Professional Documents

Culture Documents

Finite Element Analysis of A Synchronous Permanent Magnet Micromotor Through Axisymmetric and Transverse Planar Simulations

Uploaded by

arnika33Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Finite Element Analysis of A Synchronous Permanent Magnet Micromotor Through Axisymmetric and Transverse Planar Simulations

Uploaded by

arnika33Copyright:

Available Formats

IEEE TRANSACTIONS ON MAGNETICS, VOL 34, NO.

5, SEPTEMBER 1998

3604

Finite Element Analysis of a Syn

ermanent Magnet Micromotor throug

ransverse Planar Simulations

Adrian C. Agiiero, Fernando A. Actis

C1MM:Centro de Investigacion de Materiales y Metrologia, AV.VClez Sarsfield 1561- C.C. Central 884, 5000 Cordoba, Argentina

Viviane Cristine Silva, JosC Roberto Cardoso, Silvio I. Nabeta

LMAG/PEA Escola Polittcnica da Universidade de SLo Paulo, AV.Prof. Lucian0 Gualberto, T. 3 , n0158,05508-900S b Paulo SP, Brazil

Abstract - The aim of this work is to present and discuss an

original way to analyze a synchronous permanent magnet

micro-motor (SPMM) for design purposes. The analysis of the

magnetic field distribution in the motor, whose geometry would

require a 3D modeling, is instead carried out with the aid of two

2D finite-element (FE) simulations: one axisymmetric and one

on the cross-section or transverse plane. To validate the

suitability of the proposed method for torque computation, a

3D-field solution is also presented. Computed results of

distribution of magnetic induction, as well as the torque

developed by the motor in both 2D and 3D simulations, have

shown good agreement with measurements in a prototype

machine.

prototype synchronous motor with a permanent-magnet ring

rotor (refer to Appendix for the SPMM dimensions and data).

Figure 2 presents a schematic layout of the motor geometry

in two views: axisymmetric and cross section, displayed by

the geometric modeler of the FE package.

Index terms - Claw pole, synchronous permanent magnet

micro-motor, finite element analysis of synchronous machines.

I. INTRODUCTION

The SPMM is a low-cost device employed as a time

reference, which provides rotating movement with low

torque. Its main feature is its constant speed for a given

supply frequency, independent of the load until it is in an

overload state. In this condition, the motor loses

synchronization with consequential speed reduction and

oscillations. Typical applications include chart recorders,

programming devices, valve drives, etc. Figure 1 illustrates

the winding arrangement, stator claw poles and permanent

magnet multi-pole ring rotor, which are magnetized along the

radial direction [ 1-21.

Performance characteristics such as developed torque can

be obtained with the aid of 2D and 3D FE analyses by

assuming a magnetostatic behavior, since in both simulations

one is interested in the steady state operation of the

synchronous motor.

Although 2D representations of SPMMs provide less

accurate results when compared to 3D modeling, they allow

faster and lower-cost simulations [ 3 ] .

II.2D FE MODELS

The steady state operation of a SPMM has been simulated

as a 2D magnetostatic phenomenon using a 2D FE package

(FLUX2D) [4]. The domain studied consists of a 16-pole

Manuscript received November 3, 1997.

A. AgUero, fax. +54-51-699459; e-mail: aguero@com.uncor.edu;J. R.

Cardoso, fax: +55-11-814 2092; e-mail: c-irdoso@pea.usp.br.

The authors would like to acknowledge the support of Tamyr S.A.

Fig. 1 Topology of the prototype SPMM 1 - Stator housing, 2 coil, 3

claw poles, 4 -short-circuiting ring (copper), 5 - permanent-magnet rotor

The prototype machine can be seen in Fig. 2 and has the

following constructive features:

- the claw poles are made from electrical steel with a 1 mm

thickness;

- the coil has 11000 turns and is made of copper wire with a

0.06 mm diameter;

- the magnet has a remanent induction of 0.2 T.

The first simulation assumes axial symmetry (Fig. 3a) and

enables the determination of the normal component of the

flux density distribution, Bn, on the portion of the claw

surface facing the permanent magnet.

