings yet

- Warning: Operation & Maintenance ManualDocument113 pagesWarning: Operation & Maintenance ManualTatiano BrolloNo ratings yet

- Manual de Peças Xgma XG31651Document77 pagesManual de Peças Xgma XG31651Alisson LuizNo ratings yet

- LG938L E3815215ak6 PDFDocument373 pagesLG938L E3815215ak6 PDFacongNo ratings yet

- Каталог запчастей погрузчик Chenggong CG935h, двигатель TD226b-6GDocument146 pagesКаталог запчастей погрузчик Chenggong CG935h, двигатель TD226b-6GSerg100% (1)

- CLG915E 4F Service Manual201701001-ENDocument1,073 pagesCLG915E 4F Service Manual201701001-ENjaki162096No ratings yet

- Spare Parts Catalog: 4 WG-200 Case Material Number: 4644.024.131Document78 pagesSpare Parts Catalog: 4 WG-200 Case Material Number: 4644.024.131Teknik MakinaNo ratings yet

- Cargador LG918 - E1808215AK6Document262 pagesCargador LG918 - E1808215AK6jorge hernan correa50% (2)

- LG936L E3615115a36Document382 pagesLG936L E3615115a36Sun andyNo ratings yet

- Main Products IntroductionDocument99 pagesMain Products Introductionmliugong100% (1)

- FMC Second Release Cat 2016 Stick PDFDocument156 pagesFMC Second Release Cat 2016 Stick PDFhernan dueñasNo ratings yet

- C80D-9678 Catalogo ClarkDocument155 pagesC80D-9678 Catalogo ClarkJose Angel Basanta HernandezNo ratings yet

- LG936 Training Material: Chapter 3 Engine Structure PrincipleDocument51 pagesLG936 Training Material: Chapter 3 Engine Structure Principlemliugong100% (2)

- Planetary Axle Wheel Ends PDFDocument64 pagesPlanetary Axle Wheel Ends PDFКонстантин КосаревNo ratings yet

- DCE 80-100E Operator's ManualDocument52 pagesDCE 80-100E Operator's ManualEdson GoncalvesNo ratings yet

- Catalago Pá Lonking CDM 816Document138 pagesCatalago Pá Lonking CDM 816Diego ValensuelaNo ratings yet

- Catalogo de Peças JLGDocument430 pagesCatalogo de Peças JLGIgor GargaglioneNo ratings yet

- 2.BL Power TrainDocument52 pages2.BL Power TrainJorge Rojas100% (2)

- 001-Power SystemDocument96 pages001-Power Systemmohamed omerNo ratings yet

- SM LG958L - LG959 PDFDocument125 pagesSM LG958L - LG959 PDFDian Deltrax0% (1)

- Spare Parts Catalog: 4 WG 200 (555/5) (Current Date: 15.11.2012) Material Number: 4644.024.161Document92 pagesSpare Parts Catalog: 4 WG 200 (555/5) (Current Date: 15.11.2012) Material Number: 4644.024.161Mourad Chabchoub100% (1)

- OEM Parts for Liugong LoadersDocument64 pagesOEM Parts for Liugong LoadersChristian VicenteNo ratings yet

- Hangcha 5 7TN1 PDFDocument2 pagesHangcha 5 7TN1 PDFTiagoNo ratings yet

- Pellet MillDocument2 pagesPellet MillWilson LiangNo ratings yet

- Hyster H36.00-48.000, 16CH - D117Document936 pagesHyster H36.00-48.000, 16CH - D117Bernard100% (3)

- Catálogo C80DDocument141 pagesCatálogo C80DErikles Rafael100% (1)

- Wheel Loader: 144 KW (193 HP) at 2,200 RPM 136.8 KW (183 HP) at 2,200 RPM 15,000 KG 2.7 M 136 KN MMDocument2 pagesWheel Loader: 144 KW (193 HP) at 2,200 RPM 136.8 KW (183 HP) at 2,200 RPM 15,000 KG 2.7 M 136 KN MMMarcos SouzaNo ratings yet

