Professional Documents

Culture Documents

Secondary Containment Guide

Uploaded by

James Glerry AaronCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Secondary Containment Guide

Uploaded by

James Glerry AaronCopyright:

Available Formats

Secondary Containment for Hazardous Materials Storage Guidelines

Secondary containment is defined as a means of surrounding one or more primary storage

containers to collect any hazardous material spillage in the event of loss of integrity or container

failure. Hazardous materials must be stored in secondary containers to prevent or minimize the

possibility of accidental release as well as to ensure compliance with certain local, state and

federal regulations dealing with chemical storage. Hazardous materials includes, but not

limited to chemicals, hazardous waste and oil-filled equipment. Please refer to the secondary

containment flow chart below for assistance in determining if secondary containment is required.

Secondary Containment Decision Process

Is it a

hazardous

material?

Start

no

No secondary

containment needed

yes

no

Life or environmental

hazard?

Container size

yes

no

Single container no

_> 55 gal (liq) or

550 lb (solid)?

yes

Multiple vessels

_> 1,000 gal (liq) or

10,000 lb (solid)?

Will material

threaten personnel or no

the environment (e.g.,

contaminates soil or

water) if it leaks?

yes

Secondary

containment needed

yes

no

Could material

produce an

incompatible

chemical reaction

with other nearby

substances (e.g.,

emit toxic gas,

ignite, explode,

etc.)?

yes

Contain 110% of the volume of the largest container. If multiple containers, must contain either 10% of the aggregate

volume or 150% of the largest container, whichever is greater. If in an interior Haz Mat storage room, must also contain 20

minutes of sprinkler flow, at the design flow rate for that area, plus the volume of the chemical container. If stored in an

exterior storage area and open to rainfall, must contain the volume of the chemical container plus the volume of a 24hour rainfall as determined by a 25-year storm and provisions shall be made to drain accumulations of the rainwater.

SECONDARY CONTAINMENT REQUIREMENTS

All liquid hazardous materials must be in approved secondary containment to prevent

release and uncontrolled:

o mixing of incompatible chemicals

o discharge of hazardous materials through unplugged drains, cups sinks, storm

drains, sewers, etc.

o damage associated with liquid materials leaking through tile and concrete floors

to workplaces below.

All liquid hazardous materials must be in approved secondary containment whenever

stored on a floor.

All hazardous materials must be in approved secondary containment whenever it has

been declared a waste.

Hazardous materials stored in non-approved or sub-standard storage cabinets or units that

may pose an additional risk (flammables or oxidizers in wood cabinets) must be placed in

secondary containment until an approved storage unit is installed.

Secondary containment is required whenever specified by a federal, state or local

regulation.

CONTAINMENT VOLUME

Secondary containment for a single container will be 110 percent of the primary

container.

Secondary containment for multiple containers will be 150 percent of the largest

containers volume or 10 percent of the aggregate volumes of all the containers,

whichever is greater.

CONTAINMENT CONSTRUCTION

Secondary containment must be compatible with the stored materials and be constructed

of materials capable of containing a spill or leak.

You might also like

- Evaluating The Procurement Strategy Adopted in The Scottish Holyrood Parliament Building ProjectDocument13 pagesEvaluating The Procurement Strategy Adopted in The Scottish Holyrood Parliament Building ProjectNnamdi Eze100% (4)

- Fire Risk in High-Rise and Super High-Rise BuildingsDocument1 pageFire Risk in High-Rise and Super High-Rise BuildingsthaibinhkxNo ratings yet

- The Green Wall - Story and Photos by Stephen James Independent Investigative Journalism & Photography - VC Reporter - Ventura County Weekly - California Department of Corrections whistleblower D.J. Vodicka and his litigation against the CDC.Document8 pagesThe Green Wall - Story and Photos by Stephen James Independent Investigative Journalism & Photography - VC Reporter - Ventura County Weekly - California Department of Corrections whistleblower D.J. Vodicka and his litigation against the CDC.Stephen James - Independent Investigative Journalism & PhotographyNo ratings yet

- NYPE93Document0 pagesNYPE93gvsprajuNo ratings yet

- Hazardous Area Instrumentation InformationDocument6 pagesHazardous Area Instrumentation InformationMandar PhadkeNo ratings yet

- Fire Alarm Isolation Permit - Form ADocument1 pageFire Alarm Isolation Permit - Form AMuhammad Azam0% (1)