After solving the axisymmetric problem, the calculation of

Bn was carried out along a path spanning from the top to the

bottom of the permanent magnet (see dashed line in Fig. 3a).

The plot of Bn along this path can be seen in Fig. 4. This

curve will be used in the next step of the methodology: the

2D planar simulation.

To calculate the torque, a second 2D simulation assuming

planar symmetry was carried out using the geometry shown

in Fig. 3b, which represents a cross section of the prototype

0018-9464/98$10.00 0 1998 IEEE

3605

machine, taken in the mid-height of the magnets. Along the

external boundary (dashed line of Fig. 3a) a nonhomogeneous Dirichlet boundary condition was imposed, i.e.

a fixed magnetic vector potential (the state variable), which is

numerically equal to the magnetic flux per meter crossing the

cylindrical surface represented by the vertical dashed line of

Fig. 3a.

Figure 9b shows the fl~kdensity vectors in another cut

plane, which is normal to plane xOy (shown in Fig. Sa). This

is equivalent to the axisymfinetric 2D simulation.

,Path where B is

,firstly calculated

Shaft

Fig. 2. The SPMM prototype.

This magnetic flux can be determined with the aid of the Bn

curve of Fig. 4, plotted along the vertical dashed line in the

axisymmetric simulation. The magnetic flux was calculated

by taking the mean value of this curve, i.e. the value of Bn

which gives a rectangular area equal to the area delimited by

the curve in Fig. 4.

The second 2D simulation yielded the flux density

distribution, which can be seen in Fig. 5 through contours of

flux lines. The torque vs. load angle characteristic has also

been determined in one pole pitch with the aid of this

simulation. The result will be presented later on in this work.

111.3D FE MODEL

The complicated shape of the claw poles usually needs a

three-dimensional analysis. However, results from a 3D-FE

modeling of the same prototype motor have presented a very

close agreement with the proposed methodology, namely the

two 2D simulations.

The 3D simulation presented in the sequence was carried

out using a 3D finite element package, FLUX3D [5]. Fig. 6

shows the 3D FE mesh. Again, the phenomenon was

assumed as a magnetostatic one, since the interest is the

calculation of synchronous torque in steady state condition.

Therefore, only one pole pitch needs to be modeled.

Figure 8 illustrates the distribution of the flux density

vectors in a cut plane, parallel to the xOy plane of global coordinate system, which cuts the z-axis at z = 15 mm (shown

in Fig. 7). This case is equivalent to the second 2D FE model

(cross section).

boundary condition was impoted, whose value was determined in the

previous axisymmetric simulatiop.

100

200

300

400

500

600

700

h(102mm)

(path parallel to magnet height)

Fig 4 Normal flux density plotted along the bold dashed line shown in Fig 2

3606

Fig 8 Distribution of the flux density vectors in the cut plane shown in Fig 7

Fig. 5. Flux lines resulting from the second (planar) 2D simulation.

a=7.50

Flg 6. Showing one pole pitch of the prototype machine with the 3D FE mesh

.. ... .. ... ... . ... ... .. . ..- ..> ..... .. ' * I,:.: :.: -: '' :-: " " " 1 . :

. . . . . . . . . . . .

-. .. .. .. .. . .. .. .. .. .. .. .

.

. . . . . . .

. . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

Fig 9 (a) A radial cut plane (normal toxOy plane of global co-ordinate

system) in the 3D motor geometry; (b) distribution of the flux density

vectors in this cut plane

Fig. 7. A cut plane (parallel toxOy plane of global co-ordinate system) in the

3D motor geometry.

3607

111. RESULTS

IV. C~ONCLUSIONS

A curve of the reduction in torque when varying the air gap

in the range 0.2 - 0.8 mm is plotted in Fig. 10, which exhibits

a comparison between the values issued from the second 2D

simulation and from experimental measurements.

The 3D simulation for an air-gap of 0.8 mm yielded a

torque of 0.01277 kg.cm. The error is less than 8 % in

comparison with 2D simulation and the tests in the prototype

machine.

Table I shows the mesh data and CPU times. The great

difference of total CPU time between the 2D and 3D

simulations for nearly the same number of nodes can be

noticed. This is because the 3D model leads to 3 times as

many unknowns as the 2D model for the same number of

nodes (3 components of magnetic vector potential in 3D

versus 1 component in 2D).