- Shandong Lingong Wheel Loader LG918 Operation & Maintenance Manual 2nd 10.3.23Document113 pagesShandong Lingong Wheel Loader LG918 Operation & Maintenance Manual 2nd 10.3.23mliugong100% (3)

- PARTS MANUAL FOR C 20/25/30/33(35) D SERIAL NUMBER P232D - XXXX - 9677 KFDocument367 pagesPARTS MANUAL FOR C 20/25/30/33(35) D SERIAL NUMBER P232D - XXXX - 9677 KFГригорий УсачёвNo ratings yet

- Cylinder Head 10001 26678Document2 pagesCylinder Head 10001 26678Oecox Cah DjadoelNo ratings yet

- 发动机总成WP6G125E22(DHB06G0121) ENGINE PARTS CatalogDocument165 pages发动机总成WP6G125E22(DHB06G0121) ENGINE PARTS CatalogSok Bunnarang0% (1)

- SEM636 Parts Manual OverviewDocument185 pagesSEM636 Parts Manual OverviewRicardo Barreto100% (1)

- SDLG BrowsingDocument2 pagesSDLG BrowsingLukman ExmesNo ratings yet

- Manual de Servicio KubotaDocument2 pagesManual de Servicio KubotacpaolinodNo ratings yet

- Loader Maintenance ManualDocument226 pagesLoader Maintenance Manualjoanvasquez61No ratings yet

- Catalogo Hyundai - Hl740-9sDocument481 pagesCatalogo Hyundai - Hl740-9sLuian Bruno100% (1)

- Yale GP080-120VX-BTGDocument28 pagesYale GP080-120VX-BTGФедор СумовNo ratings yet

- Peças Pá Carregadeira Ensign YX636Document221 pagesPeças Pá Carregadeira Ensign YX636Luiz Gustavo Duarte100% (1)

- Pa Carregadeira SDLG LG938L E3815215gk6 2 PDFDocument402 pagesPa Carregadeira SDLG LG938L E3815215gk6 2 PDFMurilo VenancioNo ratings yet

- 35DS 40DS 45DS 50DA-7E Service ManualDocument419 pages35DS 40DS 45DS 50DA-7E Service ManualHubert Chavez67% (3)

- LG936L Parts Catalogue PDFDocument260 pagesLG936L Parts Catalogue PDFShawn Feng100% (2)

- Service Manual: ZL15 Series Power-Shift TransmissionDocument38 pagesService Manual: ZL15 Series Power-Shift TransmissionFAOUZI100% (2)

- Manual Oper. y Manten. 1TN - 3,5TN R Series (Comb. Interna) PDFDocument113 pagesManual Oper. y Manten. 1TN - 3,5TN R Series (Comb. Interna) PDFRicardo BilbaoNo ratings yet

- Toyota 8fg25bDocument369 pagesToyota 8fg25bAngelo KuibidaNo ratings yet

- Parts Manual: 55D Pivot Arm Paper Roll ClampDocument26 pagesParts Manual: 55D Pivot Arm Paper Roll Clampremeen100% (1)

- Clg835-Yuchai PartesDocument231 pagesClg835-Yuchai Partesjuliana100% (2)

- 1repair & Maintenance - ENGLISG-G9165Document39 pages1repair & Maintenance - ENGLISG-G9165George Jhonson100% (6)

- 1repair & Maintenance - ENGLISG-G9180Document44 pages1repair & Maintenance - ENGLISG-G9180George Jhonson100% (5)

- Engine Manual Provides Operation and Maintenance TipsDocument48 pagesEngine Manual Provides Operation and Maintenance TipshassanHyro4350% (2)

- GT650R Service Manual Section OverviewDocument14 pagesGT650R Service Manual Section OverviewJohn Allen ReihartNo ratings yet

- Me B EnginesDocument12 pagesMe B EnginesSabari SasichandranNo ratings yet

- Jav Forgings & Engineerings Private Limited: Quotation No.:-QI220527-VI00064 Rev .01Document19 pagesJav Forgings & Engineerings Private Limited: Quotation No.:-QI220527-VI00064 Rev .01Saiyed M FaisalNo ratings yet

