Professional Documents

Culture Documents

LVRT Notes

Uploaded by

Anonymous cj7JdRbDbOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LVRT Notes

Uploaded by

Anonymous cj7JdRbDbCopyright:

Available Formats

Available online at www.sciencedirect.

com

ScienceDirect

Energy Procedia 54 (2014) 530 540

4th International Conference on Advances in Energy Research 2013, ICAER 2013

Improving low voltage ride-through capabilities for grid connected

wind turbine generator

Shrikant Malia*, Steffy Jamesb, Ishwari Tankb

b

a

Department of Electrical Engineering, IIT Bombay, Mumbai-400076, India

Department of Electronics & Telecommunication Engineering, Sandip Foundation, Nashik-422213, India

Abstract

Low Voltage Ride-Through (LVRT) is one of the most dominant grid connection requirements to be met by Wind Energy

Conversion Systems (WECS). In presence of grid voltage dips, a mismatch is produced between the generated active power and

the active power delivered to the grid. Low voltage ride through requirement demands management of this mismatch, which is a

challenge for the WECS. In this paper, LVRT requirements provided by Wind Grid Codes have been reviewed. This paper

discusses the standards for interconnection of wind generators to local grid during healthy and fault conditions. As per LVRT

requirement, during dip occurrence, the wind power generation plant must remain connected to the grid and in addition, it has to

deliver reactive power into the grid to aid the utility to hold the grid voltage. Voltage sag proves to be the most prominent power

quality issue and the effect of voltage sag on different wind generator topologies has been investigated. Several methods for

LVRT fulfillment have been explored and the LVRT scheme has been validated based on MATLAB-SIMULINK simulation.

Mali. Published

Ltd.

This is an open access article under the CC BY-NC-ND license

2014

2014Shrikant

The Authors.

PublishedbybyElsevier

Elsevier

Ltd.

(http://creativecommons.org/licenses/by-nc-nd/3.0/).

Selection and peer-review under responsibility of Organizing Committee of ICAER 2013.

Selection and peer-review under responsibility of Organizing Committee of ICAER 2013

Keywords: IWGC; LVRT; voltage sag; WECS

1. Introduction

With increasing wind power penetration, the simultaneous disconnection of a significant percentage of generating

capacity can have a profound effect on the stability of the grid. As the wind power plants increase in size, they are

required to stay operational and not disconnect from the grid; supporting the grid with reactive power during voltage

* Corresponding author. Tel.: +91-7208603451.

E-mail address: bb.shrikant@gmail.com

1876-6102 2014 Shrikant Mali. Published by Elsevier Ltd. This is an open access article under the CC BY-NC-ND license

(http://creativecommons.org/licenses/by-nc-nd/3.0/).

Selection and peer-review under responsibility of Organizing Committee of ICAER 2013

doi:10.1016/j.egypro.2014.07.294

Shrikant Mali et al. / Energy Procedia 54 (2014) 530 540

sags. Such requirements are known as Fault Ride-Through (FRT) or Low Voltage Ride-Through (LVRT)

capability[1].

Nomenclature

DFIG

ESS

FRT

HCS

IWGC

LVRT

PMSG

PCC

SCC

SCIG

SCR

TSR

WECS

WTG

doubly fed induction generator

energy storage system

fault ride through

hill climb search

Indian wind grid code

low voltage ride through

permanent magnet synchronous generator

point of common coupling

short circuit capacity

squirrel cage induction generator

short circuit ratio

tip speed ratio

wind energy conversion system

wind turbine generator

LVRT fulfillment is required by the wind generators when the voltage in the grid is temporarily reduced due to a

fault or large load change in the grid. The required LVRT behavior is defined in grid codes issued by the grid

operators in order to maintain system stability, thereby reducing the risk of voltage collapse. The grid codes were

originally developed considering the synchronous generator generally used in conventional power plants, whereas

Wind Turbine Generators (WTG) have different characteristics as compared to conventional power plants. As per

Indian Wind Grid Code (IWGC), wind farms connected to 66kV and above shall have the operating region as shown

in figure during system faults. Wind farms can be disconnected if the operating point falls below the line in Fig. 1.