0.06

Simulation

a

001

problem, namely the

of synchronous torque

was carried out with the $d of a 2D FE computer package

and validated by 3D FE pqckage. The accuracy of the results

issued from the 2D dpproach has been verified by

measurements in a protobpe and proved to be sufficient,

thereby avoiding the need bf the costly 3D FE analysis.

~PPENDIX

SPMM DI~ENSIONALDATA

Rated power

Rated voltage

Current

Frequency

Based speed

Number of phases

2.75 W

220 v

15 mA

S O HZ

375 rpm

1

STATOR

Outer diameter

Winding type

Number of coils

Phase resistance

Self inductance

43 mm

]multi-layer

1

7200 R

4.2 H

Test

ROTOR

Number of poles

Magnet outer diameter

Magnet inner diameter

Magnet height

Magnet material

Air-gap length

0.3

0.4

0.6

0.5

0.7

Sintered Bu ferrite

10.2-0.8 mm

ACKNOWLEDGEMENT

0.2

116

2 1.5 mm

16.8 mm

8.6 mm

08

Air-gap [mm]

Fig. 10. Torque variation with air-gap length: 2D FE analysis and

experimental results.

The authors wish to expkess their most sincere gratitude to

R. Ottolini for constructidn of the prototype utilized in this

investigation and R. Moyabo, who performed the test.

I

TABLE I

MESHDATAAND CPU TIMEFOR THE 2D AND 3D FE SIMULATIONS

MFERENCES

,

[l]

2D (planar)

3D

Number of nodes

10.097

10.498

Number of elements

53 089

55 198

Number of non-linear iterations

10

Total CPU time a

15

140

[2]

[3]

[4]

Computer used: IBM PC compatible Pentium 166 MHz - 64 MB RAM

[5]

J Vogel, Grundlagen , der elektrischen Antriebstechnik mit

Berechnungsbeispielen, Dr. Alfred Huthig Verlag, Heidelberg, pp.

356-358, 1985.

I. A. Viorel, Csapo, E M inescu, L. Szabo, Claw pole brushless

D C. motor for a variable speed drive system, Intelligent Motion,

Nurnberg, DD, 127-131, 19 4,

S R H Hook, Compuier-Aided Analysis and Design of

Electromagnetic Devices, Isevier, New York, 1989

FLUX2D - CAD package $or 2D Electromagnetic Field Computation,

CEDRAT

FLUX3D - CAD package lfor 3D Electromagnetic Field Computation,

CEDRAT.

El

You might also like

- An Efficient Approach For Cogging Torque Analysis of Motors With Three-Dimensional Flux DistributionDocument3 pagesAn Efficient Approach For Cogging Torque Analysis of Motors With Three-Dimensional Flux DistributionDeni Shidqi KhaerudiniNo ratings yet

- The Simulation of Switched Reluctance Motor With The Rapid Nonlinear MethodDocument5 pagesThe Simulation of Switched Reluctance Motor With The Rapid Nonlinear MethodFairul AzharNo ratings yet

- Applied ElectromagneticsDocument269 pagesApplied ElectromagneticsNur Amiera SyuhadhaNo ratings yet

- Vibration Calculations in A Electric MotorDocument14 pagesVibration Calculations in A Electric MotorSantiago MolinaNo ratings yet

- A New Analytical Method On The Field Calculation of IPMDocument9 pagesA New Analytical Method On The Field Calculation of IPMYusuf YaşaNo ratings yet

- PM Synchronous MachineDocument14 pagesPM Synchronous MachineNguyen Duy ChungNo ratings yet

- Instantaneous Magnetic Field Distribution Brushless Permanent Magnet DC Motors, Part I: Open-Circuit FieldDocument12 pagesInstantaneous Magnetic Field Distribution Brushless Permanent Magnet DC Motors, Part I: Open-Circuit FieldadilsondissoNo ratings yet

- Analysis of Slotless-Type PM Linear Brushless Motor Using EMC MethodDocument6 pagesAnalysis of Slotless-Type PM Linear Brushless Motor Using EMC MethodHuber CallataNo ratings yet

