Professional Documents

Culture Documents

OL-12A Fire Damage

Uploaded by

Vasanthapragash Nadarajha0 ratings0% found this document useful (0 votes)

39 views4 pagesFire damage report

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFire damage report

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views4 pagesOL-12A Fire Damage

Uploaded by

Vasanthapragash NadarajhaFire damage report

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

No.

12 March 2008

Investigation of Fire-Damaged Warehouse

Figure 1. View of south and east sides of moving company warehouse.

A fire occurred in a moving company warehouse in New England in

1998. The owner of the building retained Zallen Engineering to determine the structural safety of the building as a result of the fire and the

necessary repairs. The warehouse is 153 feet long by 99 feet wide, was

constructed in 1962, and is of metal building construction.

Figure 1 shows a photo of the south end, which is the

front of the building, and the east side of the building

which contain the overhead loading doors. The front

low roof section of the building contains offices and

was not damaged by the fire.

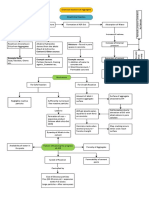

Figure 2 (next page) is a plan of the roof framing. The

principal support system of the building is composed

of 7 rigid frames1 on Lines 2 through 8, spanning the

full width of the building. Figures 3 and 4 are photos

of part of the rigid frame on Line 8; Figure 5 (page 3)

shows construction details at the eaves and defines the

various structural elements. The end wall supports on

Lines 1 and 9 consist of roof beams and columns; see

Figure 2. Figure 4 shows part of this framing on Line

9, in the background. The roofing consists of 19 gage

cold-formed corrugated steel sheets supported by 8

inch deep, 14 gage cold-formed steel purlins of Z

shape. The purlins run across the top of and are sup-

ported by the rigid frames and end wall roof beams.

Figure 4 shows some of the purlins.

The siding consists of 20 gage cold-formed corrugated

steel sheets spanning vertically. See Figure 1 for an exterior view. The sheets are supported laterally at the

bottom by the top of a low concrete enclosure wall, by

16 gage cold-formed steel intermediate girts, and at the

top by either 16 gage cold-formed steel eave struts or

the ends of the purlins. Figure 3 shows the low concrete wall and the intermediate girts.

Fire Damage

The fire started at corner A-9 and appears to have

been set. At the time of the fire, the warehouse was

filled tightly with packing crates up to the eaves, making access for firefighting difficult. Further, although

there were sprinklers, they were inoperable. The fire

2000 & 2008 Zallen Engineering

spread from the A-9 corner across

the top of the packing crates southward to beyond Line 6 and eastward

to beyond the ridge, causing structural damage of varying degrees to

roof framing and wall framing. There

was also damage to the metal roofing

and siding, the insulation, and extensive smoke damage throughout the

building.

Figure 2. Plan of roof framing.

Figure 3. View of rigid frame at

grid location A-8.

There were two types of observable

fire damage to the structural framing:

1) where the paint was burned off

indicating that the members were

subject to significant heat from the

fire; and 2) where the members were

either twisted and kinked. Figures 3

and 4 show paint burned off of the

web of a rigid frame. Figure 6 (page 3)

shows twisted and kinked roof

purlins. Figure 7 (page 4) shows corner A-9, the corner where the fire

was ignited; the corner column (A-9) is twisted and,

although not discernable in the photo, the roof beam

on the right (on Line 9) and all the roof purlins and

wall girts near the corner are twisted.

Figure 4. View of rigid frame on Line 8, west of the ridge. In the

background is the framing at the end wall on Line 9.

Forensic Engineering in Construction

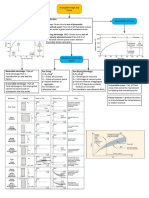

Effects of Fire on Structural Steel Members

When steel is heated, it loses strength and stiffness

and expands with the rise in temperature. Above 600

degrees Fahrenheit, its strength and stiffness will

drop significantly with further rise in temperature.