Fig. 1. Fault ride through characteristics.

Where,

Vf is 15% of nominal system voltage,

Vpf is minimum voltage mentioned in IWGC[2].

When a grid voltage dip appears, LVRT requirements demand the following conditions from power-generation

plant:

x To remain connected to the grid, if line voltage is above the limit curve in Fig. 1 and

x To support the system during fault condition by injecting reactive power.

531

532

Shrikant Mali et al. / Energy Procedia 54 (2014) 530 540

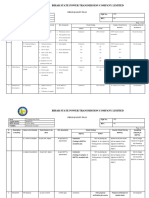

The fault clearing time for various system nominal voltage levels is given in the following table:

Table 1. Fault clearing time for various system nominal voltage levels[2].

Nominal system voltages (kV)

Fault clearing time, T (ms)

Vpf (kV)

Vf (kV)

400

100

360

60.0

220

160

200

33.0

132

160

120

19.8

110

160

96.25

16.5

66

300

60

9.9

Depending on the severity of faults, fault locations and the system conditions, the fault can cause temporary

voltage swell, voltage sag, or a complete loss of voltage (interruptions). The duration and magnitude of the fault is

dictated by protection technologies and fault characteristics; whereas the slope of the recovery likely depends on the

strength of the interconnection and reactive power support. The quantity of reactive power to be injected depends on

the percentage of grid voltage reduction during the dip, the system rated current, and the reactive power given to the

grid during the dip appearance. The paper is organized as follows: Section 2 describes the principle of extraction of

power from wind and provides an overview of different generator topologies. Section 3 highlights the characteristics

of voltage sag and significance of short circuit ratio. The effects that voltage sag has on different generator

topologies have been taken into consideration and possible LVRT solutions have been indicated. Proposed LVRT

control strategy has been elaborated in Section 4 followed by analysis of simulation results.

2. Wind energy conversion system

2.1. Wind power extraction principle

The power carried in wind cannot be completely converted to mechanical energy of a wind turbine. The

theoretical maximum of mechanical efficiency of energy extraction from wind was discovered by Betz in 1926,

according to which a wind turbine could harness only 59% of the wind power.

Pm

0.5U Av3C p

(1)

Power coefficient (Cp) indicates the aerodynamic efficiency and is given as the ratio of extracted power to the

power contained in wind. For every wind turbine, there is a distinct relationship between power coefficient and Tip

Speed Ratio (TSR), seen in Fig. 2 (a). Maximum power coefficient occurs at a specific TSR. The mechanical power

of the turbine blade is a function of the rotational speed, and the converted power is maximized at the particular

rotational speed for various wind speeds. It does not rise indefinitely as speed increases, because as speed increases

the TSR increases and Cp decreases[3].

Fig. 2. (a) Power coefficient versus the tip speed ratio; (b) Mechanical power versus rotor speed characteristics.

Shrikant Mali et al. / Energy Procedia 54 (2014) 530 540

533

2.2. Wind generator topologies

The classification of wind generator topologies is based on overall cost, component count, complexity, control

potential, protection, and integration costs[4]. As illustrated in Fig. 3 (a), wind turbine is connected to rotor of

Squirrel-Cage Induction Generator (SCIG) through a shaft and gearbox. Since SCIG often runs at constant speed,

this topology represents a fixed-speed wind turbine system. Variable speed wind generators are more commonly

used owing to higher energy capture and lower mechanical stresses compared with fixed-speed machines. With a

variable-speed unit, the generator is connected to the grid using power-electronic converter technology. This allows

the turbine speed to be controlled to maximize performance. Fig. 3 (c) shows direct driven Permanent Magnet

Synchronous Generator (PMSG) which is capable of variable speed operation; where the generator is connected to

the grid using a full converter. The Doubly-Fed Induction Generator (DFIG) is another common variable speed

topology which utilizes wound-rotor induction machines with an ac-dc-ac converter between the rotor and grid

connections, seen in Fig. 3 (b).