- Fitting Table - Iso 8015 (Jis B 0401) (Jis B 0024)Document4 pagesFitting Table - Iso 8015 (Jis B 0401) (Jis B 0024)mysoreyogishNo ratings yet

- Internet Intranet ExtranetDocument28 pagesInternet Intranet ExtranetAmeya Patil100% (1)

- Transport For London Pay To Drive in London: PO Box 344 Darlington Dl1 9qe TFL - Gov.uk/drivingDocument1 pageTransport For London Pay To Drive in London: PO Box 344 Darlington Dl1 9qe TFL - Gov.uk/drivingDanyy MaciucNo ratings yet

- Pocket Pod PresetsDocument13 pagesPocket Pod PresetsmarcusolivusNo ratings yet

- Storage and Handling of Drums & Intermediate Bulk Containers:Ppg26Document6 pagesStorage and Handling of Drums & Intermediate Bulk Containers:Ppg26TC Cüneyt ŞanNo ratings yet

- Bunding and Spill Management SADocument7 pagesBunding and Spill Management SAEvodius RweyemamuNo ratings yet

- Highly Protected Risk PDFDocument2 pagesHighly Protected Risk PDFRanjit TalpadaNo ratings yet

- Active & Passive Protection SystemDocument31 pagesActive & Passive Protection SystemAhmed GhariebNo ratings yet

- Cooper Fire Detection Systems CatalogueDocument98 pagesCooper Fire Detection Systems CatalogueAzooz ElhadiNo ratings yet

- Mining Engineer HandbookDocument2,292 pagesMining Engineer HandbookprasashivNo ratings yet

- An Overview of FM 200, Carbon Dioxide, Wet Chemical, and Dry Chemical Fire Suppression SystemsDocument5 pagesAn Overview of FM 200, Carbon Dioxide, Wet Chemical, and Dry Chemical Fire Suppression SystemsAlex ChinNo ratings yet

- Urban Transformers Safety and Environmental ChallengesDocument8 pagesUrban Transformers Safety and Environmental ChallengesNicodemus Ervino MandalaNo ratings yet

- Fire Protection: SolutionsDocument8 pagesFire Protection: SolutionsBibhu Ranjan MohantyNo ratings yet

- 697 RoddDocument12 pages697 RoddAan SupriyantoNo ratings yet

- Power Plant Fire Losses: P.G. SreejithDocument28 pagesPower Plant Fire Losses: P.G. SreejithsonaltopiwalaNo ratings yet

- Hazard Identification, Risk Assessment & ControlDocument4 pagesHazard Identification, Risk Assessment & ControlEdgar ManubagNo ratings yet

- Kingspan Understanding Smoke Control Guide en IeDocument55 pagesKingspan Understanding Smoke Control Guide en IeRasmei NgorNo ratings yet

- Fire Risk of Cold Room PanelDocument6 pagesFire Risk of Cold Room Paneldarby1028No ratings yet

- FIRE ALARM ContextPlus Addressable Catalogue 2017Document32 pagesFIRE ALARM ContextPlus Addressable Catalogue 2017Ghada SokniNo ratings yet

- Fire Assessor v2Document6 pagesFire Assessor v2Ar JunNo ratings yet

- Jetfire Darmatt LFTDocument4 pagesJetfire Darmatt LFTHyeong-Ho KimNo ratings yet

- Tameside Metropolitan Borough Council - Fire Risk AssessmentDocument34 pagesTameside Metropolitan Borough Council - Fire Risk AssessmentВладислав ПиндерNo ratings yet

- Electrical Protection MaintenanceDocument12 pagesElectrical Protection MaintenanceCyril DIPANDANo ratings yet

- NFPA ListDocument5 pagesNFPA ListmaunghkNo ratings yet

- Adi Emea 6 Fire & Gas DetectionDocument34 pagesAdi Emea 6 Fire & Gas DetectionAlbertNo ratings yet

- BTI Guide To MIC in Fire Protec - Systems 2005Document11 pagesBTI Guide To MIC in Fire Protec - Systems 2005Claudia MmsNo ratings yet

- Buckeye Semifixed SystemsDocument9 pagesBuckeye Semifixed SystemsAndrés Felipe Sarmiento SNo ratings yet

- Lecture On Fire Prevention PlanningDocument73 pagesLecture On Fire Prevention PlanningAsad MehboobNo ratings yet