- Design of A Miniature Axial-Flux Spindle Motor With Rhomboidal PCB WindingDocument3 pagesDesign of A Miniature Axial-Flux Spindle Motor With Rhomboidal PCB WindingnevesunipampaNo ratings yet

- Functional Simulation of Harmonic Drive With S.M.A. Wave GeneratorDocument5 pagesFunctional Simulation of Harmonic Drive With S.M.A. Wave GeneratorBizau ViorelNo ratings yet

- Matrix analysis techniques for induction machinesDocument7 pagesMatrix analysis techniques for induction machinesni60No ratings yet

- Analysis of Detent Torque in Hybrid Stepping Motors: Jonathan U AgberDocument7 pagesAnalysis of Detent Torque in Hybrid Stepping Motors: Jonathan U AgbertheijesNo ratings yet

- 3D-Multi Body Simulation of Wind Turbines With Flexible ComponentsDocument4 pages3D-Multi Body Simulation of Wind Turbines With Flexible ComponentsJesus MamaniNo ratings yet

- Modeling and Parameter Identification of A Double-Star Induction MachinesDocument7 pagesModeling and Parameter Identification of A Double-Star Induction MachineshaimantiNo ratings yet

- Complex Vector Model of The Squirrel-Cage Induction Machine Including Instantaneous Rotor Bar CurrentsDocument9 pagesComplex Vector Model of The Squirrel-Cage Induction Machine Including Instantaneous Rotor Bar CurrentsDaniel CamargoNo ratings yet

- Rotor Slot Shape Parametric Study Improves Induction Motor PerformanceDocument0 pagesRotor Slot Shape Parametric Study Improves Induction Motor PerformancevishiwizardNo ratings yet

- Optimal Energy Density Piezoelectric Twisting Actuators: Benjamin M. Finio and Robert J. WoodDocument6 pagesOptimal Energy Density Piezoelectric Twisting Actuators: Benjamin M. Finio and Robert J. WoodHumair ShaheenNo ratings yet

- Permanent Magnet and Wound Salient Pole Synchronous Generator Design ComparisonDocument4 pagesPermanent Magnet and Wound Salient Pole Synchronous Generator Design Comparisonchmvsraju9010No ratings yet

- Improved Design For Reduction of Torque Ripple of Brushless DC MotorDocument4 pagesImproved Design For Reduction of Torque Ripple of Brushless DC MotorPhạm Văn TưởngNo ratings yet

- Optimum Values For Magnet and Armature Winding Thickness For Axial Field PM PDFDocument6 pagesOptimum Values For Magnet and Armature Winding Thickness For Axial Field PM PDFrakeshee2007No ratings yet

- Magnetic Equivalent Circuit ModelingDocument12 pagesMagnetic Equivalent Circuit ModelingJavad Rahmany FardNo ratings yet

- Research On Cylindrical Resonators' Damping Asymmetry Trimming Method Utilizing Damping Characteristic of Piezoelectric ElectrodesDocument10 pagesResearch On Cylindrical Resonators' Damping Asymmetry Trimming Method Utilizing Damping Characteristic of Piezoelectric ElectrodesKarad KaradiasNo ratings yet

- Analytical Model For Permanent Magnet Motors With Surface Mounted MagnetsDocument6 pagesAnalytical Model For Permanent Magnet Motors With Surface Mounted MagnetsIndra PrakashNo ratings yet

- Optimal Design of A High-Speed PMSGDocument13 pagesOptimal Design of A High-Speed PMSGHuynh Thanh AnhNo ratings yet

- Influence of Essential Dimensions of Rotor Ge-Ometry On Reluctance Torque GenerationDocument5 pagesInfluence of Essential Dimensions of Rotor Ge-Ometry On Reluctance Torque GenerationBOUZ2010No ratings yet

- Free Energy Generator Construction Guidelines For A Zero Point Energy ConverterDocument67 pagesFree Energy Generator Construction Guidelines For A Zero Point Energy ConverterDan BeesonNo ratings yet

- Determination of A Synchronous Generator Characteristics Via Finite Element AnalysisDocument6 pagesDetermination of A Synchronous Generator Characteristics Via Finite Element Analysisamin342No ratings yet