Fig. 3. Wind Generator Topologies (a) SCIG (b) DFIG (c) PMSG.

3. System characteristics

3.1. Characteristics of Voltage Sag

In the context of power quality, a disturbance is a temporary deviation from the steady-state value of voltage

caused by faults of short duration, sudden changes in the system or load. It is not possible to eliminate voltage sags

even in the most robust and reliable power grids and voltage sag constitute the most significant power quality

problem that needs to be tackled. Sag is primarily a short duration rms voltage variation whose magnitude varies

between 0.1 pu and 0.9 pu for durations from 0.5 cycles to 1 min.

Fig. 4. Instantaneous voltage sag caused by LG fault

534

Shrikant Mali et al. / Energy Procedia 54 (2014) 530 540

Voltage sag indicates a sudden reduction in voltage at the Point of Common Coupling (PCC) caused by an

increase in current. Voltage drop across the network impedance reduces the voltage at PCC. Various sources of

voltage sag include:

x Faults on high voltage, medium voltage or low voltage lines: Heavy fault current affects bus voltage. All users in

the vicinity of the fault are affected, depending upon their proximity to the fault. The duration of faults depend

upon operating time of protective devices.

x System switching operations: Autoreclosers, switching operation for change-over of lines or transformers cause

voltage-dips on the system.

x Switching ON of large loads: Induction motors, arc furnaces, welding machines, heaters, boilers, capacitor-bank

normally represent short circuit while starting and draw very large starting current, causing voltage dip.

x Loose connection may introduce voltage dips intermittently.

Even a quarter second voltage sag can cause the entire machine or process to shut down for hours causing

expensive downtime, scrap material, lost productivity and long restart times. Voltage sag leads to slowdown or

stopping of induction motors, trips contactors or circuit breakers and leads to failure of inverters. Voltage sag also

causes mal-operation or tripping of adjustable speed drives and incorrect operation of control & protective devices.

Solutions for voltage sag include:

x Reducing the number of dips by improving the system and minimizing faults.

x Reducing the duration and depth of dips by improving performance of protective devices and increasing short

circuit power.

x Increasing immunity of equipment by increasing compliance of equipment and devices.

3.2. Significance of Short Circuit Ratio

To analyze the interaction between wind turbine and grid phenomena, it is important to know the characteristics

of the PCC, i.e. the grid point at which the wind power installation is connected to the grid (along with other grid

users at that location). PCC is the point where the competences of the grid operator end and the competences of the

wind turbine operator begin. The short-circuit power of the grid at the PCC is the apparent power that would flow

through a short-circuit at the PCC.

Fig. 5. Hypothetical short-circuit at the PCC to calculate the short-circuit power.

A higher short-circuit power at the PCC implies that varying load or generator currents cause only small voltage

disturbances at the PCC, and a grid user has to fear less voltage disturbances caused by other grid users at the same

PCC. Short Circuit Ratio (SCR) indicates the strength of grid such that strong grids have SCR of 20 as per German

Grid Code and 6 as per IWGC. The speed of recovery tends to degrade as the SCR is decreased and the case of SCR

of 2 is an extremely weak system[2]. In equation (2), Sbase is the greater of the demand or the wind installation and

the Short Circuit Capacity (SCC) is given by equation (3)[1].

535

Shrikant Mali et al. / Energy Procedia 54 (2014) 530 540

SCR

SCC

Sbase

(2)

SCC

Vbase 2

| Zbase |

(3)

3.3. Effects of voltage sag on various generator topologies

In the case of wind turbines, the effects of voltage sag are different depending on the particular type of wind

turbine topology used, as mentioned below:

A. Effects on SCIG:

x Generator gets demagnetized and speeds up.

B. Effects on DFIG:

x

x

The generator gets demagnetized and speeds up.

Converters may fail due to current limitations of the converters.

C. Effects on PMSG:

x Generator speeds up.

x Converters may fail due to current limitations of the converters.