- Hazardous Material StorageDocument2 pagesHazardous Material Storageone8283841553No ratings yet

- Galfar ConstructionDocument2 pagesGalfar Constructionadarshp139No ratings yet

- PROJECT STANDARD and SPECIFICATIONS Fire Proofing Vessels and Supports Rev01webDocument4 pagesPROJECT STANDARD and SPECIFICATIONS Fire Proofing Vessels and Supports Rev01webAzeem50% (2)

- Presentation ESE Type Lightning Protecton Year 2017-1Document27 pagesPresentation ESE Type Lightning Protecton Year 2017-1Manav Mahesh ChandraNo ratings yet

- Chemetics - Acid CoolersDocument65 pagesChemetics - Acid CoolersRedFahimNo ratings yet

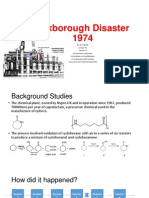

- Flixborough Disaster PresentationDocument6 pagesFlixborough Disaster PresentationTan Yong ChaiNo ratings yet

- NFPA 72 2010 UpdateDocument99 pagesNFPA 72 2010 UpdateJohn Coba Piña100% (1)

- New 2018 Mekan Engineering Services Company ProfileDocument26 pagesNew 2018 Mekan Engineering Services Company ProfileshahidkhanzNo ratings yet

- Mobile TowerDocument5 pagesMobile TowersababanNo ratings yet

- 2023.02.09 - EIT - Intro To Haz Areas and HA Classification - AG - v2 - WithRecordingDocument36 pages2023.02.09 - EIT - Intro To Haz Areas and HA Classification - AG - v2 - WithRecordingAndrewNo ratings yet

- Lightning Protection of Floating Roof TanksDocument12 pagesLightning Protection of Floating Roof TanksnaveedfndNo ratings yet

- ATEX Explosion Protection and CE MarkingsDocument6 pagesATEX Explosion Protection and CE MarkingsVASANHF1No ratings yet

- ZonesDocument19 pagesZonesVaidheeshwar VetrivelNo ratings yet

- California Retailers Guide To Hazardous Waste ComplianceDocument4 pagesCalifornia Retailers Guide To Hazardous Waste ComplianceStericycle100% (1)

- Lecture 6Document22 pagesLecture 6Ali AimranNo ratings yet

- ES Audit CheckpointsDocument12 pagesES Audit CheckpointsAnonymous j5apk2AumNo ratings yet

- BC Prelim Strat Climate Risk AssessmentDocument429 pagesBC Prelim Strat Climate Risk AssessmentEmma Crawford Hampel, BIV.comNo ratings yet

- Safety Distance RefineryDocument39 pagesSafety Distance RefineryBayu AjipNo ratings yet

- Dhammadinnā 2020 Highlights From A Comparative Study of The Sa Yukta-Āgama Quotations in The Abhidharmakośopāyikā - ĪkāDocument119 pagesDhammadinnā 2020 Highlights From A Comparative Study of The Sa Yukta-Āgama Quotations in The Abhidharmakośopāyikā - ĪkādhammadinnāNo ratings yet

- Fire Protection SystemsDocument97 pagesFire Protection SystemsjosebolisNo ratings yet

- Foam For Fixed SystemDocument2 pagesFoam For Fixed SystemRukman SetiawanNo ratings yet

- Saes B-006 (2017)Document21 pagesSaes B-006 (2017)Ralph Ian Malabanan100% (1)

- 6 - Appendix D2 - Risk Assessment PDFDocument95 pages6 - Appendix D2 - Risk Assessment PDFEmiliano VendittiNo ratings yet

- A-Ele-Lst-000-47961-B - Test Facility Schedule For Pipeline Cathodic Protection SystemDocument23 pagesA-Ele-Lst-000-47961-B - Test Facility Schedule For Pipeline Cathodic Protection SystemBadiNo ratings yet

- Undergound Fuel TanksDocument4 pagesUndergound Fuel TanksMubashar SharifNo ratings yet

- Atex Wallchart - 6ADocument1 pageAtex Wallchart - 6AfhaslfhNo ratings yet

- Scrap Specifications CircularDocument57 pagesScrap Specifications Circulargiám địnhNo ratings yet

- BRE - Fire Performance of SIPSDocument8 pagesBRE - Fire Performance of SIPSDouglas TaylorNo ratings yet