For a steel member subjected to fire in a building,

the expansion is restrained, and the restraint can

generate large axial compression forces in the member. The combined effects of loss of strength and

stiffness, superimposed load, and forces generated

by restraint can cause the member or parts of the

member to distort or collapse. If the temperature of

the steel rises above 1300 degrees Fahrenheit, there

is a metallurgical change in state. After the fire, the

member will cool gradually, mainly by air, back down

below 1300 degrees Fahrenheit, where, for ordinary

low carbon constructional steels, it will revert back to

its original metallurgical state.2

Therefore, members that were not distorted by the fire

have not been damaged structurally by the fire, except

superficially, and most members that have been distorted could be reused if bent back into shape. Further,

even in the distorted condition, a member still can

have considerable strength. Large structural members

can be heat bent back into shape. However, it is impractical to heat bend light weight members; it is more

Figure 5. Section through eaves showing

construction details. Insulation and

bracing are not shown.

economical to simply replace them. Steel items such as

high strength bolts that are quenched and tempered in

their manufacturing process, which have expanded due

to the heat of the fire, should be replaced, since their

metallurgical state may have been permanently altered.

Structural Evaluation

The various structural members were evaluated for

load capacity in the pre-fire condition and in the postfire condition. The load capacity of the rigid frames

were not affected by the fire; however, their

pre-fire capacity was deficient because lateral

bracing was omitted at the bottom flange of

the roof beam portion of the frames. Various

portions of the bottom flange will be in compression or tension under snow load and under

wind load; if unbraced the flanges will buckle

laterally and then not be able to support load.

There is a diagonal member on each side of the

rigid frame that braces the bottom flange of the

frame at the knee, as shown on Figure 3; additional diagonal braces need to be installed at

the ridge, and at an intermediate position between the knee and the ridge on each side of

the ridge. The cost of installing this bracing is

approximately $5,000, which is quite small

compared to the cost of repairing the building

Figure 6. Twisted and kinked roof purlins. Insulation has

as a whole.

been destroyed by the fire and the metal roofing is exposed.

Forensic Engineering in Construction

The snow load capacity of the rigid frames with

the additional braces is 25 psf. By comparison,

the current building code requirement is 35 psf.

The pre-fire snow load capacity of the roof purlins

is also 25 psf for the 20 foot spans (bays between Lines 2 and 8 - see Figure 2). Where the

purlins were both twisted and kinked (Figure 6),

their estimated snow load capacity is 13 psf, which

is substantially below the current building code requirement of 35 psf.

The necessary structural repair work consisted of

replacing kinked or twisted purlins and girts, and

replacing twisted columns and beams on Line 9.

This work necessitated the removal and replacement of the metal roofing, metal siding, and insulation under the roofing and siding, in the affected

areas. However, due to the soot on the insulation

and other damage to the insulation, all the metal

roofing, metal siding, and the insulation under the

roofing and siding needed to be removed and replaced, the steel framing power washed to remove

the soot, and the structural members repainted.

End Notes

1. The rigid in rigid frame refers

to the connection between the

columns and beams. These

connections are such that there

is no relative rotation between

the end of a column and the

end of the beam connected

thereto; i.e. the connection is

rigid.

2. Ordinary constructional steels

are rolled into shape at 1600

degrees Fahrenheit and air

cooled to room temperature.

Figure 7. Fire damage at corner A-9. Corner column

A-9 is twisted; the roof beam on Line 9, framing to this

column, is twisted, and the roof purlins and wall girts

near this corner are all twisted. Note the rod crossbracing in the walls and at the bottom of the roof

purlins; these are all loose as a result of the fire.

Forensic Engineering in Construction is

published by Zallen Engineering, 1101

Worcester Road, Framingham, MA 01701.

508-875-1360.

rmzallen@zallenegineering.com.

Forensic Engineering in Construction

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Circular Column DesignDocument10 pagesCircular Column DesignVasanthapragash Nadarajha100% (1)

- Integrated Finite Elements Analysis and Design of StructuresDocument50 pagesIntegrated Finite Elements Analysis and Design of Structuresaeiou321No ratings yet

- Integrated Finite Elements Analysis and Design of StructuresDocument50 pagesIntegrated Finite Elements Analysis and Design of Structuresaeiou321No ratings yet

- Integrated Finite Elements Analysis and Design of StructuresDocument50 pagesIntegrated Finite Elements Analysis and Design of Structuresaeiou321No ratings yet

- Simple Stress & StrainDocument34 pagesSimple Stress & StrainfaisalasgharNo ratings yet