3.4. Solutions for LVRT

Alternative solutions for LVRT technologies have been proposed as follows:

x Inserting a chopper resistor into the DC-link so as to dissipate the excessive energy in the form of heat during

grid voltage dips. However, the temperature increase in the resistor may be a problem when voltage dip lasts

relatively longer[5].

x Dumping the energy in an Energy Storage System (ESS), such as super-capacitor, batteries etc. In spite of high

cost of ESS, it possesses a number of advantages: it can be accessed at any operating condition, the operation of

the machine need not be modified, and it can also enhance LVRT, potentially resulting in transient stability

improvements[6].

x A certain amount of energy can be stored in rotating masses in the form of inertia; however, this is finite due to

the maximum allowable rotor operating speed[7].

x By avoiding operation of generator at MPPT during fault condition, the generated power can be reduced and this

would help in reducing the size of battery connected at DC-link.

4. LVRT realization and simulation results

A control scheme for implementing LVRT requirements for a 5MW direct driven PMSG based WTG system has

been simulated using MATLAB-SIMULINK[8]. Vector Control has been implemented at the generator side and

grid side[9,10]. Generator side control aims at controlling the speed of generator wherein the generator is operated at

maximum power point with the help of modified Hill Climb Search (HCS) algorithm. Variable step size method has

been implemented to obtain the reference rotor speed[11,12]. Under normal conditions, grid side control maintains

the DC-link voltage and controls the flow of active and reactive power whereas during fault occurrence, grid side

536

Shrikant Mali et al. / Energy Procedia 54 (2014) 530 540

control targets at reducing the active and reactive power to zero. Chopper resistor connected at DC-link maintains

the DC-link voltage constant during grid fault. As per LVRT specifications, active power is not supplied to the grid

during fault condition. This excess energy is dissipated in the form of heat through the braking resistor connected at

DC-link.

Fig. 6. Block schematic of proposed LVRT scheme.

4.1. Generator and Grid side Control

Field oriented control has been used to implement decoupled control of Permanent Magnet Synchronous

Generator. The Field Orientated Control (FOC) consists of controlling the stator current represented by a vector.

This control is based upon transforming a three phase quantity into a two phase (d and q) quantity. Field orientated

controlled machines need two constants as input references: the torque component (aligned with the q-axis) and the

flux component (aligned with the d-axis).

Fig. 7. Field oriented control of generator side converter.

In case of line side vector control, current represented by d-axis is equivalent to active power reference whereas

current represented by q-axis is equivalent to reactive power reference.

Fig. 8. Vector control of line side converter.

Shrikant Mali et al. / Energy Procedia 54 (2014) 530 540

4.2. Simulation Analysis

The fault may occur in one, two or all the three phases of the AC grid. The results shown below are obtained

when an LLLG fault is applied to the system from 1 sec to 1.1 sec. The system has been simulated for the duration

of 2 sec based on unity power factor configuration without injecting reactive power. System exhibits transient

behavior till 0.25 sec. The overlapping of mechanical and electromagnetic torque for rated wind speed indicates

stable operation of the system throughout the simulation[13]. Generator speed remains constant at 1.2 rad/sec for

rated wind speed. Voltage level at PCC is 400kV. The maximum fault clearing time specified by IWGC for 400kV

grid is 0.1 sec.

Fig. 9. Rated wind speed, generator speed, torque, generator current and generator output power.

Fig. 10. Varying wind speed, generator speed, torque, generator current and generator output power.

The transformer secondary voltage reduces exactly to zero during fault condition, owing to control action of grid

side converter. Increase in DC-link voltage for rated wind speed is within acceptable limits. It is important to

537

538

Shrikant Mali et al. / Energy Procedia 54 (2014) 530 540

maintain the DC-link voltage constant as system may get unstable if the DC-link voltage increases beyond certain

limit and it also leads to power electronic converter failure. For varying wind speed, DC-link voltage is held

constant at 3194V during fault condition. This is obtained by the switching action of chopper resistor during fault

period. The 3 phase nominal rated generator output voltage is 2.2kV rms. The graph of generator voltage indicates

that the generator side is not affected by grid fault and produces the expected power precisely.