- Hazardous Areas Are Defined by Three Main CriteriaDocument5 pagesHazardous Areas Are Defined by Three Main Criteriaswarm62No ratings yet

- E PB 83 Req Chemical WarehouseDocument2 pagesE PB 83 Req Chemical WarehouseQuan Pham BaNo ratings yet

- Chemical TankersDocument22 pagesChemical Tankers16 - AniruthNo ratings yet

- Hazardous Chemical Safe Storage Compliance: ContainmentDocument17 pagesHazardous Chemical Safe Storage Compliance: Containmentb.r.kuppanNo ratings yet

- Water Damage Restoration and Clean Up ChecklistFrom EverandWater Damage Restoration and Clean Up ChecklistRating: 1 out of 5 stars1/5 (1)

- Powder Coating Pretreatment Manual PDFDocument28 pagesPowder Coating Pretreatment Manual PDFJames Glerry AaronNo ratings yet

- BS ISO 8015 - 1985 - Technical Drawings - Fundamental Tolerancing PrincipleDocument12 pagesBS ISO 8015 - 1985 - Technical Drawings - Fundamental Tolerancing PrincipledarlanschulzNo ratings yet

- Air Pollution Control Measures For Hot Dip Galvanizing KettlesDocument9 pagesAir Pollution Control Measures For Hot Dip Galvanizing KettlesJames Glerry AaronNo ratings yet

- Prueba de PreeceDocument18 pagesPrueba de PreeceSebastián AlmagroNo ratings yet

- S K Sharma Water Chemistry in Thermal Power Plants PDFDocument42 pagesS K Sharma Water Chemistry in Thermal Power Plants PDFrajpal146100% (2)

- Gantt Chart Excel TemplateDocument3 pagesGantt Chart Excel TemplateJames Glerry AaronNo ratings yet

- Estimation of The Kinetic Parameters (Chemical Reactions and Stoichiometry)Document3 pagesEstimation of The Kinetic Parameters (Chemical Reactions and Stoichiometry)James Glerry AaronNo ratings yet

- Heat Ex SPR 2010Document21 pagesHeat Ex SPR 2010James Glerry AaronNo ratings yet

- BS ISO 8015 - 1985 - Technical Drawings - Fundamental Tolerancing PrincipleDocument12 pagesBS ISO 8015 - 1985 - Technical Drawings - Fundamental Tolerancing PrincipledarlanschulzNo ratings yet

- Prueba de PreeceDocument18 pagesPrueba de PreeceSebastián AlmagroNo ratings yet

- HiligaynonLessons CecileMotus PDFDocument454 pagesHiligaynonLessons CecileMotus PDFJames Glerry AaronNo ratings yet

- Biodata Format FinalDocument2 pagesBiodata Format Finalanon-90865197% (120)

- BS ISO 8015 - 1985 - Technical Drawings - Fundamental Tolerancing PrincipleDocument12 pagesBS ISO 8015 - 1985 - Technical Drawings - Fundamental Tolerancing PrincipledarlanschulzNo ratings yet

- Phantich Nuoc Moi TruongDocument90 pagesPhantich Nuoc Moi TruongVan Thanh TranNo ratings yet

- Filtration (Plate and Frame Press)Document5 pagesFiltration (Plate and Frame Press)James Glerry AaronNo ratings yet

- AdsooprptionDocument5 pagesAdsooprptionJames Glerry AaronNo ratings yet

- Lecture 1: Introduction To Strategic Management (Chapter 1)Document27 pagesLecture 1: Introduction To Strategic Management (Chapter 1)Imam AliNo ratings yet

- Mass Transfer T2 - 12Document1 pageMass Transfer T2 - 12James Glerry AaronNo ratings yet

- SOP1 Heat ConductionDocument1 pageSOP1 Heat ConductionJames Glerry AaronNo ratings yet

- FiltrationDocument75 pagesFiltrationJames Glerry AaronNo ratings yet

- AlcoholDocument7 pagesAlcoholcrazeeboyz941761No ratings yet

- Valves and FittingsDocument5 pagesValves and FittingsJames Glerry AaronNo ratings yet

- Chemical Name: Ca Crystal Structure: Face Centered Atomic Mass: Density at 20 CDocument1 pageChemical Name: Ca Crystal Structure: Face Centered Atomic Mass: Density at 20 CJames Glerry AaronNo ratings yet