- KMSC Mystery School of Self Spiritual MasteryDocument7 pagesKMSC Mystery School of Self Spiritual MasteryRalphNo ratings yet

- Composite Function Worksheet-02Document4 pagesComposite Function Worksheet-02Marcus Maccoy AcordaNo ratings yet

- Tower Crane Operation ManualDocument31 pagesTower Crane Operation ManualMahmoud Sarhan100% (1)

- Gabion Wall and Sheet PilesDocument18 pagesGabion Wall and Sheet PilesVasanthapragash NadarajhaNo ratings yet

- COLUMN EFFECTIVE LENGTH - Yura1971q2Document6 pagesCOLUMN EFFECTIVE LENGTH - Yura1971q2ellisbl100% (1)

- Unit 29 Sentence Structure in EnglishDocument11 pagesUnit 29 Sentence Structure in Englishj pcNo ratings yet

- Gabion Retaining Wall Design GuideDocument30 pagesGabion Retaining Wall Design GuideThomas Hill80% (5)

- Day03-01 Introduction To CSIBridge 120506Document82 pagesDay03-01 Introduction To CSIBridge 120506Vasanthapragash NadarajhaNo ratings yet

- Observation ChecklistDocument4 pagesObservation ChecklistNiketa Joseph100% (5)

- Ethnic Groups and RacismDocument21 pagesEthnic Groups and RacismNichaella BiscochoNo ratings yet

- Aci435 PDFDocument89 pagesAci435 PDFVasanthapragash NadarajhaNo ratings yet

- Self-Compacting ConcreteDocument68 pagesSelf-Compacting ConcreteMisgun SamuelNo ratings yet

- Strut & Tie ModelDocument67 pagesStrut & Tie Modelahmed adel100% (9)

- Ca1 Pu 12Document100 pagesCa1 Pu 12Shabbeer ZafarNo ratings yet

- NATURAL SELECTION (Battle of The Beaks)Document5 pagesNATURAL SELECTION (Battle of The Beaks)Julius CortezoNo ratings yet

- Meek 1989Document19 pagesMeek 1989Vasanthapragash NadarajhaNo ratings yet

- List of Key Things That We Learn From Introduction and Building Structural SystemsDocument3 pagesList of Key Things That We Learn From Introduction and Building Structural SystemsVasanthapragash NadarajhaNo ratings yet

- Alkali Aggregate Reaction, Alkali Carbonate Reaction and Pyrite AttackDocument3 pagesAlkali Aggregate Reaction, Alkali Carbonate Reaction and Pyrite AttackVasanthapragash NadarajhaNo ratings yet

- Drying Shrinkage, Creep, Thermal Shrinkage & Elastic ModulasDocument3 pagesDrying Shrinkage, Creep, Thermal Shrinkage & Elastic ModulasVasanthapragash NadarajhaNo ratings yet

- Crack Inspection FormDocument1 pageCrack Inspection FormVasanthapragash NadarajhaNo ratings yet

- Assignment#09-Using Ultrasonic Pulse Velocity Method To Estimate Crack DepthDocument1 pageAssignment#09-Using Ultrasonic Pulse Velocity Method To Estimate Crack DepthVasanthapragash NadarajhaNo ratings yet

- Load Test On Beam - 3 Point Load TestDocument1 pageLoad Test On Beam - 3 Point Load TestVasanthapragash NadarajhaNo ratings yet

- Two Way SlabDocument17 pagesTwo Way SlabVasanthapragash NadarajhaNo ratings yet

- List of Key Things That We Learn From Introduction and Building Structural SystemsDocument2 pagesList of Key Things That We Learn From Introduction and Building Structural SystemsVasanthapragash NadarajhaNo ratings yet

- Ductility of Unconfined Beam SectionsDocument5 pagesDuctility of Unconfined Beam SectionsVasanthapragash NadarajhaNo ratings yet

- Cableways Tramways and Suspension BridgesDocument14 pagesCableways Tramways and Suspension BridgesChristian MavarezNo ratings yet

- Proposed Residential Development: No. 418, R.A. de Mel Mawatha, Colombo 03Document1 pageProposed Residential Development: No. 418, R.A. de Mel Mawatha, Colombo 03Vasanthapragash NadarajhaNo ratings yet

- Common Irregular Verb ListDocument4 pagesCommon Irregular Verb Listapi-27488371100% (1)