Fig. 11. Voltage across DC-link for rated wind speed.

Fig. 12. Voltage across DC-link for varying wind speed.

Fig. 13. Generator output voltage.

Shrikant Mali et al. / Energy Procedia 54 (2014) 530 540

539

Fig. 14. Voltage at PCC.

5. Conclusion

Low voltage ride-through plays a significant role in maintaining voltage stability of a grid-connected wind power

system. Premature tripping of numerous wind generators due to local disturbances can further risk the stability of the

system, contributing to amplification of the effects of the grid disturbances. Variable speed WTGs equipped with

full or partial rating power electronic converters have the ability to extract maximum power from the wind and

exhibit strong FRT capability during the grid faults. Simulation results confirm the fulfillment of LVRT

requirement, i.e., the generator remains connected to the grid and excess energy is dissipated through chopper

resistor in the form of heat during fault occurrence. Generator and grid side control strategies work concurrently to

fulfill the LVRT requirements. The main function of the DC-link capacitor is to store energy and to act as a

decoupling between the rectifier and the inverter so that each can be controlled separately and isolate the wind

turbine systems from the grid which provides protection.

Appendix

Table 2. Simulation parameters.

Parameter

Value

Nominal wind speed

12 m/s

Nominal generator power

5 MW

Nominal generator voltage

2.2kV

Nominal generator current

1.3 kA

Nominal DC-link voltage

3200 V

Voltage at PCC

400 kV

References

[1] Wen-Tsan L, Yuan-Kang W, Ching-Yin L, and Chao-Rong C. Effect of low-voltage-ride-through technologies on the first Taiwan offshore

wind farm planning. IEEE Trans. Sustain. Energy. 2011; 2(1).

[2] Indian Wind Grid Code Draft. 2009; PP (15-18).

[3] Muyeen SM, Takahashi R, Murata T, and Tamura J. A variable speed wind turbine control strategy to meet wind farm grid code requirements.

IEEE Trans. Power Syst. 2010; 25(1).

[4] Abbey C, and Joos G. Effect of low voltage ride through (LVRT) characteristic on voltage stability.

[5] Li J, Li D, Hong L, Xie C and Chen G. A novel power-flow balance LVRT control strategy for low-speed direct-drive PMSG wind generation

system. IEEE 2010.

[6] Abbey C, and Joos G. Supercapacitor energy storage for wind energy applications. IEEE Trans. Ind. Appl. 2007; 43(3).

[7] Qureshi WA, and Nair NC-K. Systematic development of low voltage ride through (LVRT) envelope for grids. IEEE 2010.

540

Shrikant Mali et al. / Energy Procedia 54 (2014) 530 540

[8] Sheng-wen L and Guang-qing B. A novel LVRT of permanent magnet direct-driven wind turbine. IEEE 2011.

[9] Wang W, Ge B, Bi D, Qin M and Liu W. Energy storage based LVRT and stabilizing power control for direct-drive wind power system.

Int. Conf. on Power Syst. Tech., IEEE 2010.

[10] Yang S and Zhang L. Modeling and control of the PMSG wind generation system with a novel controller. 3rd Int. Conf. on Intelligent Syst.

Design and Engg. Appl., IEEE 2013.

[11] Alizadeh L, and Yazdani A. A strategy for real power control in a direct-drive PMSG-based wind energy conversion system. IEEE Trans.

Power Del. 2013.

[12] Sizhan Z, Jinjun L, Linyuan Z and Yangque Z. Improved DC-link voltage control of PMSG WECS based on feedback linearization under

grid faults. IEEE 2013.

[13] Alepuz S, Calle A, Busquets-Monge S, Kouro S and Wu B. Use of stored energy in PMSG rotor inertia for low voltage ride through in backto-back NPC converter based wind power systems. IEEE Trans. Ind. Electron. 2012; PP(99).