- Magnetic Analysis of The Synchronous Machine and The Supporting StructureDocument5 pagesMagnetic Analysis of The Synchronous Machine and The Supporting StructureIrina AtudoreiNo ratings yet

- Arindam Seminar 11Document6 pagesArindam Seminar 11Arindam BhattacharjeeNo ratings yet

- Practical Induction 01Document5 pagesPractical Induction 01sathishNo ratings yet

- Transient States Analysis of 3D Transformer Structure: K. Komeza, H. Welfle and S. WiakDocument5 pagesTransient States Analysis of 3D Transformer Structure: K. Komeza, H. Welfle and S. WiakConstantin DorinelNo ratings yet

- Antenna and EM Modeling With MATLABDocument21 pagesAntenna and EM Modeling With MATLABNatasha SearsNo ratings yet

- DQ Modeling and Dynamic CharacteristicsDocument9 pagesDQ Modeling and Dynamic CharacteristicsNAENWI YAABARINo ratings yet

- Sitti Al 2001Document8 pagesSitti Al 2001scribdcheealleNo ratings yet

- Unbalanced Magnetic ForcesDocument10 pagesUnbalanced Magnetic Forcesrakeshee2007No ratings yet

- Modeling of Permanent Magnet Motor Drives: Ieee Transactions On Industrial Electronics, Vol. NO 4, NovemberDocument5 pagesModeling of Permanent Magnet Motor Drives: Ieee Transactions On Industrial Electronics, Vol. NO 4, NovemberMeena RamNo ratings yet

- 492 FerreiraDocument6 pages492 FerreiraRonald LiemNo ratings yet

- Simulation Modelling Practice and Theory: Abdallah Barakat, Slim Tnani, Gérard Champenois, Emile MouniDocument15 pagesSimulation Modelling Practice and Theory: Abdallah Barakat, Slim Tnani, Gérard Champenois, Emile Mounigurunathan14No ratings yet

- Xiicleee RBP 1754revDocument6 pagesXiicleee RBP 1754revrbargallo0No ratings yet

- 09 - Chapter 3Document11 pages09 - Chapter 3Mani Rathinam RajamaniNo ratings yet

- 385 BacherDocument4 pages385 BacherManuel PerezNo ratings yet

- IPM Motor Optimization for HEVsDocument8 pagesIPM Motor Optimization for HEVsReshmi Parikal RaghavanNo ratings yet

- 3D MSC/EMAS Simulation of a Three Phase Power TransformerDocument11 pages3D MSC/EMAS Simulation of a Three Phase Power TransformerConstantin DorinelNo ratings yet

- Simulation of The Magnetic Field of The VINCY CyclotronDocument5 pagesSimulation of The Magnetic Field of The VINCY CyclotronNguyễn Thành CôngNo ratings yet

- 1 s2.0 S0378475418300983 MainDocument15 pages1 s2.0 S0378475418300983 MainFaiza OuiddirNo ratings yet

- Torque Production in Permanent-MagnetDocument6 pagesTorque Production in Permanent-MagnetTien Dung TranNo ratings yet

- IEEE Trans Ind Elect FinalDocument14 pagesIEEE Trans Ind Elect Finalivan.vazdar5482No ratings yet

- Characteristic Analysis of A Permanent Magnet Transverse Flux Linear Motor With Spiral CoreDocument6 pagesCharacteristic Analysis of A Permanent Magnet Transverse Flux Linear Motor With Spiral CoreKi ChunNo ratings yet

- Analysis and Comparison of Two Brushless DC Generators With Doubly Salient Structure and Stator Field WindingDocument4 pagesAnalysis and Comparison of Two Brushless DC Generators With Doubly Salient Structure and Stator Field WindingmohammadNo ratings yet

- Economic Design of Sleeve Rotor InductioDocument10 pagesEconomic Design of Sleeve Rotor InductioIraqi stormNo ratings yet

- ANSYS Analysis of Single Phase Induction Motor - Hani Aziz AmeenDocument74 pagesANSYS Analysis of Single Phase Induction Motor - Hani Aziz AmeenHani Aziz Ameen50% (2)

