Professional Documents

Culture Documents

Sulphur, Spurrite, and Rings in Cement Kilns PDF

Uploaded by

Anonymous NxpnI6jCOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sulphur, Spurrite, and Rings in Cement Kilns PDF

Uploaded by

Anonymous NxpnI6jCCopyright:

Available Formats

RHI Bulletin >2 > 2007, pp.

3538

Josef Nievoll, Susanne Jrg, Klaus Dsinger, and Juan Corpus

Sulphur, Spurrite, and RingsAlways a

Headache for the Cement Kiln Operator?

Sulphospurrite (2C2S.CaSO4) is the mineral phase responsible for ring formation in the preheating zone of cement rotary kilns. Samples from rings of three different kilns have been

analysed chemically and studied microscopically to explain sulphospurrite crystallization and

growth. SiO2 impregnated alumina bricks impede sulphospurrite crystallization by stabilizing

dicalcium silicate (C2S) very efficiently and are much more economic than existing antisticking refractories.

Introduction

Many cement rotary kilns are plagued by rings in the inlet

or preheating section. The effects of rings are well known

[1]:

>> The flow of the kiln feed is restricted; with sufficient

height, hot meal is retained until the kiln inlet and flows

out through the kiln inlet seal (Figure 1), posing a serious safety risk and damaging the kiln inlet seal.

>> Increase of the pressure drop, augmenting thus the

energy consumption of the induced draft (ID) fan.

>> Increase of gas velocities in the ring area, entraining

thus more dust into the kiln gas.

These effects destabilize the clinker burning process. The

ultimate consequence may be an unplanned kiln stop and

the subsequent cleaning of the kiln. Despite its operational

impact, the ring material is rarely examined in detail. Sometimes it is analysed chemically or by X-ray diffraction to

confirm its spurrite nature; publications of microscopic

analyses are very limited [2,3].

The present paper summarizes the results of several studies

on rings from different kilns, which were carried out at the

RHI Technology Center as a customer service in order to

improve the kiln operation. It deals only with spurrite

rings from the inlet and preheating zone of rotary kilns and,

given the complex compositions found, should serve as a

starting point for further investigations.

Spurrite and Sulphur

It should be remembered that spurrite is used widely

without distinguishing between true spurrite (Ca5(SiO4)2CO3)

and the more ubiquitous, but structurally unrelated calcium

silicosulphate (Ca5(SiO4)2SO4), which is sometimes called

sulphospurrite [4,5]. In the German literature the latter is

frequently referred to as Sulfatspurrit [2,6], therefore sulpho

spurrite will be used further on in this paper. Besides the

structural formula (see above) sulphospurrite is also written

as Ca5Si2(SO4)O8, 2C2S.CaSO4, and C5S2S.

The relationship between ring formation, sulphur, and sulphospurrite in modern precalciner and suspension preheater

kilns is quite obvious: Rings form easily when a pronounced

excess of sulphur over alkalis in the kiln atmosphere exists.

In most kilns, the excess sulphur is introduced by the fuel

(e.g., when firing sulphur-rich petcoke), but rings are also

observed in kilns fired with sulphur-free fuels (e.g., natural

gas). In this case, the sulphur excess in the kiln atmosphere

results from the lack of alkalis in the raw meal. Reducing

conditions and raw meals of difficult burnability are also

known to increase the amount of sulphur in the kiln atmosphere, therefore favouring ring formation. Other factors influencing the sulphur cycle are the flame shape and the burner

position.

Composition of Rings

The chemical analyses were carried out by X-ray fluorescence after dissolution of the sample in Li2B4O7 (according

to DIN 51001); sodium and potassium were analysed by

inductive coupled plasma-optical emission spectrometry

(ICP-OES), sulphur and carbon using a LECO analyser, and

chlorine by titration with silver nitrate. For the mineralogic

investigation polished sections were prepared and investigated by light microscope and scanning electron microscope, combined with energy-dispersive X-ray analysis.

Additionally, X-ray diffraction was carried out. The spectra

evaluation was done according to the international database.

Figure 1. Hot meal flowing out through the kiln inlet seal.