- Koro - Espresso - Instant - 220v 50-60hz May 2011Document48 pagesKoro - Espresso - Instant - 220v 50-60hz May 2011Leah LopezNo ratings yet

- Shimano Compatabilty PDFDocument28 pagesShimano Compatabilty PDFChristorey Abucay100% (1)

- CH 8 Slides M PDFDocument96 pagesCH 8 Slides M PDFAnkit NayakNo ratings yet

- FPDieselNov PDFDocument5 pagesFPDieselNov PDFRobert HutapeaNo ratings yet

- 9853 6795 20 Spare Parts Catalogue New Cylinders PDFDocument42 pages9853 6795 20 Spare Parts Catalogue New Cylinders PDFHercules StyliarasNo ratings yet

- Engine Manual Sc25r Sc28r Saic MaxusDocument81 pagesEngine Manual Sc25r Sc28r Saic Maxusangelica lopez100% (4)

- Stanadyne de Pump Timing InstructionsDocument1 pageStanadyne de Pump Timing InstructionsPiotr Kowal100% (5)

- Chapter 4Document10 pagesChapter 4igorNo ratings yet

- CLG418 Operation &maintainance ManualDocument66 pagesCLG418 Operation &maintainance ManualLYCANTROPOFAGO89% (9)

- Peugeot 505Document300 pagesPeugeot 505Артуро Игнасио Муньос СильваNo ratings yet

- Bevel Gear ManualDocument8 pagesBevel Gear ManualPiort ZelaskiNo ratings yet

- Juki MO-6704S-OE4, MO-6714S-BE6, MO-6716S-DE4 PDFDocument48 pagesJuki MO-6704S-OE4, MO-6714S-BE6, MO-6716S-DE4 PDFAdrian LinaresNo ratings yet

- 2003 Nissan Altima 2.5 Serivce Manual FWDDocument12 pages2003 Nissan Altima 2.5 Serivce Manual FWDAndy DellingerNo ratings yet

- GT and ST Spare Parts ListDocument14 pagesGT and ST Spare Parts Listprasana balaji100% (1)

- PARTS CATALOGUE FOR SUZUKI GSX150FL6Document92 pagesPARTS CATALOGUE FOR SUZUKI GSX150FL6Nelson Rodrigo75% (16)

- Ranger Repair Manual PDFDocument1,335 pagesRanger Repair Manual PDFscodavnx87% (83)

- Gerinda MT955 PDFDocument3 pagesGerinda MT955 PDF0.1 JayanNo ratings yet

- Bevel Gear Transmission AnglesDocument6 pagesBevel Gear Transmission AnglesNabende UmarNo ratings yet

- 3736a G9T Common Rail SystemDocument180 pages3736a G9T Common Rail Systemplamenvp21100% (1)

- 21vzb Vspec ManualDocument38 pages21vzb Vspec ManualIvan RodriguezNo ratings yet

- Part Diagram STIHL HT75Document82 pagesPart Diagram STIHL HT75Ira P AnggasariNo ratings yet

- Part BD 01Document2 pagesPart BD 01Spareparts Alat BeratNo ratings yet

- Engine EME 35 ManualDocument8 pagesEngine EME 35 ManualYahdi Safa'at NasutionNo ratings yet

- GRT9165 SM CTRL699 01 LightDocument328 pagesGRT9165 SM CTRL699 01 LightShakir HussainNo ratings yet

- Title: Automotive Powertrain Date: Objective: To Understand The Power Train Components of Automobiles Both Observation/TheoryDocument17 pagesTitle: Automotive Powertrain Date: Objective: To Understand The Power Train Components of Automobiles Both Observation/TheorybroNo ratings yet

- Final Project ReportDocument11 pagesFinal Project ReportoddomancanNo ratings yet

- Espace III Service Repair ManualDocument1,452 pagesEspace III Service Repair ManualCorrado MeassoNo ratings yet

- PAHF 20-40 Pump Disassembly and Reassembly InstructionsDocument13 pagesPAHF 20-40 Pump Disassembly and Reassembly InstructionsCátia RodriguesNo ratings yet