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- IEEE STD 519-1992 Harmonic Limits - 07 - TMBDocument9 pagesIEEE STD 519-1992 Harmonic Limits - 07 - TMBAN.ADAMMSNo ratings yet

- Simulation of A Wind TurbineDocument15 pagesSimulation of A Wind TurbinesudeeraranjanNo ratings yet

- Wind Turbine DesignDocument58 pagesWind Turbine Designlogicvirus100% (1)

- Annexure 7 - 220V Speci MSETCL Trombay Nerul 260419 20190903173116Document54 pagesAnnexure 7 - 220V Speci MSETCL Trombay Nerul 260419 20190903173116Anonymous cj7JdRbDbNo ratings yet

- Structure Equipment and Systems For Offshore Wind FarmsDocument252 pagesStructure Equipment and Systems For Offshore Wind Farmsfamiralis100% (4)

- Hover PerformanceDocument74 pagesHover PerformancedeeNo ratings yet

- 2008 PDFDocument8 pages2008 PDFAnonymous cj7JdRbDbNo ratings yet

- Q-Blade Turbine - 2Document45 pagesQ-Blade Turbine - 2OLANIYINo ratings yet

- ISO Tolerance LimitsDocument3 pagesISO Tolerance Limitsbpsgeeta0% (1)

- Iso Dis 45001Document46 pagesIso Dis 45001gmg210981No ratings yet

- Micro-Grid Modeling and ControlDocument24 pagesMicro-Grid Modeling and Controldebjyoti chatterjeeNo ratings yet

- Advances in Wind PowerDocument374 pagesAdvances in Wind PowerCesar CarácterNo ratings yet

- Marine Operations - Offshore Wind 2020 - NewDocument88 pagesMarine Operations - Offshore Wind 2020 - NewManoj GuptaNo ratings yet

- Ims-Sop-F01-Ehv ConcretingDocument13 pagesIms-Sop-F01-Ehv ConcretingAnonymous cj7JdRbDbNo ratings yet

- Ims-Sop-F02-Ehv Tower Erection StringingDocument7 pagesIms-Sop-F02-Ehv Tower Erection StringingAnonymous cj7JdRbDbNo ratings yet

- 16tech Spec RSJ Pole 10.07.2019 Revised Dt. 10.11.2020 1Document7 pages16tech Spec RSJ Pole 10.07.2019 Revised Dt. 10.11.2020 1Anonymous cj7JdRbDbNo ratings yet

- Compartive Studies IS 802Document7 pagesCompartive Studies IS 802Anonymous cj7JdRbDbNo ratings yet

- Results of 2019 IMS Objective and 2020 IMS ObjectiveDocument6 pagesResults of 2019 IMS Objective and 2020 IMS ObjectiveAnonymous cj7JdRbDbNo ratings yet

- LKocewiak - 201510 - Overview, Status and Outline of The New Standards Series - IEC 61400 - 21Document6 pagesLKocewiak - 201510 - Overview, Status and Outline of The New Standards Series - IEC 61400 - 21Anonymous cj7JdRbDbNo ratings yet

- Polymer Testing Inspection and Problem Solving BrochureDocument2 pagesPolymer Testing Inspection and Problem Solving BrochureAnonymous cj7JdRbDbNo ratings yet

- Astm E143-02Document5 pagesAstm E143-02Anonymous cj7JdRbDbNo ratings yet

- Bihar State Power Transmission Company LimitedDocument28 pagesBihar State Power Transmission Company LimitedAnonymous cj7JdRbDbNo ratings yet

- Parthasarthy-Vijayasarthy - 27-VI-4 PDFDocument72 pagesParthasarthy-Vijayasarthy - 27-VI-4 PDFAnonymous cj7JdRbDbNo ratings yet

- Hello World: I Am Already CreatedDocument1 pageHello World: I Am Already CreatedAnonymous cj7JdRbDbNo ratings yet

- 10 11 12 Lightning ProtectionDocument8 pages10 11 12 Lightning ProtectionAnonymous cj7JdRbDbNo ratings yet