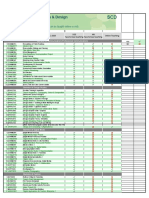

Nine samples from three different suspension preheater

kilns (Kilns AC) were studied chemically and microscopically (Table I). From Kiln A five samples from two kiln campaigns were analysed. From Kiln B the ring which formed

between running metre (rm) 4751 had a thickness of

> 35

RHI Bulletin >2 > 2007

Kiln

Kiln dimensions

4.20 x 72 m

5.18 x 82 m

4.45 x 70 m

40

42

outer layer

(hot face)

42

middle layer

42

inner layer

(cold face)

52

47

outer layer

(hot face)

47

middle layer

47

inner layer

(cold face)

45

MgO

1.78

1.18

1.30

1.18

0.94

1.02

0.88

0.76

1.13

Al2O3

4.84

4.17

4.75

4.12

3.45

4.91

4.91

4.91

4.82

SiO2

18.20

19.60

20.90

19.70

20.90

19.10

18.70

18.60

19.90

CaO

67.30

63.20

63.10

62.70

60.70

64.70

64.30

63.60

57.80

Fe2O3

3.12

3.01

3.32

3.13

5.41

3.49

3.56

4.12

2.93

Loss on ignition

4.11

3.22

7.57

3.89

9.52

4.88

1.42

9.84

4.35

K2O

0.36

0.94

0.74

0.89

1.43

1.31

1.78

2.27

1.31

Na2O

0.08

0.16

0.17

0.16

0.19

0.41

0.53

0.61

0.65

Ring position (rm)

Chemical analysis (wt.%)

Cl

0.05

0.09

< 0.05

0.11

0.58

0.06

0.15

0.12

0.39

SO3

4.34

5.41

1.77

5.29

4.89

4.99

4.89

8.03

10.10

Table I. Chemical composition of ring materials from three different suspension preheater kilns.

30 inch (762 mm), divided into three layers (Figure 2). Each

layer showed internally a more or less pronounced fine layering.

Conventional light microscopy revealed the highly porous

nature of the ring material and the internal layering, resulting from varying densities. The mineral phases were best

studied using scanning electron microscopy because of the

small grain size (< 10 m) and the frequently off-stoichiometric composition.

A fresh surface from within the outer layer of Kiln A showed

plate-like crystals of sulphospurrite (Figure 3).

In polished section, sulphospurrite appeared as thin needles

(Figure 4). C4AF (brownmillerite (Ca4Al2Fe2O10) formed skelet-like, relative coarse crystals. Free lime (CaO) was easily

recognizable by its relief, caused by the incipient hydration.

C2S formed round to elongate grains, Ca-langbeinite

(K2SO4.2CaSO4), as a low melting phase, filled pores and

interstices.

Figure 3. Plate-like crystals of sulphospurrite (Kiln A, rm 42,

outer layer).

3

2

1

Figure 2. Ring in Kiln B, rm 47, with location of samples from

outer layer (1), middle layer (2), and inner layer (3).

36 <

Figure 4. Polished section from Kiln B, middle layer, with needle

shaped sulphospurrite crystals (1). For further explanation see

text.

RHI Bulletin >2 > 2007

In the polished section from the inner layer from Kiln A

(Figure 5) sulphospurrite was partly decomposed into C2S,

probably because of cooling down beneath the temperature

of the lower stability of sulphospurrite. Yeelimite [Ca4(Al6O12)

(SO4)] forms the lowest melting sulphate phase.

While sulphospurrite was found in all samples, spurrite

(2C2S.CaCO3) could only be identified in four samples; its

contribution in forming rings seemed to be much less than

sulphospurrite whose calculated content was between 10

and 60%; typical values are around 2530%.

As mentioned earlier, the analysed samples showed an

internal stratification that probably reflects the variations in

composition and temperature of the kiln gases. Thus, it

would be interesting to compare ring growth (via temperature scanning of the kiln shell) with the recordings of temperature and gas composition at the kiln inlet.

Figure 5. Relicts of sulphospurrite surrounded by C2S (1) and

yeelimite (2). Sample from Kiln A, inner layer.