- Amendment Sheet Lift Machimg Room - EditedDocument1 pageAmendment Sheet Lift Machimg Room - EditedVasanthapragash NadarajhaNo ratings yet

- Water Retaining StructureDocument27 pagesWater Retaining StructureVasanthapragash NadarajhaNo ratings yet

- Scope of Consultancy Services - Ictad-Consult-4Document39 pagesScope of Consultancy Services - Ictad-Consult-4Vasanthapragash Nadarajha100% (2)

- Performance Analysis of The Proposed Reservoir Project in The State of West BengalDocument17 pagesPerformance Analysis of The Proposed Reservoir Project in The State of West BengalVasanthapragash NadarajhaNo ratings yet

- Principles of Marketing: Strategic Planning and The Marketing ProcessDocument16 pagesPrinciples of Marketing: Strategic Planning and The Marketing ProcessVasanthapragash NadarajhaNo ratings yet

- Available C and I Sections From Colonial HardwareDocument2 pagesAvailable C and I Sections From Colonial HardwareVasanthapragash NadarajhaNo ratings yet

- Master of Business Administration - MBA Semester 3 ProjectDocument2 pagesMaster of Business Administration - MBA Semester 3 ProjectAnkur SharmaNo ratings yet

- Multicast Live Video Broadcasting Using Real Time TransmissionDocument2 pagesMulticast Live Video Broadcasting Using Real Time Transmissionaruna2707No ratings yet

- Fatigue Assessment Analysis of Offshore Structures With Application To An Existing Platform in Suez Gulf, EgyptDocument21 pagesFatigue Assessment Analysis of Offshore Structures With Application To An Existing Platform in Suez Gulf, EgyptthuanNo ratings yet

- Factors Affecting Employee Turnover and Job SatisfactionDocument14 pagesFactors Affecting Employee Turnover and Job Satisfactionfarah goharNo ratings yet

- WS DrawingDocument16 pagesWS DrawingSuparnoNo ratings yet

- Humanities Social Sciences DistinctionsDocument3 pagesHumanities Social Sciences DistinctionsDavid0% (1)

- Demo On Tableau DesktopDocument46 pagesDemo On Tableau DesktopDeepak GuptaNo ratings yet

- Online Assignment 1 Math Econ 2021 22Document6 pagesOnline Assignment 1 Math Econ 2021 22Panagiotis ScordisNo ratings yet

- Developing Training Program For Effective and Quality Volleyball PlayersDocument13 pagesDeveloping Training Program For Effective and Quality Volleyball PlayersDeogracia BorresNo ratings yet

- Design and Fabrication Dual Side Shaper MachineDocument2 pagesDesign and Fabrication Dual Side Shaper MachineKarthik DmNo ratings yet

- Midterm Written DunhamDocument6 pagesMidterm Written Dunhamapi-320665379No ratings yet

- Karatina University: University Examinations 2018/2019 ACADEMIC YEARDocument5 pagesKaratina University: University Examinations 2018/2019 ACADEMIC YEARtimNo ratings yet

- KG 2 Week 5 - (133089689484163457) - 0Document3 pagesKG 2 Week 5 - (133089689484163457) - 0Nahdat Al Ghad International SchoolNo ratings yet

- Pulse / Pulsefit: Software For Electrophysiological Research, Data Acquisition, Review and Online AnalysisDocument8 pagesPulse / Pulsefit: Software For Electrophysiological Research, Data Acquisition, Review and Online AnalysisHRCNo ratings yet

- Cs 1410Document2 pagesCs 1410David DengNo ratings yet

- Onity AdvanceRFIDDocument4 pagesOnity AdvanceRFIDLittle_Bit77No ratings yet

- Samcef RotorDocument4 pagesSamcef RotorChihiya Fitria NurhayatiNo ratings yet

- The Collection of Mining and Metallurgical Art of The Institute of Engineering of Porto (Isep)Document1 pageThe Collection of Mining and Metallurgical Art of The Institute of Engineering of Porto (Isep)Costa, PatríciaNo ratings yet

- Oracle OTL Timecard Layout CustomicationDocument138 pagesOracle OTL Timecard Layout CustomicationFoolIshNo ratings yet

- History 541gDocument21 pagesHistory 541gkarl1802No ratings yet