- Is 1852Document26 pagesIs 1852sid_adhikaryNo ratings yet

- Railway Recruitment Board (RRB) NotificationDocument16 pagesRailway Recruitment Board (RRB) NotificationFreshers Plane India100% (2)

- Manwell Lift Versus Drag MachinesDocument2 pagesManwell Lift Versus Drag MachinesNeneng MashuriNo ratings yet

- BEM NREL Phase VI PDFDocument218 pagesBEM NREL Phase VI PDFIjaz FazilNo ratings yet

- 05 - PAPER - Taher G - Investigation Performance Darieus VAWTDocument12 pages05 - PAPER - Taher G - Investigation Performance Darieus VAWTZamalludin HermawanNo ratings yet

- Renewable Energy Sources and Global Warming FactorsDocument23 pagesRenewable Energy Sources and Global Warming FactorsKarthikeyan GovindarajNo ratings yet

- Generating Electricity from Moving Electric Cars Using Roof-Mounted Wind TurbinesDocument11 pagesGenerating Electricity from Moving Electric Cars Using Roof-Mounted Wind TurbinesMohamed Sayed SolimanNo ratings yet

- Simulation of Power Control of A Wind Turbine PMSGDocument94 pagesSimulation of Power Control of A Wind Turbine PMSGEd-dahmani ChafikNo ratings yet

- 10 Wind Power EnergyDocument61 pages10 Wind Power EnergyVegahdz HusinNo ratings yet

- WindDocument5 pagesWindAndi WjayaNo ratings yet

- Wind Tunnel Tests of a Novel Two-Bladed Savonius TurbineDocument9 pagesWind Tunnel Tests of a Novel Two-Bladed Savonius TurbineDriss ZiedNo ratings yet

- Wind Power Fundamentals SlidesDocument45 pagesWind Power Fundamentals SlidesrollramsNo ratings yet

- Modeling of Type 4 Wind Turbine Generators - UVIG Modeling WikiDocument11 pagesModeling of Type 4 Wind Turbine Generators - UVIG Modeling WikielchicogrisNo ratings yet

- Wind Energy Harvesting: FIGURE 2.8 Power Coefficient Curve of A Wind TurbineDocument1 pageWind Energy Harvesting: FIGURE 2.8 Power Coefficient Curve of A Wind TurbineFuad AnwarNo ratings yet

- RES Two MarksDocument16 pagesRES Two Marksramk1987No ratings yet

- WTG CalculationDocument7 pagesWTG Calculation1382aceNo ratings yet

- 1 Power&EnergyDocument23 pages1 Power&EnergyarielaNo ratings yet

- Introduction to Wind Turbine Aerodynamics TheoryDocument23 pagesIntroduction to Wind Turbine Aerodynamics TheoryAlexandreSidantNo ratings yet

- Aerodynamic Optimization and Open Field Testing of A 1 KW Vertical-Axis Wind TurbineDocument12 pagesAerodynamic Optimization and Open Field Testing of A 1 KW Vertical-Axis Wind TurbineaenergieNo ratings yet

- IDP Final ReportDocument107 pagesIDP Final ReportMuhaimen RahmanNo ratings yet

- Effect of Number of Blades and Blade Chord Length On The Performance of Darrieus Wind TurbineDocument10 pagesEffect of Number of Blades and Blade Chord Length On The Performance of Darrieus Wind TurbineNEDALNo ratings yet

- Swes Unit 3Document64 pagesSwes Unit 3pradeepNo ratings yet

- Methodology for Selecting Wind Turbines Based on Site ConditionsDocument10 pagesMethodology for Selecting Wind Turbines Based on Site ConditionsBehruz NuralievNo ratings yet

- Department of Mechanical Engineering-2Document16 pagesDepartment of Mechanical Engineering-2Pankaj Gaurav100% (1)

- Optimize Vertical Axis Wind Turbine DesignDocument42 pagesOptimize Vertical Axis Wind Turbine DesignRudl1100% (1)