- CMOS-MEMS Scanner Design OptimizationDocument4 pagesCMOS-MEMS Scanner Design Optimizationwenhao chenNo ratings yet

- 10 1 1 1034 5168 PDFDocument6 pages10 1 1 1034 5168 PDFRosa Elvira Montalvo MartínezNo ratings yet

- MD Robotic DeburringDocument6 pagesMD Robotic DeburringAldo BustamanteNo ratings yet

- Rigorous Combined Mode Matching Intgeral Eqn Analysis of Horn AntennaDocument8 pagesRigorous Combined Mode Matching Intgeral Eqn Analysis of Horn Antennaవేలుసామి లింగాసామిNo ratings yet

- Generic Torque-Maximizing Design Methodology of Surface Permanent - Magnet Vernier MachineDocument8 pagesGeneric Torque-Maximizing Design Methodology of Surface Permanent - Magnet Vernier MachineJohn McLovenNo ratings yet

- From Microstructure Investigations to Multiscale Modeling: Bridging the GapFrom EverandFrom Microstructure Investigations to Multiscale Modeling: Bridging the GapDelphine BrancherieNo ratings yet

- Photovoltaic Modeling HandbookFrom EverandPhotovoltaic Modeling HandbookMonika Freunek MüllerNo ratings yet

- Characteristic Modes: Theory and Applications in Antenna EngineeringFrom EverandCharacteristic Modes: Theory and Applications in Antenna EngineeringNo ratings yet

- Optimization of New Geometries of Switched Reluctances Motors Using FEM and Multi Objective Genetic AlgorithmDocument16 pagesOptimization of New Geometries of Switched Reluctances Motors Using FEM and Multi Objective Genetic Algorithmarnika33No ratings yet

- Design of A 43kW Switched Reluctance Machine For A High-Performance Hybrid Electric VehicleDocument6 pagesDesign of A 43kW Switched Reluctance Machine For A High-Performance Hybrid Electric Vehiclearnika33No ratings yet

- Novel Permanent Magnet Tubular Linear Generator For Wave Energy ConvertersDocument5 pagesNovel Permanent Magnet Tubular Linear Generator For Wave Energy Convertersarnika33No ratings yet

- On The Use of Rotary-Linear Generators in Floating Hybrid Wind and Wave Energy Conversion SystemsDocument6 pagesOn The Use of Rotary-Linear Generators in Floating Hybrid Wind and Wave Energy Conversion Systemsarnika33No ratings yet

- The History of Using Solar EnergyDocument8 pagesThe History of Using Solar Energyarnika33No ratings yet

- FEM Based Prototype of Moving-Coil Coreless Linear-Generator (MCCLG) For Wave Energy ExtractionDocument6 pagesFEM Based Prototype of Moving-Coil Coreless Linear-Generator (MCCLG) For Wave Energy Extractionarnika33No ratings yet

- Cannizzaro 2016 JEDocument7 pagesCannizzaro 2016 JEarnika33No ratings yet

- Control of Switched Reluctance Motor by Current Profiling Under Normal and Open Phase Operating ConditionDocument9 pagesControl of Switched Reluctance Motor by Current Profiling Under Normal and Open Phase Operating Conditionarnika33No ratings yet

- A Survey On Rotary-Linear Motors Used in Emerging ApplicationsDocument6 pagesA Survey On Rotary-Linear Motors Used in Emerging Applicationsarnika33No ratings yet

- Design and Fabrication of Magnetic Engine: Ganesh Bairavan.P, Anojan.TDocument5 pagesDesign and Fabrication of Magnetic Engine: Ganesh Bairavan.P, Anojan.Tarnika33No ratings yet

- Using Maximum Correlated Kurtosis Deconvolution Method in The Bearing Fault Detection of Wind Turbine GeneratorsDocument4 pagesUsing Maximum Correlated Kurtosis Deconvolution Method in The Bearing Fault Detection of Wind Turbine Generatorsarnika33No ratings yet

- 03 Paper 1010 CepoiDocument6 pages03 Paper 1010 Cepoiarnika33No ratings yet

- Cannizzaro 2016 JEDocument7 pagesCannizzaro 2016 JEarnika33No ratings yet

- Design and Fabrication of Magnetic Engine: Ganesh Bairavan.P, Anojan.TDocument5 pagesDesign and Fabrication of Magnetic Engine: Ganesh Bairavan.P, Anojan.Tarnika33No ratings yet