The presence of liquid Ca-langbeinite (K2SO4.2CaSO4) would

also explain the good adherence of the sulphospurrite crystals on the refractory substrate and its subsequent rapid

growth. Without molten Ca-K-sulphate, transport of nonvolatile CaO and SiO2 to the growing sulphospurrite crystals

would be too slow. The role of Ca-langbeinite in sulpho

spurrite formation is also supported by small, but systematic amounts of K2O in the sulphospurrite composition,

probably substituting SiO2.

Zircon bricks were the first refractories installed specifically

to combat ring formation. The drawback of these bricks was

their brittleness, so that the lining was crushed mechanically soon after the installation. This product line was,

therefore, abandoned about 1015 years ago. Zircon containing castables are, however, still part of the product

range, but are for obvious reasons not appropriate for the

rotary kiln. SiC containing high alumina bricks have for 23

years gained some reputation as a ring-inhibiting material,

but customers are complaining about the high price. The

latest material to provide ring-inhibiting properties are SiO2

impregnated alumina bricks [7], which are significantly

cheaper than SiC containing bricks. SiO2 impregnated alumina bricks also have a technical advantage: While in zircon

and in silicon carbide bricks the required SiO2 is bound in

the silicate and carbide structure, respectively, it is not fixed

in a crystalline structure in the SiO2 impregnated alumina

bricks and is therefore more readily available for impeding

sulphospurrite formation. A photograph of a precalciner kiln

(4.0 m diameter x 65 m long, 2300 tonnes per day) which is

fired with petcoke and liquid waste fuel and where with

conventional alumina bricks always rings formed, is shown

in Figure 6. On SiO2 impregnated alumina bricks (i.e.,

RESISTAL B50ZIS) no rings formed in the preheating zone

(rm 29.536.5). For people not familiar with cement rotary

kilns the picture showing a clean, smooth lining surface

may seem unspectacular; but for the plant engineers it documents one headache less in clinker production. Meanwhile

RESISTAL B50ZIS bricks have also been installed in the preheating zone of the second precalciner kiln at this plant.

Refractory Materials Against Ring Formation

The following refractory materials are reported to inhibit

ring formation or at least to reduce ring stability:

>> Zircon bricks

>> Andalusite-SiC bricks

>> Mullite-SiC bricks

>> SiO2 impregnated alumina bricks

>> Zircon containing castables

>> SiC containing castables

The common feature of all these materials is that they contain a component that at operating conditions makes SiO2

available for the following chemical reaction:

2 (2Ca2SiO4. CaSO4) + SiO2 5 Ca2SiO4 + 2 SO3

With SiO2, the thermodynamically more stable C2S is

formed instead of sulphospurrite. In absence of SiO2, the

formation of sulphospurrite may occur according to the following reaction:

4 Ca2SiO4 + K2SO4.2CaSO4 2 (2Ca2SiO4. CaSO4) + K2SO4

Figure 6. Surface of preheating zone in a precalciner kiln after 18

months operation. Sulphospurrite ring formation was impeded

by RESISTAL B50ZIS, a SiO2 impregnated alumina brick. Residual thickness after 18 months operation was 160190 mm.

> 37

RHI Bulletin >2 > 2007

Conclusion

Sulphospurrite (2C2S.CaSO4) was confirmed to be the main

ring-building mineral phase in the samples investigated

from three different suspension preheater kilns. Due to the

minute size of the mineral phases and their off-stoichiometric composition, scanning electron microscopy combined

with an energy-dispersive analysis system is the most

appropriate way to study ring material. Crystallization of

sulphospurrite crystals on the surface of the refractory lining and subsequent rapid growth of the ring in a SO3 rich

kiln atmosphere is probably enhanced by liquid Ca-K-sulphate.

SiO2 impregnated alumina bricks are an economic solution

to eliminate sulphospurrite rings. The SiO2 residue from the

impregnation plays the key role in stabilizing C2S and inhibiting sulphospurrite formation. Contrary to zircon and SiC

containing refractory materials, which also show antisticking properties, in SiO2 impregnated alumina bricks the silica

is not bound crystallographically and is thus more readily

available for impeding sulphospurrite formation.