- Analytical Shape Computation of Macromolecules: I. Molecular Area and Volume Through Alpha ShapeDocument17 pagesAnalytical Shape Computation of Macromolecules: I. Molecular Area and Volume Through Alpha ShapeJames Glerry AaronNo ratings yet

- Ethics NotesDocument8 pagesEthics NotesJames Glerry AaronNo ratings yet

- Identification of An UnknownDocument8 pagesIdentification of An UnknownJames Glerry Aaron100% (1)

- Presidential Decree No 1151, S 1. Presidential Decree No 1151, S 4Document18 pagesPresidential Decree No 1151, S 1. Presidential Decree No 1151, S 4Myles LaboriaNo ratings yet

- SyllabusDocument3 pagesSyllabusJames Glerry AaronNo ratings yet

- 7779 19506 1 PBDocument24 pages7779 19506 1 PBAyessa FerrerNo ratings yet

- MN502 Lecture 3 Basic CryptographyDocument45 pagesMN502 Lecture 3 Basic CryptographySajan JoshiNo ratings yet

- PRANIR ProfileDocument14 pagesPRANIR ProfileManish VadanereNo ratings yet

- The Mechanism of Notifying and Record Keeping Three Forms Are Used For Notifying and Record KeepingDocument6 pagesThe Mechanism of Notifying and Record Keeping Three Forms Are Used For Notifying and Record KeepingRoger FernandezNo ratings yet

- BSNL PRBT IMImobile HPDocument13 pagesBSNL PRBT IMImobile HPMithil AgrawalNo ratings yet

- Labor LawDocument6 pagesLabor LawElden Cunanan BonillaNo ratings yet

- Area & Perimeter - CRACK SSC PDFDocument10 pagesArea & Perimeter - CRACK SSC PDFSai Swaroop AttadaNo ratings yet

- 1-10 Clariant - Prasant KumarDocument10 pages1-10 Clariant - Prasant Kumarmsh43No ratings yet

- 737-11 Tikona Bill Free Plan Leaflet - v2Document1 page737-11 Tikona Bill Free Plan Leaflet - v2alok singhNo ratings yet

- Direct Marketing CRM and Interactive MarketingDocument37 pagesDirect Marketing CRM and Interactive MarketingSanjana KalanniNo ratings yet

- Good Quality Practices at NTPC KudgiDocument8 pagesGood Quality Practices at NTPC KudgisheelNo ratings yet

- The Soyuzist JournalDocument15 pagesThe Soyuzist Journalcatatonical thingsNo ratings yet

- Assignment No. 1: Semester Fall 2021 Data Warehousing - CS614Document3 pagesAssignment No. 1: Semester Fall 2021 Data Warehousing - CS614Hamza Khan AbduhuNo ratings yet

- Engineering MetallurgyDocument540 pagesEngineering Metallurgymadhuriaddepalli100% (1)

- Fadm Project 5 ReportDocument4 pagesFadm Project 5 ReportVimal AgrawalNo ratings yet

- E Sevai RegistrationDocument18 pagesE Sevai RegistrationSatheesh PNo ratings yet

- Hetron CR 197Document3 pagesHetron CR 197Faidhi SobriNo ratings yet

- Notice Format 2024 BatchDocument1 pageNotice Format 2024 BatchAriNo ratings yet

- Document 3Document6 pagesDocument 3Nurjaman SyahidanNo ratings yet

- Digest of Agrarian From DAR WebsiteDocument261 pagesDigest of Agrarian From DAR WebsiteHuzzain PangcogaNo ratings yet

- Geigermullerteller (Nuts and Volts 2004-01)Document5 pagesGeigermullerteller (Nuts and Volts 2004-01)Peeters GuyNo ratings yet

- Virtual Vacancy Round 2 Mbbs - Bds Ug Counselling 20Document90 pagesVirtual Vacancy Round 2 Mbbs - Bds Ug Counselling 20Jaydev DegloorkarNo ratings yet

- E2 Lab 2 8 2 InstructorDocument10 pagesE2 Lab 2 8 2 InstructorOkta WijayaNo ratings yet

- Spark - Eastern Peripheral Road Project (Epr) Weekly Quality MeetingDocument6 pagesSpark - Eastern Peripheral Road Project (Epr) Weekly Quality Meetingengr.s.a.malik6424No ratings yet