- Preliminary Comparative Study of Several Structures of Permanent-Magnet Synchronous Generator Used in Wind Energy System OptimizationDocument9 pagesPreliminary Comparative Study of Several Structures of Permanent-Magnet Synchronous Generator Used in Wind Energy System Optimizationarnika33No ratings yet

- The Determination of Effects of Primary and Secondary Geometry of Tubular Linear GeneratorDocument6 pagesThe Determination of Effects of Primary and Secondary Geometry of Tubular Linear Generatorarnika33No ratings yet

- The History of Using Solar EnergyDocument8 pagesThe History of Using Solar Energyarnika33No ratings yet

- Ferkova 2017 EDPEDocument4 pagesFerkova 2017 EDPEarnika33No ratings yet

- Using Maximum Correlated Kurtosis Deconvolution Method in The Bearing Fault Detection of Wind Turbine GeneratorsDocument4 pagesUsing Maximum Correlated Kurtosis Deconvolution Method in The Bearing Fault Detection of Wind Turbine Generatorsarnika33No ratings yet

- Transverse Flux Motor Drive DynamicsDocument4 pagesTransverse Flux Motor Drive Dynamicsarnika33No ratings yet

- Direct Drive System With Two Phase Transverse Flux Disc-Type MotorDocument6 pagesDirect Drive System With Two Phase Transverse Flux Disc-Type Motorarnika33No ratings yet

- Computer Aided Modeling and Simulation of Bio-Inspired Hardware SystemsDocument6 pagesComputer Aided Modeling and Simulation of Bio-Inspired Hardware Systemsarnika33No ratings yet

- Wavelet Transform Approach To Rotor Faults Detection in Induction MotorsDocument6 pagesWavelet Transform Approach To Rotor Faults Detection in Induction Motorsarnika33No ratings yet

- Developing Control Techniques For Two-Coordinate Planar Positioning Systems by Means of Coupled Advanced Simulation ToolsDocument6 pagesDeveloping Control Techniques For Two-Coordinate Planar Positioning Systems by Means of Coupled Advanced Simulation Toolsarnika33No ratings yet

- Modular Stator Switched Reluctance Motor For Fault Tolerant Drive SystemsDocument11 pagesModular Stator Switched Reluctance Motor For Fault Tolerant Drive Systemsarnika33No ratings yet

- Theoretical and Experimental Study of A Modular Tubular Transverse Flux Reluctance MachineDocument15 pagesTheoretical and Experimental Study of A Modular Tubular Transverse Flux Reluctance Machinearnika33No ratings yet

- The Evolution of CapacitorsDocument5 pagesThe Evolution of Capacitorsarnika33No ratings yet

- Software Environment For Online Simulation of Switched Reluctance MachinesDocument25 pagesSoftware Environment For Online Simulation of Switched Reluctance Machinesarnika33No ratings yet

- Torque Smoothing of A Fault Tolerant Segmental Stator Switched Reluctance MotorDocument7 pagesTorque Smoothing of A Fault Tolerant Segmental Stator Switched Reluctance Motorarnika33No ratings yet

- Comparative Study of Switched and Synchronous Reluctance Machines For Electric PropulsionDocument4 pagesComparative Study of Switched and Synchronous Reluctance Machines For Electric Propulsionarnika33No ratings yet

- ANSYS SimplorerDocument2 pagesANSYS Simplorerahcene2010No ratings yet

- Fried BergDocument3 pagesFried BergneedmyscribdNo ratings yet

- Supplement A: Example 6Document4 pagesSupplement A: Example 6Yiechin NgNo ratings yet

- Working With Excel Refreshing Math Skills For ManagementDocument148 pagesWorking With Excel Refreshing Math Skills For ManagementKulbir Singh100% (1)