References

[1] Dover, P. Practical Solutions to Kiln and Preheater Build-Up Problems. Proceedings Cemtech, Lisbon, Portugal, 2003; pp. 121131.

[2] Bonn, W. and Lang, T. Brennverfahren. ZKG International. 1986, 39, 105114.

[3] Palmer, G. Ring formations in cement kilns. World Cement. 1990, December, 538543.

[4] Taylor, H.F.W. Cement Chemistry; Academic Press: London, 1990; p 475.

[5] Choi, G. and Glasser, F.P. The Sulphur Cycle in Cement Kilns: Vapour Pressures and Solid-Phase Stability of the Sulphate Phases. Cement and

Concrete Research. 1988, 18, 367374.

[6] Weisweiler, W. and Dallibor, W. Bildung von Sulfatspurrit 2C2S.CaSO4 aus Rohmehlkomponenten und Klinkerbestandteilen. ZKG International.

1987, 40, 430433.

[7] Nievoll, J. and Monsberger, G. The Performance of Specially Impregnated Alumina Bricks. RHI Bulletin. 2004, 2, 1114.

Authors

Josef Nievoll, RHI AG, Industrial Division, Vienna, Austria.

Susanne Jrg, RHI AG, Technology Center, Leoben, Austria.

Klaus Dsinger, RHI AG, Industrial Division, Vienna, Austria.

Juan Corpus, RHI REFMEX, Ramos Arizpe, Mexico.

Corresponding author: Josef Nievoll, josef.nievoll@rhi-ag.com

38 <

You might also like

- 7-Mineral Phases of Portland CementDocument28 pages7-Mineral Phases of Portland CementzamriseramikNo ratings yet

- Alite Modification by SO3 in Cement Clinker - An Industrial TrialDocument7 pagesAlite Modification by SO3 in Cement Clinker - An Industrial TrialRaúl Marcelo Veloz100% (2)

- Alkali & Sulphur RatioDocument2 pagesAlkali & Sulphur RatioManish KumarNo ratings yet

- Coating Rings and Balls PDFDocument8 pagesCoating Rings and Balls PDFAnonymous NxpnI6jC100% (1)

- By Pass SystemDocument56 pagesBy Pass SystemIrshad Hussain100% (2)

- Pyro ProcessingDocument29 pagesPyro ProcessingMKPashaPasha100% (2)

- Cement Process Engineering Vade-Mecum: 3. QualityDocument22 pagesCement Process Engineering Vade-Mecum: 3. QualityRaúl Marcelo VelozNo ratings yet

- Snowman CompositionDocument7 pagesSnowman CompositionSunil MohanNo ratings yet

- Infinity For Cement Equipment: Quality & Composition of Cement ClinkerDocument48 pagesInfinity For Cement Equipment: Quality & Composition of Cement ClinkerYhaneNo ratings yet

- Classification Wirsing 2015Document49 pagesClassification Wirsing 2015Moud Sakly100% (1)

- Viscosity PDFDocument1 pageViscosity PDFElwathig BakhietNo ratings yet

- RMO - KFUI UnderstandingDocument30 pagesRMO - KFUI Understandingmustaf100% (1)

- Cement KilnsDocument26 pagesCement KilnsEngr Nabeel AhmadNo ratings yet

- Cement Kiln Liquid PhaseDocument5 pagesCement Kiln Liquid Phaseمعاوية محمد50% (2)

- Calculation of Raw MixDocument35 pagesCalculation of Raw MixIrshad HussainNo ratings yet

- Calculation of The Formation Process of Clinker inDocument7 pagesCalculation of The Formation Process of Clinker inYounas BugtiNo ratings yet

- Ring Formation in KilnDocument12 pagesRing Formation in KilnAbul Qasim100% (2)

- Cement Manufacturing Technology: Cemnet Training - Course Tcm01 Module 6 - Session 1Document13 pagesCement Manufacturing Technology: Cemnet Training - Course Tcm01 Module 6 - Session 1PiNGPooNGNo ratings yet

- Monolithics - Basten 2018Document69 pagesMonolithics - Basten 2018Yhane Hermann BackNo ratings yet

- Coating, Rings and BallsDocument8 pagesCoating, Rings and BallsHazem Diab100% (1)

- Influence of The Clinker SO3 On The Cement CharacteristicsDocument1 pageInfluence of The Clinker SO3 On The Cement Characteristicsroshan_geo078896No ratings yet

- A Better Kiln CoatingDocument2 pagesA Better Kiln Coatingamir100% (4)

- Cement Kiln RefractoryDocument166 pagesCement Kiln RefractorySyed Kazam RazaNo ratings yet

- Kiln Coating ReasonsDocument4 pagesKiln Coating ReasonsYousra UsmNo ratings yet

- Coating RingsDocument8 pagesCoating RingsIrshad HussainNo ratings yet

- 117 - DWP Difficult Solid Fuel Burning 191207 - RDB&YJBDocument10 pages117 - DWP Difficult Solid Fuel Burning 191207 - RDB&YJBMKPashaPashaNo ratings yet

- 10-Lecture 10 PDFDocument106 pages10-Lecture 10 PDFmustaf100% (1)

- Wear Phenomena of RefractoriesDocument66 pagesWear Phenomena of RefractoriesMehmet C100% (2)

- Chemical AnalysisDocument8 pagesChemical Analysisصفاء رجبNo ratings yet

- Flame For Cement Kilns KP Pradeep KumarDocument62 pagesFlame For Cement Kilns KP Pradeep KumarHuyentrang Nguyen100% (1)

- Cement Technology Cement ChemistryDocument22 pagesCement Technology Cement Chemistryshani5573No ratings yet

- Ask and AnswerDocument108 pagesAsk and AnswerHazem Diab100% (5)

- Ring Formation in Rotary KilnsDocument30 pagesRing Formation in Rotary Kilnsmohamed ElsayedNo ratings yet

- PPE Reference Guide 05Document184 pagesPPE Reference Guide 05Anonymous I0JAds2SP100% (1)

- The Effects of Oxygen Enrichment On ClinkerDocument9 pagesThe Effects of Oxygen Enrichment On ClinkerNael100% (1)

- Coatin &ring FormationDocument6 pagesCoatin &ring FormationMustafa RamadanNo ratings yet

- Granulometry of ClinkerDocument18 pagesGranulometry of ClinkerNael100% (12)

- Influence of Clinker Micro-Structure On Clinker QualityDocument68 pagesInfluence of Clinker Micro-Structure On Clinker Qualitytom havatyi100% (3)

- The Chemistry of Kiln Feed and ClinkerDocument19 pagesThe Chemistry of Kiln Feed and Clinkermahendra sen100% (1)

- 7 Most Common Problem in Pyro Processing For Kiln and CoolerDocument10 pages7 Most Common Problem in Pyro Processing For Kiln and CoolerVipan Kumar DograNo ratings yet

- Cement - Manufacturing Process & Unit Operations: F:/plant/sranga/general/cement - Doc Page 1 of 14Document14 pagesCement - Manufacturing Process & Unit Operations: F:/plant/sranga/general/cement - Doc Page 1 of 14Senthilkumar PragasamNo ratings yet

- Transcript: Download Granulometry of ClinkerDocument4 pagesTranscript: Download Granulometry of ClinkerfaheemqcNo ratings yet

- Raw Material BurnabilityDocument12 pagesRaw Material Burnabilitym_verma21No ratings yet

- Clinker Manufacture - Clinker FormationDocument30 pagesClinker Manufacture - Clinker Formationamjed_de_enim100% (2)

- Cement Kiln Process Chemistry: Module 2. Cement Clinker Quality and CompositionDocument2 pagesCement Kiln Process Chemistry: Module 2. Cement Clinker Quality and CompositionalbertbunguriNo ratings yet

- It's A Product of An Intimate Mixture of Correctly ProportionedDocument28 pagesIt's A Product of An Intimate Mixture of Correctly ProportionedshahriarNo ratings yet

- Burnability and Clinkerization of Cement Raw-MixesDocument47 pagesBurnability and Clinkerization of Cement Raw-MixesNguyen Tuan100% (4)