- Chad SheetDocument2 pagesChad SheetMatthew TongNo ratings yet

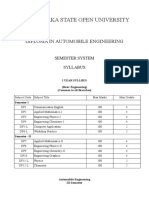

- Distance Automobile Engineering Diploma KSOU, Syllabus Automobile Engineering Distance ModeDocument56 pagesDistance Automobile Engineering Diploma KSOU, Syllabus Automobile Engineering Distance ModeSunil JhaNo ratings yet

- Lagrangian Dynamics HomeworkDocument10 pagesLagrangian Dynamics HomeworkAnyiNo ratings yet

- MIT2 29S15 Lecture10Document26 pagesMIT2 29S15 Lecture10Ihab OmarNo ratings yet

- Vimal's ResumeDocument3 pagesVimal's Resumevimaljss91No ratings yet

- Newton's Second Law AnalysisDocument2 pagesNewton's Second Law AnalysisJamiel CatapangNo ratings yet

- Chapter 8 Indefinite Integration OnlyDocument7 pagesChapter 8 Indefinite Integration Onlyapi-3728615No ratings yet

- Decomposing lattice matrices into symmetric and skew-symmetric partsDocument10 pagesDecomposing lattice matrices into symmetric and skew-symmetric partssdprvNo ratings yet

- 4 Unit Maths - Complex NumbersDocument4 pages4 Unit Maths - Complex NumbersganeshrudraNo ratings yet

- Sankalp Monthly Test Notice Class 12Document2 pagesSankalp Monthly Test Notice Class 12rakeshNo ratings yet

- Structural Analysis Lab ManualDocument30 pagesStructural Analysis Lab ManualdoktorterNo ratings yet

- Ee360 13 1Document19 pagesEe360 13 1Rawad SalemNo ratings yet

- Arm Exercises For LabDocument3 pagesArm Exercises For Labnizamhaider123No ratings yet

- Kuliah5.1 - (Integrasi Numerik)Document120 pagesKuliah5.1 - (Integrasi Numerik)adrian bargasNo ratings yet

- Dynamic Optimization of Bioreactors: A Review: Julio R. Banga, Eva Balsa-Canto, Carmen G. Moles and Antonio A. AlonsoDocument21 pagesDynamic Optimization of Bioreactors: A Review: Julio R. Banga, Eva Balsa-Canto, Carmen G. Moles and Antonio A. Alonsojmrozo3No ratings yet

- Fungsi Dan PerubahanDocument10 pagesFungsi Dan PerubahanYofin GrecyaagathaNo ratings yet

- Implementing Logic Gates Using Neural Networks (Part 1) - by Vedant Kumar - Analytics Vidhya - MediumDocument3 pagesImplementing Logic Gates Using Neural Networks (Part 1) - by Vedant Kumar - Analytics Vidhya - Mediumhelen leeNo ratings yet

- Understanding Numbers: Numbers and Number LineDocument30 pagesUnderstanding Numbers: Numbers and Number LinerajatNo ratings yet

- STEM - BC11LC IIIc 1Document5 pagesSTEM - BC11LC IIIc 1ALJON TABUADANo ratings yet

- The Numbers Have An End: Mohamed Ababou Strengthens His Proof of a Finite Digit TheoryDocument15 pagesThe Numbers Have An End: Mohamed Ababou Strengthens His Proof of a Finite Digit TheoryFredNo ratings yet

- Game Theory1Document15 pagesGame Theory1Vishwas tomarNo ratings yet

- Amrita Btech Automation Robotics Curriculum Syllabus 2022Document133 pagesAmrita Btech Automation Robotics Curriculum Syllabus 2022adithyaNo ratings yet

- Transport Phenomena. Professor Sunando Dasgupta. Department of Chemical Engineering. Indian Institute of Technology Kharagpur. Lecture-28. DragDocument10 pagesTransport Phenomena. Professor Sunando Dasgupta. Department of Chemical Engineering. Indian Institute of Technology Kharagpur. Lecture-28. DragGowri ShankarNo ratings yet

- Dbms OutlineDocument6 pagesDbms OutlineGeorge Mbiriri MuindiNo ratings yet

- Chapter 8 - Cmos ComparatorsDocument39 pagesChapter 8 - Cmos Comparatorsfabio-delima8012100% (1)

- Quadratics CH 4Document48 pagesQuadratics CH 4yddapNo ratings yet