- 1,2,6a - Flames and Gas FiringDocument29 pages1,2,6a - Flames and Gas FiringMohamed SaadNo ratings yet

- PREHEATER BLOCKAGES Problem Diagnosis and Solution - INFINITY FOR CEMENT EQUIPMENTDocument19 pagesPREHEATER BLOCKAGES Problem Diagnosis and Solution - INFINITY FOR CEMENT EQUIPMENTali100% (2)

- Rings & Buildups Formation in Cement KilnDocument13 pagesRings & Buildups Formation in Cement KilnNael93% (14)

- SOx Emmissions Absortion FLSDocument14 pagesSOx Emmissions Absortion FLSMartha Carolina Gomez MartinezNo ratings yet

- Rotary Kilns: Transport Phenomena and Transport ProcessesFrom EverandRotary Kilns: Transport Phenomena and Transport ProcessesRating: 4.5 out of 5 stars4.5/5 (4)

- 2007 Bullentin Rel. 2 WearMechanism-DataDocument4 pages2007 Bullentin Rel. 2 WearMechanism-Data1977julNo ratings yet

- Crystallization of Belite - Melilite Clinker Minerals in The Presence of Liquid PhaseDocument5 pagesCrystallization of Belite - Melilite Clinker Minerals in The Presence of Liquid PhaseAnonymous NxpnI6jCNo ratings yet

- Silicon CarbideDocument23 pagesSilicon CarbideMuhammad BilalNo ratings yet

- Background and Manufacturing of SiCDocument79 pagesBackground and Manufacturing of SiCuygunberkayNo ratings yet

- A New Approach To Ductile Iron InoculationDocument12 pagesA New Approach To Ductile Iron InoculationZody YtuNo ratings yet

- Silicon EpitaxyDocument33 pagesSilicon EpitaxyAkanksha BhardwajNo ratings yet

- Improved Refractories Systems Waste To Energy ApplicationsDocument8 pagesImproved Refractories Systems Waste To Energy Applicationsmuhammad abidinNo ratings yet

- Study On Treatment Methods of Phenol in Industrial WastewaterDocument3 pagesStudy On Treatment Methods of Phenol in Industrial WastewaterAnonymous NxpnI6jCNo ratings yet

- Horizontal Shaft Impact CrusherDocument13 pagesHorizontal Shaft Impact CrusherAnonymous NxpnI6jCNo ratings yet

- Process Simulation Study Using CHEMCAD Software For The Separation Columns For Linear Alkyl Benzene (LAB) PlantDocument103 pagesProcess Simulation Study Using CHEMCAD Software For The Separation Columns For Linear Alkyl Benzene (LAB) PlantAnonymous NxpnI6jC100% (1)

- The Notion of Milliequivalence MEq A Brief NoteDocument2 pagesThe Notion of Milliequivalence MEq A Brief NoteAnonymous NxpnI6jCNo ratings yet

- Digital Weighing IndicatorDocument1 pageDigital Weighing IndicatorAnonymous NxpnI6jCNo ratings yet

- Meka Primary Impact CrushersDocument15 pagesMeka Primary Impact CrushersAnonymous NxpnI6jCNo ratings yet

- GA6 Iron Ore Titr Rev4 94Document3 pagesGA6 Iron Ore Titr Rev4 94pathisharmaNo ratings yet

- How Microsilica Improves Concrete - tcm45-346441Document4 pagesHow Microsilica Improves Concrete - tcm45-346441Feraydoon NasratzadaNo ratings yet

- A Step by Step Approach To The Modeling of Chemical Engineering Processes, Using Excel For Simulation (2018)Document182 pagesA Step by Step Approach To The Modeling of Chemical Engineering Processes, Using Excel For Simulation (2018)Anonymous NxpnI6jC100% (7)

- How To Prepare For IELTS PDFDocument126 pagesHow To Prepare For IELTS PDFAnonymous NxpnI6jCNo ratings yet

- The Creature From Jekyll Island by G. Edward Griffin PDFDocument315 pagesThe Creature From Jekyll Island by G. Edward Griffin PDFPedro Alejandro Velásquez83% (6)

- 45-Vibrating Screens PDFDocument12 pages45-Vibrating Screens PDFAnonymous NxpnI6jC100% (2)

- Aromatic Compounds ProductionDocument49 pagesAromatic Compounds ProductionAnonymous NxpnI6jCNo ratings yet

- Bulk Density ChartDocument15 pagesBulk Density Chartvparthibban37No ratings yet

- Chapter 3 ClinkerDocument179 pagesChapter 3 ClinkerAli Hüthüt100% (1)

- Core Logging GuideDocument23 pagesCore Logging GuidepaNo ratings yet

- Influence of The SO Content of Cement On The DurabilityDocument113 pagesInfluence of The SO Content of Cement On The DurabilityAnonymous NxpnI6jCNo ratings yet

- Mesh /Micron/Inch Conversions: USA UK Canada CanadaDocument2 pagesMesh /Micron/Inch Conversions: USA UK Canada CanadaAnonymous NxpnI6jCNo ratings yet

- Mast or AkosDocument22 pagesMast or AkosMohammed Shafi AhmedNo ratings yet

- Bulk Material Density Property ChartDocument40 pagesBulk Material Density Property ChartMauricio Sandoval CardozoNo ratings yet

- Soap Stone PowderDocument1 pageSoap Stone PowderAnonymous NxpnI6jCNo ratings yet

- ASTM E 11-01 Standard Specification For Wire Cloth and Sieves For Testing PurposesDocument5 pagesASTM E 11-01 Standard Specification For Wire Cloth and Sieves For Testing PurposesPablo Antonio Valcárcel VargasNo ratings yet

- Sieve Analysis of LimestoneDocument1 pageSieve Analysis of LimestoneAnonymous NxpnI6jCNo ratings yet

- Compare Sizing Methods PDFDocument14 pagesCompare Sizing Methods PDFAnonymous NxpnI6jCNo ratings yet

- Fuel - Consumption - Chart - Standard Diesel EngineDocument1 pageFuel - Consumption - Chart - Standard Diesel EngineCaptIsqanNo ratings yet

- Electrochemical Kinetics of Corrosion-Unit-4: CHE-545-172 DR Ime B.ObotDocument21 pagesElectrochemical Kinetics of Corrosion-Unit-4: CHE-545-172 DR Ime B.ObotAnonymous NxpnI6jCNo ratings yet

- Electrochemical Thermodynamics of Corrosion and Pourbaix Diagrams-Unit-2Document34 pagesElectrochemical Thermodynamics of Corrosion and Pourbaix Diagrams-Unit-2Anonymous NxpnI6jCNo ratings yet

- Introduction To Corrosion Science and Engineering-Unit-1: CHE-545-172 DR Ime B.ObotDocument14 pagesIntroduction To Corrosion Science and Engineering-Unit-1: CHE-545-172 DR Ime B.ObotAnonymous NxpnI6jCNo ratings yet

- Forms of Corrosion: CHE-545-172 DR Ime B.ObotDocument17 pagesForms of Corrosion: CHE-545-172 DR Ime B.ObotAnonymous NxpnI6jCNo ratings yet

- The Operating Experience of Nitrophosphate Plant PDFDocument6 pagesThe Operating Experience of Nitrophosphate Plant PDFasad100% (1)

- solidworks ขั้นพื้นฐานDocument74 pagessolidworks ขั้นพื้นฐานChonTicha'No ratings yet

- Source:: APJMR-Socio-Economic-Impact-of-Business-Establishments - PDF (Lpubatangas - Edu.ph)Document2 pagesSource:: APJMR-Socio-Economic-Impact-of-Business-Establishments - PDF (Lpubatangas - Edu.ph)Ian EncarnacionNo ratings yet

- Department of Education: Consolidated Data On Learners' Grade Per QuarterDocument4 pagesDepartment of Education: Consolidated Data On Learners' Grade Per QuarterUsagi HamadaNo ratings yet

- Atmel 46003 SE M90E32AS DatasheetDocument84 pagesAtmel 46003 SE M90E32AS DatasheetNagarajNo ratings yet

- Chapter 2 Short-Term SchedulingDocument49 pagesChapter 2 Short-Term SchedulingBOUAZIZ LINANo ratings yet

- Jurnal Job DescriptionDocument13 pagesJurnal Job DescriptionAji Mulia PrasNo ratings yet

- SCD Course List in Sem 2.2020 (FTF or Online) (Updated 02 July 2020)Document2 pagesSCD Course List in Sem 2.2020 (FTF or Online) (Updated 02 July 2020)Nguyễn Hồng AnhNo ratings yet

- Superlab Manual PDFDocument76 pagesSuperlab Manual PDFGabriela Soares100% (1)

- Calculating Free Energies Using Adaptive Biasing Force MethodDocument14 pagesCalculating Free Energies Using Adaptive Biasing Force MethodAmin SagarNo ratings yet

- Daftar ObatDocument18 pagesDaftar Obatyuyun hanakoNo ratings yet

- Poster-Shading PaperDocument1 pagePoster-Shading PaperOsama AljenabiNo ratings yet

- I. Choose The Best Option (From A, B, C or D) To Complete Each Sentence: (3.0pts)Document5 pagesI. Choose The Best Option (From A, B, C or D) To Complete Each Sentence: (3.0pts)thmeiz.17sNo ratings yet

- Statistical Process Control and Process Capability PPT EXPLANATIONDocument2 pagesStatistical Process Control and Process Capability PPT EXPLANATIONJohn Carlo SantiagoNo ratings yet

- Spanish Greeting Card Lesson PlanDocument5 pagesSpanish Greeting Card Lesson Planrobert_gentil4528No ratings yet

- Data SheetDocument56 pagesData SheetfaycelNo ratings yet

- SAMPLE MCQuestions ByTopicsDocument45 pagesSAMPLE MCQuestions ByTopicsVeeru ManikantaNo ratings yet

- Etag 002 PT 2 PDFDocument13 pagesEtag 002 PT 2 PDFRui RibeiroNo ratings yet

- 7 - Monte-Carlo-Simulation With XL STAT - English GuidelineDocument8 pages7 - Monte-Carlo-Simulation With XL STAT - English GuidelineGauravShelkeNo ratings yet

- TTDM - JithinDocument24 pagesTTDM - JithinAditya jainNo ratings yet

- Code of Ethics For Civil Engineers PiceDocument3 pagesCode of Ethics For Civil Engineers PiceEdwin Ramos Policarpio100% (3)

- (Gray Meyer) Analysis and Design of Analog Integrated Circuits 5th CroppedDocument60 pages(Gray Meyer) Analysis and Design of Analog Integrated Circuits 5th CroppedvishalwinsNo ratings yet

- Sony x300 ManualDocument8 pagesSony x300 ManualMarcosCanforaNo ratings yet

- White Paper: 1 Definitive Guide To Data QualityDocument18 pagesWhite Paper: 1 Definitive Guide To Data QualityGonçalo MartinsNo ratings yet

- Spectroscopic Methods For Determination of DexketoprofenDocument8 pagesSpectroscopic Methods For Determination of DexketoprofenManuel VanegasNo ratings yet

- Core CompetenciesDocument3 pagesCore Competenciesapi-521620733No ratings yet

- Amity School of Business:, Semester IV Research Methodology and Report Preparation Dr. Deepa KapoorDocument23 pagesAmity School of Business:, Semester IV Research Methodology and Report Preparation Dr. Deepa KapoorMayank TayalNo ratings yet

- CHAPTER 2 Part2 csc159Document26 pagesCHAPTER 2 Part2 csc159Wan Syazwan ImanNo ratings yet

- ChatGPT & EducationDocument47 pagesChatGPT & EducationAn Lê Trường88% (8)

- MATM1534 Main Exam 2022 PDFDocument7 pagesMATM1534 Main Exam 2022 PDFGiftNo ratings yet

- Man Bni PNT XXX 105 Z015 I17 Dok 886160 03 000Document36 pagesMan Bni PNT XXX 105 Z015 I17 Dok 886160 03 000Eozz JaorNo ratings yet